Method and apparatus for evaluating characteristics of coal direct liquefaction reaction

A technology for direct liquefaction and reaction of coal, applied in the petroleum industry, hydrotreating process, processing hydrocarbon oil, etc., can solve the problems of expensive equipment, inaccurate models, inaccurate calculation results, etc. The effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] This example illustrates the method for evaluating the reaction characteristics of direct coal liquefaction according to the present invention.

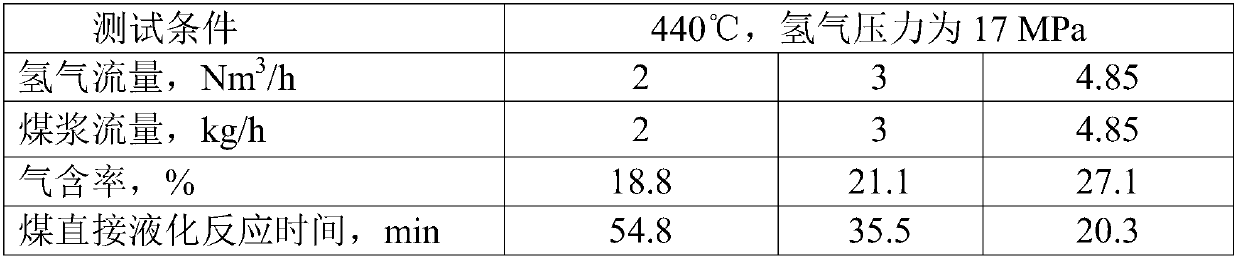

[0118] (1) Gas holdup in direct coal liquefaction reaction

[0119] The density of the circulating solvent for direct coal liquefaction was measured at 20°C, 40°C, 60°C, 80°C and 90°C, and the relationship between the density and temperature of the direct coal liquefaction circulating solvent was obtained by linear regression:

[0120] ρ=0.99-0.0006×T; (where, T is the temperature, °C; ρ is the density of the circulating solvent for direct coal liquefaction, g / cm 3 ).

[0121] Further extrapolation obtained the density of the coal direct liquefaction circulating solvent at 440°C for the following experiments.

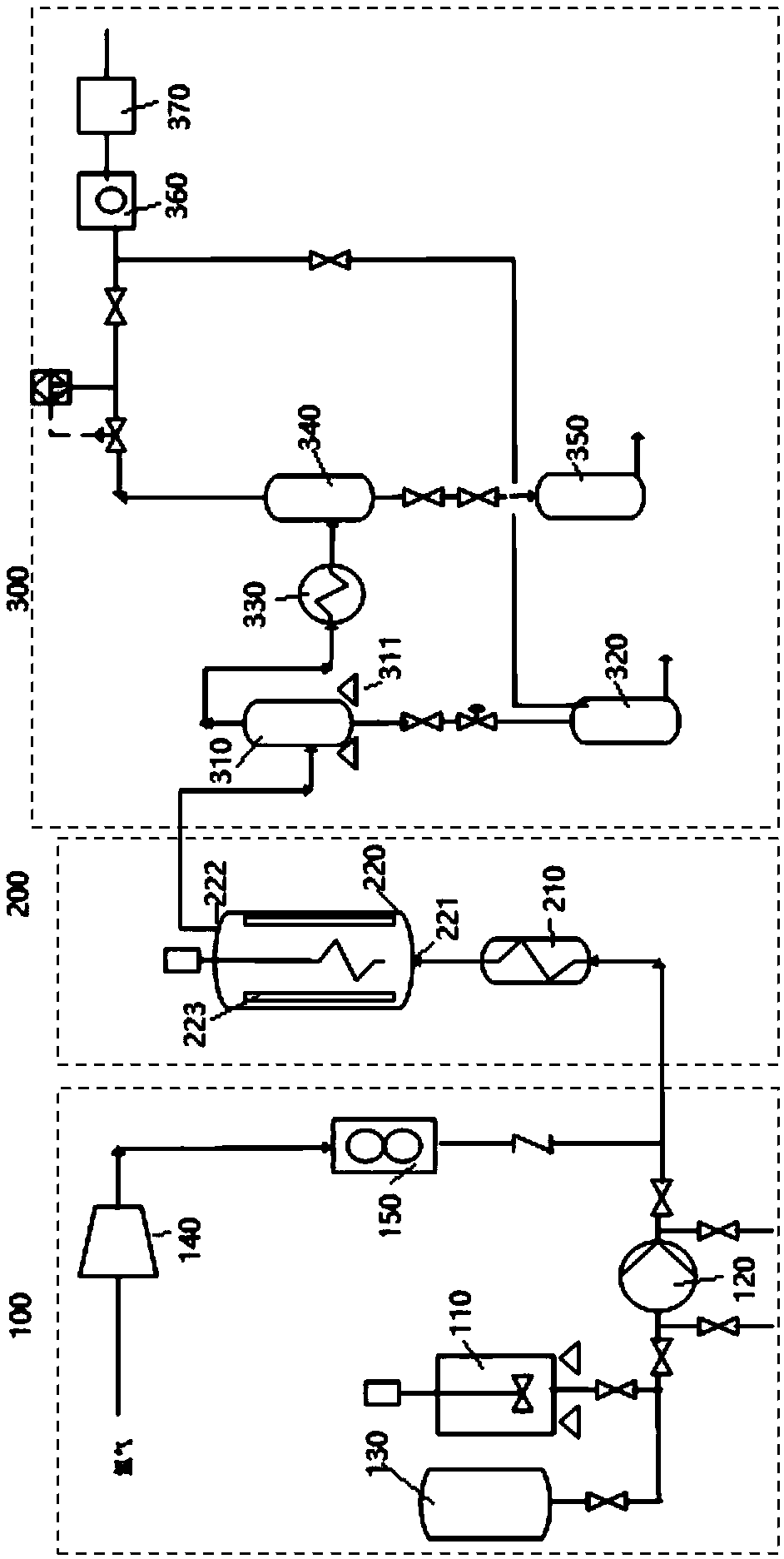

[0122] Start the device (such as figure 1 ), wherein the effective volume of the stirred tank reactor is 1.8L. Add the coal direct liquefaction circulating solvent in the oil washing tank (with 80 mesh screen), and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com