Method for co-processing coal high in inertinite content and heavy oil

A heavy oil, co-processing technology, applied in the direction of hydrocarbon oil treatment products, hydrocarbon oil treatment, hydrogenation treatment process, etc., can solve the problems of reducing coal processing capacity, reducing equipment utilization rate, unfavorable pump transportation, etc., to avoid The effect of secondary cracking, improving hydrogen supply capacity, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

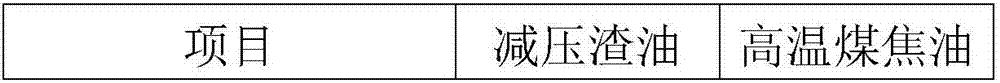

[0051] The properties of the vacuum residue in this example are shown in Table 1; the coal component with high inertinite content in this example is low-order bituminous coal in Xinjiang, and its properties are shown in Table 2.

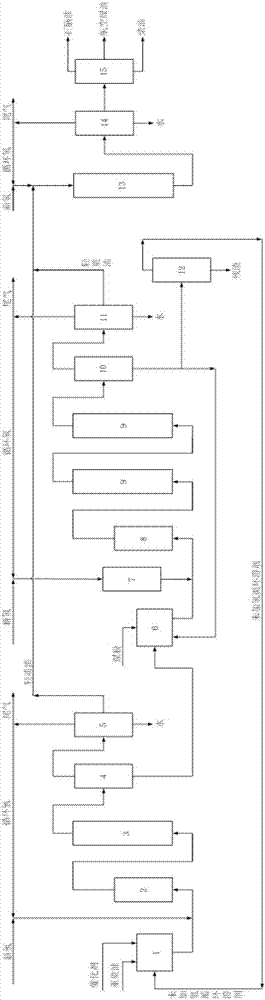

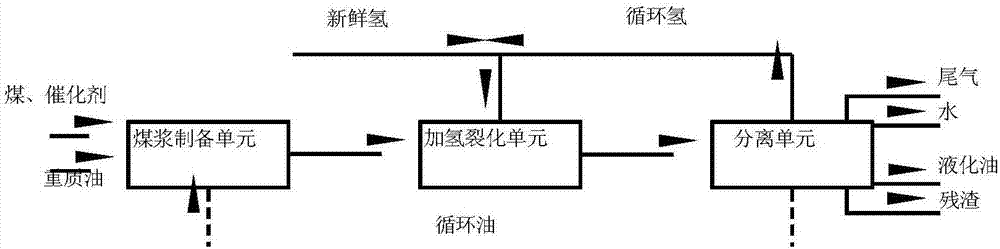

[0052] A method for co-processing coal and heavy oil with high inertinite content proposed by an embodiment of the present invention, comprising:

[0053] (1) The vacuum residue in Table 1 and the first unhydrogenated circulating solvent are prepared in a ratio of 7:3 to make an oil slurry, and in the presence of an oil-soluble Mo catalyst, at a temperature of 400 ° C, a pressure of 17 MPa, and a gas-liquid ratio of 1000 Carry out the first pre-hydrogenation reaction below, obtain the first light distillate oil and the first heavy distillate oil, the addition amount of Mo catalyst is 0.03% of vacuum residue weight;

[0054] (2) The first heavy distillate oil, the bituminous coal A in Table 2 and the second unhydrogenated circulating solvent are made ...

Embodiment 2

[0058] The high-temperature coal tar components and properties in this example are shown in Table 1; the coal components with high inertinite content in this example are low-rank bituminous coals in Xinjiang, and their properties are shown in Table 2.

[0059] A method for co-processing coal and heavy oil with high inertinite content proposed by an embodiment of the present invention, comprising:

[0060] (1) Prepare high-temperature coal tar in Table 1 and the first unhydrogenated circulating solvent at a ratio of 9:1 to make an oil slurry, in the presence of an oil-soluble Mo catalyst, at a temperature of 390 ° C, a pressure of 17 MPa, and a gas-liquid ratio of 1000 Carry out the first pre-hydrogenation reaction, obtain the first light distillate oil and the first heavy distillate oil, the addition amount of Mo catalyst is 0.02% of the oil slurry weight;

[0061] (2) The first heavy distillate oil, the bituminous coal B in Table 2 and the second unhydrogenated circulating so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com