Iso-butane production device and method

A production device and a technology for isobutane, applied in the field of C4 light hydrocarbons, can solve the problems of excess n-butane and insufficient isobutane, and achieve the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

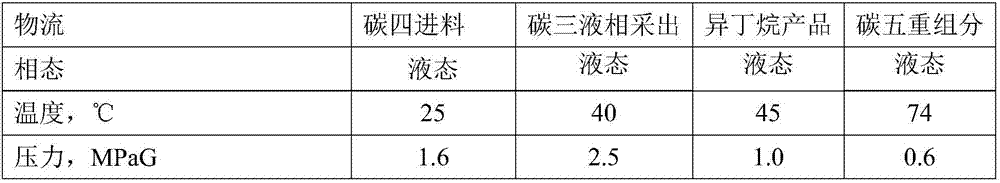

[0083] Preferred embodiments of the present invention will be described in more detail below with reference to the accompanying drawings.

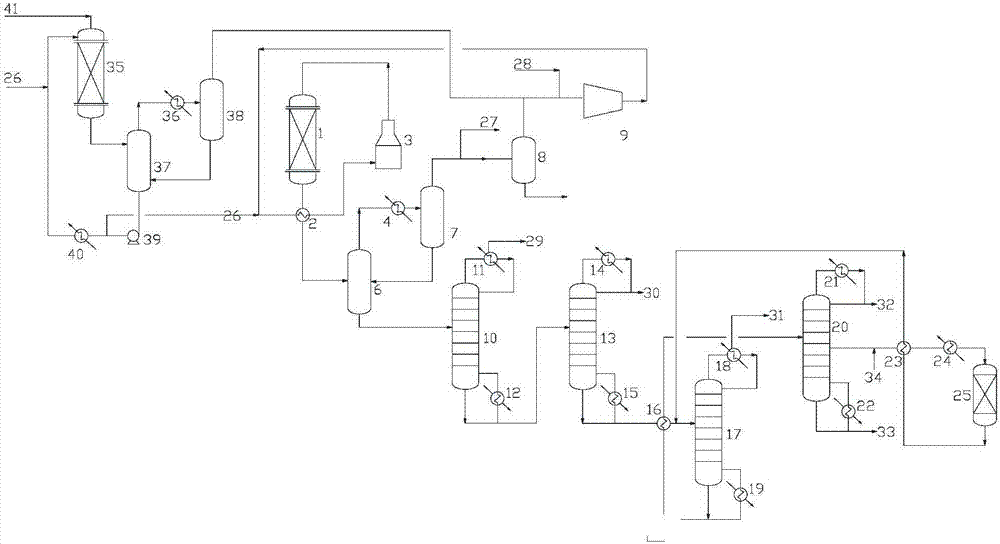

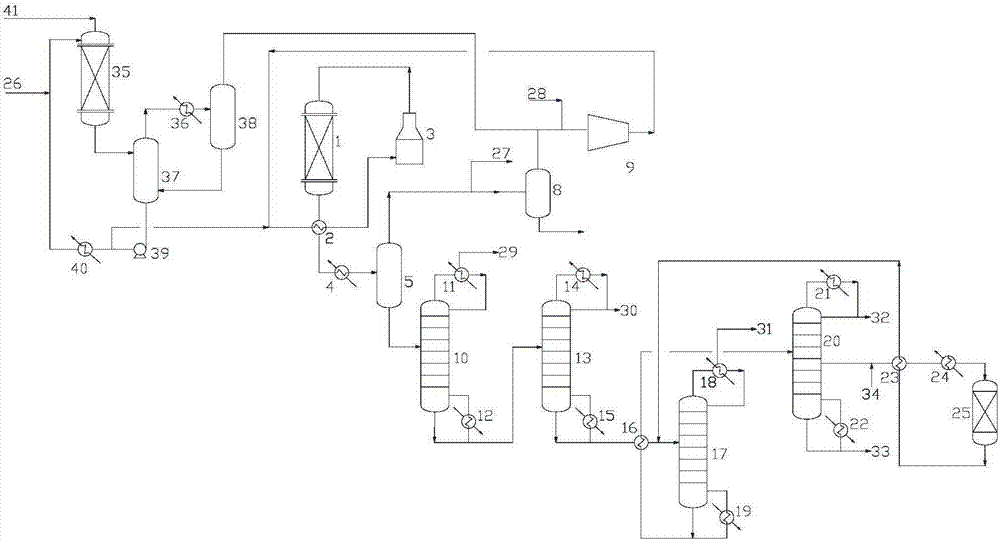

[0084] use as figure 1 The plant shown produces isobutane.

[0085] The isobutane production device includes: a first-stage hydrogenation reactor 35, a first-stage hydrogenation separation device, a first-stage hydrogenation circulation pump 39, a first-stage circulating cooler 40, a second-stage hydrogenation reactor 1, and heat exchange for hydrogenation inlet and outlet 2, second-stage hydrogenation feed heater 3, second-stage hydrogenation separation device, deethanizer 10, depropanizer 13, stabilization tower 17, isobutane product tower 20, isomerization inlet and outlet heat exchanger 23. An isomerization feed heater 24 and an isomerization reactor 25; wherein,

[0086] The C4 feed pipeline is connected to the first-stage hydrogenation reactor 35, the first-stage hydrogenation separation device, the hydrogenation inlet and outlet h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com