Auxiliary system for controllable temperature-control pressure gas sealing test platform

A technology of gas sealing and testing platform, which is applied in control/regulation system, liquid tightness measurement using liquid/vacuum degree, liquid/fluid solid measurement, etc. The effect of inflation rate and pressure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples (taking hydrogen charging and discharging as an example), but the embodiment of the present invention is not limited to this one.

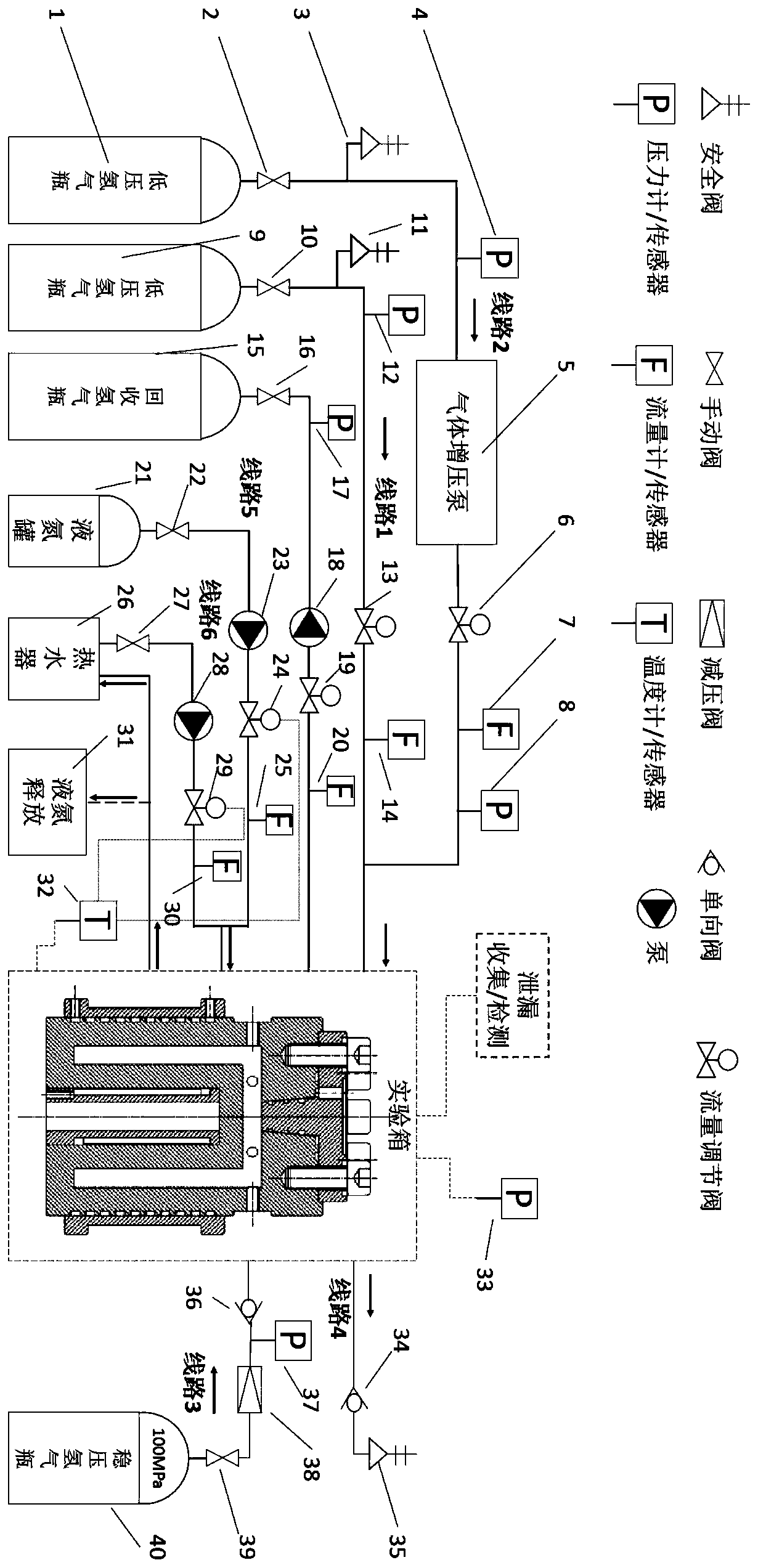

[0028] Such as figure 1 As shown, an auxiliary system for a temperature-controllable and pressure-controlled gas seal test platform is connected to the experiment box through pipelines, and is used to simulate the service environment of the high-pressure hydrogen storage seal. Tank voltage stabilization system, temperature control system and leak detection system, of which:

[0029] The gas increase / depressurization cycle system includes a low-pressure hydrogen supply system that fills the test box with low-pressure hydrogen, a high-pressure hydrogen supply system that fills the test box with high-pressure hydrogen, and a hydrogen recovery system that recovers hydrogen from the test box; the low-pressure hydrogen supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com