Flocking roller

A flocking roller and flocking technology, applied in the field of flocking rollers, can solve the problems of unsustainable elasticity, loss of elasticity and durability, and achieve the effect of prolonging the service life and working stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] For further elaborating the technical means and effects that the present invention adopts to achieve the predetermined purpose, please refer to the following detailed description and accompanying drawings of the present invention. It should be understood that the drawings and embodiments are only provided for reference and description, and are not intended to limit the present invention.

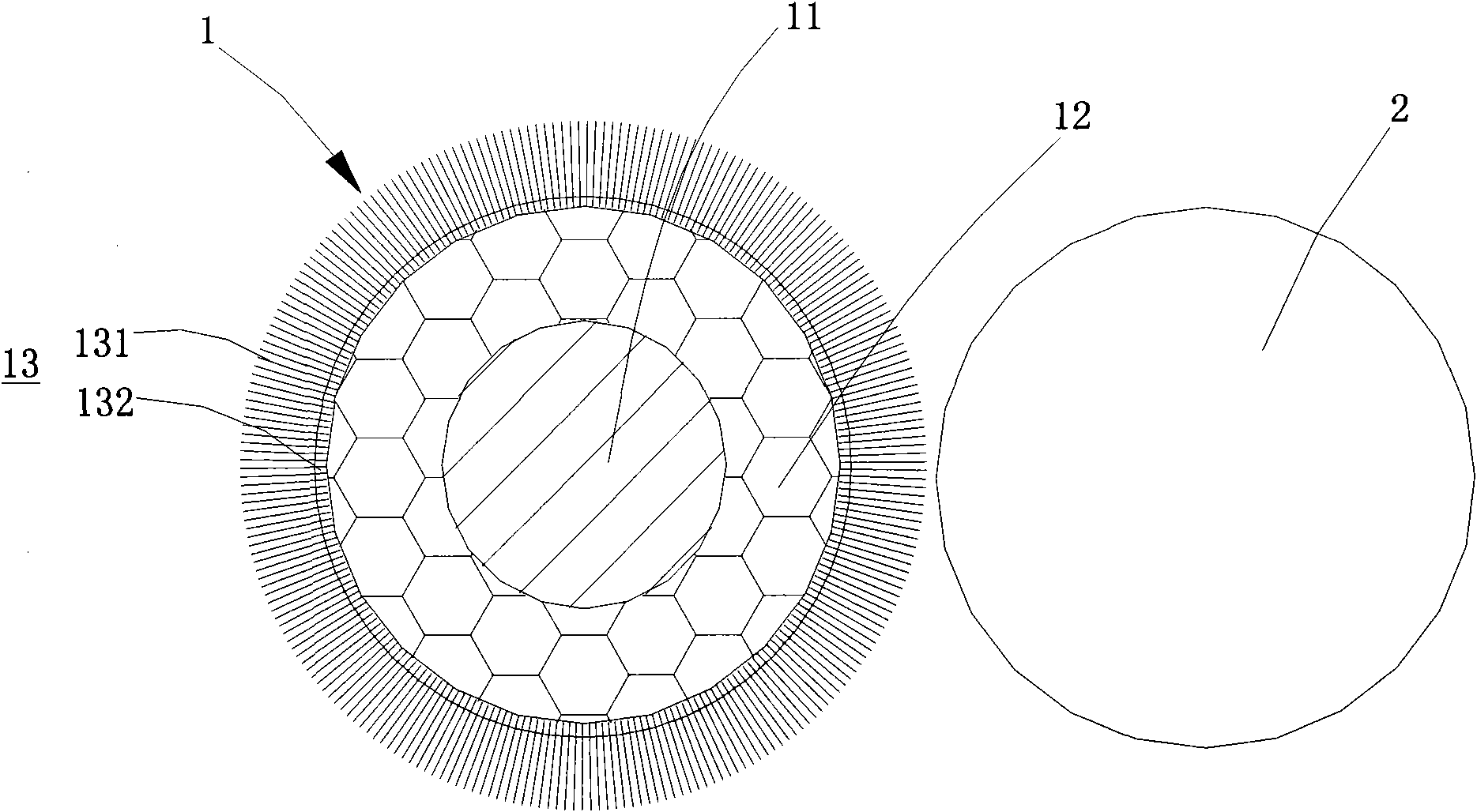

[0035] Such as figure 1 As shown, the flocking roller 1 of the present invention abuts against the mating roller 2 in a matched manner, and the mating roller 2 can be a flocking roller or other roller shafts, which are only schematically shown in the figure.

[0036] The flocking roller 1 includes a roller core 11 and a composite working layer that forms a matching abutment with the mating roller 2;

[0037] The roller core 11 can be made of metal materials or resin plastics, and its shape can be cylindrical as shown in the figure. In other embodiments, the roller core 11 can also be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com