Superimposed oil hydrotreating device and superimposed oil hydrotreating method

A technology for hydrotreating and superimposing oil, which is applied in the field of olefin hydrogenation, can solve the problems that the isooctene hydrogenation process cannot be applied on a large scale, has no practical industrial application value, and does not involve hydrogenation devices and methods, etc. Reaction conversion and selectivity, reduced light component formation, reduced partial deactivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

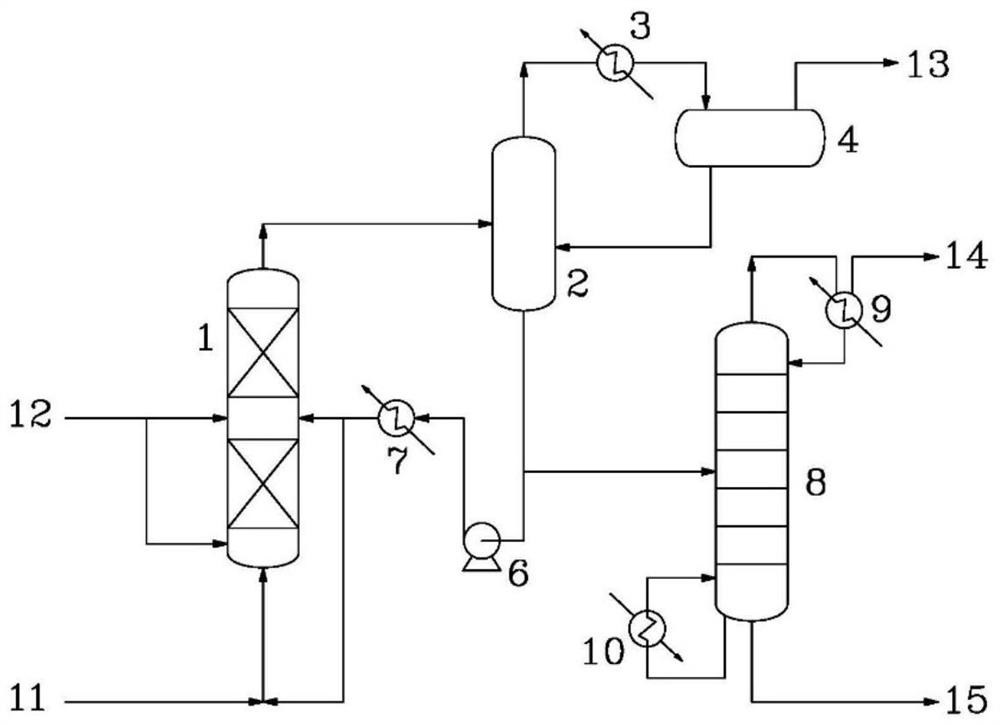

[0048] use as figure 1 The shown composite oil hydrotreating unit is for hydrotreating the composite oil feedstock rich in carbon octaolefins. The device includes: a hydrogenation reactor 1, a hydrogenation thermal separation tank 2, a hydrogenation aftercooler 3, a hydrogenation cold separation tank 4, a hydrogenation circulation pump 6, a hydrogenation circulation cooler 7, a stripping tower 8, Stripper condenser 9, stripper reboiler 10;

[0049] The superimposed oil feed pipeline rich in olefins is connected to the bottom inlet of hydrogenation reactor 1;

[0050] The top outlet of hydrogenation reactor 1 is connected to hydrogenation thermal separation tank 2; the bed layer of hydrogenation reactor 1 is divided into two sections;

[0051] The top of the hydrogenation heat separation tank 2 is sequentially connected to the hydrogenation aftercooler 3 and the hydrogenation cold separation tank 4, and the discharge pipeline at the top of the hydrogenation cold separation ta...

Embodiment 2

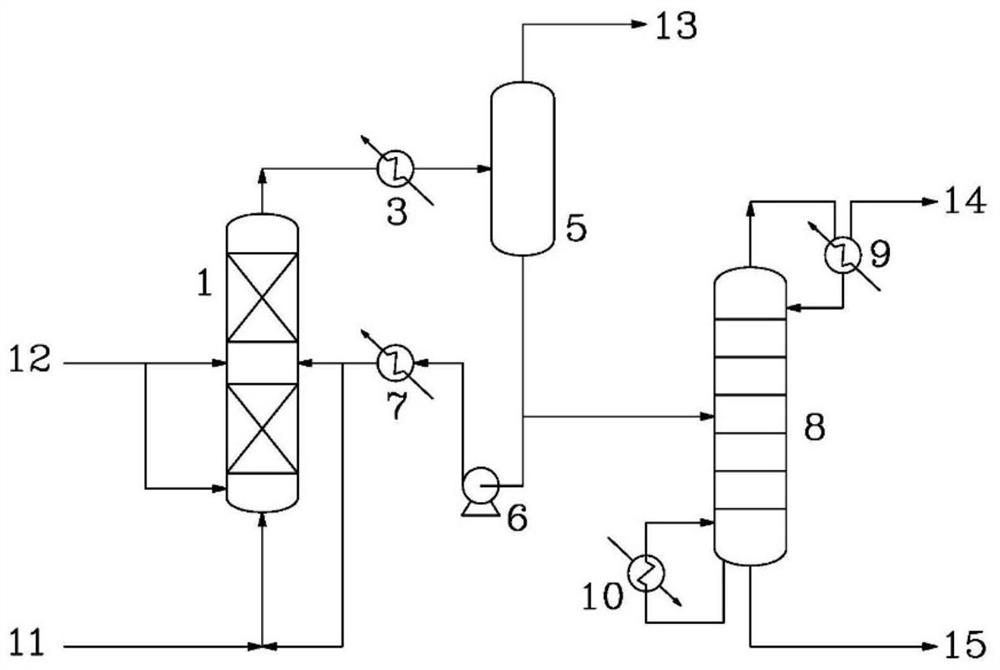

[0062] use as figure 2 The shown composite oil hydrotreating unit is for hydrotreating the composite oil feedstock rich in carbon octaolefins. The device includes: hydrogenation reactor 1, hydrogenation aftercooler 3, hydrogenation separation tank 5, hydrogenation circulation pump 6, hydrogenation circulation cooler 7, stripper 8, stripper condenser 9, steam Column reboiler 10;

[0063] The superimposed oil feed pipeline rich in olefins is connected to the bottom inlet of hydrogenation reactor 1;

[0064] The outlet at the top of the hydrogenation reactor 1 is sequentially connected to the hydrogenation aftercooler 3 and the hydrogenation separation tank 5; the bed of the hydrogenation reactor 1 is divided into two sections;

[0065] The discharge pipeline at the top of the hydrogenation separation tank 5 is used as the hydrogenation tail gas production pipeline; the discharge pipeline at the bottom of the hydrogenation separation tank 5 is divided into two lines, one is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com