Patents

Literature

34results about How to "Reduce oxidation corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

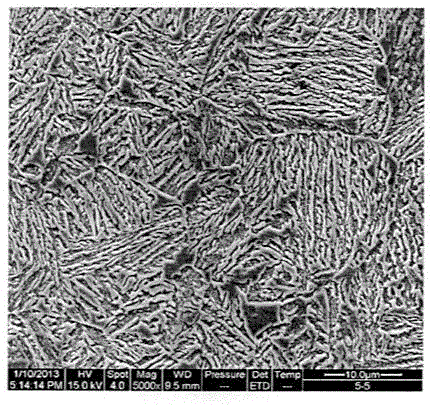

Boron-containing high-silicon bainite wear-resistant corrosion-resistant alloy and manufacturing method thereof

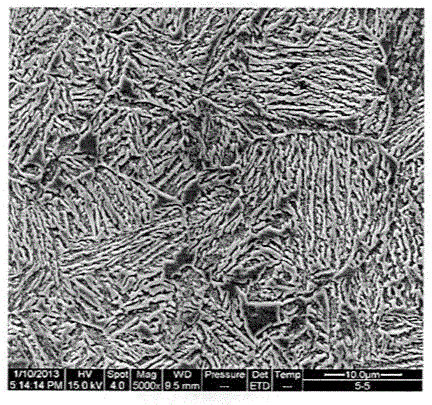

The invention relates to a boron-containing high-silicon bainite wear-resistant corrosion-resistant alloy and a manufacturing method thereof. The alloy comprises the following chemical components in percentage by weight: 0.3-0.6% of C, 1.6-2.6% of Si, 0.6-1.0% of Mn, 0.6-4.0% of Cr, 0.3-0.5% of Mo, 0.3-0.5% of Ni, 0.3-0.5% of Cu, 0.1-0.3% of Ti, 0.05-0.1% of B, 0.05-0.15% of Ce, 0.05-0.15% of Nb, less than 0.04% of P, less than 0.04% of S and the balance of Fe. The manufacturing method comprises the following steps: carrying out electric-furnace smelting, carrying out secondary aluminum insertion deoxidization, putting on the bottom of a casting ladle to form a casting, austenizing the casting at 850-950 DEG C, keeping the temperature for some time, putting in a salt bath at 200-260 DEG C to carry out primary isothermal quenching, keeping the temperature for 5-10 minutes, carrying out secondary isothermal quenching in a salt bath at 260-400 DEG C, keeping the temperature for 0.5-4 hours, and cooling in air to obtain the wear-resistant corrosion-resistant alloy of which the austenite-bainite base is distributed with boride. The alloy is low in preparation cost and suitable for marine silt erosion and corrosion environments, has favorable comprehensive properties of toughness, wear resistance and corrosion resistance, and can be used for dredger cutter teeth, slurry pipelines, centrifugal-pump impellers, blades and the like.

Owner:CHANGXING DETIAN ENG MACHINERY

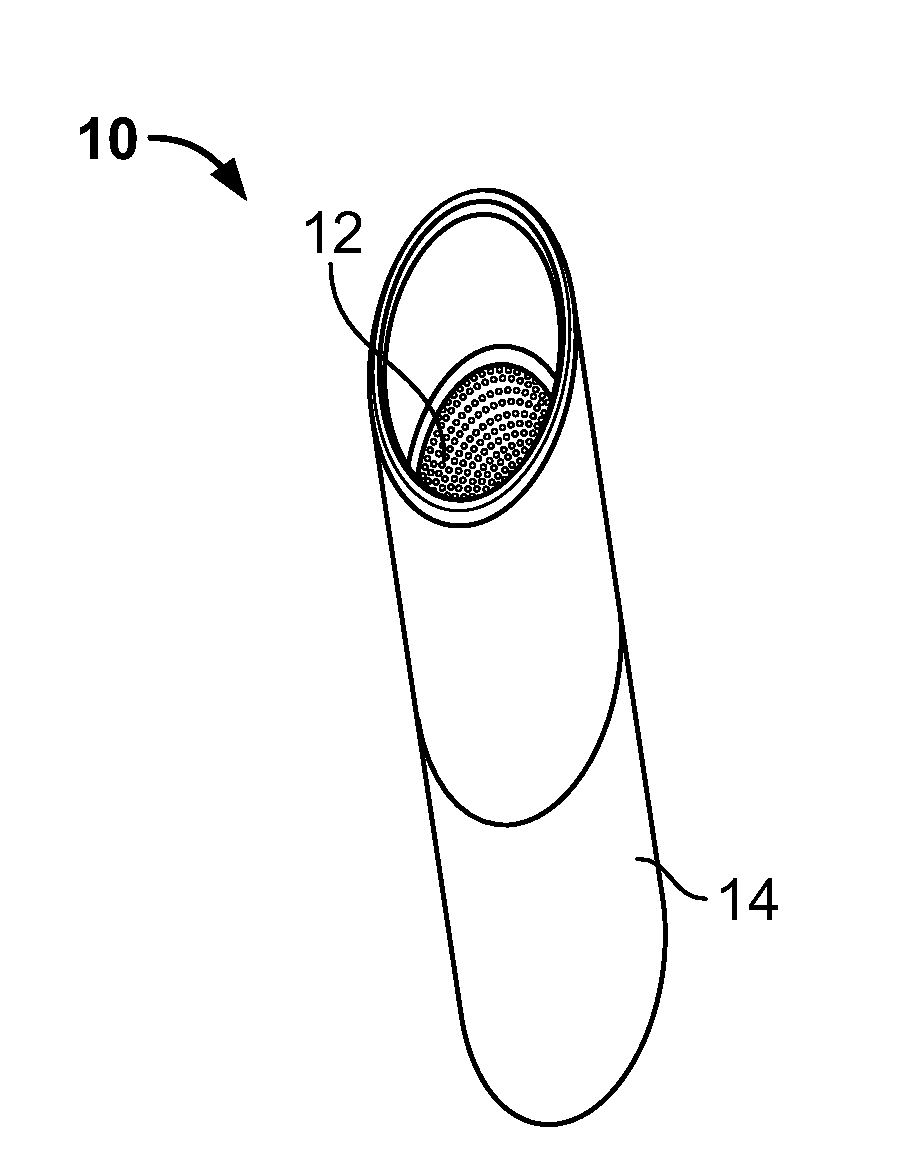

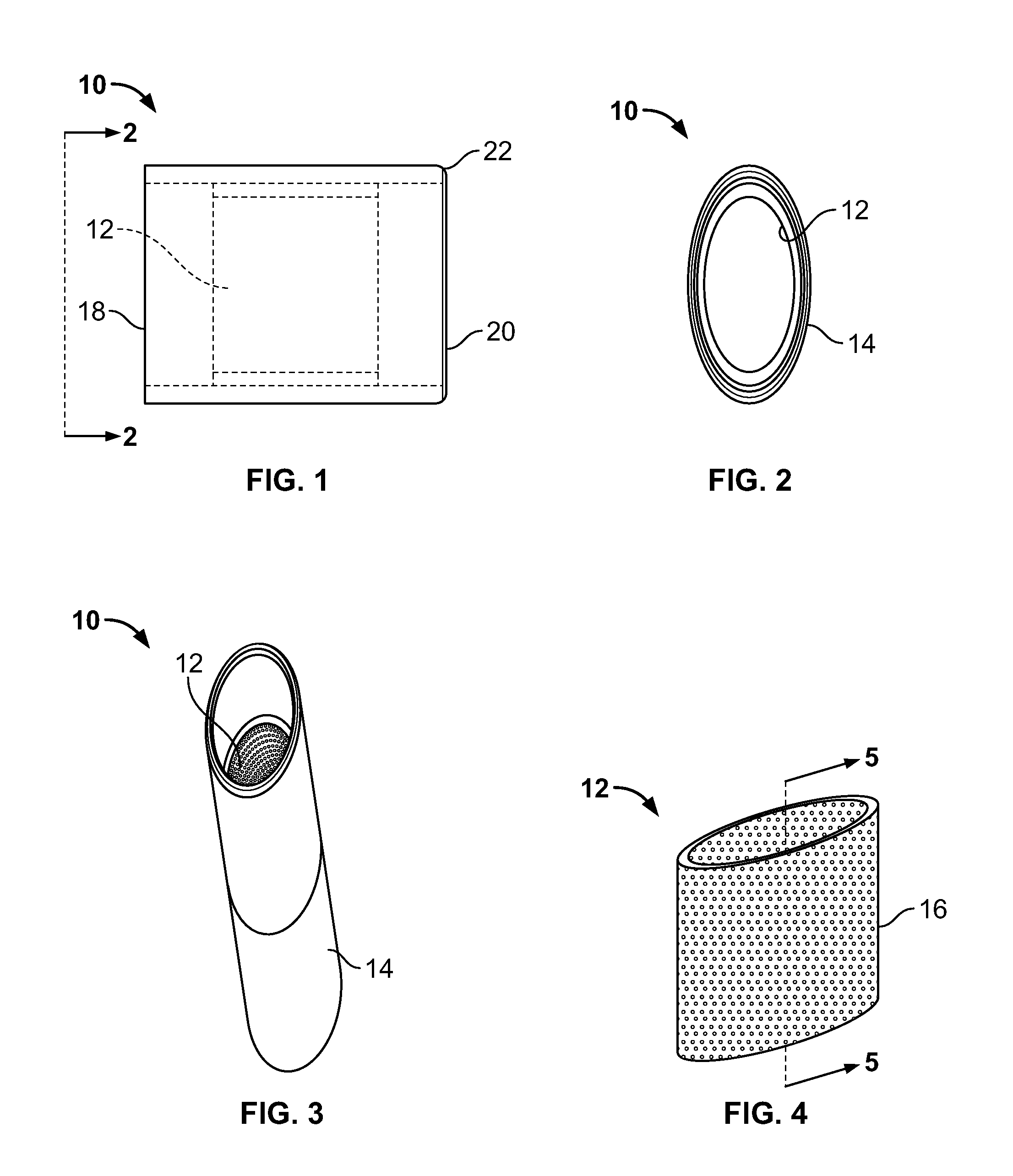

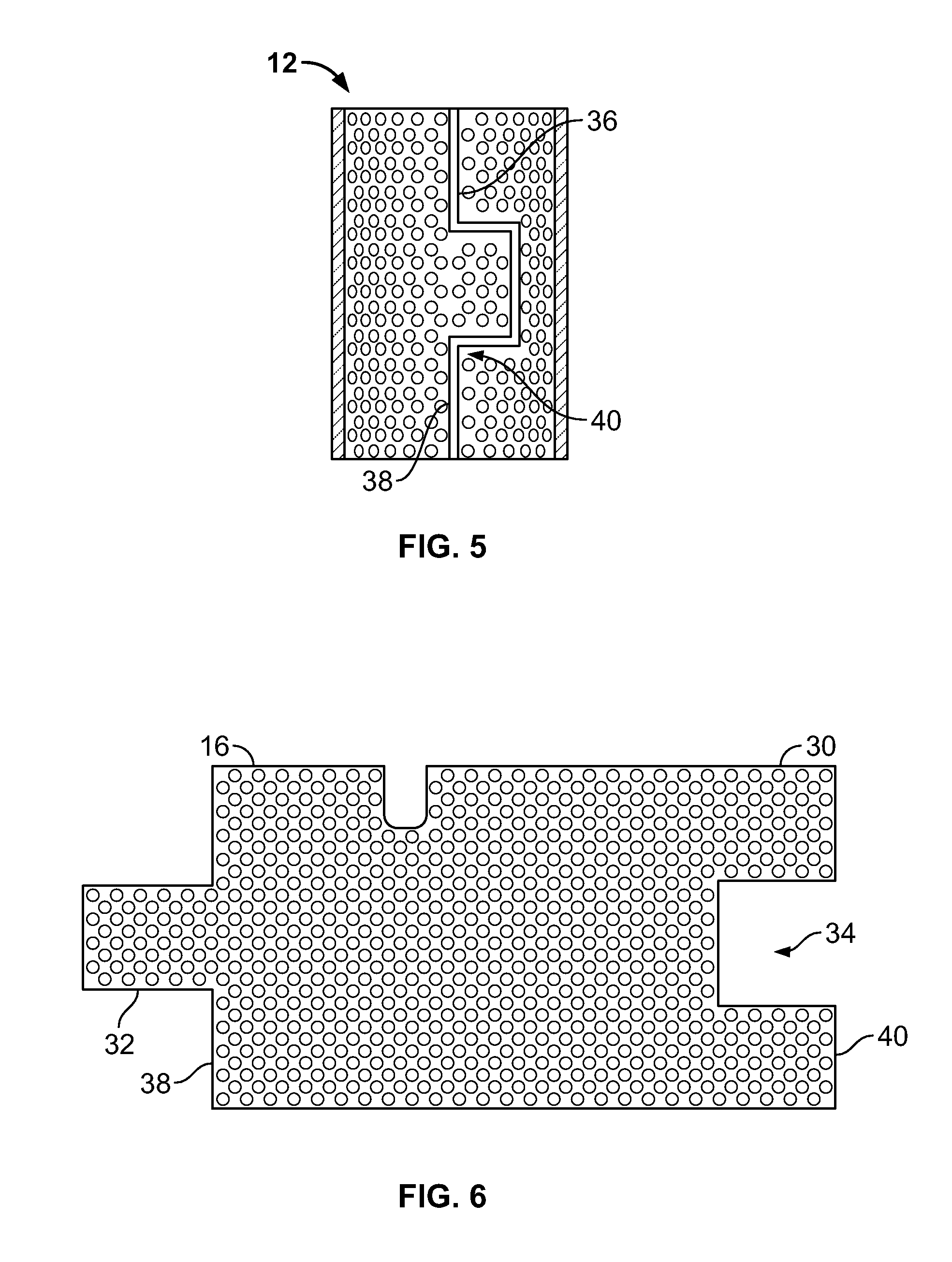

Copper to aluminum bimetallic termination

InactiveUS7413489B1Reduce oxidation corrosionCoupling contact membersConnections effected by permanent deformationElectrical connectionMetal

The connector includes an annular connector body that is substantially comprised of copper, and an annular insert portion made of brass and clad with tin. Apertures are made through the wall of the insert portion. The insert portion is configured to have an exterior frictionally fit within the connector body. Inserting a stranded aluminum cable into the annular insert portion and crimping the connector body, the insert portion and the cable, causes the outer strands of the stranded aluminum cable to be extruded through the plurality of apertures, removing oxide film on the exterior surface of the aluminum cable and forming a sealed electrical connection between the aluminum cable and the copper connector body.

Owner:TYCO ELECTRONICS BRASIL

Leadless soft soldering material and manufacturing method

InactiveCN101143409ALow oxygenDense alloy structureWelding/cutting media/materialsSoldering mediaSolderingNickel

The invention discloses a lead-free soft soldering. Calculated by weight percentage, the lead-free soft soldering consists of following compositions: 0.1 to 3.9 per cent of Al, 0.0001 to 0.5 per cent of Se and rest of Sn. The method of manufacturing the invention is: (a) after refined tin is added into a plumbago pot to be melted, temperature rises to 1100 DEG C. refined copper is added and evenly mixed. The refined tin and the refined copper are melted to be liquid tin copper alloy. The liquid tin and copper alloy becomes the alloy ingot of tin and copper after standing for 30 minutes; (b) the refined Ag is added and melted again and the temperature rises to above 1600 DEG C. Pure nickel is added and melted. The liquid Ag and nickel becomes the alloy ingot of Ag and selenium after standing for 30 minutes; (c) with the refined tin added into and melted and the temperature rising to above 600 to 1000 DEG C, covering agent is added to isolate the liquid level of tin from oxygen in the air. Pure selenium is added and melted. The liquid tin and selenium becomes the alloy ingot of tin and selenium after standing for 30 minutes; (d) three gold ingots, Ga or Cu and the rest of tin and put into a stainless steel kettle to be melted according to the required formulation, which can be made into a tin wire, a tin bar and a tin ball.

Owner:昆山成利焊锡制造有限公司

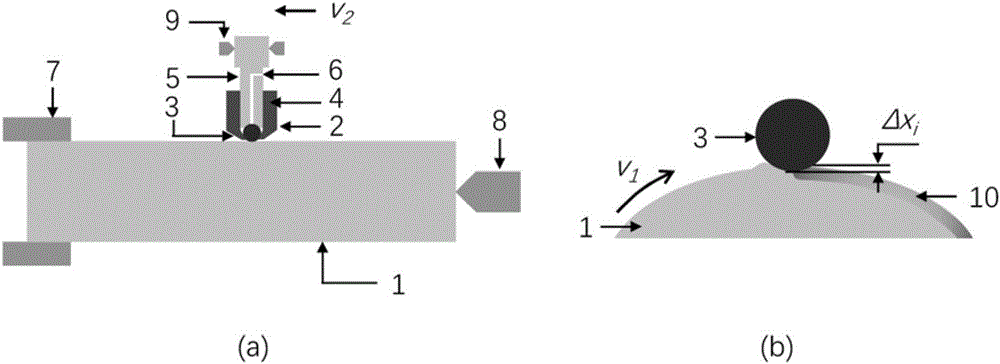

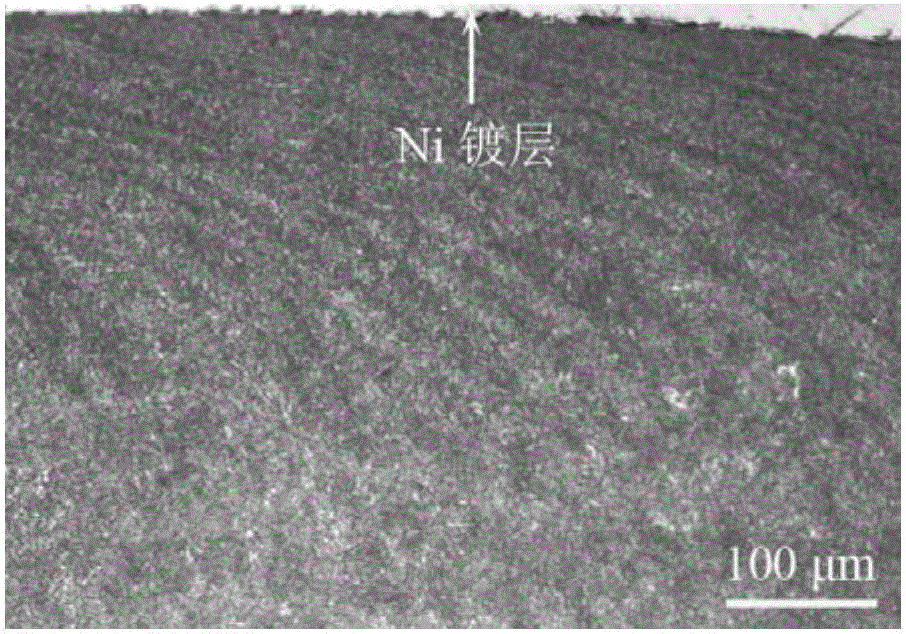

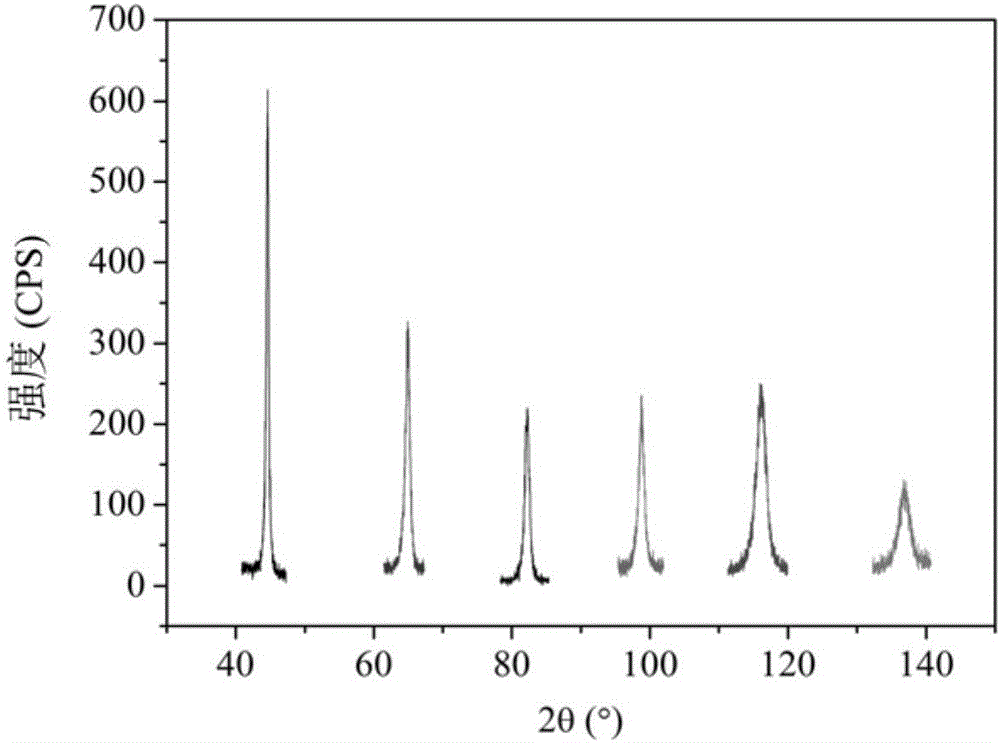

Method for improving lead bismuth alloy corrosion resistance of nuclear power structural material

The invention discloses a method for improving the lead bismuth alloy corrosion resistance of a nuclear power structural material. According to the method for improving the lead bismuth alloy corrosion resistance of the nuclear power structural material, surface treatment is conducted on the nuclear power structural material through the surface nanocrystallization technology, the surface of the nuclear power structural material is made to form a gradient nano-structure and a structure refined structural layer, the nuclear power structural material obtained after surface nanocrystallization generates a compact passivation coating with the thickness smaller than 5 [mu]m in liquid-state lead bismuth alloy, the passivation coating relieves the corrosion of the nuclear power structural material in the liquid-state lead bismuth alloy, and therefore the lead bismuth alloy corrosion resistance of the nuclear power structural material is improved. After surface treatment, the thickness of the surface gradient nanometer crystals and the structure refined structural layer of the nuclear power structural material reaches over 150[mu]m, the surface crystallite dimension is refined to be below 50 nm, and the surface roughness Ra is controlled to be below 0.3 [mu]m. After the nuclear power structural material is treated by the adoption of the method, compared with the nuclear power structural material which is not treated, the lead bismuth alloy corrosion resistance of the nuclear power structural material can be significantly improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

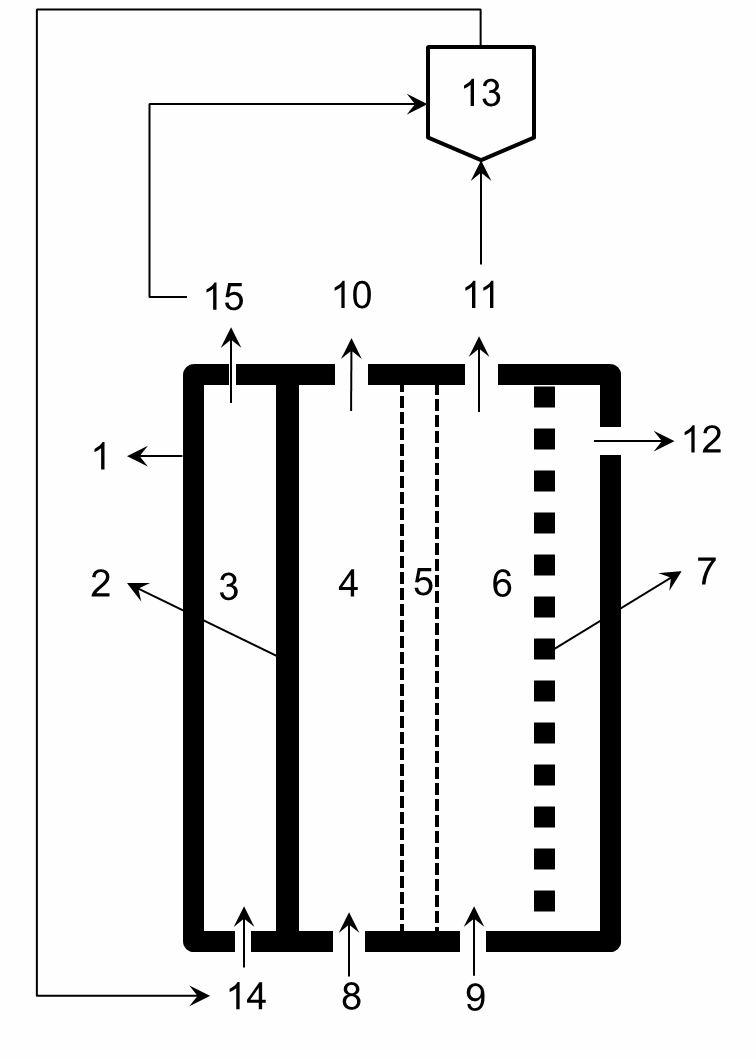

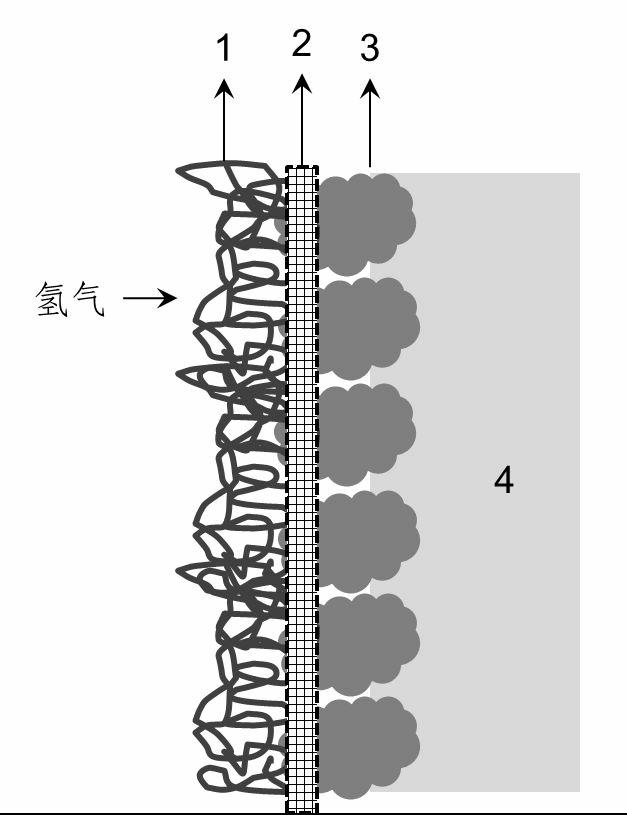

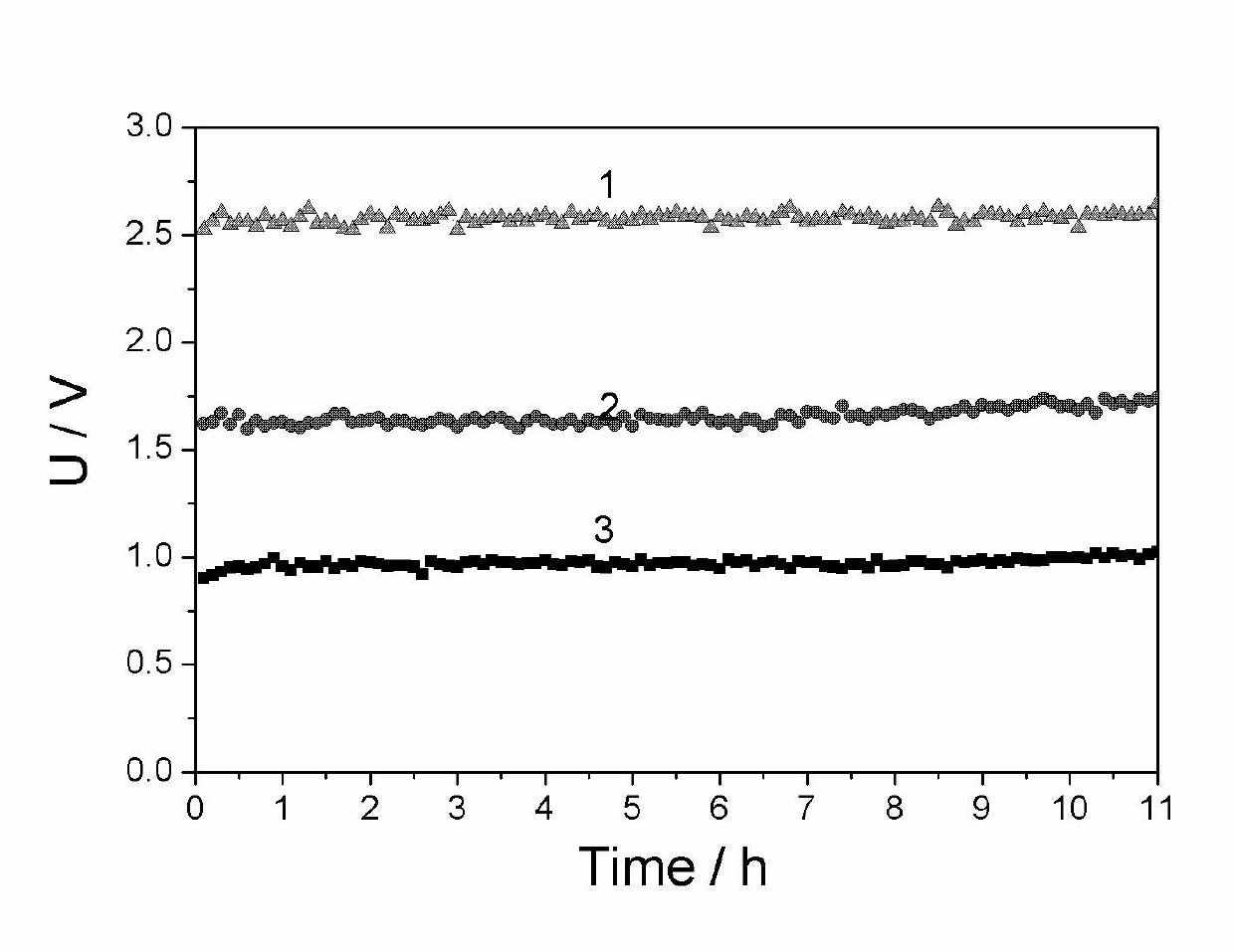

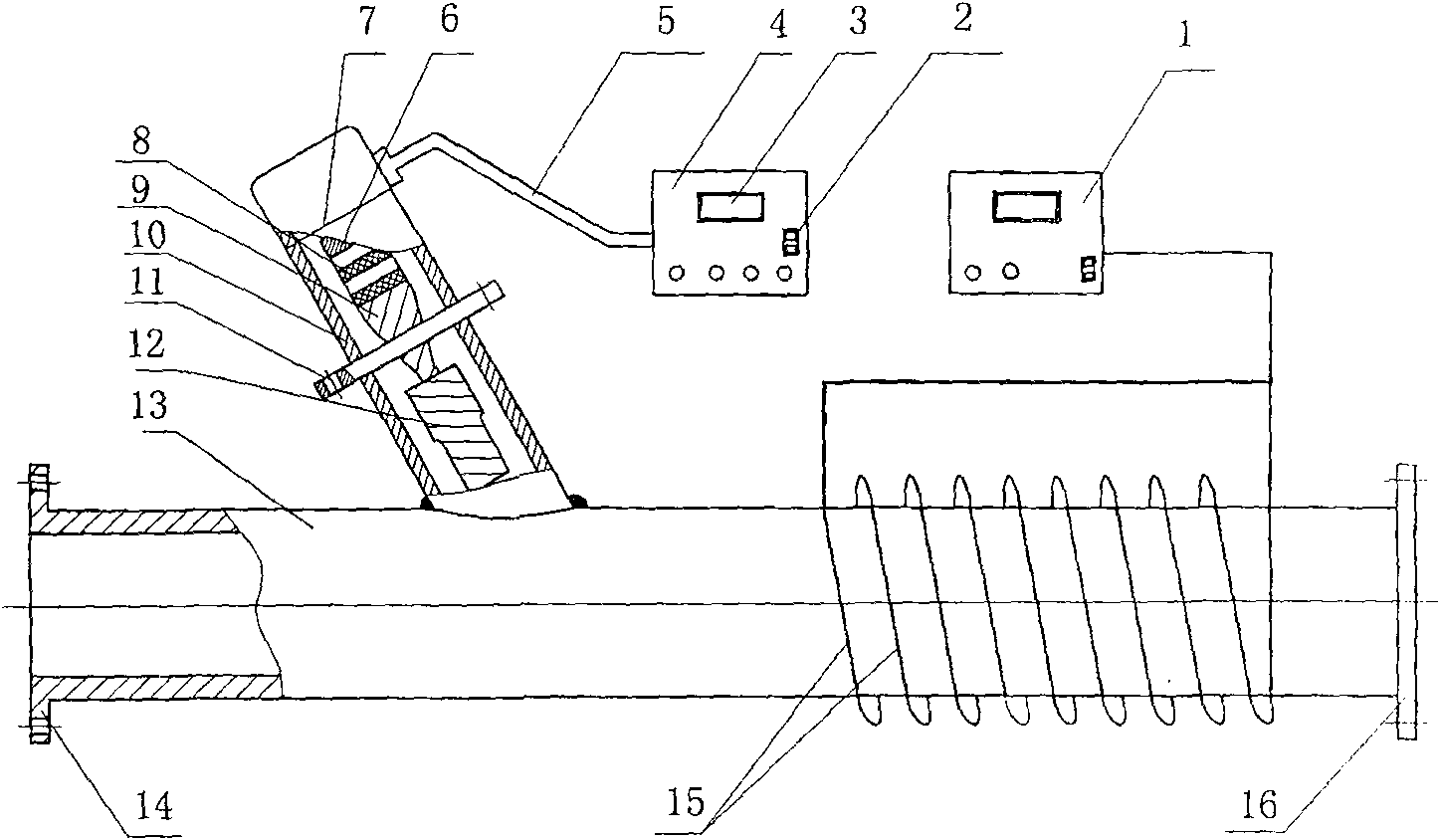

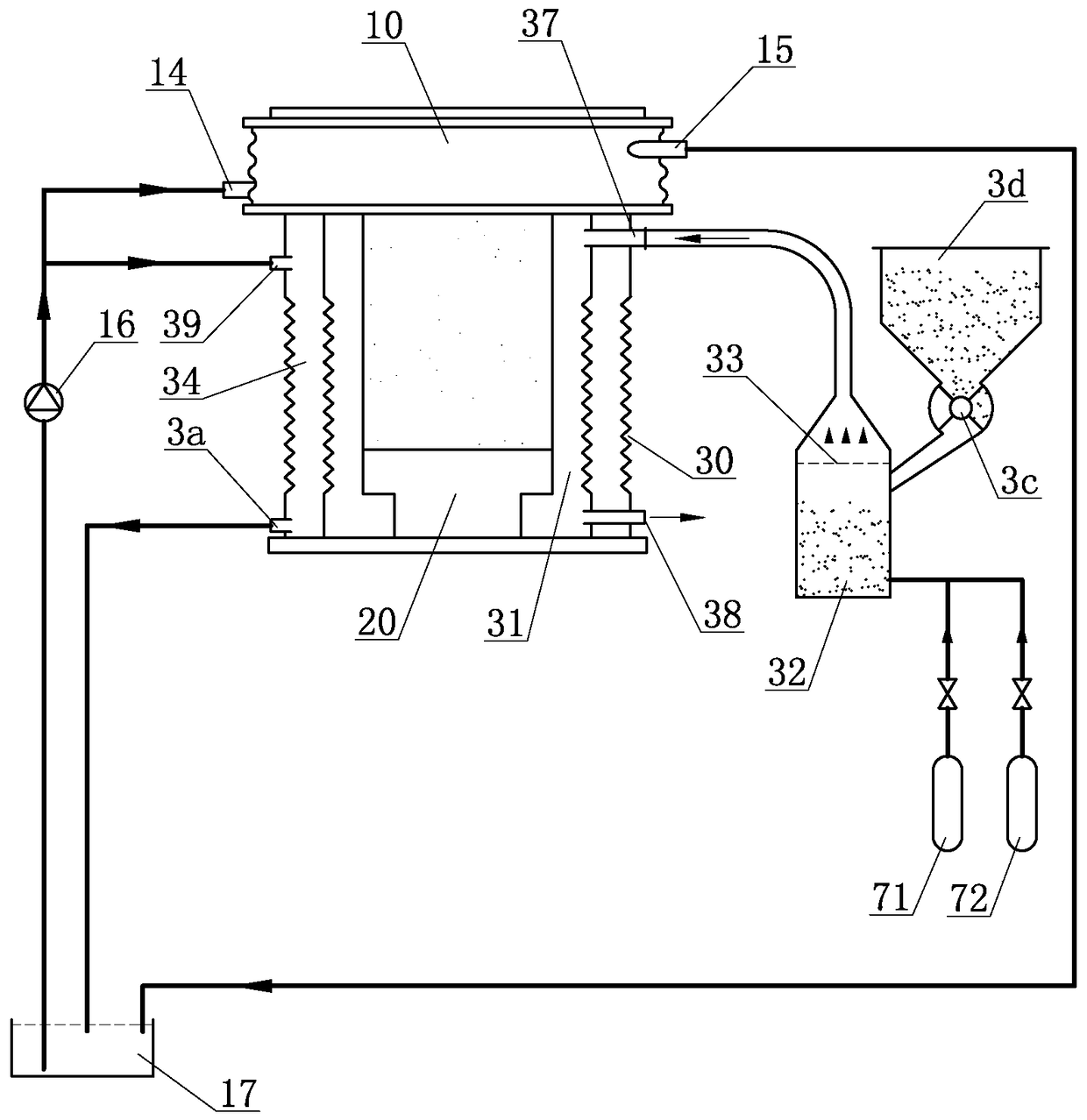

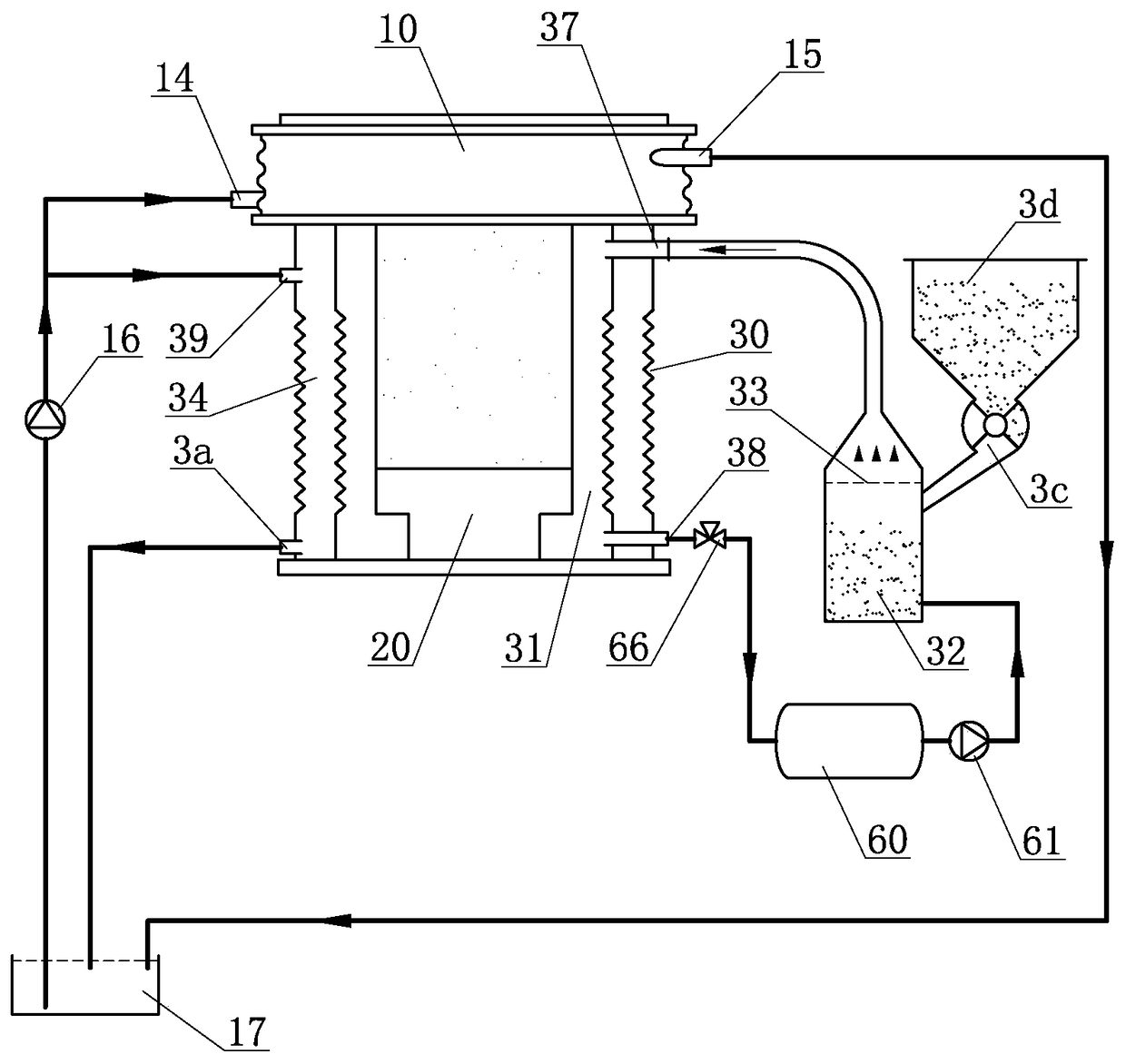

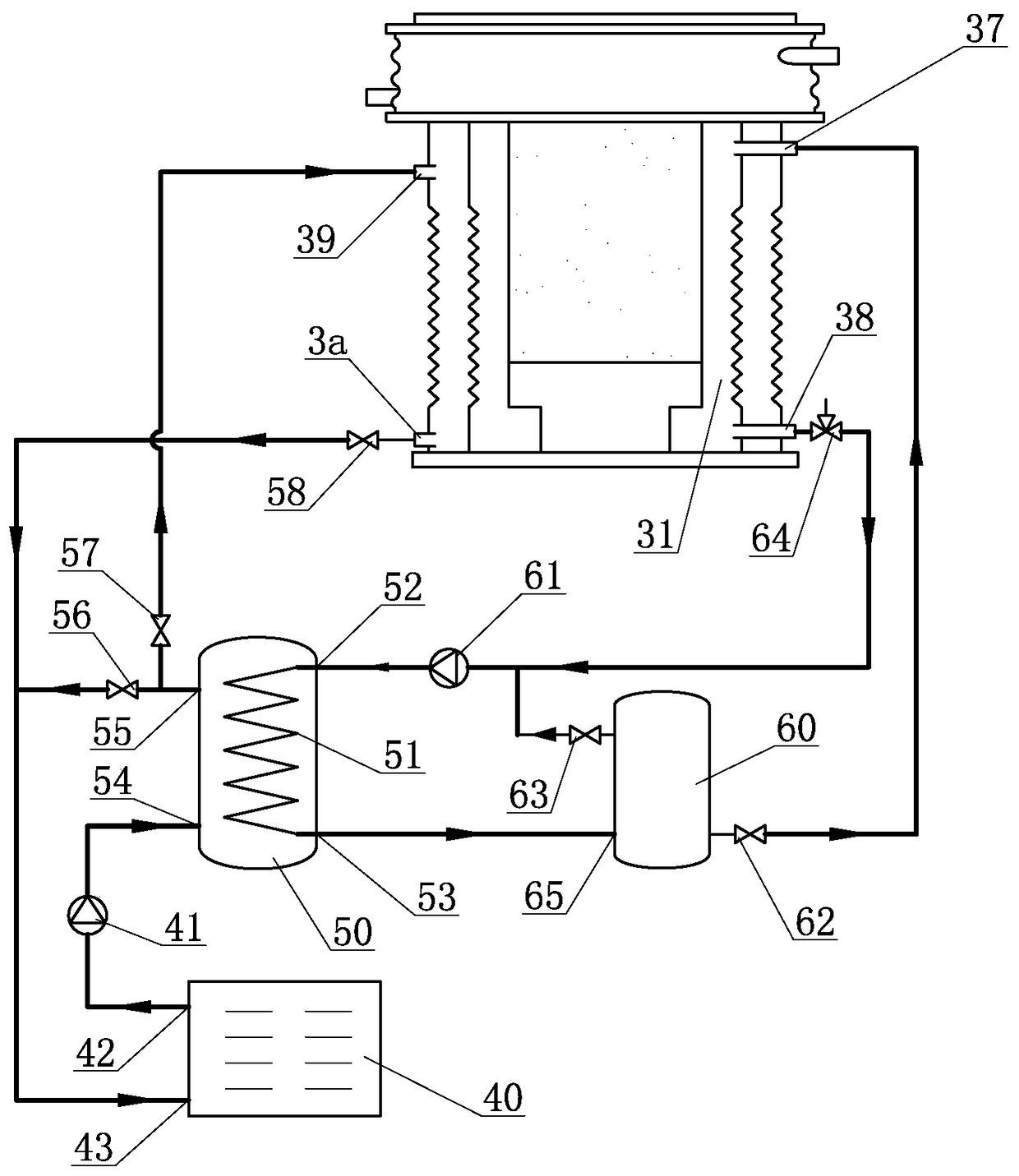

Method and device for hydrogen-circulating electrolysis and application of the method and device in production of aluminum oxide

ActiveCN102605383AReduce oxidation corrosionImprove corrosion resistanceCellsSodium bicarbonateCarbonization

The invention discloses a device for electrolyzing a water solution by hydrogen circulation. The device comprises a hydrogen anode, a hydrogen evolution cathode, an electrolytic cell and a hydrogen collecting and processing device, wherein the electrolytic cell is divided into an anode chamber and a cathode chamber via a diaphragm. The electrolysis method comprises the following steps: collecting the hydrogen generated by the cathode, introducing the hydrogen into an anode gas chamber, and oxidizing the hydrogen at the anode into hydrogen ions in the solution, wherein the reaction at the cathode is a hydrogen evolution reaction; and hydrogen generated by the cathode is effectively utilized at the anode, so that the hydrogen circulation is achieved, and the cell voltage is reduced to 0.9-1.3V, and the power consumption is greatly reduced. The electrolysis method and device can be applied to the production process of aluminum oxide by an alkali-dissolution and carbonization-precipitation method, i.e., sodium carbonate solution is electrolyzed based on a hydrogen-circulating electrolysis technology to obtain a sodium hydroxide solution at the cathode zone and a sodium bicarbonate solution at the anode zone, and the sodium hydroxide solution and the sodium bicarbonate solution are used for dissolving ore and breaking down a sodium aluminate solution, respectively. By using the hydrogen-circulating electrolysis for breaking down the sodium carbonate solution, the power consumption of the aluminum oxide production by the alkali-dissolution and carbonization-precipitation method can be significantly reduced.

Owner:BEIJING UNIV OF CHEM TECH

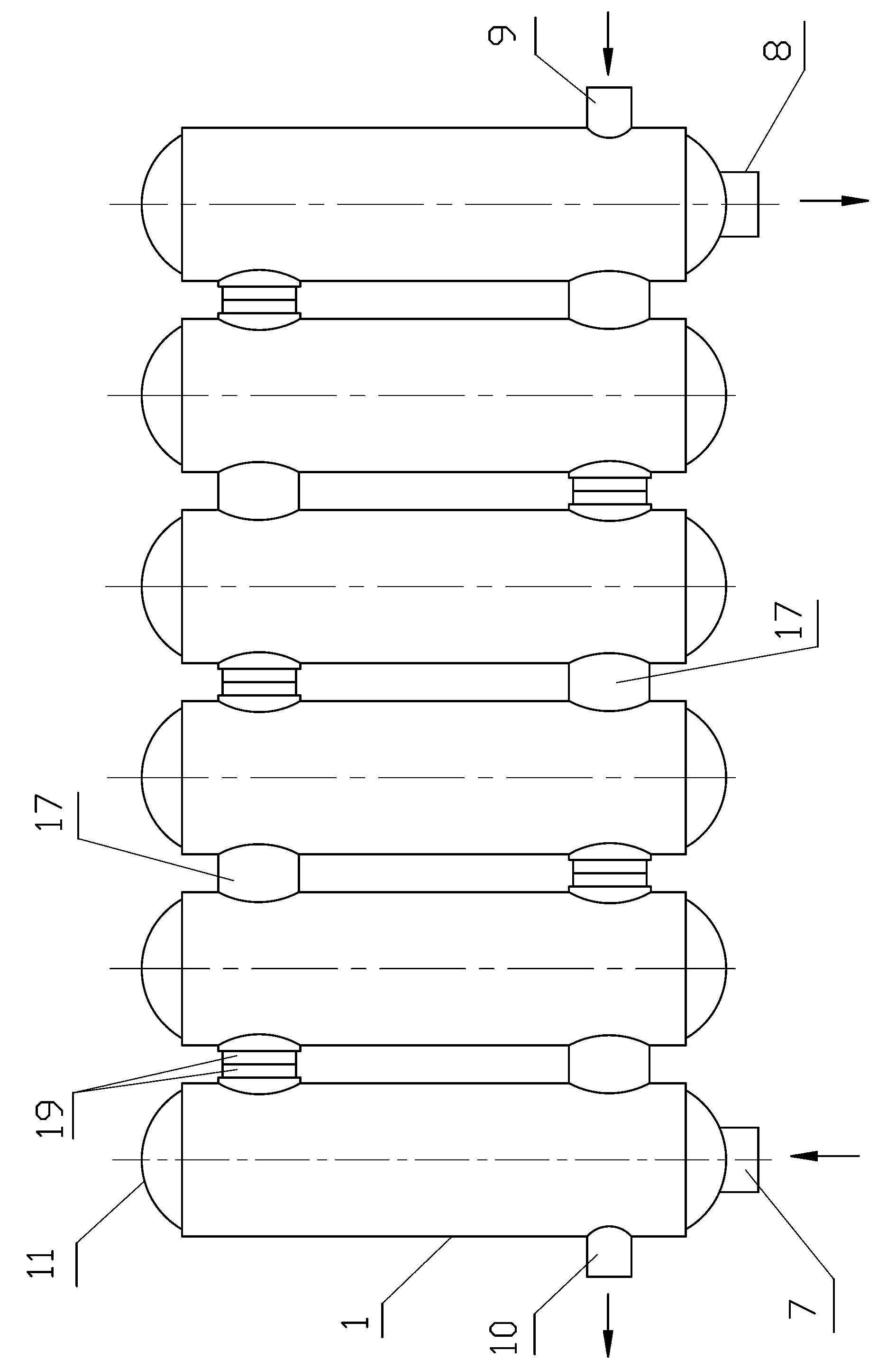

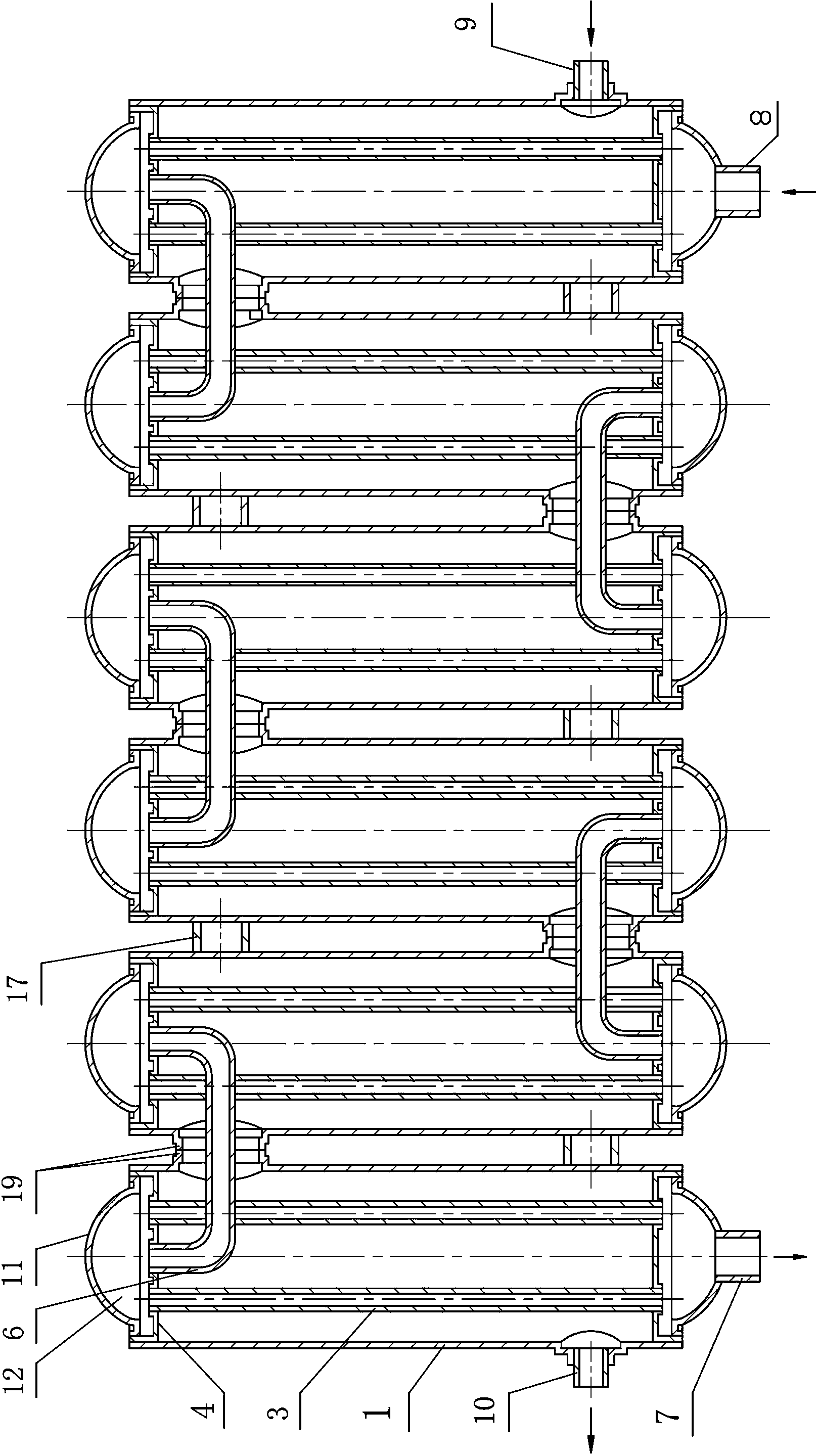

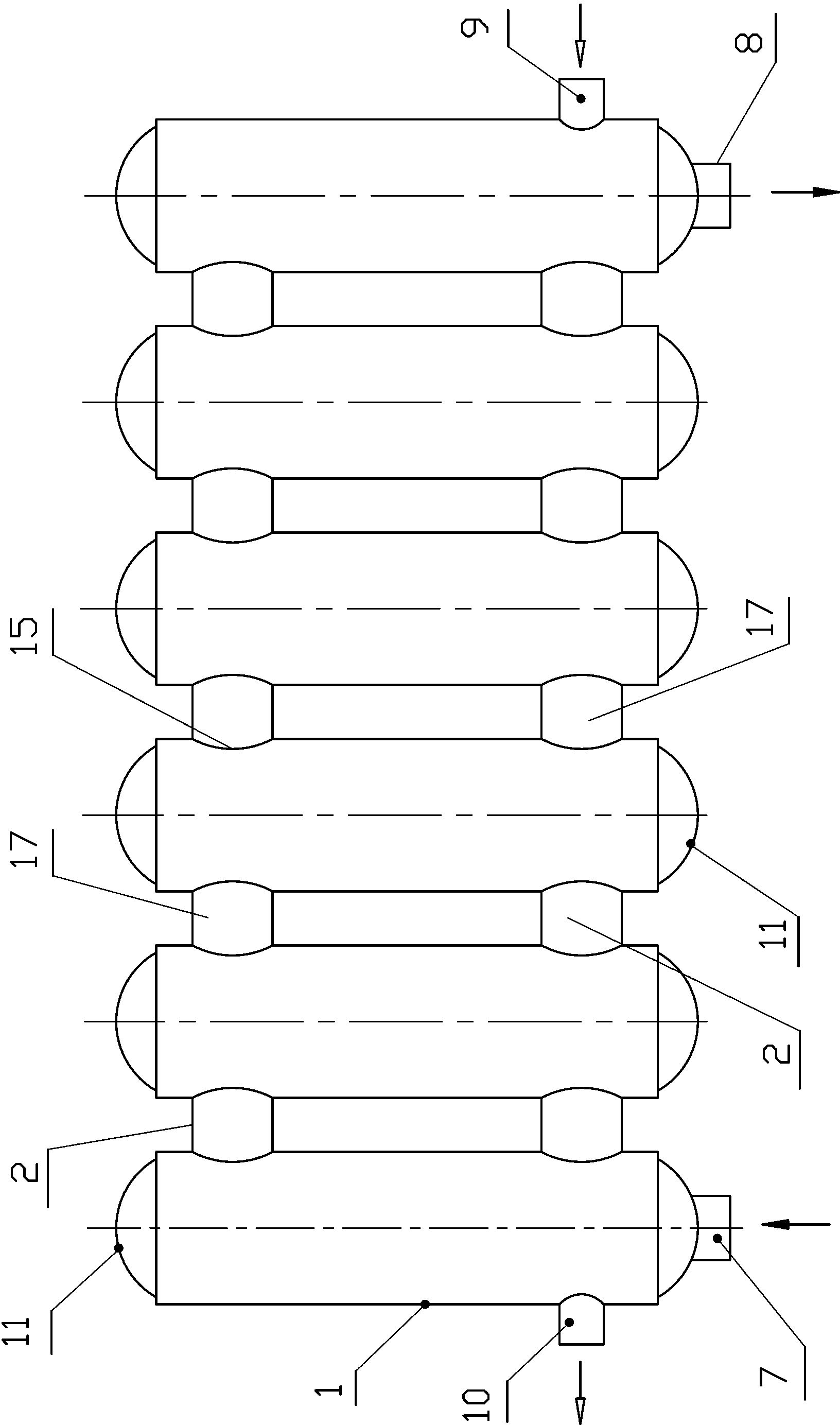

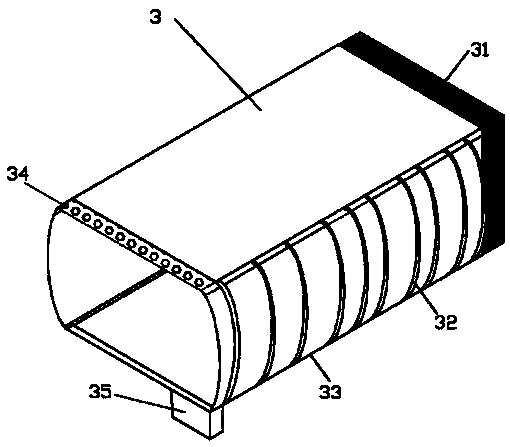

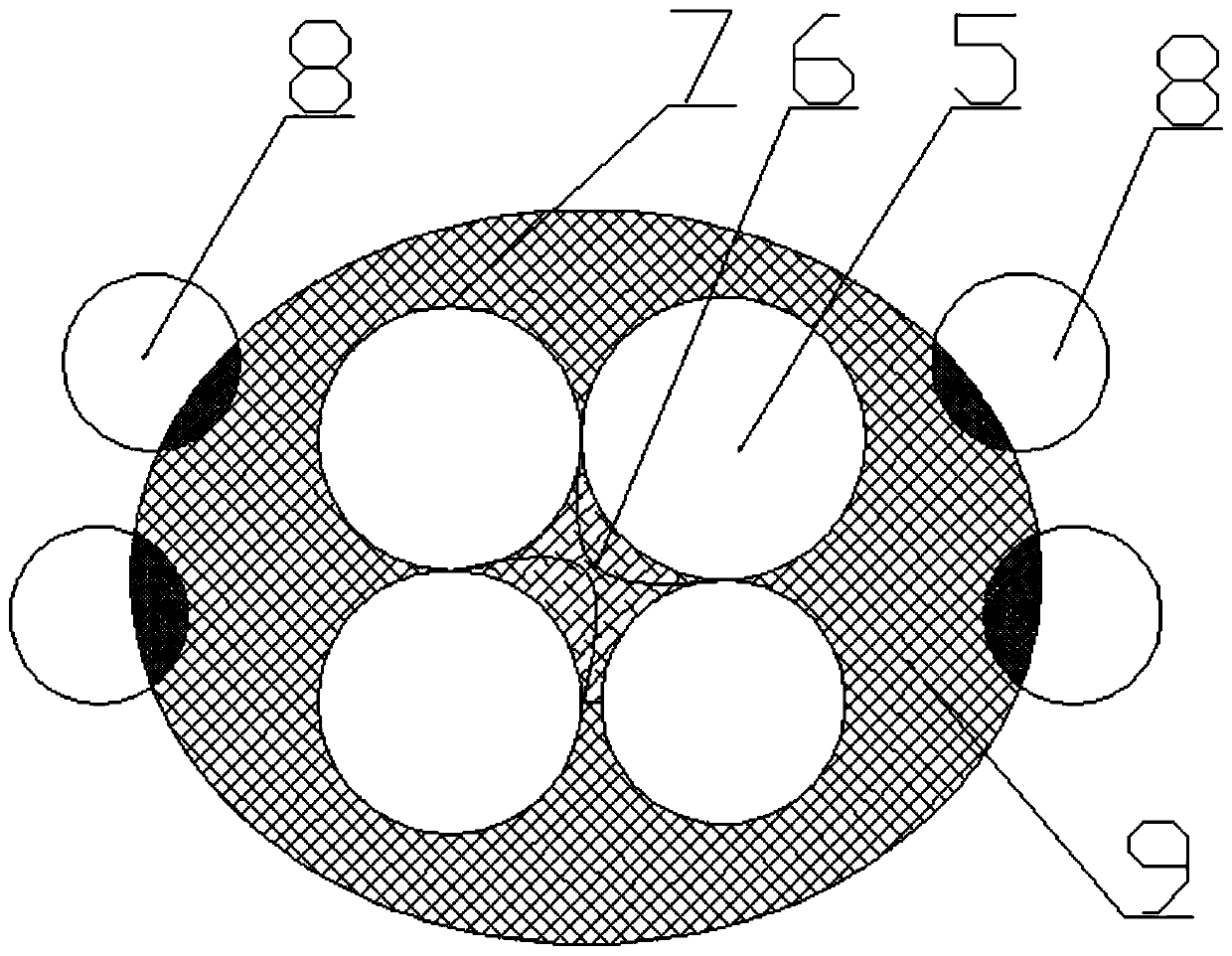

Heater multi-pipe heat conducting type shell-tube water storage bearing heat interchanger and manufacturing technology thereof

ActiveCN103851936ASave Unicom pipe materialsSave materialHeat exchanger casingsStationary tubular conduit assembliesWater storageManufacturing technology

The invention provides a heater multi-pipe heat conducting type shell-tube water storage bearing heat interchanger and a manufacturing technology thereof. The heat interchanger comprises multiple round cold water pipes; head external blocking plates are welded at two ends of the round cold water pipes; heater pipe connecting blocking plates are welded in pipe openings at two ends of the round cold water pipes; round heater pipe connecting openings are formed on the heating pipe connecting blocking plates; pipe cavities are directly welded and communicated by the adjacent round cold water pipes through straight round cold water communicating pipes or butt-welded wall pulling pipes; at least one round heater pipe is penetrated into the cavity of each round cold water pipe; pipe openings of two ends of each round heater pipe are in welded connection with connecting openings of the round heater pipe on the heater pipe connecting blocking plates; round heater communicating pipes are in welded communication with the heater pipe connecting blocking plates or the round heater communicating pipes are sequentially welded and communicated with the head external blocking plates and are communicated with a thermal fluid shunting cavity to form a thermal fluid circulated heat transmission passage. The heat interchanging structure is more scientific and reasonable; the heat transmission area is improved by 55%-100%; the heat conduction rate is accelerated; the heat exchanging effect is excellent. The welding joints of the communicating pipes among the cavities are difficultly subjected to water leakage.

Owner:山东利能换热器有限公司

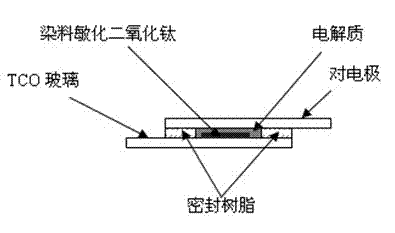

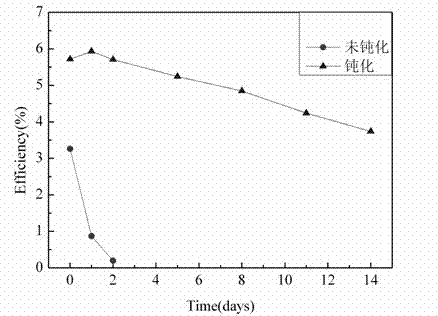

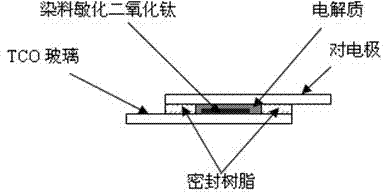

Method for preparing dye sensitized solar cell with stainless steel substrate

InactiveCN102509631AReduce oxidation corrosionImprove long-term stabilityLight-sensitive devicesFinal product manufactureDye-sensitized solar cellCorrosion

The invention discloses a method for preparing a dye sensitized solar cell with a stainless steel substrate, which includes the following steps: (1) placing the stainless steel substrate in pickle liquor for pickling treatment, (2) placing the stainless steel substrate after pickling in passivation solution for passivation treatment, (3) plating platinum on the surface of the passivated stainless steel substrate, and (4) assembling the platinum-plated stainless steel substrate serving as a counter electrode, an photoanode and electrolyte together to form the dye sensitized solar cell. By means of the method, the stainless steel substrate is performed with pickling and passivation treatment, the counter electrode used as the dye sensitized solar cell is sintered and plated with platinum at high temperature, a layer of stable oxidation film is formed on the stainless steel surface after passivation, and the layer of stable oxidation film effectively relieves oxidation corrosion on the stainless steel substrate during high-temperature platinum plating. Simultaneously, the layer of stable oxidation film prevents iodine-containing electrolyte from corroding the stainless steel substrate after the battery is formed through packaging, further pollution on the electrolyte caused by corrosion products is reduced, and long-period stability of the dye sensitized solar cell with the stainless steel substrate is effectively improved.

Owner:CHONGQING UNIV

Anti-oxidative and environment-friendly water-based paint remover and preparation method thereof

InactiveCN106519788AImprove stabilityImprove antioxidant capacityChemical paints/ink removersWater basedMicrocrystalline wax

The invention discloses anti-oxidative and environment-friendly water-based paint remover. The water-based paint remover is prepared from raw materials in parts by weight as follows: 1.2-1.4 parts of nano-montmorillonite, 1.5-2 parts of a penetrant T, 42-46 parts of benzyl alcohol, 11-12 parts of acetone, 10-11 parts of hydrogen peroxide, 3-3.5 parts of methyl cellulose, 2-2.4 parts of urotropine, 1.3-1.5 parts of dodecyl benzene sulfonate, 1.6-1.9 parts of microporous starch, 2.2-2.5 parts of microcrystalline wax, 0.8-1 part of tetrabutyl titanate, a proper amount of ammonium hydroxide, a proper amount of ethanol, 50-55 parts of water, 1-1.3 parts of gluconic acid, 1-1.3 parts of butylated hydroxyanisole and 1-2 parts of menthol. The water-based paint remover has good permeability, can quickly peel a paint film, can also protect the surface of metal and prevent oxidation corrosion and has less irritation to human bodies due to adoption of gluconic acid, butylated hydroxyanisole and menthol.

Owner:MAANSHAN TUORUI METAL SURFACE TECH

Remote digital type ultrasound wave/frequency conversion antiscaling descaling equipment

InactiveCN100579670CHelp clearReduce oxidation corrosionWater/sewage treatment with mechanical oscillationsMechanical vibrations separationCavitationShortest distance

Owner:刘利华

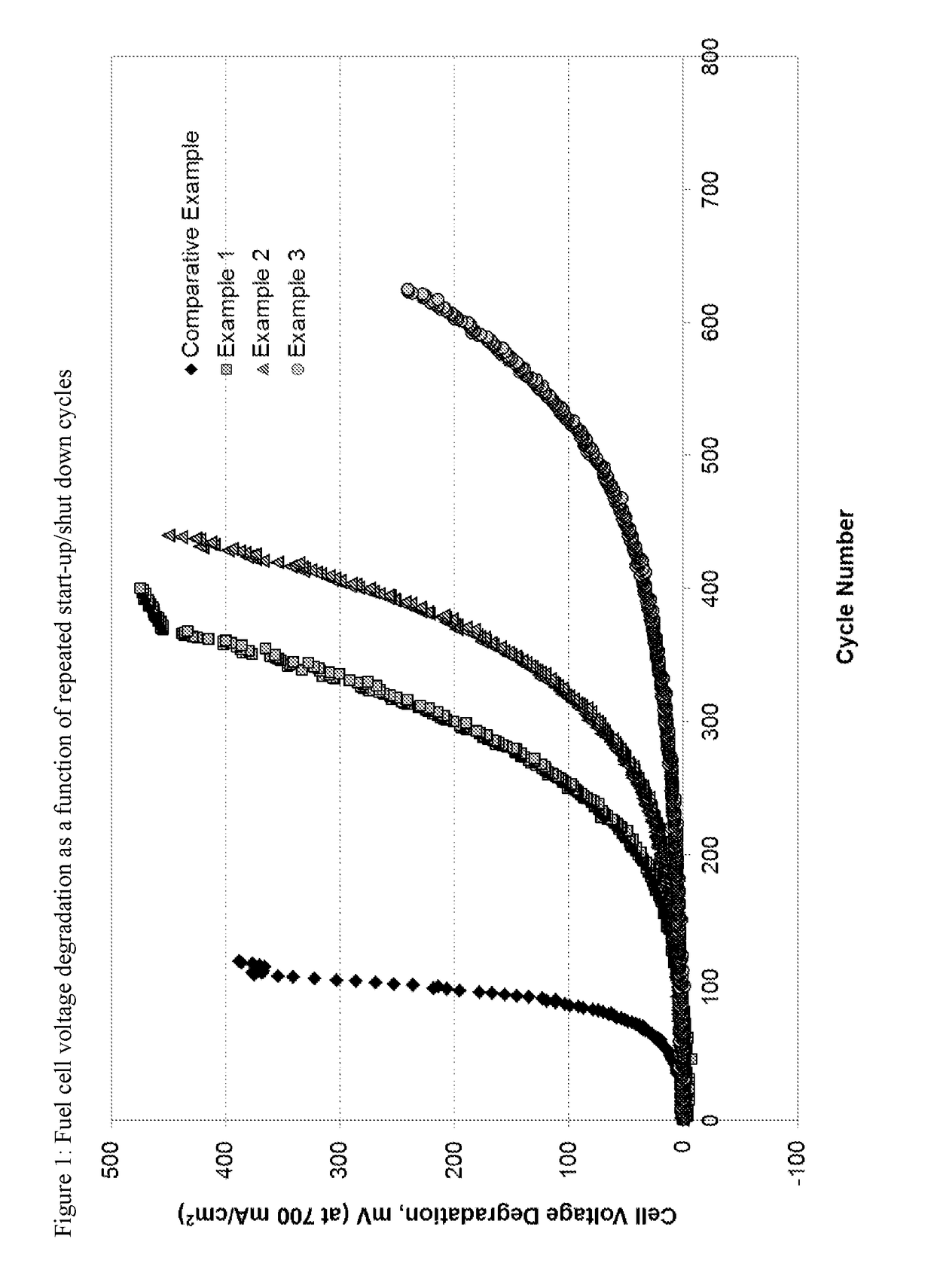

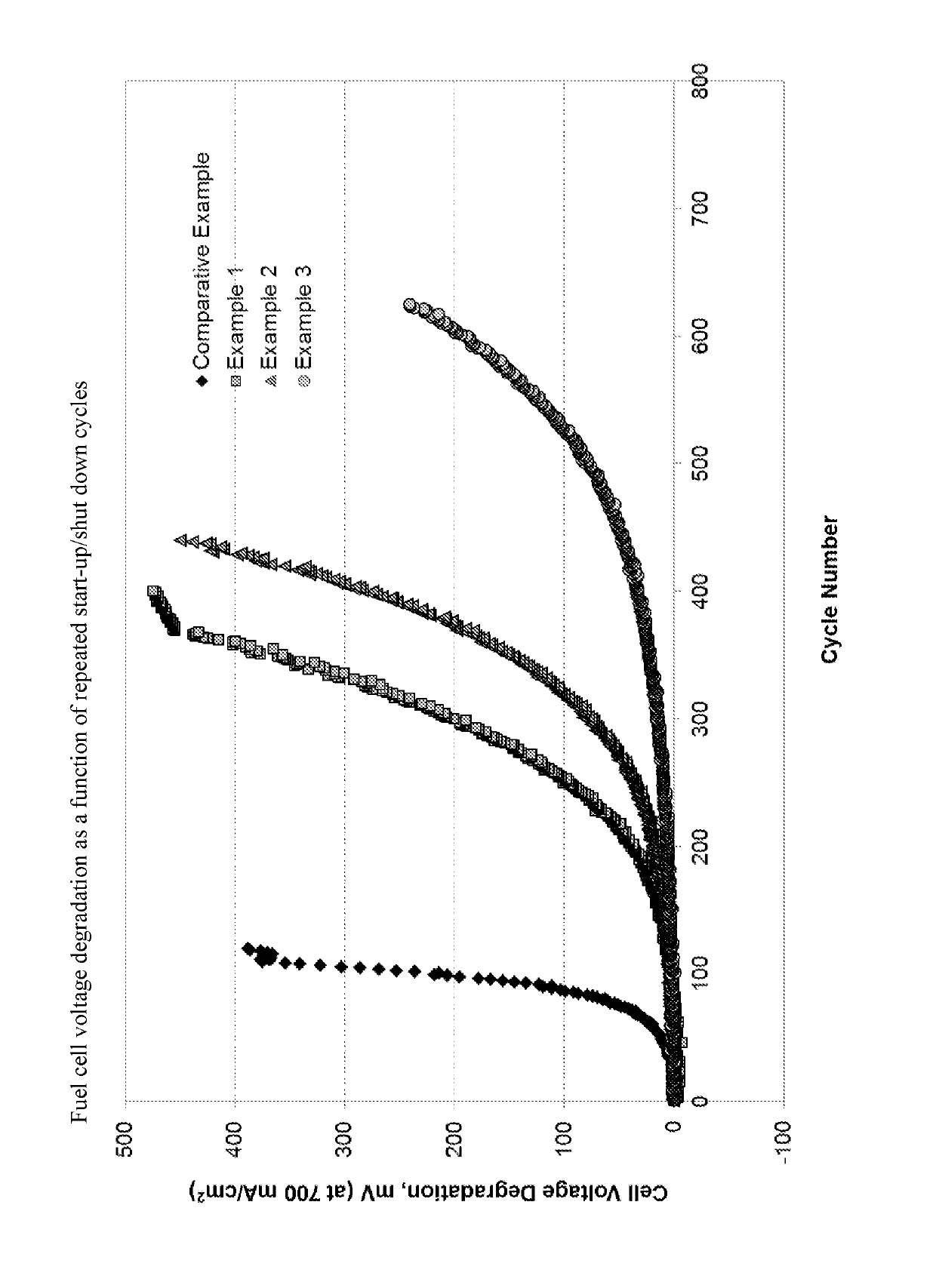

Membrane Electrode Assembly

ActiveUS20170155163A1Improve toleranceWithout compromising performanceCell electrodesFuel cellsPlatinumOxygen evolution

The invention includes a catalysed membrane and membrane electrode assembly. The membrane and membrane electrode assembly comprise an ion-conducting membrane component comprising an ion-conducting membrane, an anode catalyst layer, and a cathode catalyst layer. The anode catalyst layer comprises a first electrocatalyst component comprising a first platinum-containing electrocatalyst and a first carbon support. The first carbon support supports the first platinum-containing electrocatalyst, and the electrochemical platinum surface area in the anode catalyst layer is 5-100 cm2Pt / cm2 of the geometric electrode area of the anode catalyst layer. The cathode catalyst layer comprises a second electrocatalyst component and a second oxygen evolution reaction electrocatalyst. The second electrocatalyst component comprises a second platinum-containing electrocatalyst and a second carbon support, wherein the second carbon support supports the second platinum-containing electrocatalyst component.

Owner:JOHNSON MATTHEY HYDROGEN TECH LTD

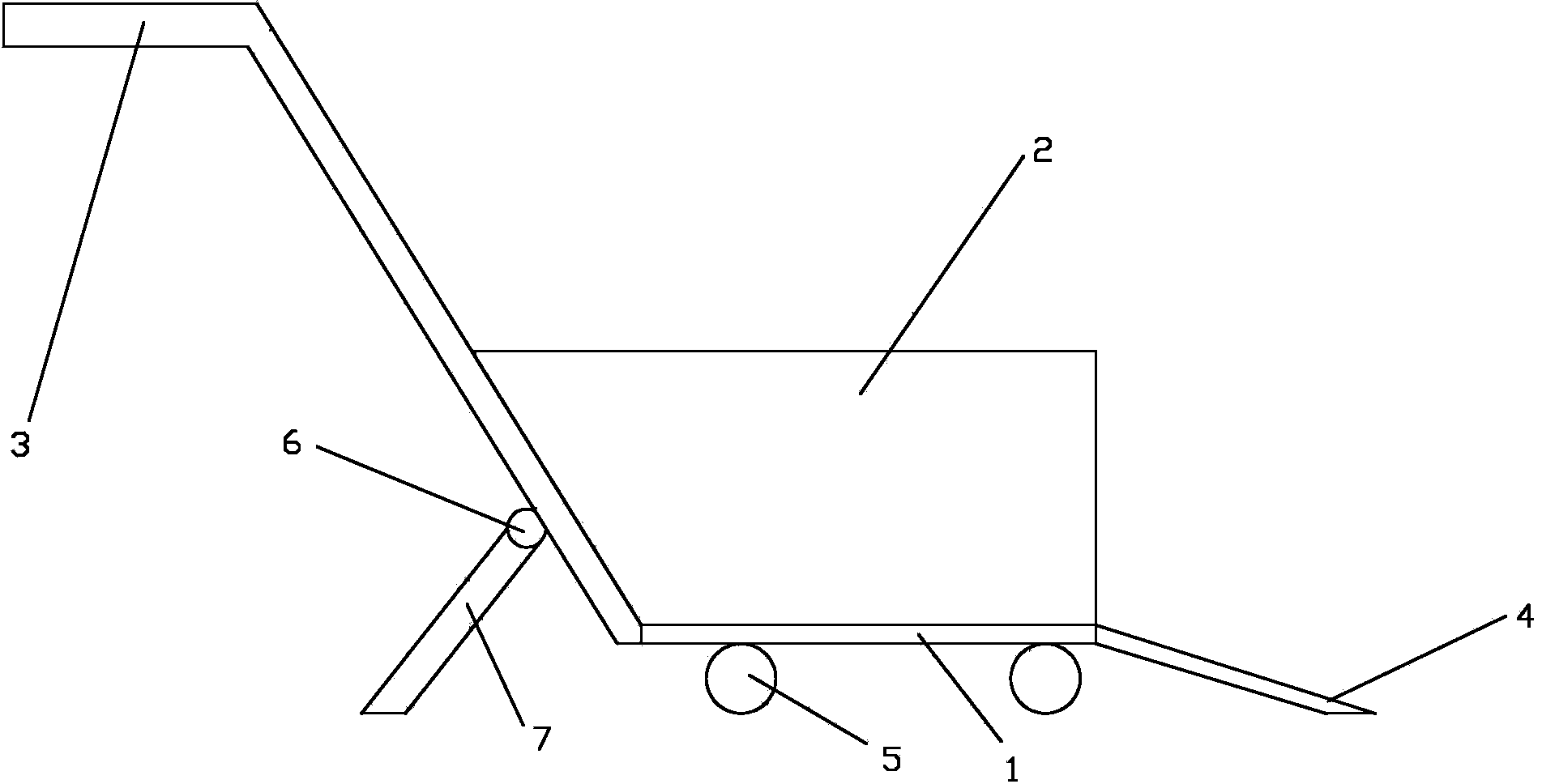

Corrugated board transfer trolley

InactiveCN104326001AReduce oxidation corrosionReduce shakingHand carts with multiple axesSurface layerFixed frame

The invention provides a corrugated board transfer trolley. According to the technical scheme of the invention, the corrugated board transfer trolley is characterized by comprising a chassis, wherein wheels are arranged below the chassis; a side baffle plate is fixed above the chassis; the chassis is provided with a movable feeding slope; one side opposite to the feeding slope is provided with a handrail; a fixing frame is arranged on the back side of the handrail; the fixing frame is fixed on the back side of the handrail through a fixing frame revolving shaft; the surface of the inner wall of a space defined by the chassis, the side baffle plate, the handrail and the feeding slope is glazed or provided with a ceramic surface layer. The corrugated board transfer trolley has the beneficial effects that the chassis and the side baffle plate are glazed, so that corrosion caused by oxidization of air is lowered; the fixing frame is designed, so that shaking of a trolley during feeding is reduced, single-person operation becomes possible, and a part of labor force is liberated.

Owner:TIANJIN YUANJING PACKAGING

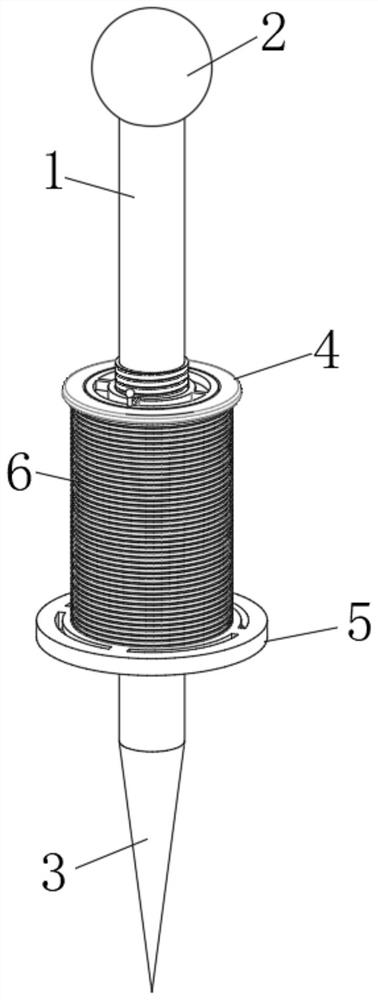

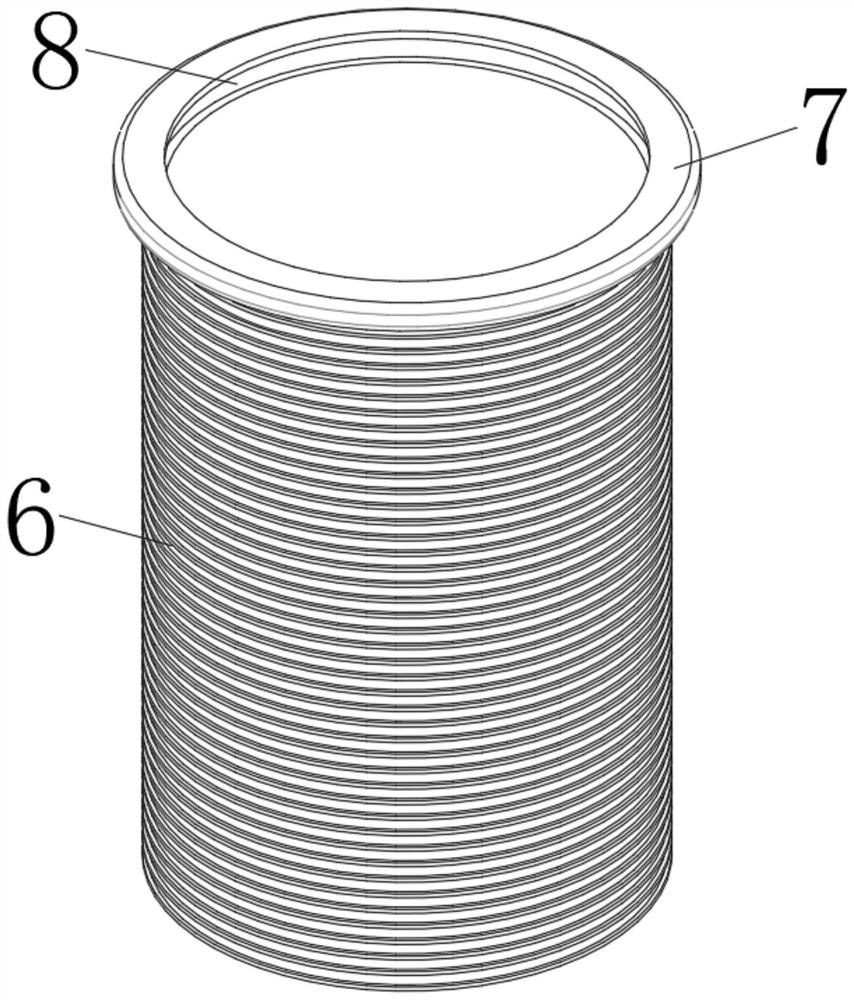

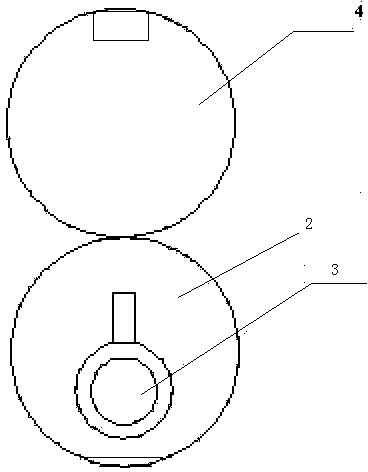

Marine monitoring equipment corrosion protection device

ActiveCN113008210AImprove the protective effectAvoid Rapid Corrosion SituationsNon-rotating vibration suppressionOpen water surveyControl engineeringStructural engineering

The present invention provides a marine monitoring equipment corrosion protection device which comprises a monitoring device main body, the monitoring device main body is of a cylindrical structure, an anti-corrosion assembly is fixedly installed at the middle section position of the monitoring device main body, the anti-corrosion assembly comprises a fixed disc, and the fixed disc is close to the lower end position of the monitoring device main body. A rubber sleeve is fixedly installed at the upper end of the fixing disc, a fixing ring is fixedly connected to the upper end of the rubber sleeve, a circle of sliding groove is formed in the inner wall of the fixing ring, a threaded sleeve is fixedly installed at the position, close to the upper end, in the monitoring device body, and a threaded ring is in threaded connection with the outer portion of the threaded sleeve. A plurality of connecting shafts are fixedly connected to the exterior of the threaded ring, a limiting ring is fixedly connected to the other end of each connecting shaft, a rotating handle is fixedly connected to the upper end of the limiting ring, a circle of sliding rail is fixedly connected to the outer wall of the limiting ring, the sliding rail is matched with the sliding groove in size, and the sliding rail is movably connected to the interior of the sliding groove.

Owner:QINGDAO HEADWAY TECH

Switch cabinet

InactiveCN103618218AAvoid damageReduce oxidation corrosionSubstation/switching arrangement casingsEngineering

The invention relates to a switch cabinet which includes a cabinet door. The cabinet door is provided with a concave circular groove; the concave circular groove is internally provided with a handle; the cabinet door is provided with a circular handle baffle; one side of the circular handle baffle is installed on an edge of the circular groove through a pin, and can rotate with the pin as an origin; the other side of the circular handle baffle is provided with a protrusion; and a notch matching the protrusion is arranged at a corresponding position of the circular groove. When the switch cabinet is in use, the circular handle baffle is closed to cover the circular groove; the notch and the protrusion are cooperated so that the circular handle baffle and the circular groove are locked; through cooperation between the circular handle baffle and the circular groove, the handle is closed, so that the damage to the handle in the transportation project can be effectively avoided, and the oxidation corrosion of the handle is effectively reduced.

Owner:TIANYUAN HUAWEI GRP

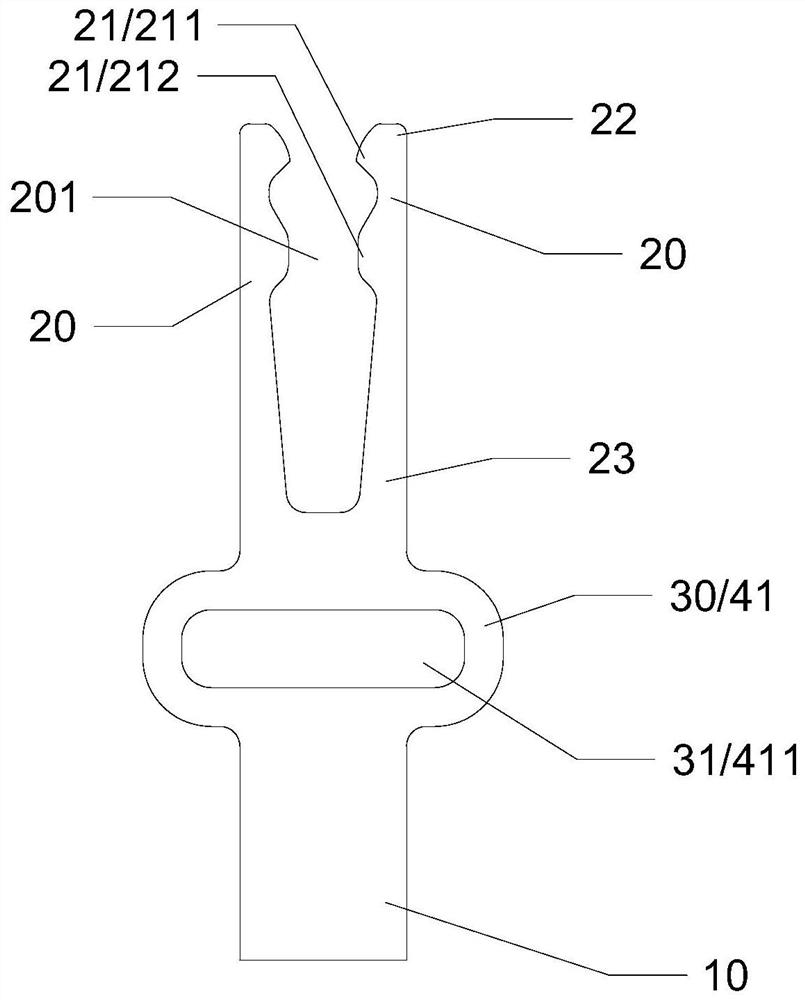

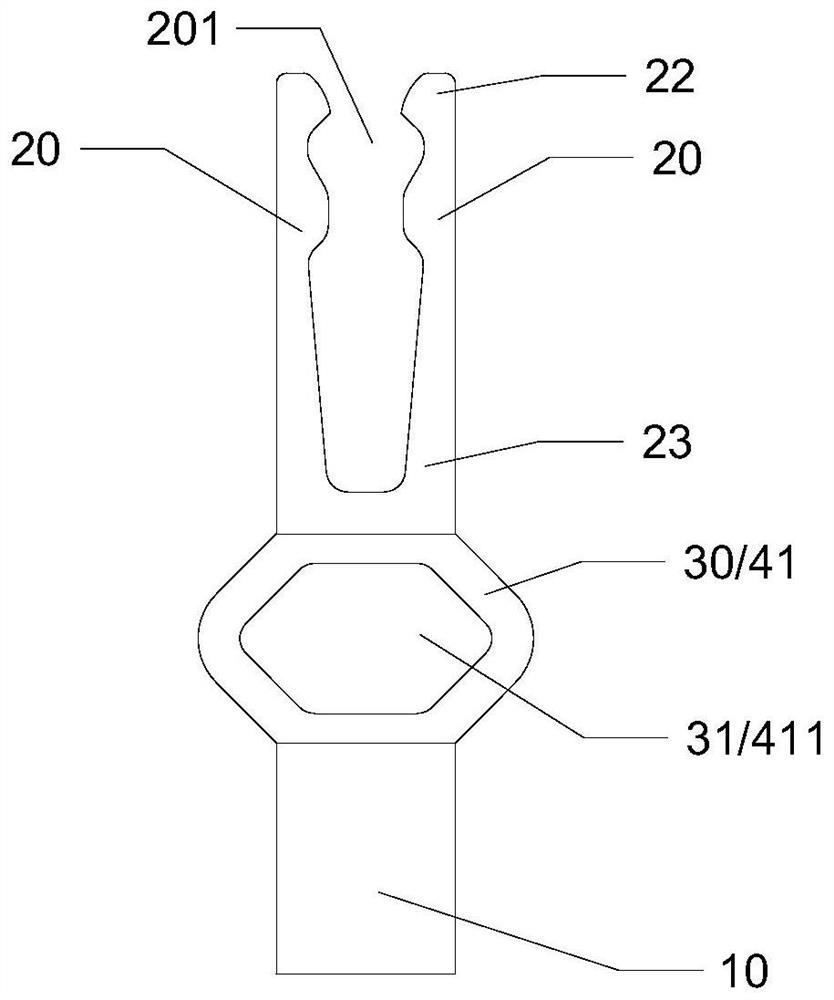

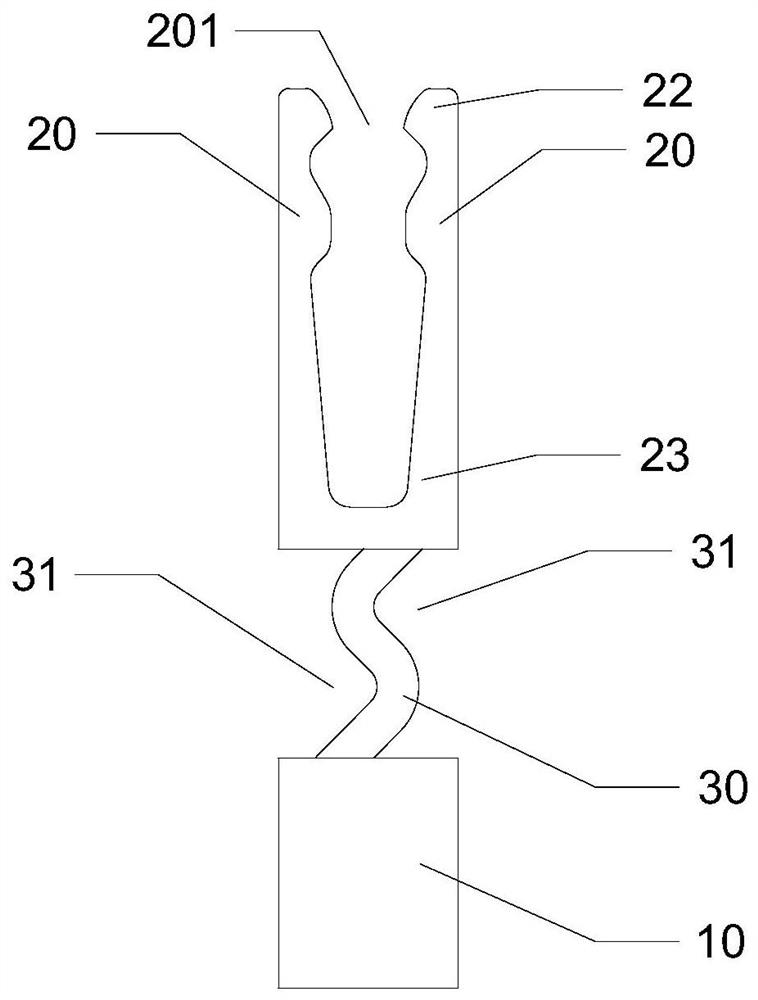

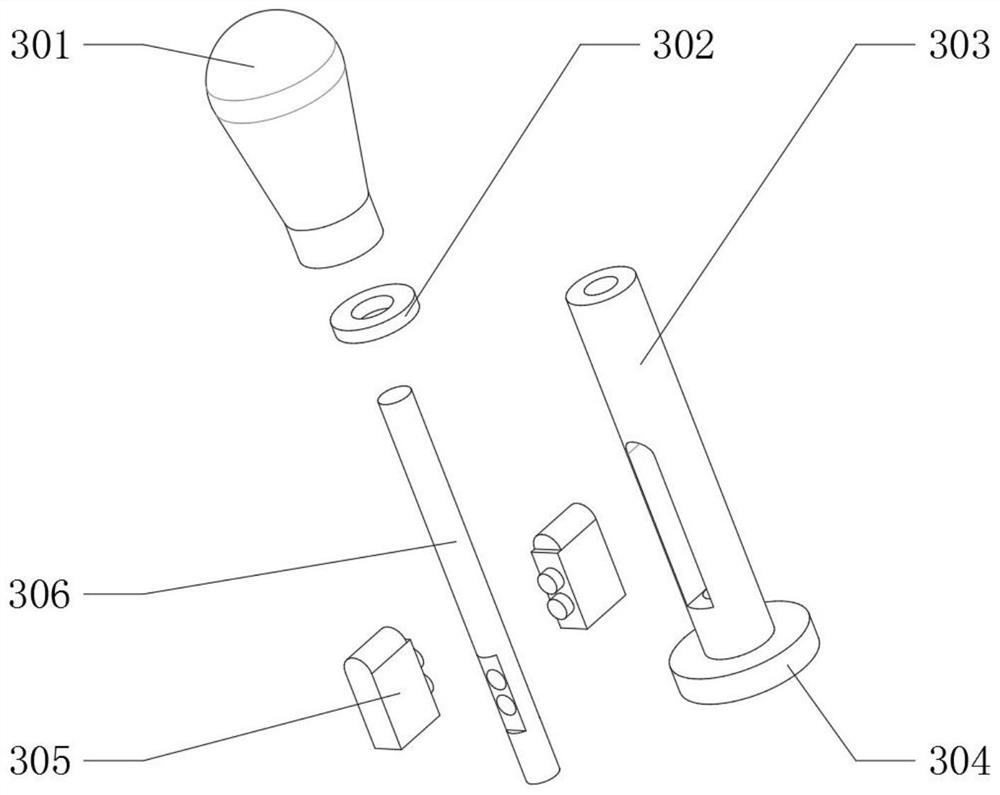

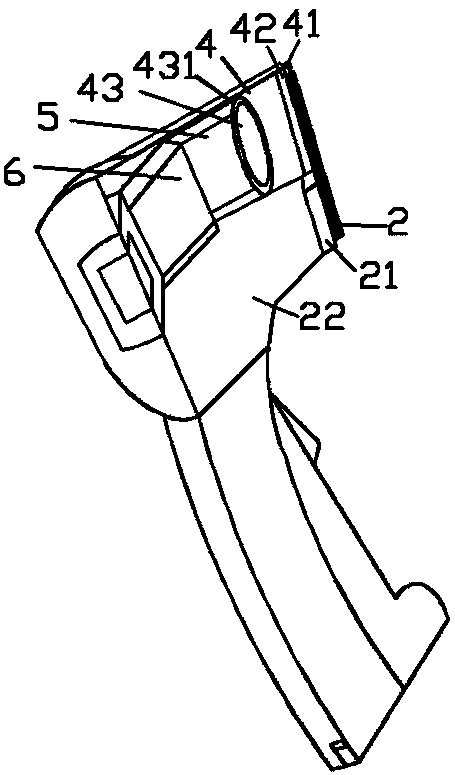

Micro-vibration terminal, plug-in structure and motor vehicle

PendingCN113571935AImprove elastic deformation abilityAvoiding Fretting Corrosion ProblemsSecuring/insulating coupling contact membersCoupling contact membersMotorized vehicleMechanical engineering

The invention provides a micro-vibration terminal, a plug-in structure and a motor vehicle. The micro-vibration terminal comprises a terminal fixing part, a vibrating body and a connecting arm which are distributed in sequence, wherein the vibrating body is fixedly connected to the terminal fixing part, and the terminal fixing part is used for being electrically connected with a cable; the connecting arm comprises an overhanging end and a fixed end, the fixed end is fixedly connected to the vibrating body, and the overhanging end is used for being in contact fit with a butt joint terminal; and the vibrating body is provided with a recess. According to the invention, the technical problem that the service life of the plug-in terminal is shortened because the contact area of the plug-in terminal is easy to oxidize is solved.

Owner:CHANGCHUN JETTY AUTOMOTIVE PARTS CORP

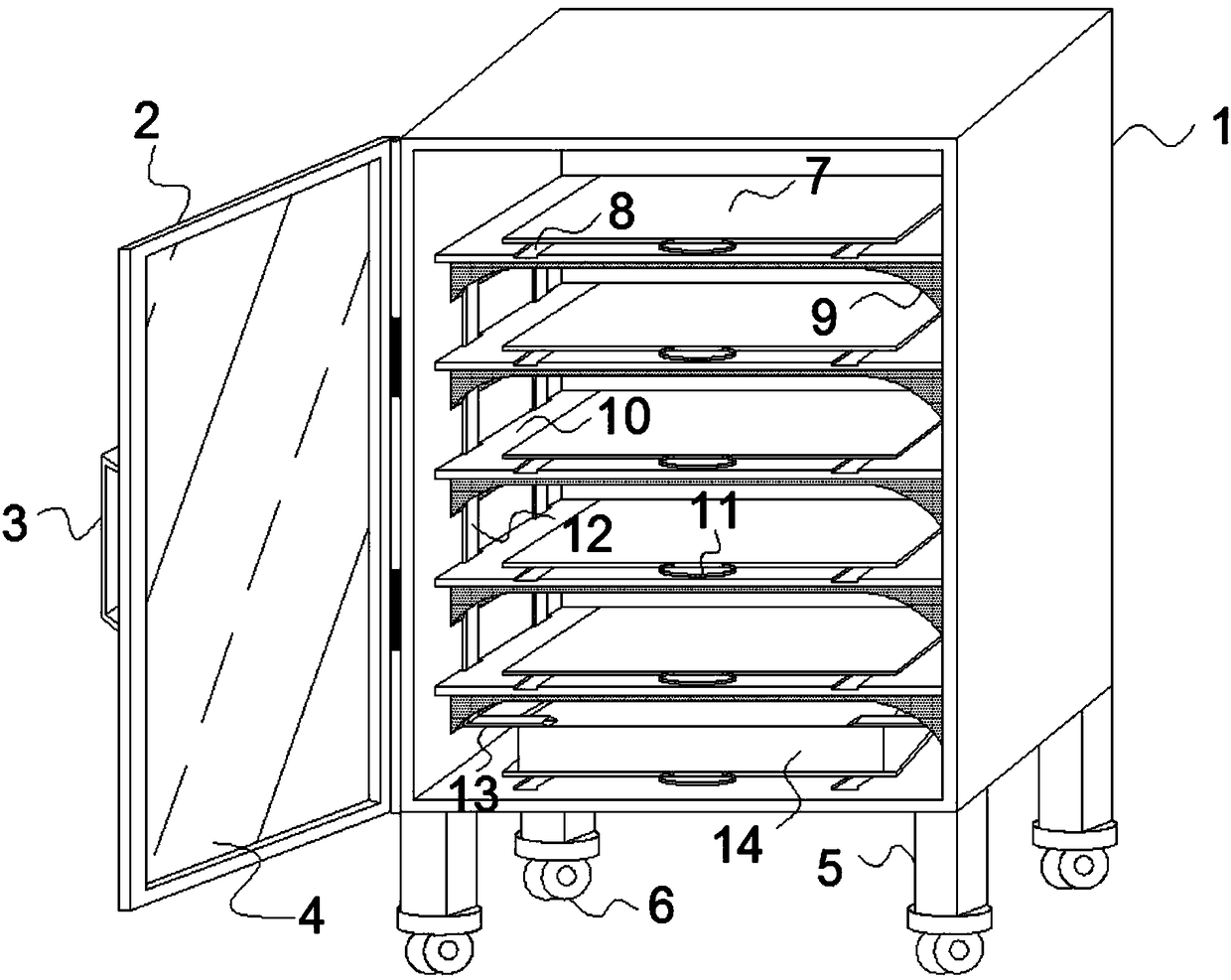

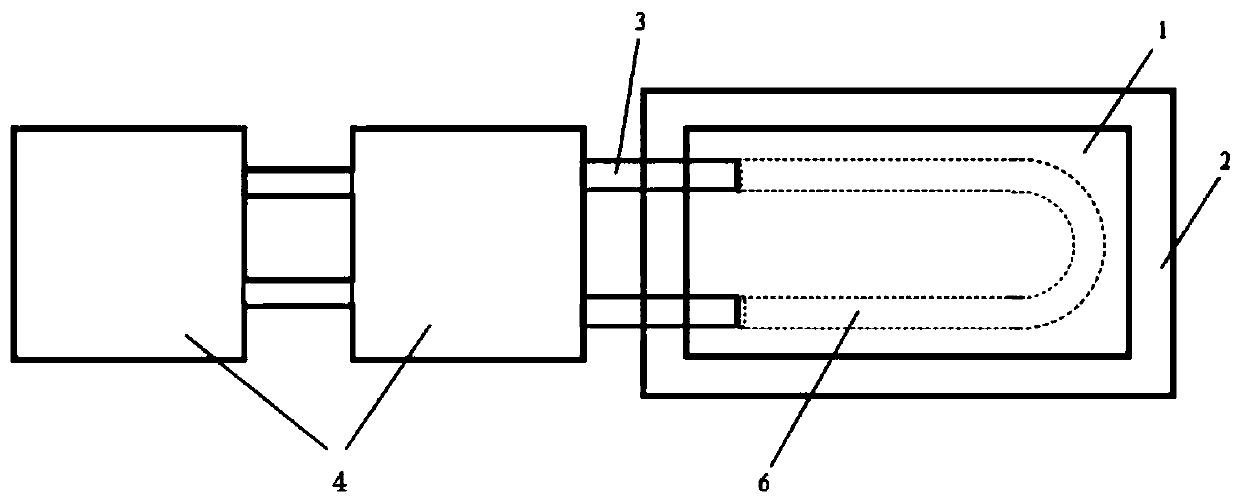

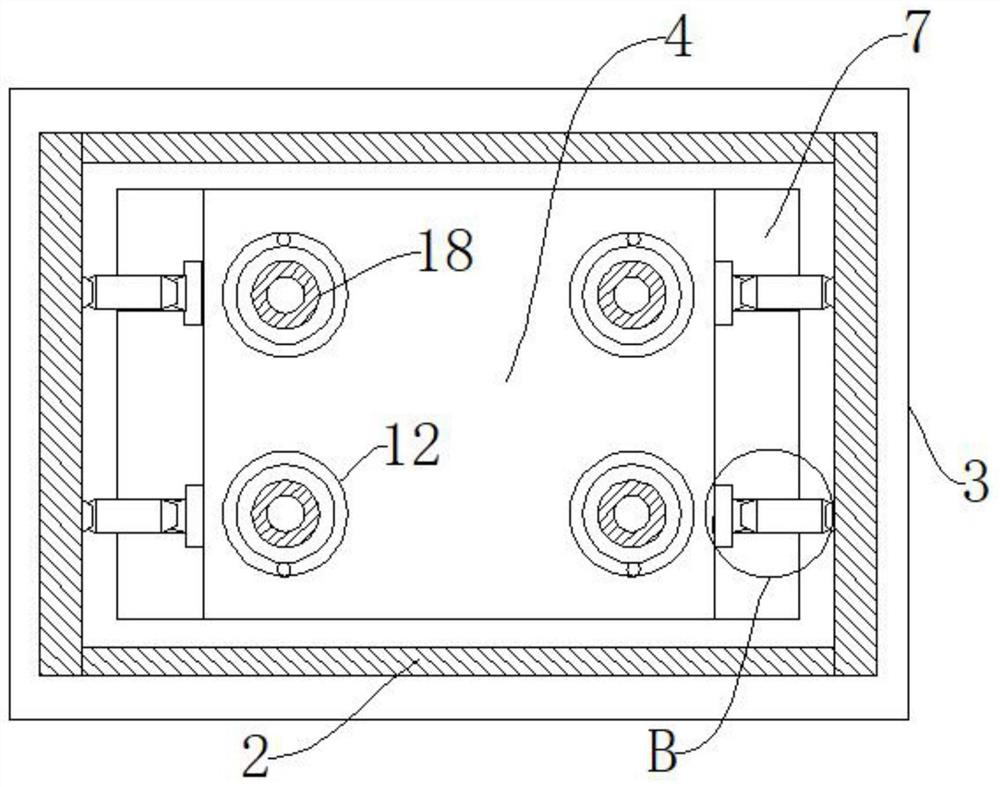

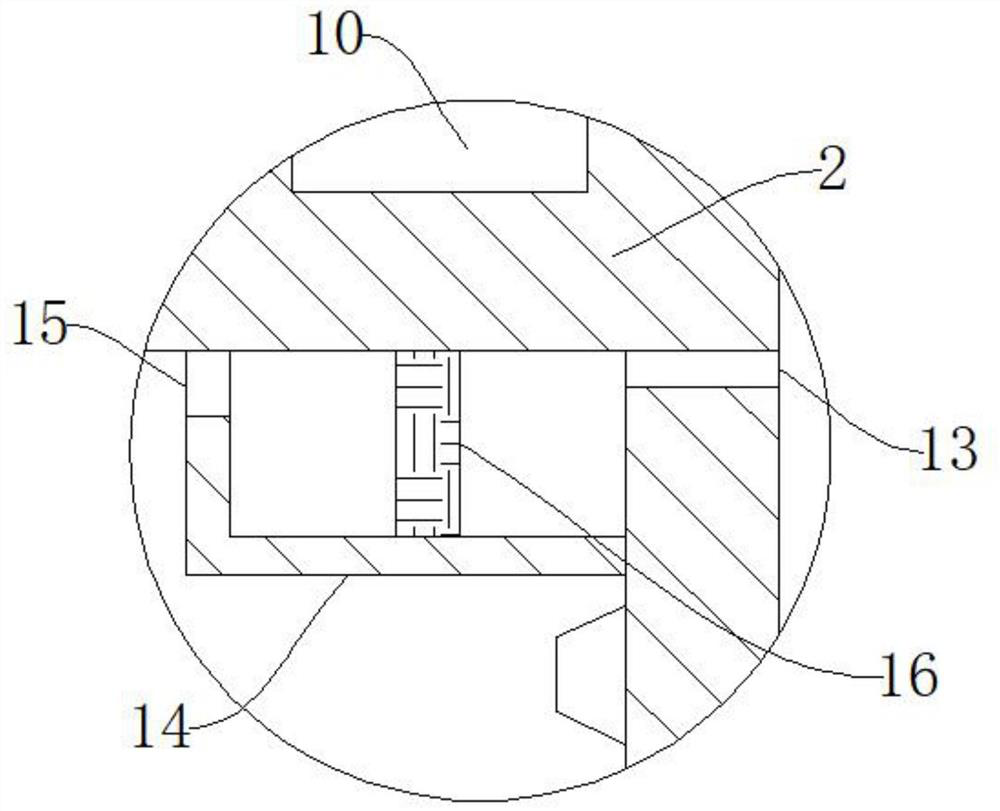

Vertical board baking device

PendingCN108282965AReduce oxidation corrosionEasy to watchPrinted circuit dryingWater tanksAerospace engineering

The invention relates to the technical field of PCB (printed circuit boards) baking boards, in particular to a vertical board baking device which comprises a baking oven. Four groups of bottom columnsare arranged at four corners of the bottom of the baking oven, brake universal wheels are connected with the bottom of the bottom columns, a door which is matched with the baking oven is rotationallyconnected with the left side of the front surface of the baking oven, transparent glass is penetratingly embedded in an inner cavity of the door, a handle is arranged in the center of a frame on theleft side surface of the door, baking boards are uniformly arranged in an inner cavity of the baking oven at intervals, U-shaped water storage cavities are arranged at the bottoms of the baking boards, delivery pipes are penetratingly connected with the bottoms of the left side and the right side of the top U-shaped water storage cavity in the front-back directions, first slide rails are embeddedin the left side and the right side of the top of each baking board and the left side and the right side of the bottom of the inner cavity of the baking oven, an accommodating disc is slidably clampedin inner cavities of the first slide rails on the left side and the right side of each of the tops of the baking boards and the bottom of the inner cavity of the baking oven, handles are arranged inthe centers of the front surfaces of the accommodating discs, and a topless water tank is fixedly connected with the top of the bottom accommodating disc. The vertical board baking device has the advantage that the shortcoming of inconvenience in baking existing PCB in the prior art can be effectively overcome by the aid of the vertical board baking device.

Owner:湖北金禄科技有限公司

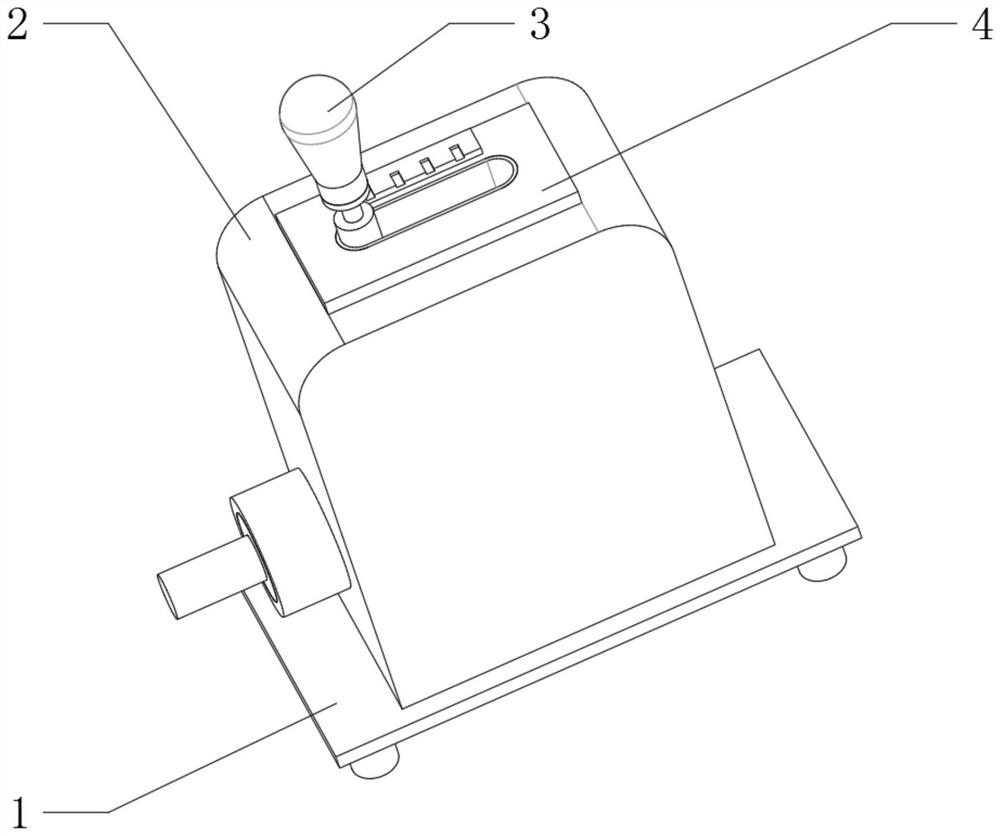

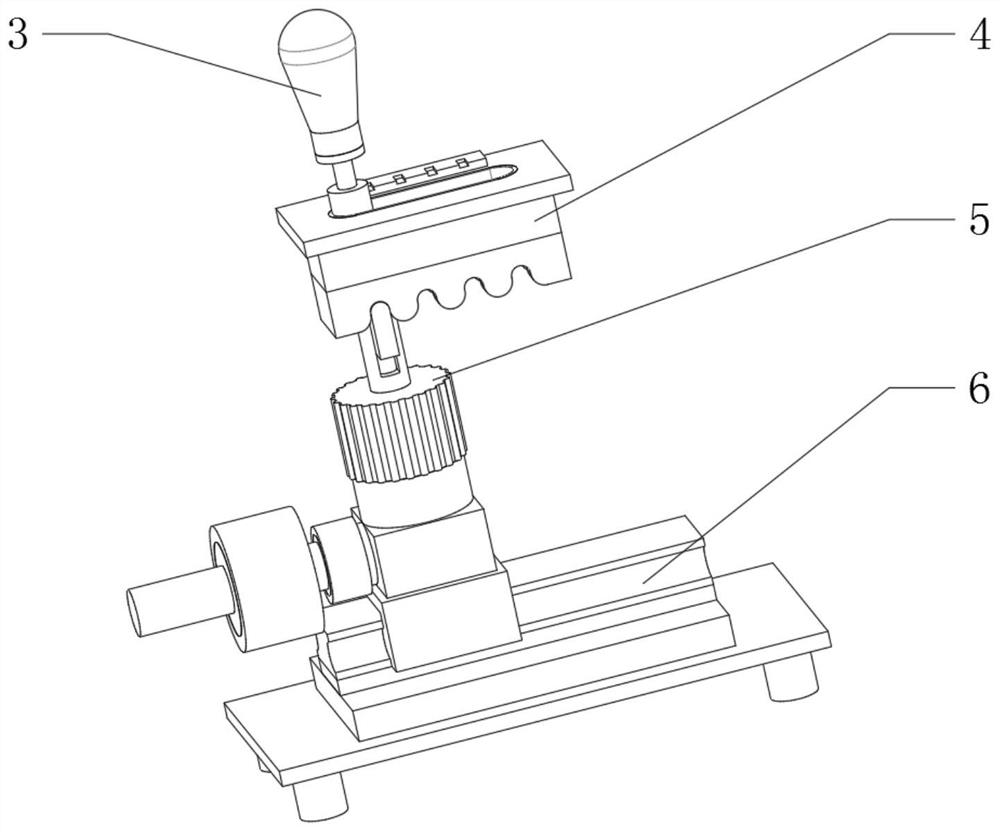

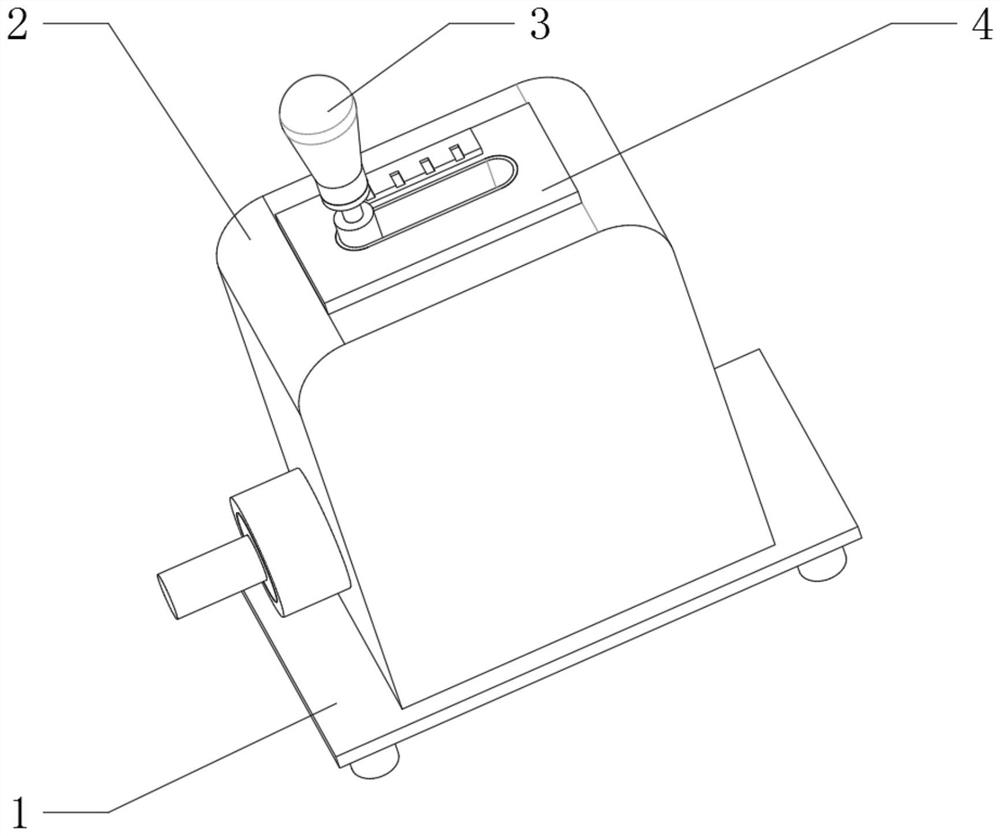

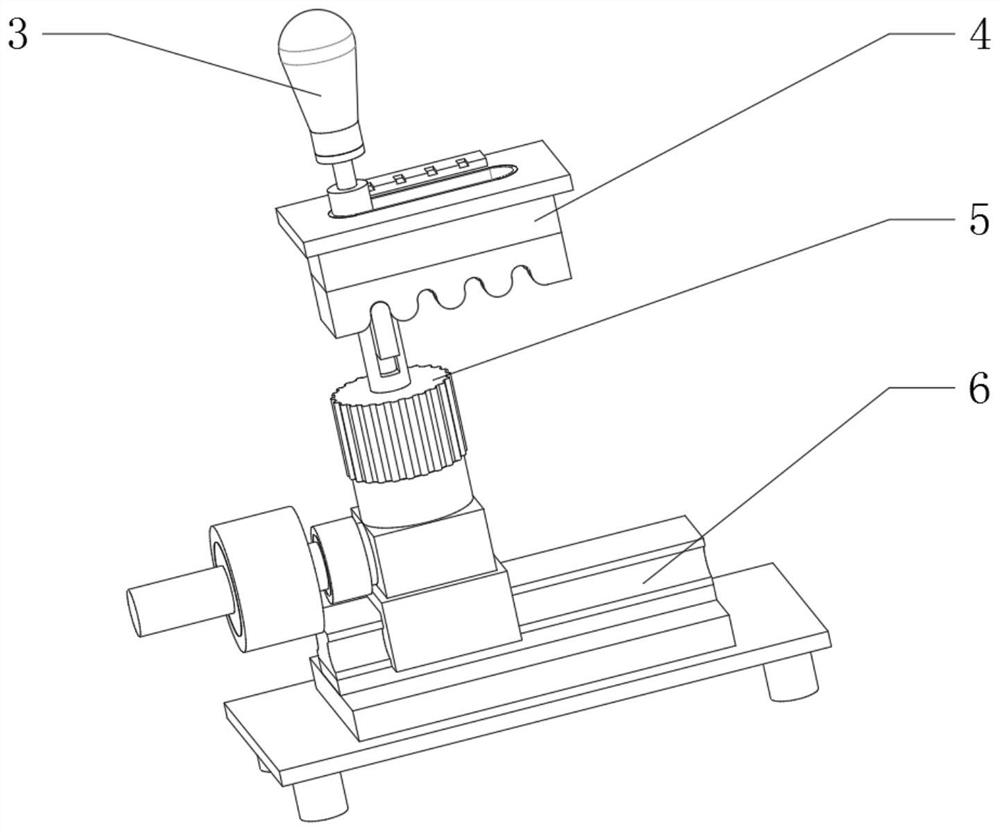

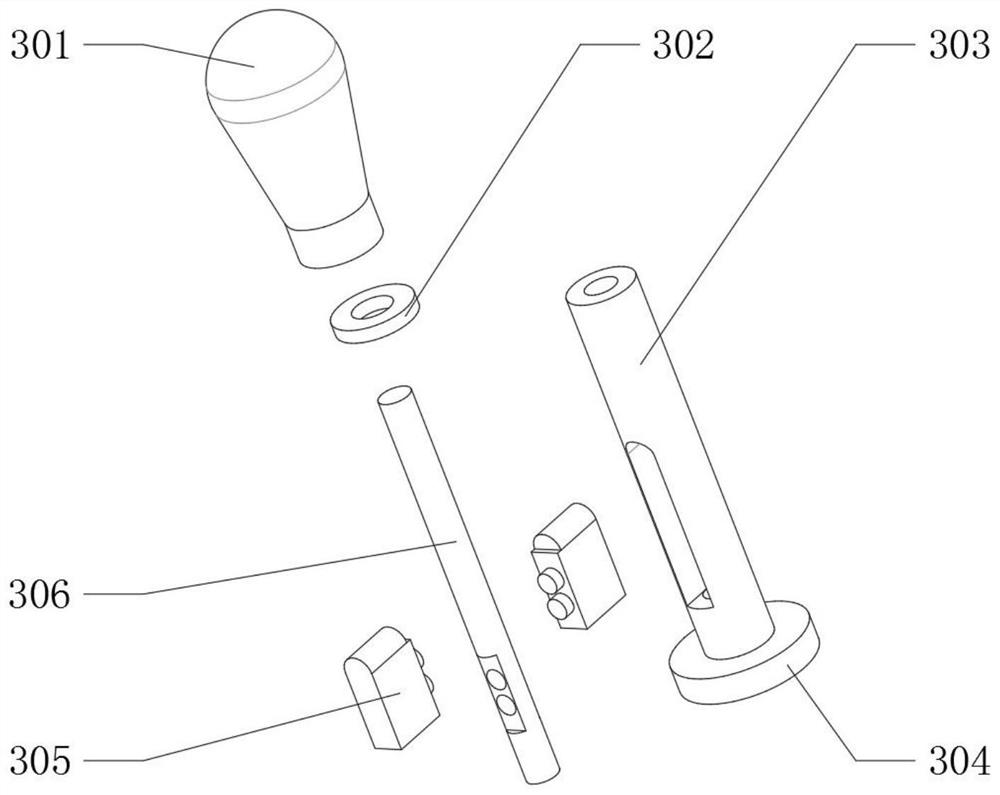

Injection molding part used for automobile gear shifting cable connection assembly with anti-falling structure

The invention discloses an injection molding part used for an automobile gear shifting cable connection assembly with an anti-falling structure, and relates to the technical field of automobiles. Theinjection molding part aims to solve the problem of gear lever movement after gear switching. The injection molding part comprises an outer shell, a handle assembly, a gear assembly, a movable assembly and a resetting assembly; the gear assembly comprises an indicator label and a first fixed block; a rectangular through hole is formed in the outer wall at the top of the outer shell; a boss is arranged on the outer wall at the bottom of the first fixed block; the outer wall of the boss is fixedly connected with the inner wall of the rectangular through hole; the outer wall at the bottom of thefirst fixed block is attached to the outer wall at the top of the outer shell; the outer wall at the bottom of the indicator label is connected with the outer wall at the top of the first fixed blockvia bolts; a U-shaped groove is formed in the inner wall of the first fixed block; an anti-abrasion sleeve is fixedly connected with the inner wall of the U-shaped groove; a gear block is fixedly connected with the outer wall at the bottom of the boss; and a wave-shaped clamping groove is formed in the outer wall at the bottom of the gear block. Through the arrangement of the gar block, by virtueof the wave-shaped clamping groove on the outer wall at the bottom of the gear block, fixation of relevant parts after gear shifting can be realized.

Owner:黄松檀

Membrane electrode assembly

ActiveUS10256491B2Performance is not affectedReduce oxidation corrosionCell electrodesSolid electrolyte fuel cellsPlatinumOxygen evolution

The invention includes a catalysed membrane and membrane electrode assembly. The membrane and membrane electrode assembly comprise an ion-conducting membrane component comprising an ion-conducting membrane, an anode catalyst layer, and a cathode catalyst layer. The anode catalyst layer comprises a first electrocatalyst component comprising a first platinum-containing electrocatalyst and a first carbon support. The first carbon support supports the first platinum-containing electrocatalyst, and the electrochemical platinum surface area in the anode catalyst layer is 5-100 cm2Pt / cm2 of the geometric electrode area of the anode catalyst layer. The cathode catalyst layer comprises a second electrocatalyst component and a second oxygen evolution reaction electrocatalyst. The second electrocatalyst component comprises a second platinum-containing electrocatalyst and a second carbon support, wherein the second carbon support supports the second platinum-containing electrocatalyst component.

Owner:JOHNSON MATTHEY HYDROGEN TECH LTD

Sanitation type insect trap

InactiveCN114304098AEasy to useEffective in controlling mosquitoesSpraying apparatusWaste collection and transferRefuse collectionHusk

The environmental sanitation type insect trap comprises an insect trap body and a garbage can arranged at the bottom of the insect trap body, and the insect trap body comprises an outer shell, a trap lamp, an electric wire net, a liquid medicine box, a pheromone storage barrel, a spraying plate, a power supply box and a solar panel; a plurality of trap lamps are distributed on the inner side wall of the outer shell, the electric wire net is arranged in the outer shell, a supporting column is arranged on a bottom plate of the outer shell, and a power supply box, a liquid medicine box and a pheromone storage barrel are sequentially arranged at the top of the supporting column; a pesticide is put into the pesticide liquid box, a spraying head connected with the pesticide liquid box is arranged on the spraying plate, multiple sets of pheromone storage grids are installed in an inner cavity of the pheromone storage barrel, and pheromones of different pests are injected into the pheromone storage grids; the interior of a dustbin body of the dustbin is divided into a solid-liquid separation bin and a garbage collection bin through a partition plate, and a solid-liquid separation device is arranged in the solid-liquid separation bin. According to the environmental sanitation type insect trap, the problem of pollution of mosquitoes and flies near the dustbin can be effectively solved, and the environmental protection effect is improved.

Owner:湖南天长农业科技发展有限公司

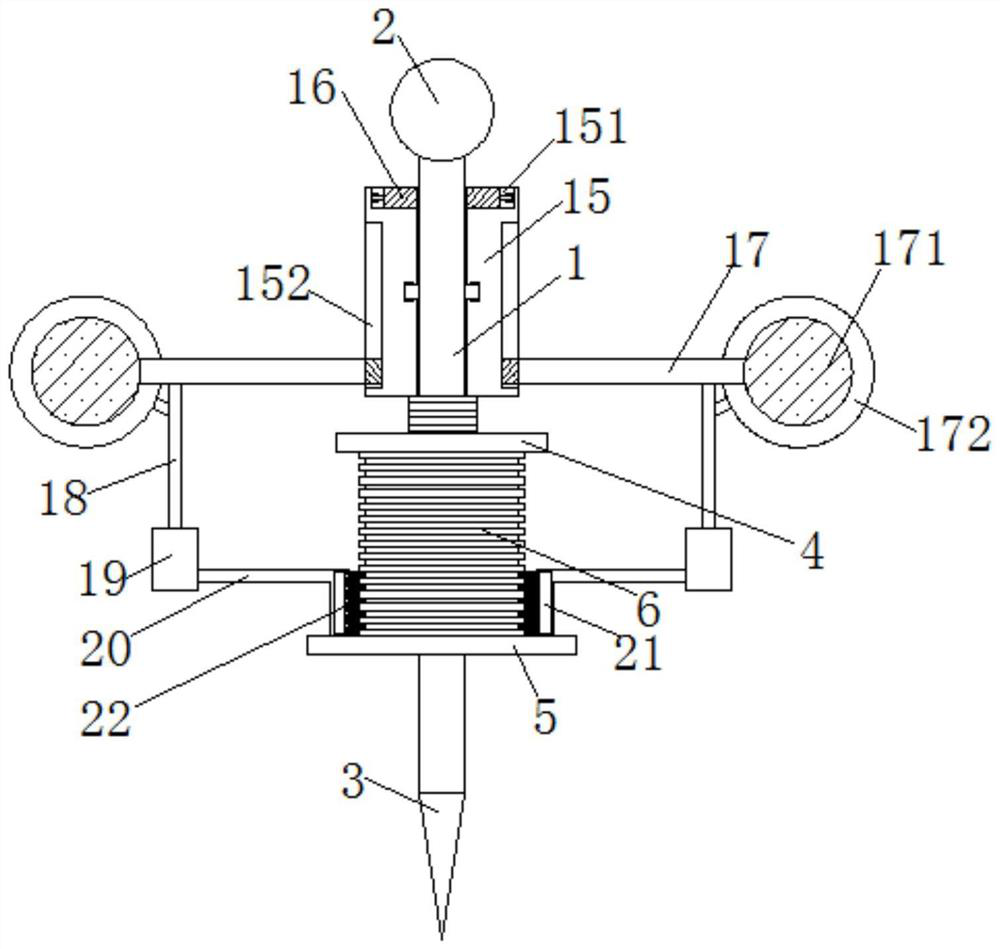

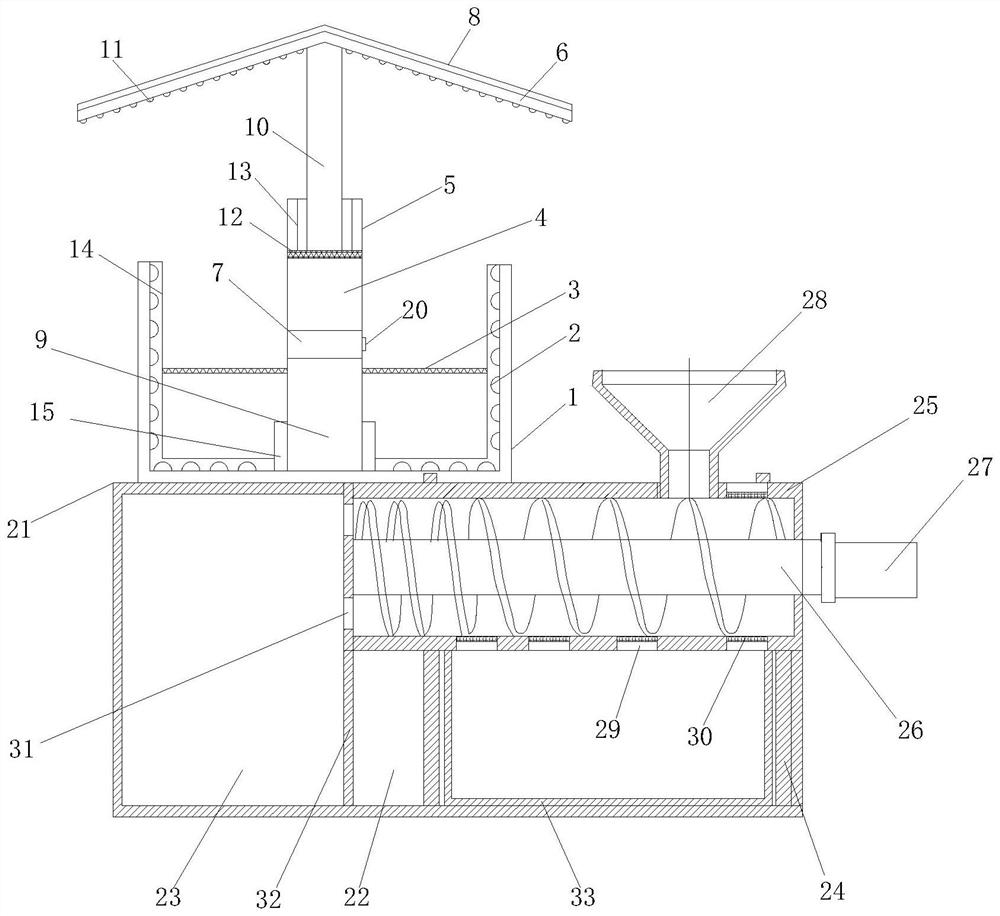

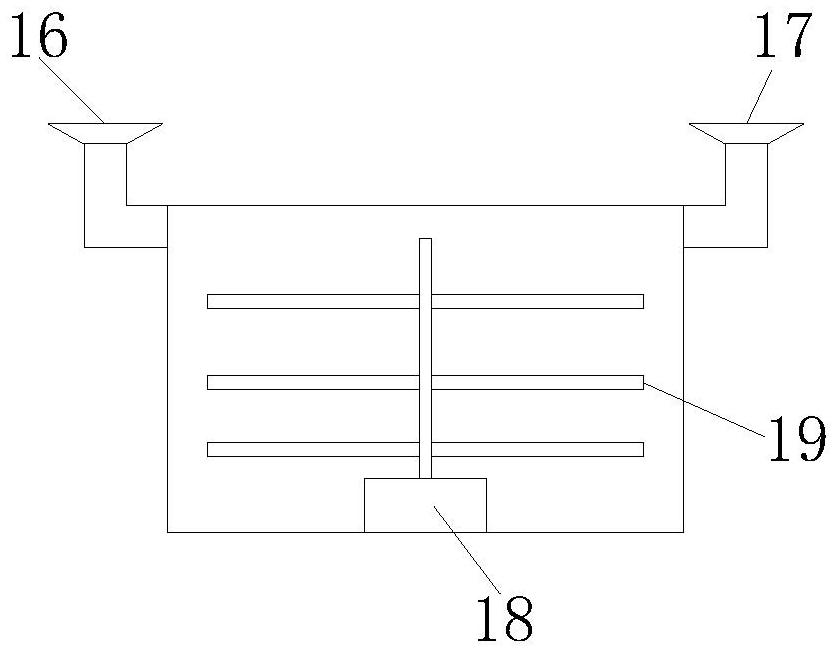

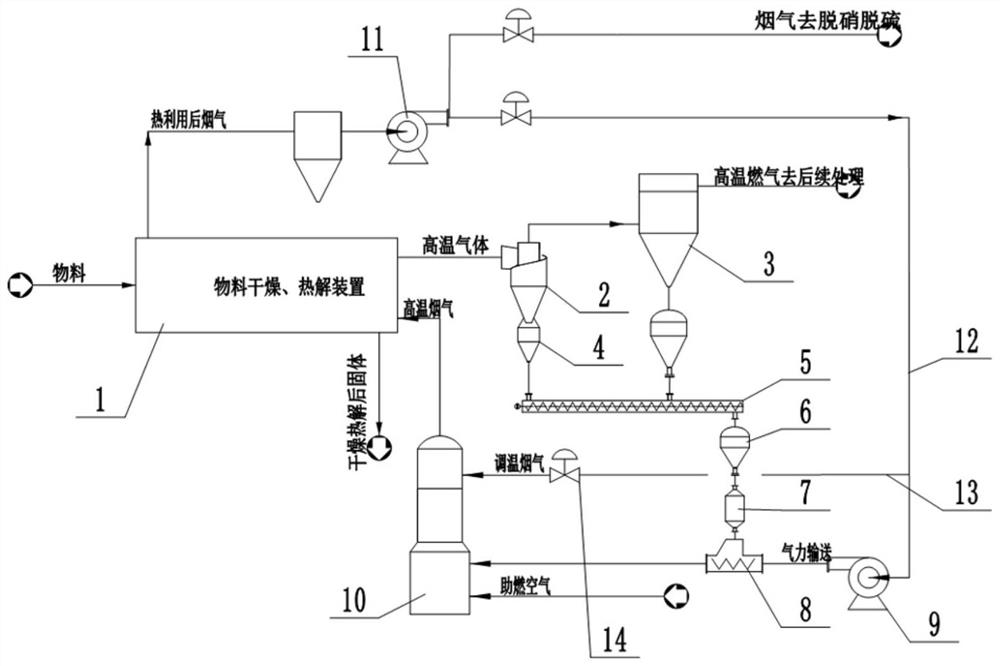

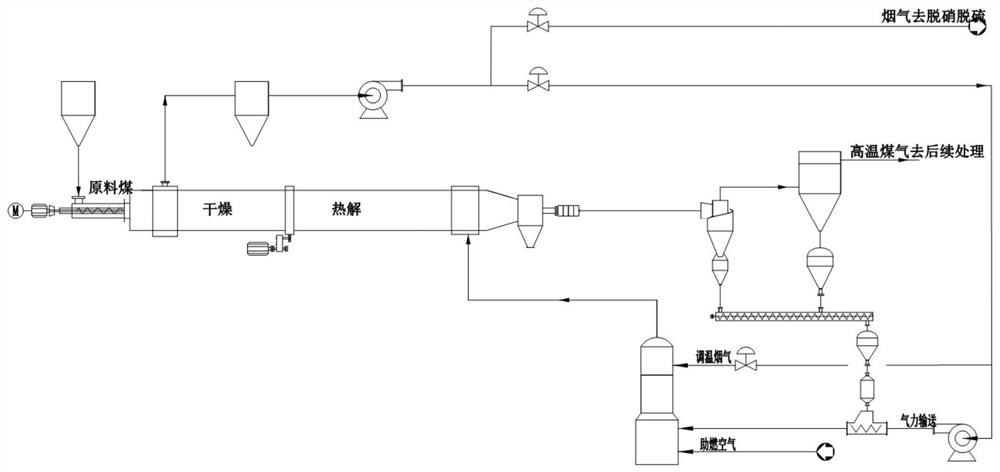

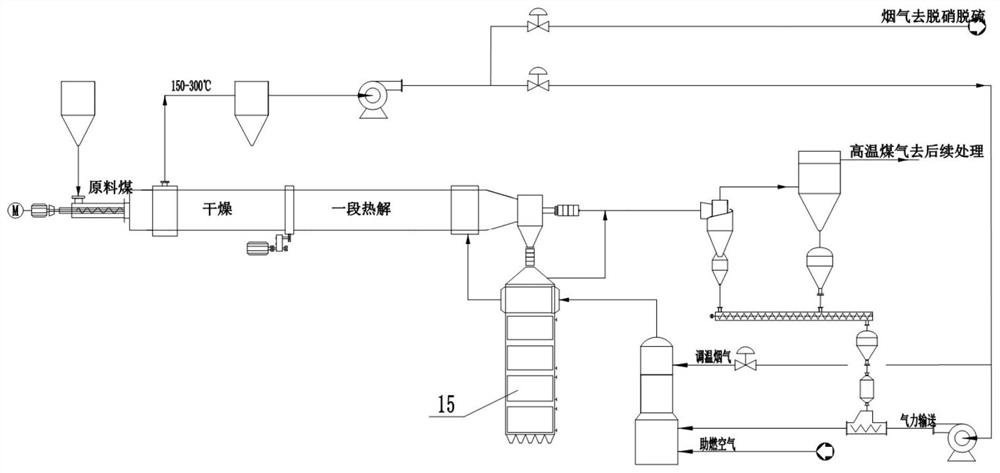

Fine pulverized coal recycling system for pulverized coal pyrolysis and utilization method of fine pulverized coal recycling system

PendingCN113512437ASmall particle sizeSimple structureDirect heating destructive distillationIndirect heating destructive distillationThermodynamicsFlue gas

The invention relates to a raw gas dust recycling system and method for pulverized coal pyrolysis, and belongs to the technical field of pulverized coal pyrolysis. The raw gas dust recycling system specifically comprises a high-temperature coarse dust remover and a high-temperature fine dust remover, and a bottom discharge port of the high-temperature fine dust remover is connected with a spiral conveyor through a first dust collecting tank; a discharge port of the spiral conveyor is connected with a pulverized coal injection device through a second dust collecting tank, a discharge port of the pulverized coal injection device is connected with a process heating furnace through a pipeline, one part of low-temperature flue gas discharged by the pulverized coal pyrolysis device enters a desulfurization and denitrification system, and the other part of the low-temperature flue gas enters the pulverized coal injection device through a flue gas recycling pipeline; and a temperature adjusting pipeline is further arranged on the flue gas recycling pipeline, and the temperature adjusting pipeline is connected with a flue gas chamber of the process heating furnace. The system is simple in structure and convenient to use, can effectively solve the problem of utilization of fine pulverized coal contained in the low-rank pulverized coal pyrolysis raw gas, realizes on-site utilization, improves the utilization rate of the pulverized coal, fully utilizes effective resources, and reduces the investment and operation cost of the device.

Owner:南阳三鑫诚达化工科技有限公司

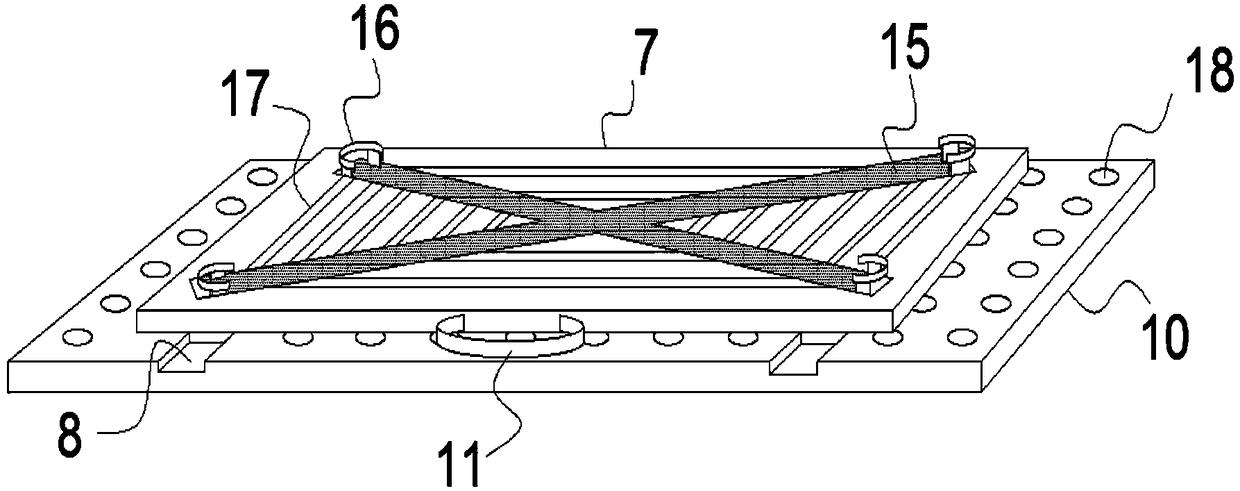

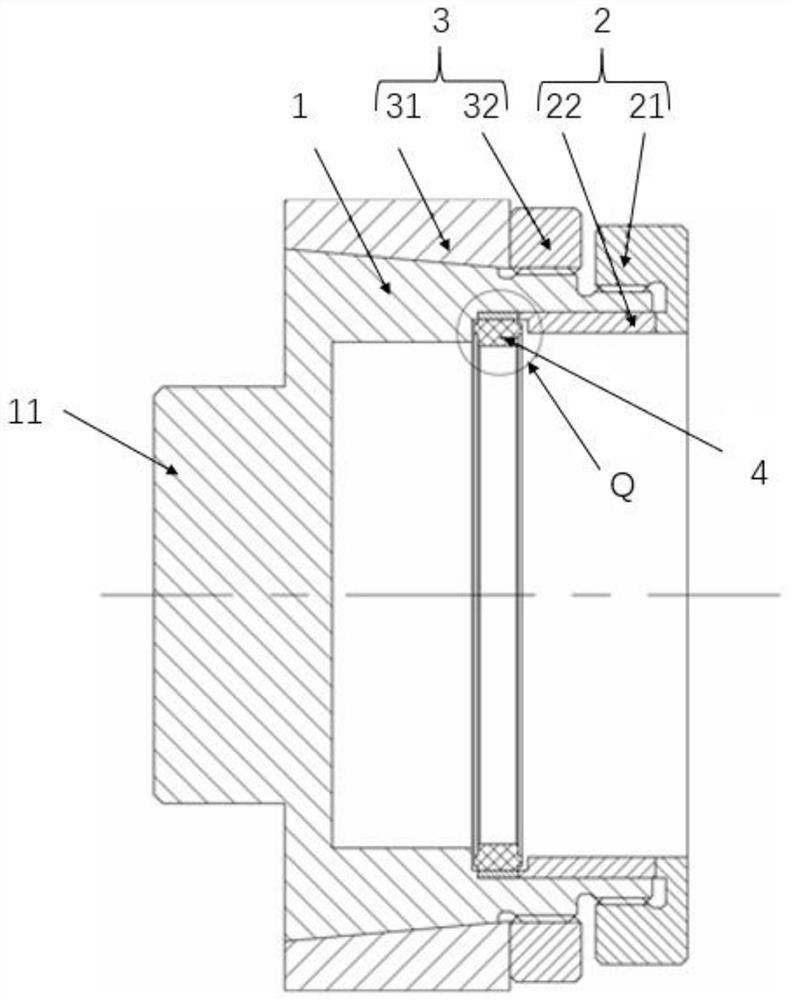

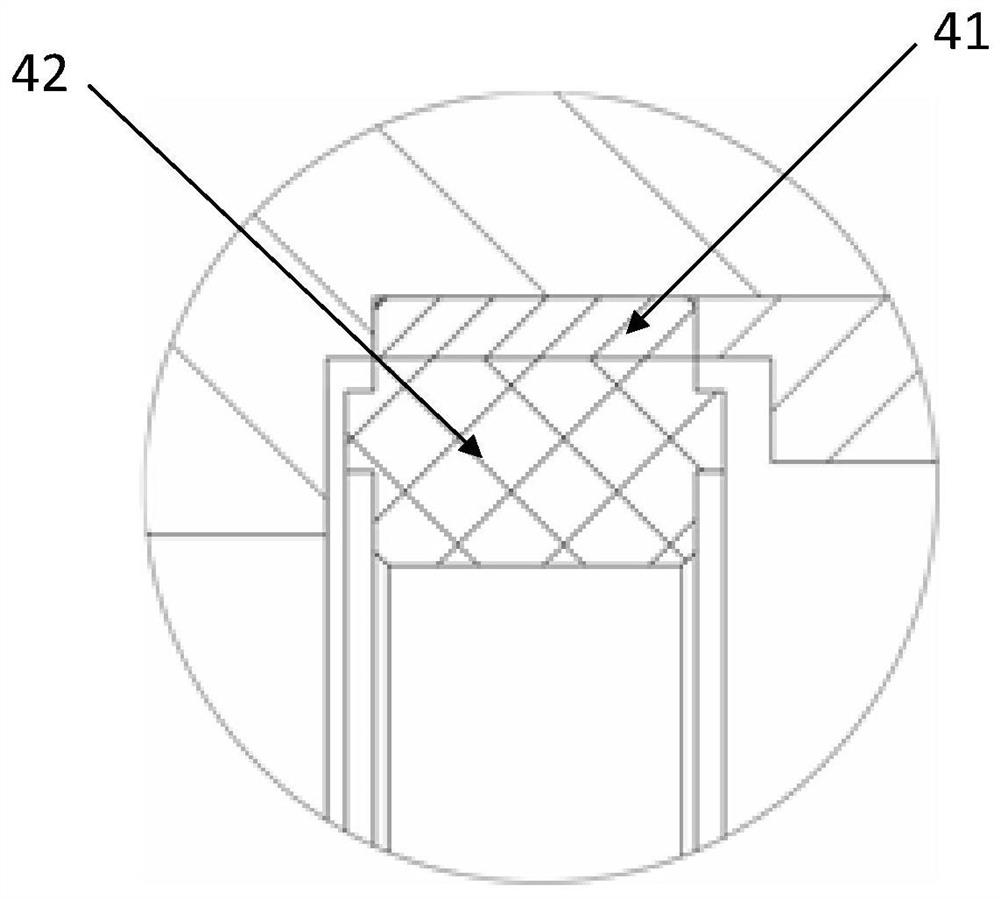

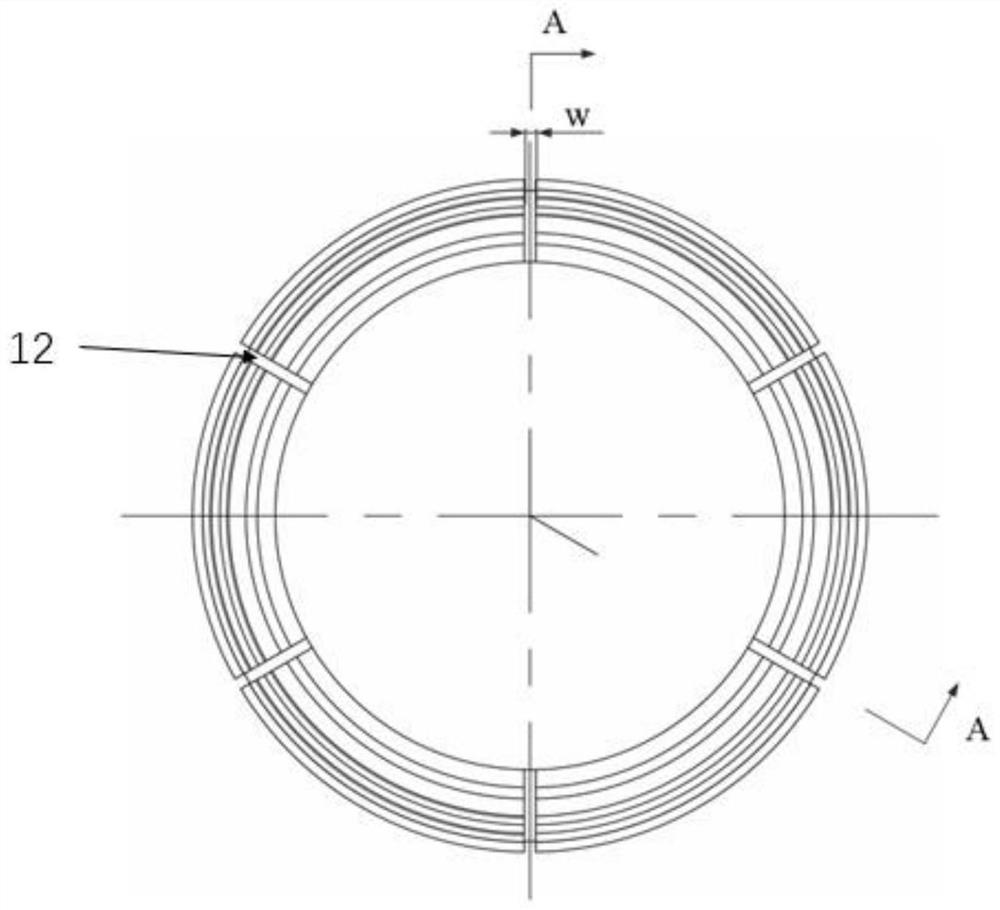

Machining tool and machining method for embedded sealing ring

PendingCN113878739AHigh dimensional accuracyCompensation for radial backlashWorking accessoriesMetal working apparatusMetallic materialsEngineering

The invention relates to an embedded sealing ring machining technology, in particular to a machining tool and a machining method for an embedded sealing ring. The machining tool and the machining method for the embedded sealing ring are used for solving the problems that in the existing embedded sealing ring press-fitting technology, graphite is locally trimmed and even fractured, or the design requirement cannot be met due to the fact that the performance of a metal material is changed, and meanwhile, the surface oxidation corrosion of a metal ring seat is accelerated, so that the sealing reliability of the end face is reduced; and an existing axial clamping machining tool is insufficient in size precision and form and location tolerance precision, low in product percent of pass and poor in sealing reliability of the end face. The machining tool for the embedded sealing ring comprises a clamp base, an axial positioning device and a radial positioning device. The machining tool has the radial clearance compensation function and the axial positioning and clamping function, and the size precision and the form and location tolerance precision of the embedded sealing ring can be remarkably improved. Meanwhile, the invention further provides a machining method of the embedded sealing ring.

Owner:XIAN AEROSPACE PROPULSION INST

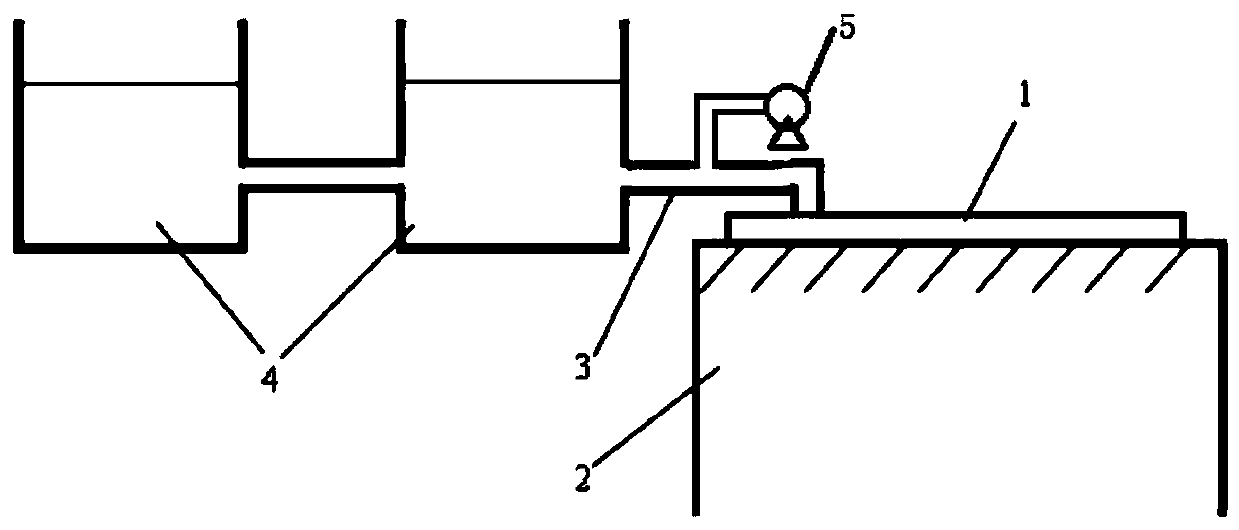

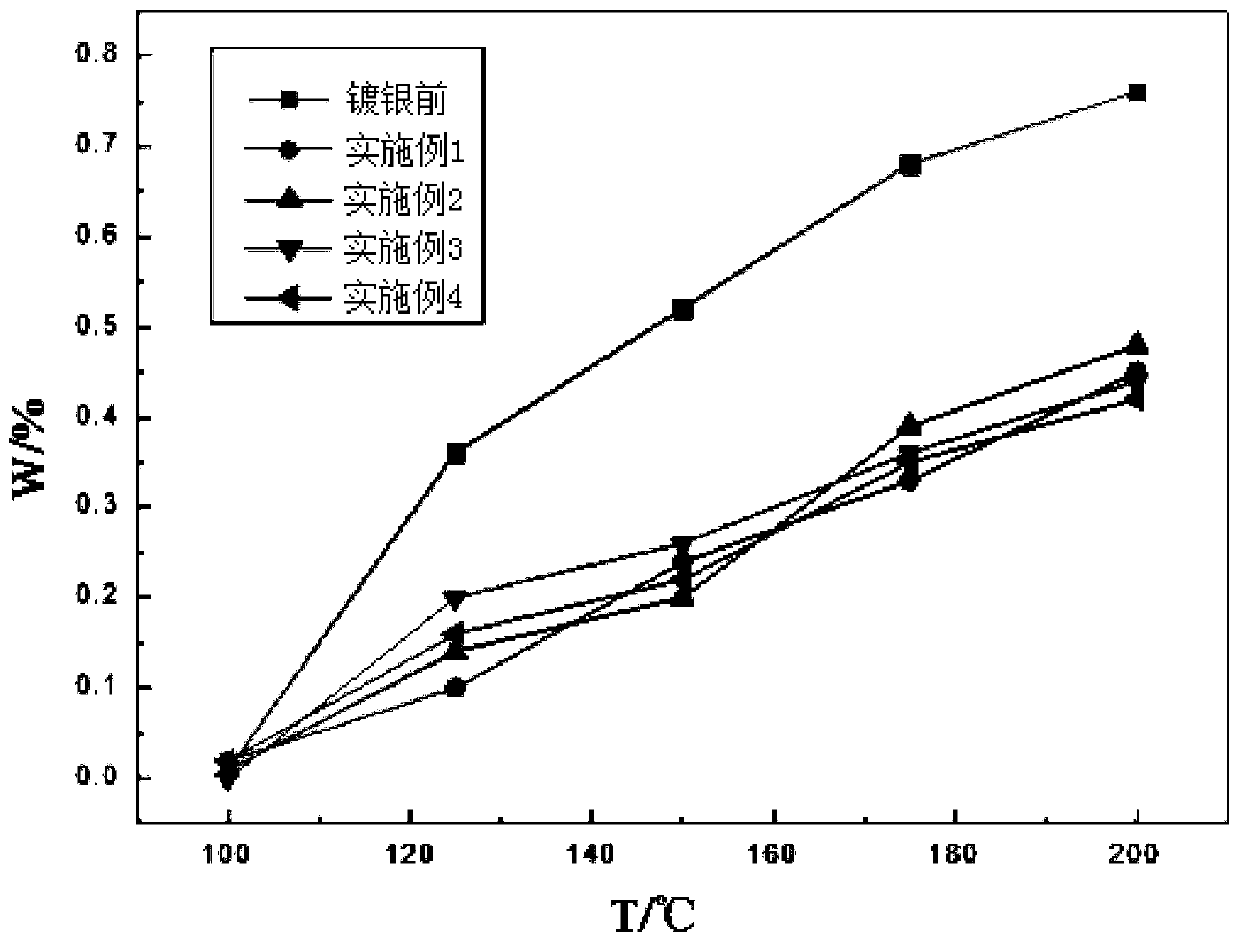

Chemical plating protection method of copper back plate water path

InactiveCN110284129AImprove cooling effectHigh Chemical Stability FluidVacuum evaporation coatingSputtering coatingChemical platingOrganic solvent

The invention provides a chemical plating protection method of a copper back plate water path, and belongs to the technical field of target material preparing. The chemical plating protection method of the copper back plate water path comprises the following steps that the copper back plate water path is subjected to oil removal treatment; a plating solution is led into the copper back plate water path obtained after oil removal treatment for the redox reaction; deposition is carried out on the surface of the copper back plate water path obtained after oil removal treatment to form a coating, and through cleaning and drying, the copper back plate water path protection coating is obtained; and the plating solution circularly flows and comprises silver salt, a reducing agent, a complexing agent, a surface tension conditioning agent, an organic solvent and water. According to the chemical plating protection method of the copper back plate water path, the silver coating can be rapidly prepared on the surface of the copper back plate water path, and the oxidation resistance and the cooling performance of the copper back plate can be improved.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

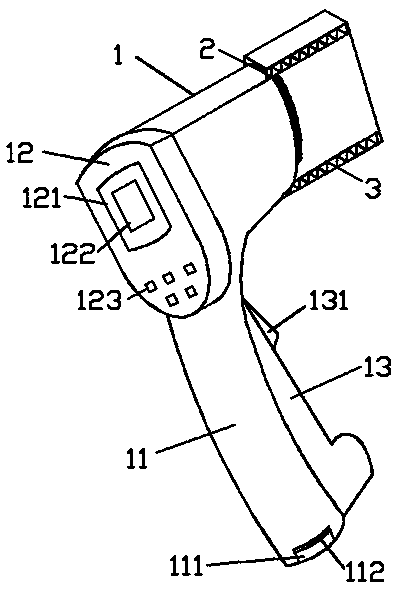

An anti-corrosion dual-purpose temperature detector

ActiveCN109060142BCorrosive damage reductionReduce measurement impactThermometer detailsRadiation pyrometryOptical processingAir pump

The invention provides an anti-corrosion dual-purpose temperature detector, which includes a body shell and a body body, the body shell is connected with a telescopic device, and the end of the telescopic device far away from the body shell is provided with an adsorption block, and the adsorption block is connected to a bracket , the inside of the bracket is provided with a spring, and the end of the bracket away from the adsorption block is provided with an exhaust device. An air pump is provided, the bracket is connected to the main body, the main body includes an optical system and a sensing module, the optical system includes a sampling device, the sampling device is connected to an optical processing unit, and the optical processing system is far away from the sampling device. One end is connected to an electronic amplifier, the other end of the electronic amplifier is connected to an intelligent processing module, the other end of the intelligent processing module is connected to a display system, the sensor module includes a sensor and a thermal resistor, and an inert gas is provided inside the body.

Owner:南京久鼎电气科技有限公司

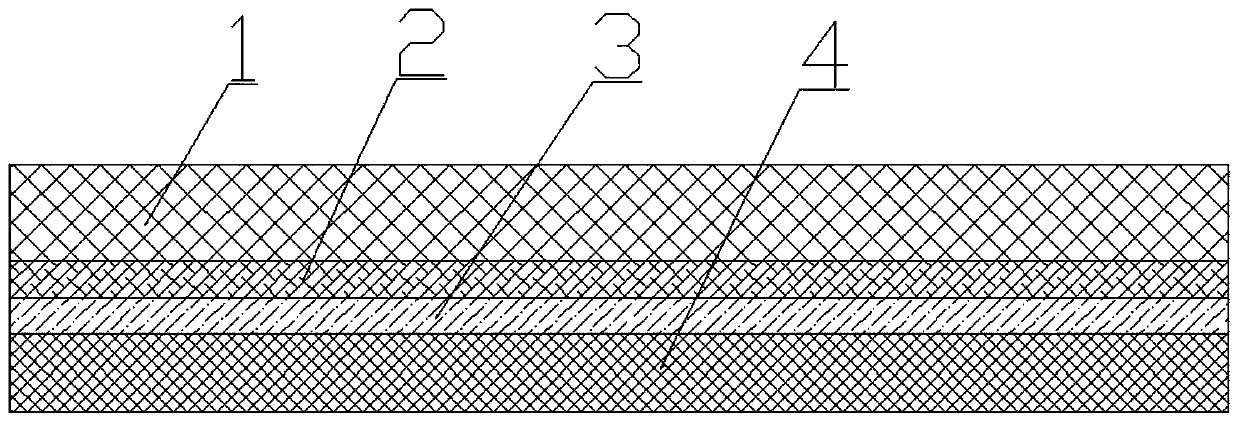

Novel shading awning cloth

InactiveCN109927362AExtended service lifeRealize self-cleaning abilitySynthetic resin layered productsRemovable external protective coveringsComposite effectYarn

The invention discloses novel shading awning cloth, and belongs to the technical field of shading cloth. An upper cloth layer is formed by interweaving the twisted yarns and the carbon fiber yarns; the twisted yarns are provided with stable air holes and have good air permeability and structural strength, so that the service life of the shading tarpaulin is prolonged. The adsorption filtering layer is a fiber medium layer composed of carbon nano tubes, nano-titanium dioxide and a fiber capturing medium, and the carbon nano tubes have a good adsorption filtering effect; nanoscale titanium dioxide contained in the adsorption filtering layer can shield ultraviolet rays well, the nanoscale titanium dioxide has a good reflection effect on the ultraviolet rays, meanwhile, the nanoscale titaniumdioxide can decompose impurities attached to the surface of the fiber capturing medium through photocatalysis of the nanoscale titanium dioxide, and the self-cleaning function of the shading awning cloth is achieved. Meta-aramid paper and a flame retardant in the fireproof flame-retardant layer are matched with each other to achieve a high-strength flame-retardant composite effect, so that the safety level of the shading tarpaulin used for automobile protection is improved.

Owner:青岛甜昊新材料科技有限公司

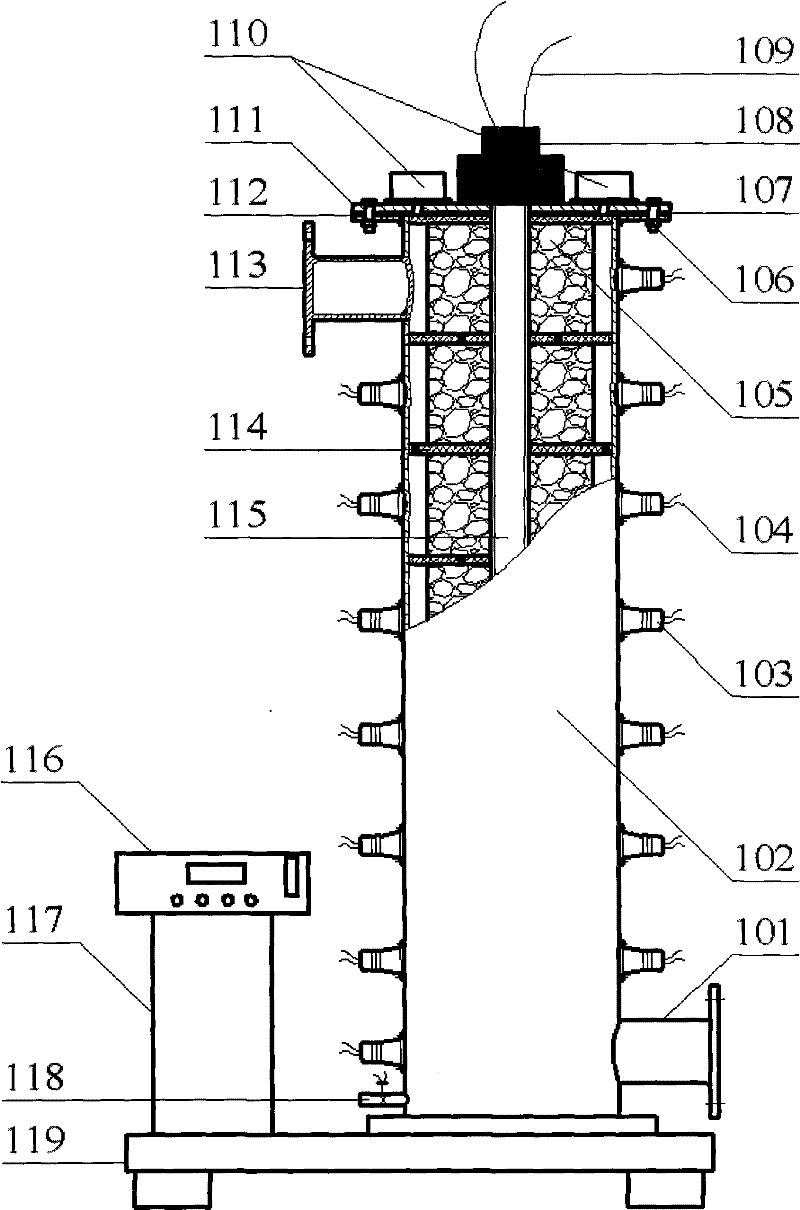

Photo-catalytic reaction device using ultrasonic for scale prevention and removal

InactiveCN101612545BAvoid badExtended service lifeEnergy based chemical/physical/physico-chemical processesPhotocatalytic reactionEngineering

The invention discloses a photo-catalytic reaction device using ultrasonic for scale prevention and removal. The device consists of a photo-catalytic reactor and an ultrasonic generator arranged on a base, as well as an electric cabinet; wherein the photo-catalytic reactor comprises a water inlet pipe, a sleeve, a metal mesh, bolts, gaskets, tube terminals, a power cord, a top cover, sleeve flanges, a water outlet pipe, a metal mesh support frame and an ultraviolet tube; a plurality of through-holes corresponding to the inner metal mesh layer are arranged on the outer surface of the sleeve along the axial direction in a bilateral symmetry way, and ultrasonic transducers are mounted at all the through-holes; a cleaning solution box is mounted on the top cover and communicated with the inner part of the sleeve; the ultrasonic transducers are connected to the ultrasonic generator via transmission cable wires; and a draining valve is mounted at the bottom of the sleeve. The invention can prevent the scale from forming in the inner metal mesh during the operating process of the photo-catalytic reactor, meanwhile, the invention can carry out shutdown scale removal on the inner wall of the sleeve of the photo-catalytic reactor and the inner metal mesh, thereby achieving the double effects of preventing the scale from forming and destroying the formed scale.

Owner:GUANGDONG UNIV OF TECH

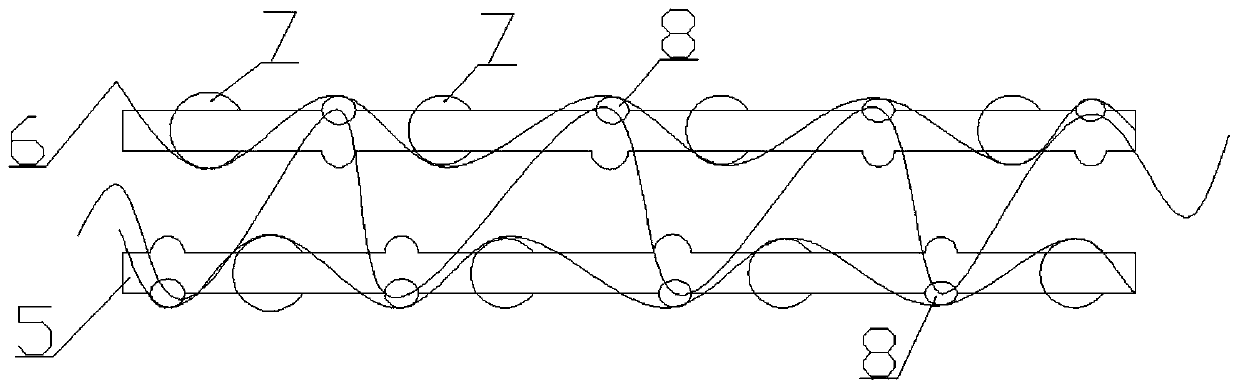

Anti-oxidation protection mechanism for data line connector in humid environment

InactiveCN113708142AExtended service lifeReduce oxidation corrosionDispersed particle separationCouplings bases/casesEngineeringStructural engineering

The invention discloses an anti-oxidation protection mechanism for a data line connector in a humid environment, which comprises a data line connector shell, a metal connector is fixedly mounted at the right end of the data line connector shell, an external host is inserted into the right end of the metal connector, the data line connector shell is sleeved with a protective sleeve, and a drying ring is inserted into the right end of the protective sleeve. The drying ring is located at the joint of the protective sleeve and the external host. The right end of the drying ring is tightly attached to the external host, an iron sheet is fixedly installed at the left end of the drying ring, a magnet is arranged on the left side of the iron sheet, the magnet is fixedly installed in the right end of the protective sleeve, the iron sheet is attracted to the magnet, a push plate is arranged on the left side of the iron sheet, and the left end of the iron sheet is attached to the push plate. A connecting rod is fixedly installed at the left end of the push plate. When the anti-oxidation protection mechanism is used, a metal connector of a data line can be protected in a humid environment when the data line protection device is used or not used, oxidation corrosion of moisture in the environment to a metal flat cable is reduced, and therefore the service life of the data line is prolonged.

Owner:新晃都源电子科技有限公司

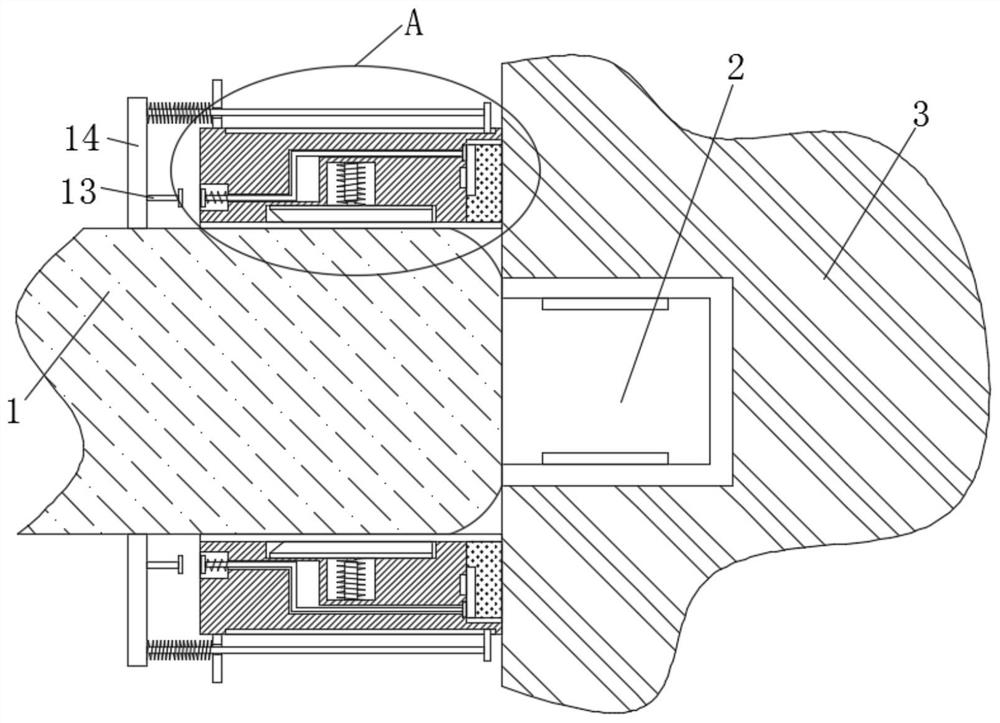

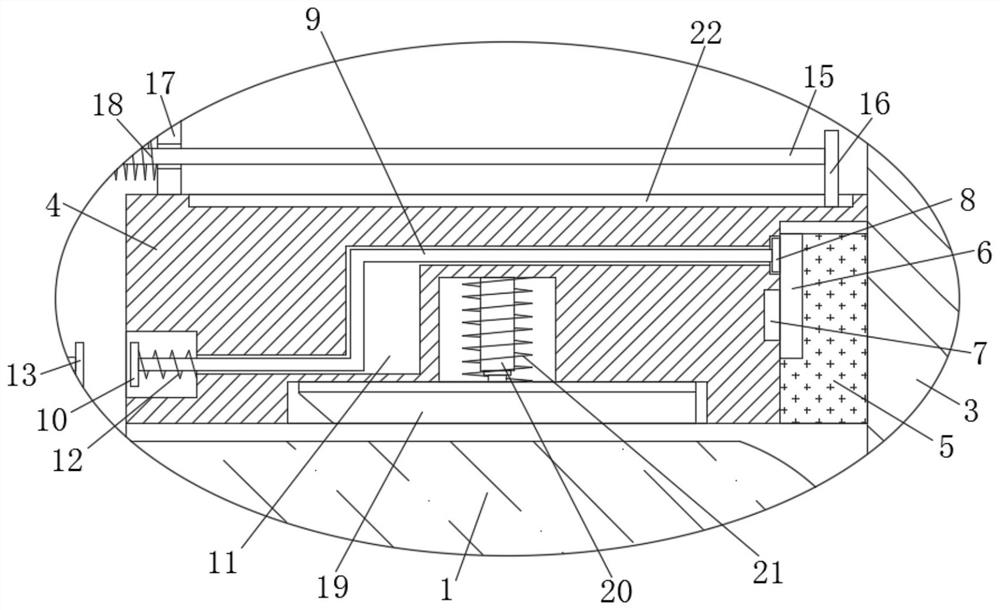

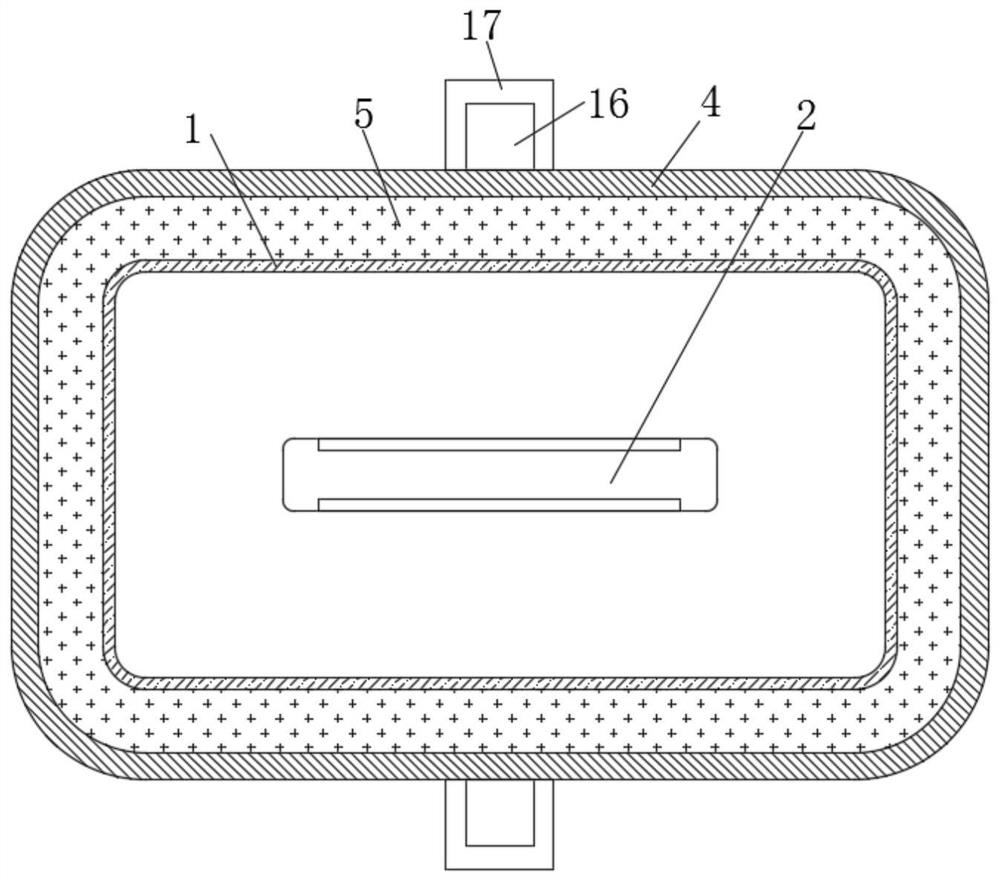

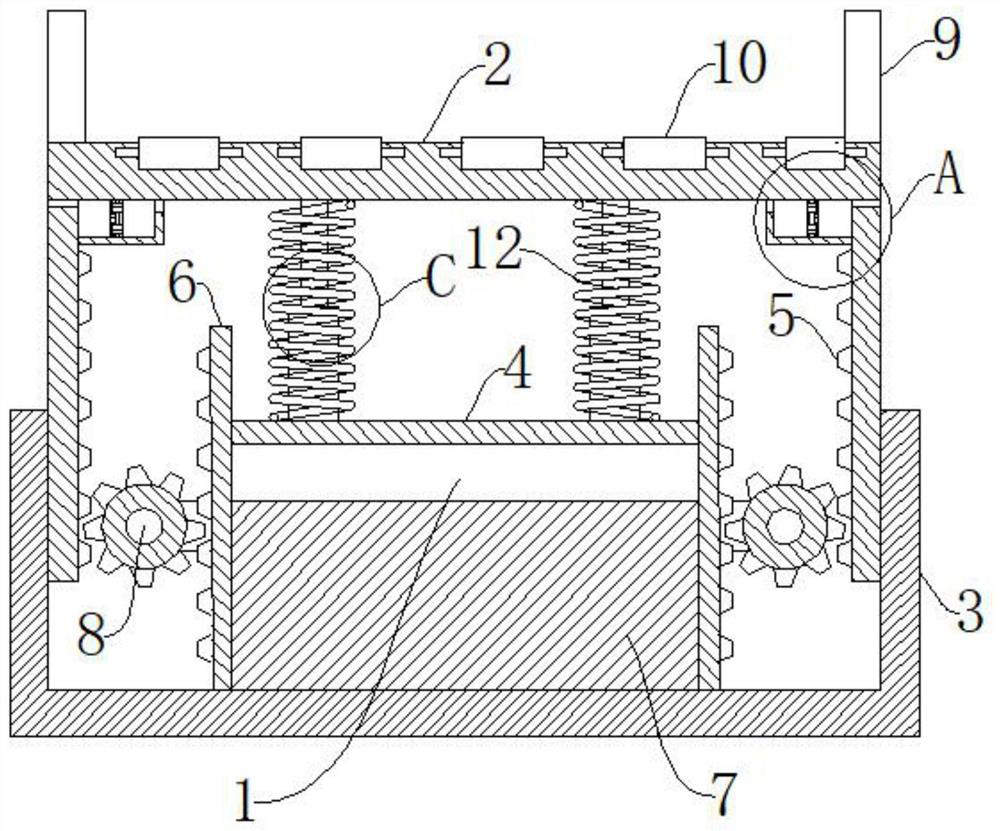

Industrial device with sensor and weighing method

ActiveCN112161688BReduce oppressionPrevent crushingWeighing auxillary devicesGear wheelControl engineering

Owner:克莱门斯工业传感器南京有限公司

A kind of wear-resistant and corrosion-resistant boron-containing high-silicon bainite alloy and its manufacturing method

The invention relates to a boron-containing high-silicon bainite wear-resistant corrosion-resistant alloy and a manufacturing method thereof. The alloy comprises the following chemical components in percentage by weight: 0.3-0.6% of C, 1.6-2.6% of Si, 0.6-1.0% of Mn, 0.6-4.0% of Cr, 0.3-0.5% of Mo, 0.3-0.5% of Ni, 0.3-0.5% of Cu, 0.1-0.3% of Ti, 0.05-0.1% of B, 0.05-0.15% of Ce, 0.05-0.15% of Nb, less than 0.04% of P, less than 0.04% of S and the balance of Fe. The manufacturing method comprises the following steps: carrying out electric-furnace smelting, carrying out secondary aluminum insertion deoxidization, putting on the bottom of a casting ladle to form a casting, austenizing the casting at 850-950 DEG C, keeping the temperature for some time, putting in a salt bath at 200-260 DEG C to carry out primary isothermal quenching, keeping the temperature for 5-10 minutes, carrying out secondary isothermal quenching in a salt bath at 260-400 DEG C, keeping the temperature for 0.5-4 hours, and cooling in air to obtain the wear-resistant corrosion-resistant alloy of which the austenite-bainite base is distributed with boride. The alloy is low in preparation cost and suitable for marine silt erosion and corrosion environments, has favorable comprehensive properties of toughness, wear resistance and corrosion resistance, and can be used for dredger cutter teeth, slurry pipelines, centrifugal-pump impellers, blades and the like.

Owner:CHANGXING DETIAN ENG MACHINERY

Leadless soft soldering material and manufacturing method

InactiveCN100509259CLow oxygenReduce outputWelding/cutting media/materialsSoldering mediaIngotOxygen

The invention discloses a lead-free soft soldering. Calculated by weight percentage, the lead-free soft soldering consists of following compositions: 0.1 to 3.9 per cent of Al, 0.0001 to 0.5 per cent of Se and rest of Sn. The method of manufacturing the invention is: (a) after refined tin is added into a plumbago pot to be melted, temperature rises to 1100 DEG C. refined copper is added and evenly mixed. The refined tin and the refined copper are melted to be liquid tin copper alloy. The liquid tin and copper alloy becomes the alloy ingot of tin and copper after standing for 30 minutes; (b) the refined Ag is added and melted again and the temperature rises to above 1600 DEG C. Pure nickel is added and melted. The liquid Ag and nickel becomes the alloy ingot of Ag and selenium after standing for 30 minutes; (c) with the refined tin added into and melted and the temperature rising to above 600 to 1000 DEG C, covering agent is added to isolate the liquid level of tin from oxygen in the air. Pure selenium is added and melted. The liquid tin and selenium becomes the alloy ingot of tin and selenium after standing for 30 minutes; (d) three gold ingots, Ga or Cu and the rest of tin and put into a stainless steel kettle to be melted according to the required formulation, which can be made into a tin wire, a tin bar and a tin ball.

Owner:昆山成利焊锡制造有限公司

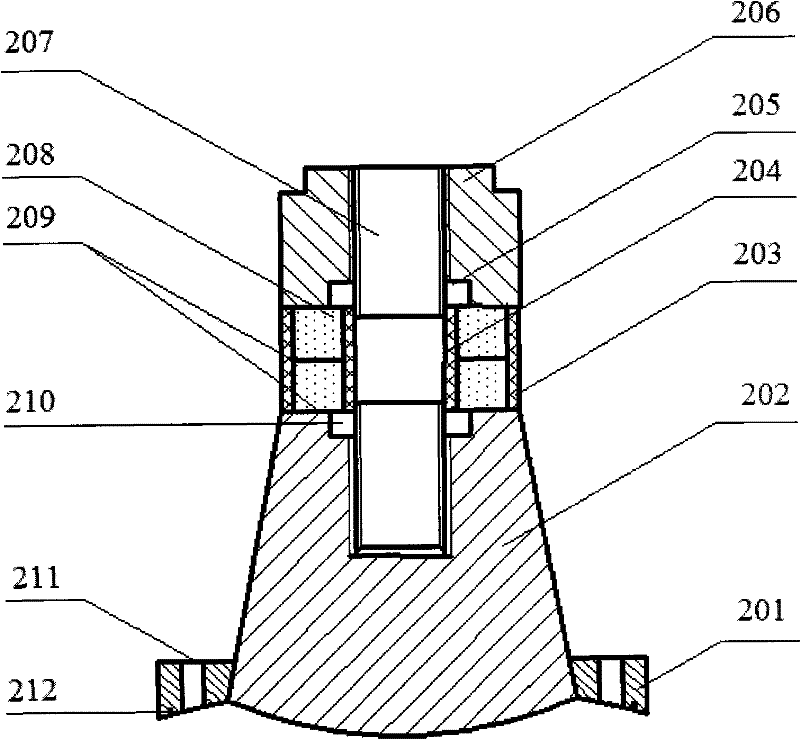

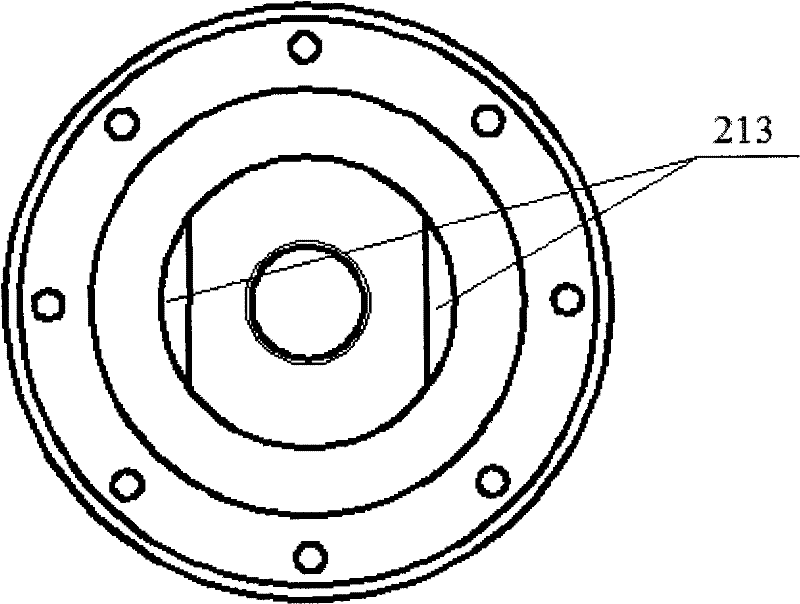

Novel cooling method and device applied to semi-continuous casting of magnesium alloy

The invention relates to a novel cooling method and device applied to semi-continuous casting of magnesium alloy. The novel cooling method comprises the following steps: a, performing primary coolingon liquid magnesium for orderly condensation; and b, orderly pulling the condensed liquid magnesium downwards, and performing secondary cooling to form a casting blank. In the step b, a protective gasis adopted to perform secondary cooling and is cooled down. The novel cooling device comprises a crystallizer and a dummy bar head, wherein a secondary cooler for secondary cooling of a magnesium alloy casting blank is arranged below the crystallizer and provided with a secondary cooling gas cavity which surrounds the dummy bar head and allows the protective gas to be pumped therein. The novel cooling method and device have the following beneficial effects: since the protective gas is adopted to perform secondary cooling on the magnesium alloy casting blank, the casting blank is prevented from oxidation corrosion; the protective gas is cooled down, so that the magnesium alloy casting blank can be quickly cooled down; the quality of the magnesium alloy casting blank can be remarkably improved; and meanwhile, combustion and explosion accidents can be prevented.

Owner:威海万华镁业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com