Inner stator assembly of hollow cup brush direct-current motor

A DC motor and inner stator technology, applied in the direction of magnetic circuit static parts, magnetic circuit shape/style/structure, etc., can solve the problem of affecting the working life and reliability of the motor, unfavorable bonding between the inner stator bracket and the permanent magnet, and the operation of the motor Sparks and electromagnetic interference and other problems, to achieve the effect of magnetization, saving permanent magnet materials, and improving magnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0039] The present invention mainly solves the problems that the existing permanent magnets adopt ring-shaped permanent magnets, which are not easy to process, high processing cost, waste of materials, etc., and the problems of large commutation sparks, high noise and short service life of the motor.

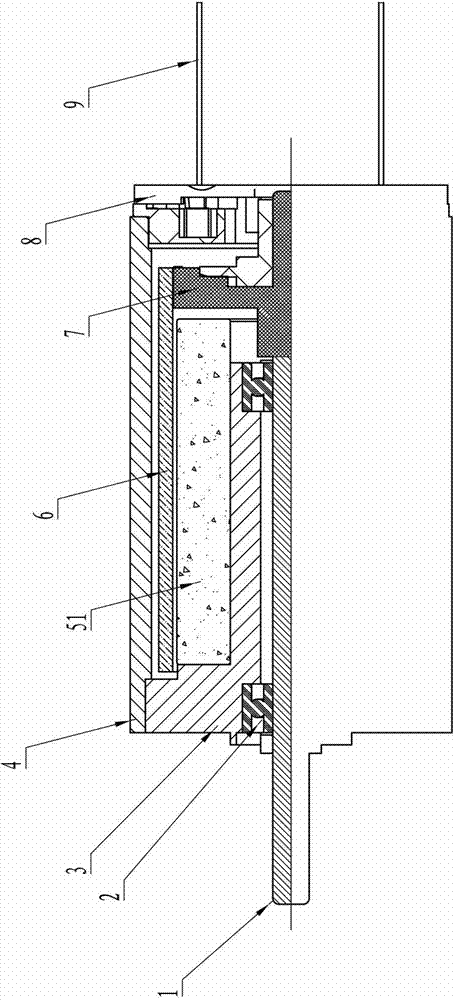

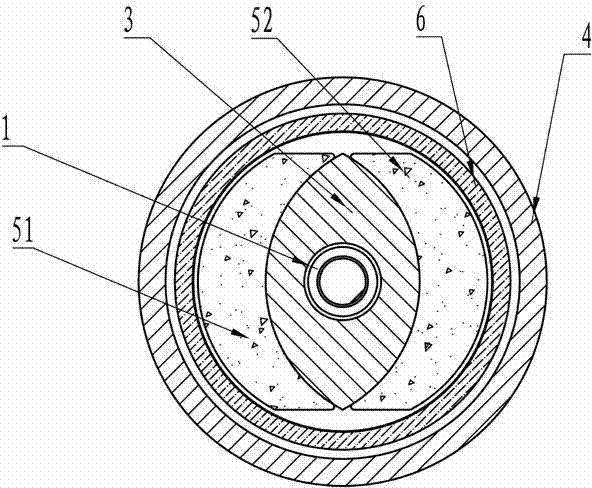

[0040] see figure 1 and figure 2 , a hollow cup brushed DC motor of the present invention, including a rotating shaft 1, bearings 2 (two), an inner stator bracket 3, a casing 4, a first permanent magnet 51 and a second permanent magnet 52, a wire cup 6, a Director 7, rear end cover 8 and brush 9 (two). The assembly relationship between them is described as follows: the rotating shaft 1, the commutator 7 and the wire cup 6 are combined into a rotor component, and the inner and outer diameters of the wire cup 6, the outer diameter of the commutator 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com