Fluorocarbon/palladium/magnesium-scandium hydrogen-induced color-change film and preparation method thereof

A technology of causing color change and fluorocarbon film, which is applied in the field of fluorocarbon/palladium/magnesium-scandium gas-induced dimming film and its preparation, which can solve the problems that need to be further improved, the dimming range is reduced, etc., and can improve the microstructure and The effect of composition, large dimming range and uniform film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

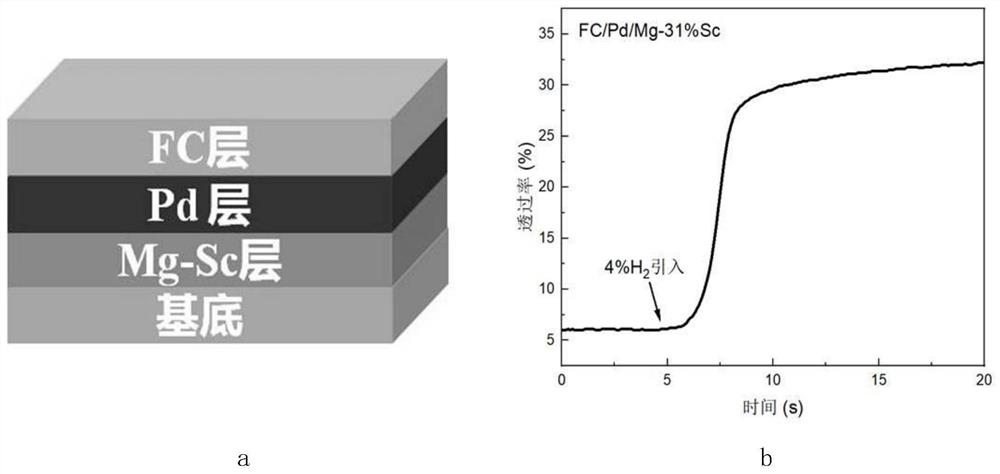

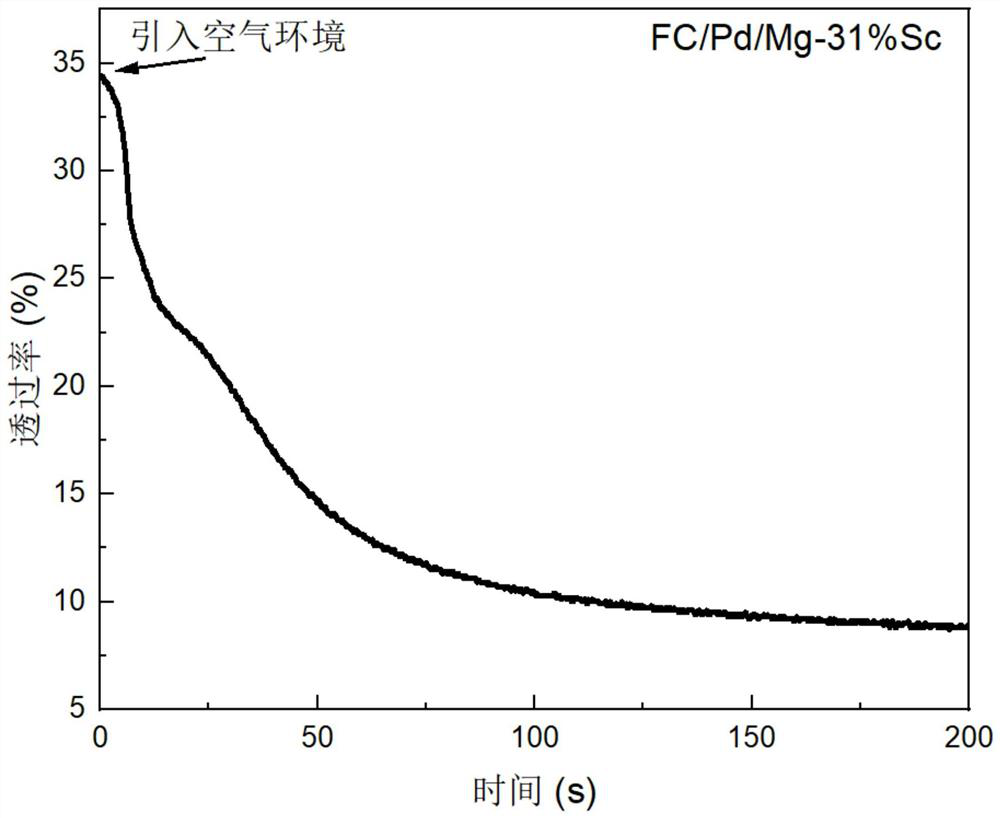

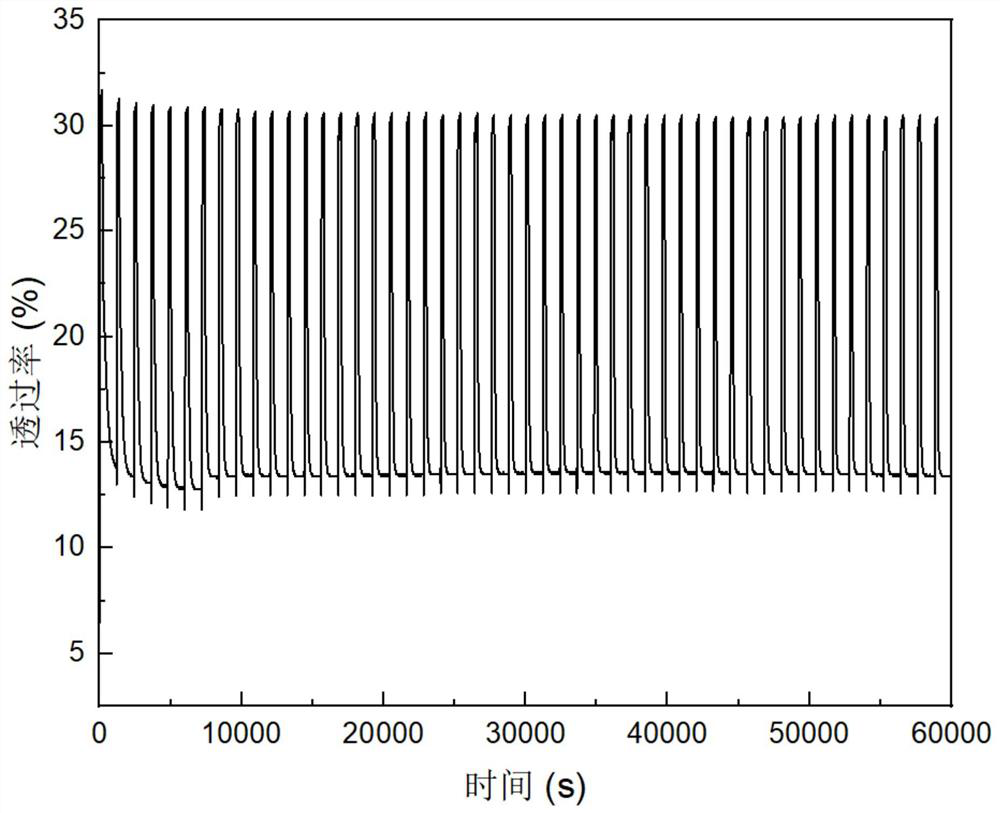

[0047] This embodiment provides a method for preparing a hydrogen-induced chromic thin film of fluorocarbon / palladium / magnesium-scandium, comprising the following steps:

[0048] (1) Use scandium powder with a purity (mass fraction) of 99.99% to make a scandium target, and attach a copper back plate. The same scandium target is used in the following examples 2 to 6;

[0049] (2) Soak the quartz glass sheet with the prepared cleaning solution for 15 minutes successively, and rinse the quartz glass sheet with deionized water for 1 minute; the cleaning solution is a mixed solution of concentrated sulfuric acid and hydrogen peroxide, and the ratio is 3:1; the cleaned quartz glass The substrate is placed in the magnetron sputtering reaction chamber, and the vacuum system is turned on for vacuuming until the background vacuum is 3×10 -4 Pa;

[0050] (3) Heating the substrate so that the temperature of the substrate is 20-25°C, inject working gas A (argon) and maintain a pressure of...

Embodiment 2

[0057] This embodiment provides a method for preparing a hydrogen-induced chromic thin film of fluorocarbon / palladium / magnesium-scandium, comprising the following steps:

[0058] (1) Soak the quartz glass sheet with the prepared cleaning solution for 15 minutes successively, and rinse the quartz glass sheet with deionized water for 1 minute; the cleaning solution is a mixed solution of concentrated sulfuric acid and hydrogen peroxide, and the ratio is 3:1; the cleaned quartz glass The substrate is placed in the magnetron sputtering reaction chamber, and the vacuum system is turned on for vacuuming until the background vacuum is 3×10 -4 Pa;

[0059] (2) Heat the substrate so that the temperature of the substrate is 20-25°C, pass in the working gas A (argon), and maintain a pressure of 0.4-0.6Pa. After the pressure is stable, turn on the power of the palladium, magnesium and scandium targets, and turn off The baffle in front of each target was pre-sputtered to clean the target ...

Embodiment 3

[0065] This embodiment provides a method for preparing a palladium / magnesium-scandium hydrogen-induced chromic film, comprising the following steps:

[0066] (1) Soak the quartz glass sheet with the prepared cleaning solution for 15 minutes successively, and rinse the quartz glass sheet with deionized water for 1 minute; the cleaning solution is a mixed solution of concentrated sulfuric acid and hydrogen peroxide, and the ratio is 3:1; the cleaned quartz glass The substrate is placed in the magnetron sputtering reaction chamber, and the vacuum system is turned on for vacuuming until the background vacuum is 9×10 -5 Pa;

[0067] (2) Heat the substrate so that the temperature of the substrate is 20-25°C, pass in the working gas A (argon), and maintain a pressure of 0.4-0.6Pa. After the pressure is stable, turn on the power of the palladium, magnesium and scandium targets, and turn off The baffle in front of each target was pre-sputtered to clean the target for 10 minutes. Then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com