Industrial device with sensor and weighing method

An industrial device and sensor technology, which is applied in the direction of measuring devices, detailed information of weighing equipment, instruments, etc., can solve the problems of insufficient weighing detection accuracy, and the weighing device does not have overload protection, so as to reduce oxidation corrosion and pressure , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

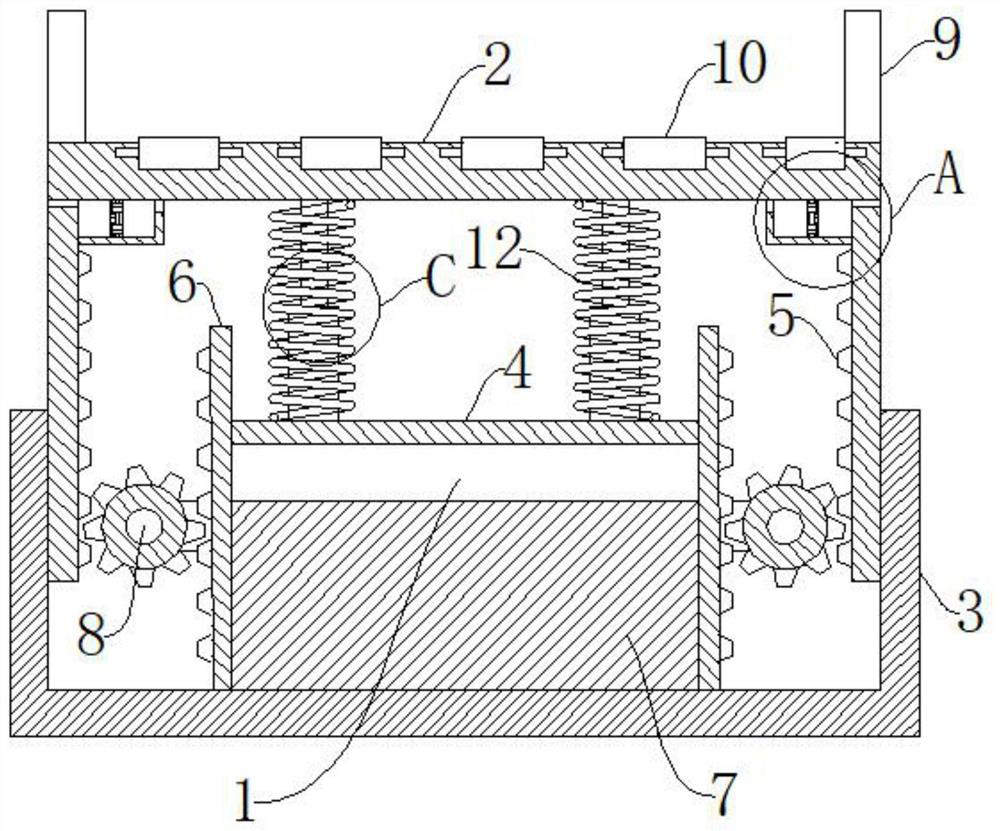

[0035] refer to Figure 1-5 , an industrial device with a sensor, including a sensor 1 and a base 3, the base 3 is fixedly connected to a support block 7, the sensor 1 is fixedly connected to the upper end of the support block 7, and the base 3 is slidably connected to a placement table 2;

[0036] A chute 11 is provided in the support block 7, a sliding plate 6 is slidably connected in the chute 11, and a reversing gear 8 is rotatably connected in the chute 11, and the sliding plate 6 is provided with transmission teeth matched with the reversing gear 8, Both sides of the placing table 2 are provided with multiple groups of fixed teeth 5, and the fixed teeth 5 match with the reversing gear 8;

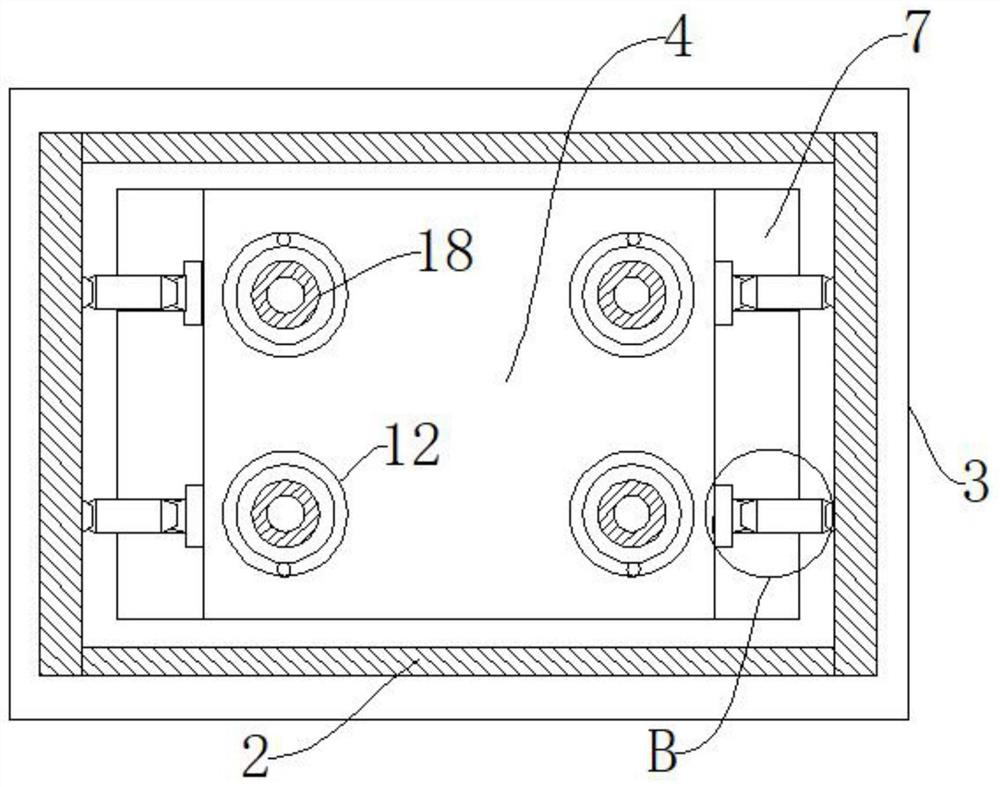

[0037] The upper end of the sensor 1 is connected to the load-bearing plate 4, the upper end of the load-bearing plate 4 is fixedly connected to the sleeve 18, and the telescopic rod 17 is slidably connected to the sleeve 18, and the upper end of the telescopic rod 17 is fixedly connec...

Embodiment 2

[0041] refer to Figure 1-5 , the industrial device equipped with sensors is basically the same as that of Embodiment 1, and furthermore: the two sides of the upper end of the placement table 2 are fixedly connected with baffle plates 9, and the placement table 2 is rotatably connected with multiple groups of rollers 10, which is convenient for pushing heavy objects Walk, and at the same time prevent heavy objects from slipping during sliding.

Embodiment 3

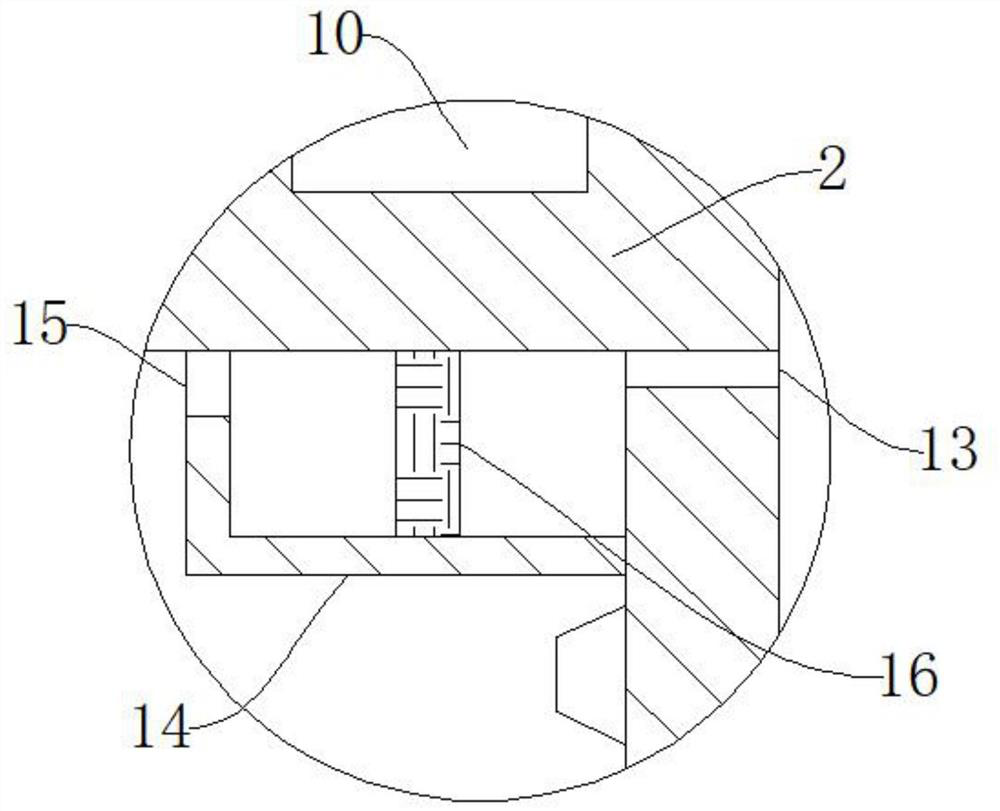

[0043] refer to Figure 1-5 , the industrial device equipped with sensors is basically the same as that of Embodiment 1, furthermore: the transition chamber 14 is symmetrically fixedly connected to the bottom end of the placement table 2, and the side of the placement table 2 near the transition chamber 14 is provided with a first air hole 13, and the transition The end of cavity 14 far away from first air hole 13 is provided with second air hole 15, and filter block 16 is connected between first air hole 13 and second air hole 15, and the air between base 3 and placing table 2 is separated from the outside world through transition chamber 14. The atmosphere is connected to avoid negative pressure inside and affect the measurement accuracy of the sensor 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com