Low-temperature hydrogen liquefaction device and use method

A low-temperature, hydrogen technology, applied in the field of hydrogen energy, can solve the problems of high energy consumption and complicated hydrogen purification process, and achieve the effects of low energy consumption, storage stability and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

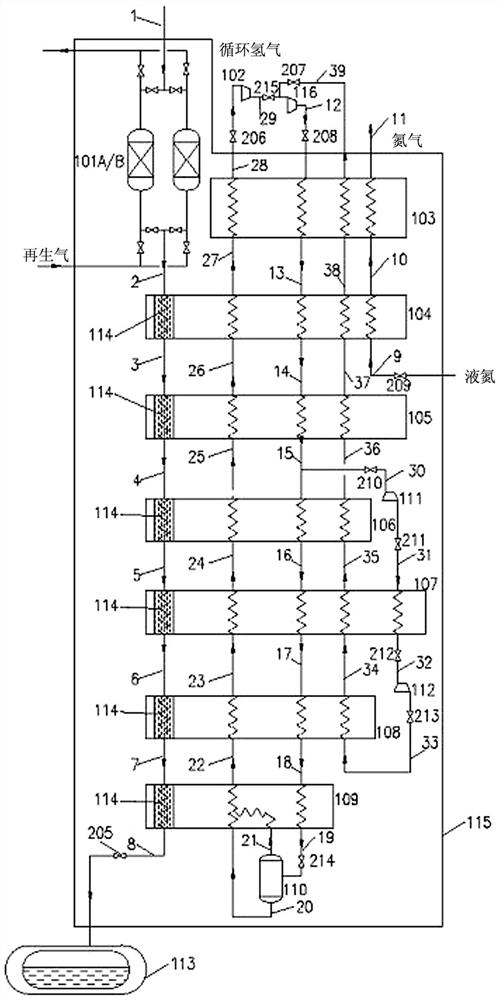

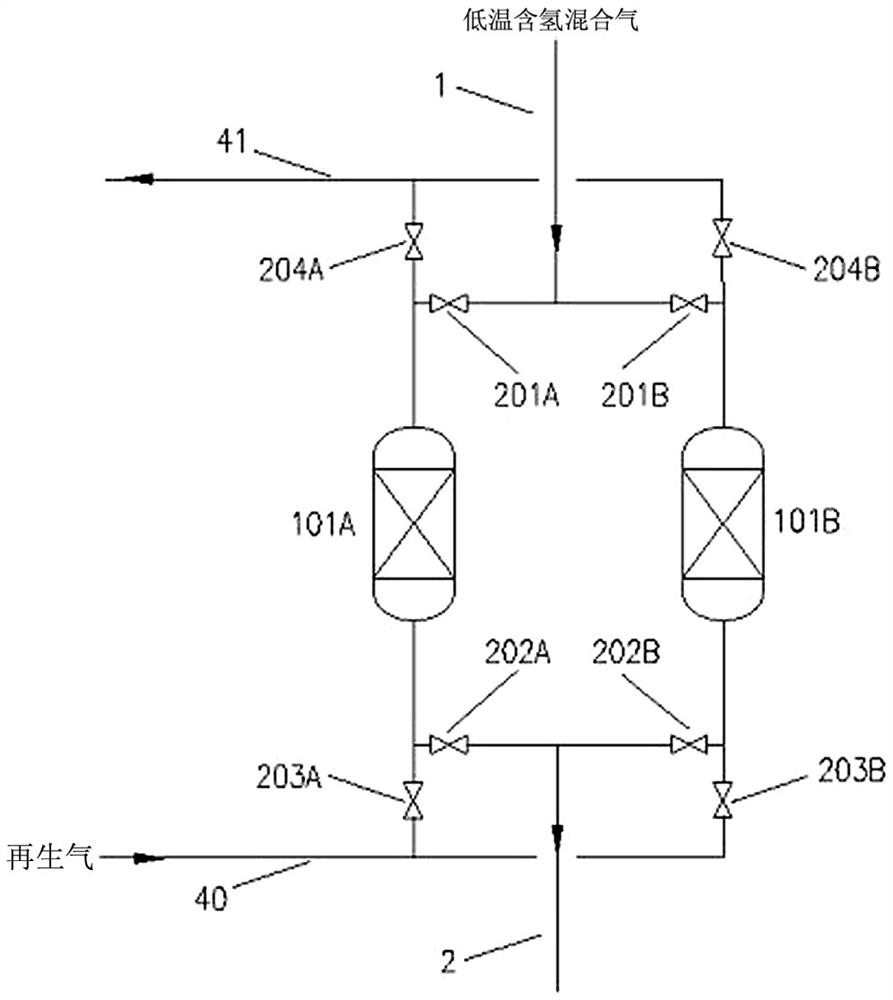

[0029] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the embodiment of the present invention provides a low-temperature hydrogen liquefaction device, which includes a vacuum cold box 115 made of stainless steel or carbon steel. The vacuum cold box 115 is provided with a first cryogenic adsorber 101A, a second cryogenic adsorber 101B, first-stage heat exchanger 103, second-stage heat exchanger 104, third-stage heat exchanger 105, fourth-stage heat exchanger 106, fifth-stage heat exchanger 107, sixth-stage heat exchanger 108 , the seventh-stage heat exchanger 109, the gas-liquid separator 110, the first-stage expander 111, and the second-stage expander 112 are connected to each other through valves and pipelines, wherein the second-stage heat exchanger 104 to the seventh-stage heat exchanger An ortho-parahydrogen catalyst 114 is arranged in 109, and a first-stage circulating hydrogen compressor unit 102 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com