A kind of wear-resistant and corrosion-resistant boron-containing high-silicon bainite alloy and its manufacturing method

A technology of corrosion-resistant alloy and manufacturing method, which is applied in the field of steel preparation, can solve problems such as insufficient toughness, poor wear resistance, and difficulty in welding and repairing, and achieve the effects of improving seawater corrosion resistance, excellent strength and toughness, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

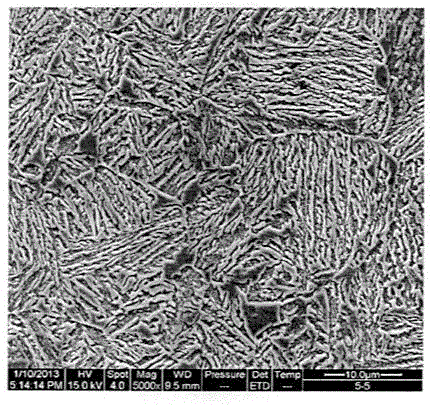

Image

Examples

Embodiment 1

[0046]A boron-containing high-silicon bainite wear-resistant and corrosion-resistant alloy, its chemical composition is 0.45%C, 2.15%Si, 0.92%Mn, 2.6%Cr, 0.35%Mo, 0.38%Ni, 0.41%Cu, 0.2%Ti , 0.1% B, 0.05% Ce, 0.08% Nb, 0.016% P, 0.011% S, and the rest is Fe. The specific preparation steps are as follows: first put the calculated and weighed returned materials and ordinary steel scrap into the induction furnace for smelting, and add calculated and weighed ferromolybdenum, nickel plate, ferrochrome, copper plate, ferroniobium and ferromanganese during the smelting process , ferrosilicon, after the furnace charge is melted, use a carburant to adjust the carbon content; then raise the melt temperature to 1600-1620°C and then insert aluminum for one-time deoxidation, the amount of aluminum added is 0.15-0.3% of the weight of the alloy melt; then Add ferro-titanium and ferro-boron. After the molten steel is melted and slag removed, aluminum is inserted for secondary deoxidation. The ...

Embodiment 2

[0048] A boron-containing high-silicon bainite wear-resistant and corrosion-resistant alloy, its chemical composition is 0.42%C, 2.25%Si, 0.85%Mn, 2.32%Cr, 0.37%Mo, 0.31%Ni, 0.35%Cu, 0.22%Ti , 0.1% B, 0.055% Ce, 0.07% Nb, 0.014% P, 0.010% S, and the rest is Fe. The specific preparation steps are as follows: first put the calculated and weighed returned materials and ordinary steel scrap into the induction furnace for smelting, and add calculated and weighed ferromolybdenum, nickel plate, ferrochrome, copper plate, ferroniobium and ferromanganese during the smelting process , ferrosilicon, after the furnace charge is melted, use a carburant to adjust the carbon content; then raise the melt temperature to 1600-1620°C and then insert aluminum for one-time deoxidation, the amount of aluminum added is 0.15-0.3% of the weight of the alloy melt; then Add ferro-titanium and ferro-boron. After the molten steel is melted and slag removed, aluminum is inserted for secondary deoxidation. ...

Embodiment 3

[0050] A boron-containing high-silicon bainite wear-resistant and corrosion-resistant alloy, its chemical composition is 0.35%C, 2.12%Si, 0.95%Mn, 1.92%Cr, 0.34%Mo, 0.41%Ni, 0.32%Cu, 0.18%Ti , 0.1% B, 0.054% Ce, 0.06% Nb, 0.018% P, 0.014% S, and the rest is Fe. The specific preparation steps are as follows: first put the calculated and weighed returned materials and ordinary steel scrap into the induction furnace for smelting, and add calculated and weighed ferromolybdenum, nickel plate, ferrochrome, copper plate, ferroniobium and ferromanganese during the smelting process , ferrosilicon, after the furnace charge is melted, use a carburant to adjust the carbon content; then raise the melt temperature to 1600-1620°C and then insert aluminum for one-time deoxidation, the amount of aluminum added is 0.15-0.3% of the weight of the alloy melt; then Add ferro-titanium and ferro-boron. After the molten steel is melted and slag removed, aluminum is inserted for secondary deoxidation. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com