Biogas hydrogen production circulating system and technology for PTA sewage treatment

A sewage treatment and circulation system technology, applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve high operating costs, resource waste environment, and biogas without effective treatment and other issues to achieve the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

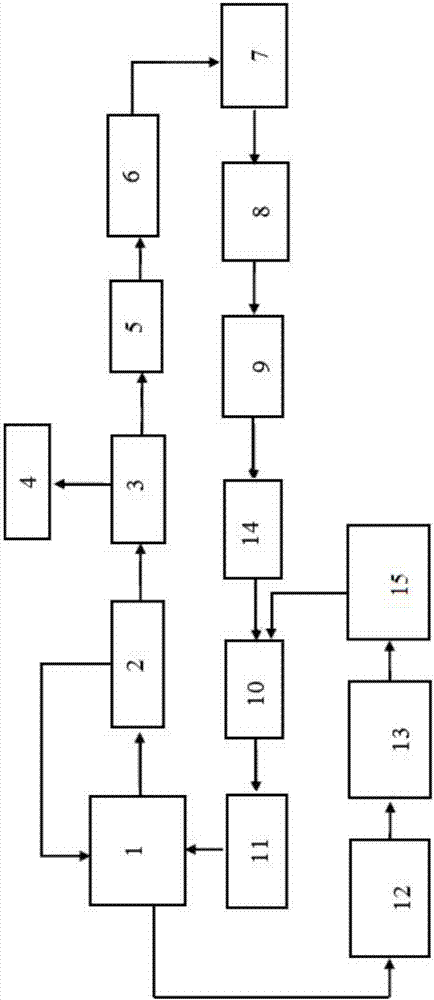

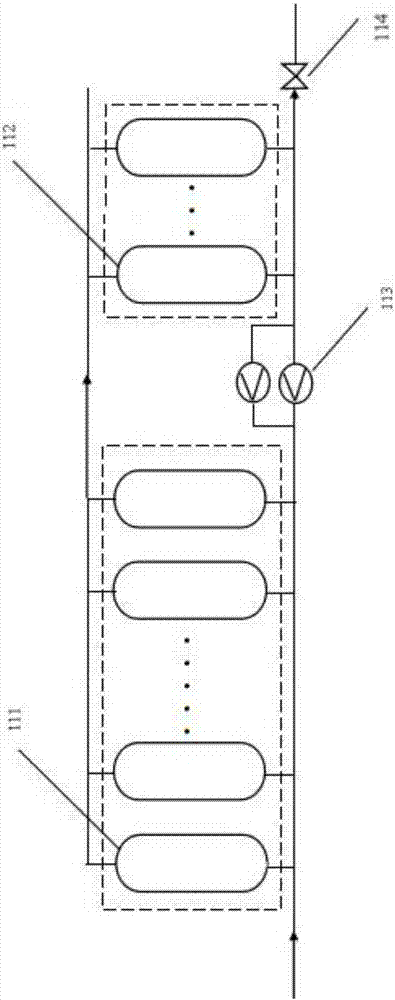

[0021] Such as figure 1 As shown, the biogas hydrogen production cycle system for PTA sewage treatment includes: PTA device 1, settling tank 2, anaerobic baffle reactor 3, sedimentation tank 4, biogas collection tank 5, desulfurization adsorption device 6, nitrogen and oxygen removal device 7. Cracking reactor 8, alkali scrubber I9, gas-liquid separator 10, pressure swing adsorption device 11, steam heat exchanger 12, alkali scrubber II13, desalted water scrubber I14 and desalted water scrubber II15; The pressure swing adsorption device 11 includes an adsorption tower 111, a buffer tank 112, a vacuum pump 113 and a program-controlled valve 114;

[0022] The PTA device 1 is a crude PTA refining device, the settling tank 2 is connected with the PTA device 1 by a pipeline, the outlet of the settling tank 2 is connected with the inlet of the anaer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com