Device for lifting and moving coiled material through synchronous clamping and fixing in three-coordinate mode

A three-coordinate, coiled material technology, applied in the direction of transportation and packaging, manipulators, program control manipulators, etc., can solve the problems of heavy coils, slow progress, limited efficiency, etc., and achieve enhanced transportation stability, enhanced service life, and improved safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

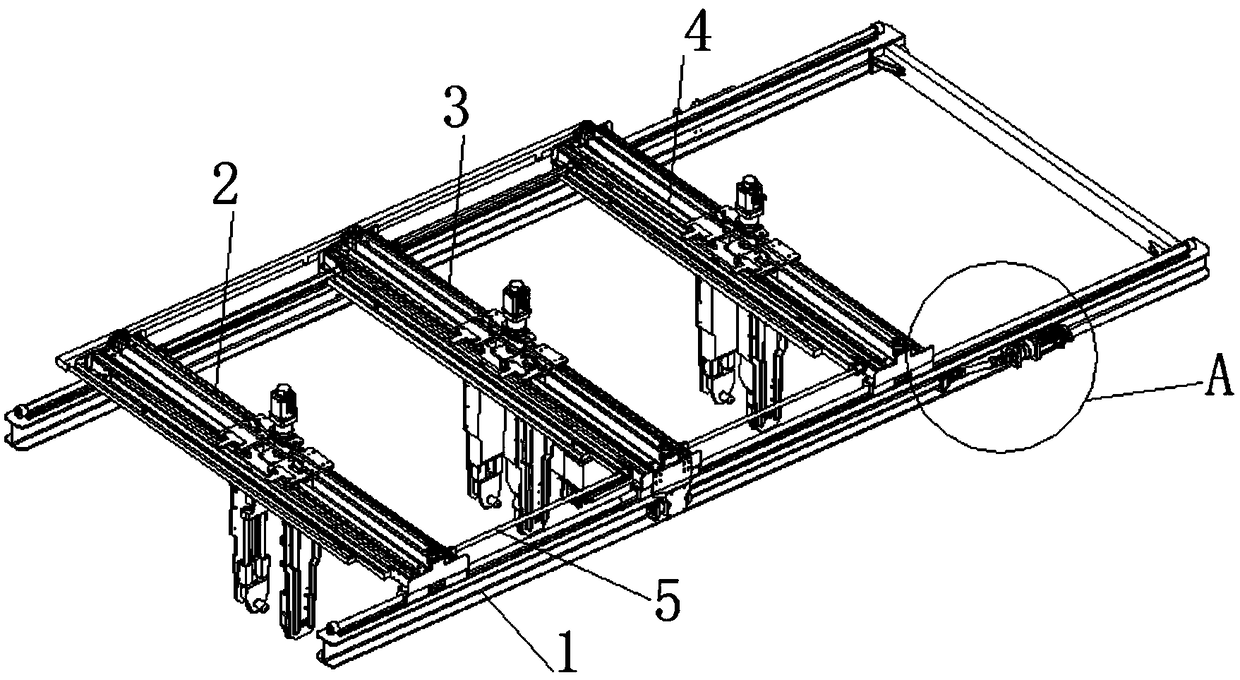

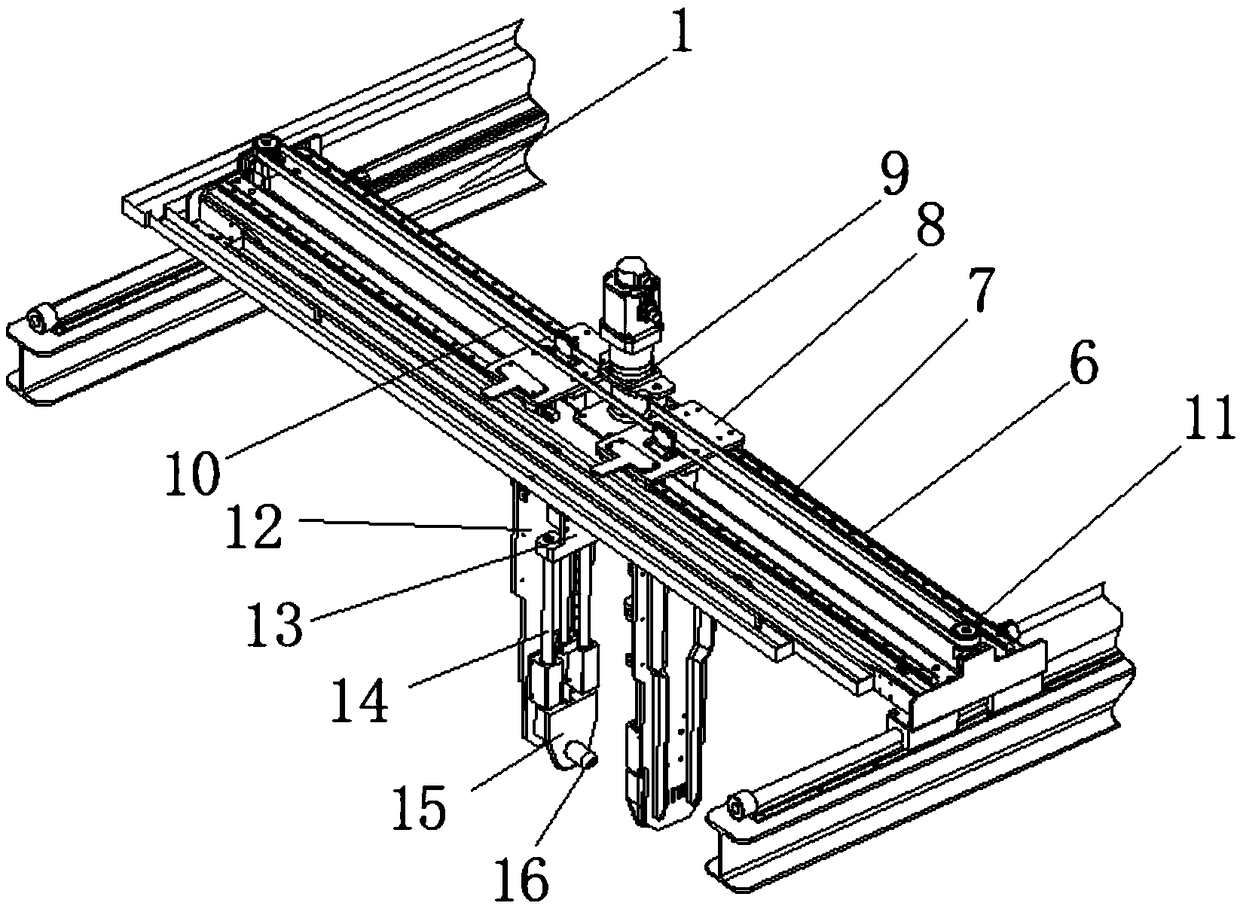

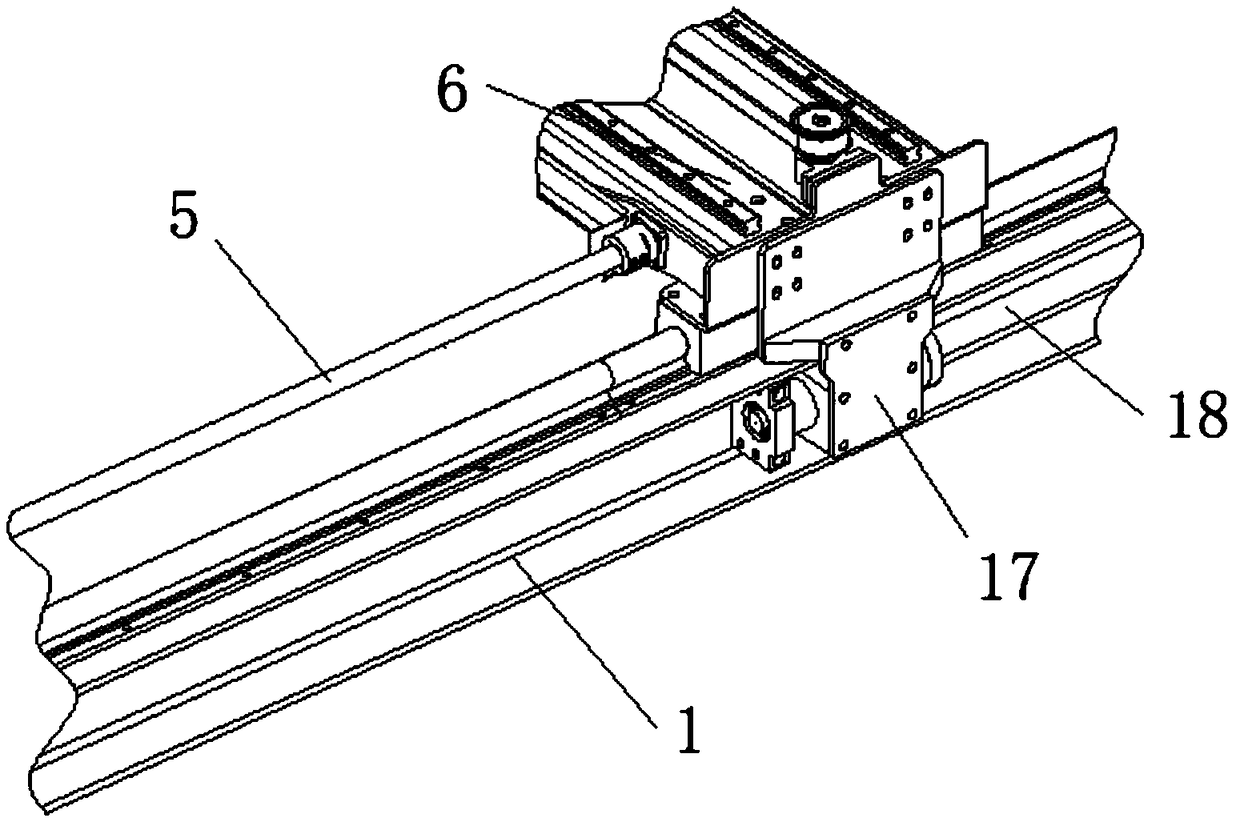

[0038] see Figure 1-4, a device for synchronously clamping and fixing three-coordinate lifting and moving coils, including a truss I-beam 1, characterized in that: the upper end of the truss I-beam 1 is fixedly connected with a longitudinal sliding rod, and the upper end of the longitudinal sliding rod slides from left to right Connected with the body 2 of the paper cover processing and grabbing robot arm, the shrinking processing grabbing robot arm body 3 and the hot-melt processing grabbing robot arm body 4, the paper cover processing and grabbing robot arm body 2 and the shrinking processing grabbing robot arm body 3 Two driven connecting rods 5 are fixedly connected between the shrinkage processing grabbing robot body 3 and the hot-melt processing grabbing robot body 4. The paper cover processing grabbing robot body 2 and the shrinking processing grabbing robot The upper ends of the main body 3 and the hot-melt processing grasping mechanical arm body 4 are fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com