Anti-oxidation protection mechanism for data line connector in humid environment

A technology that protects the mechanism in a humid environment and is used in connection, chemical instruments and methods, and components of connection devices. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

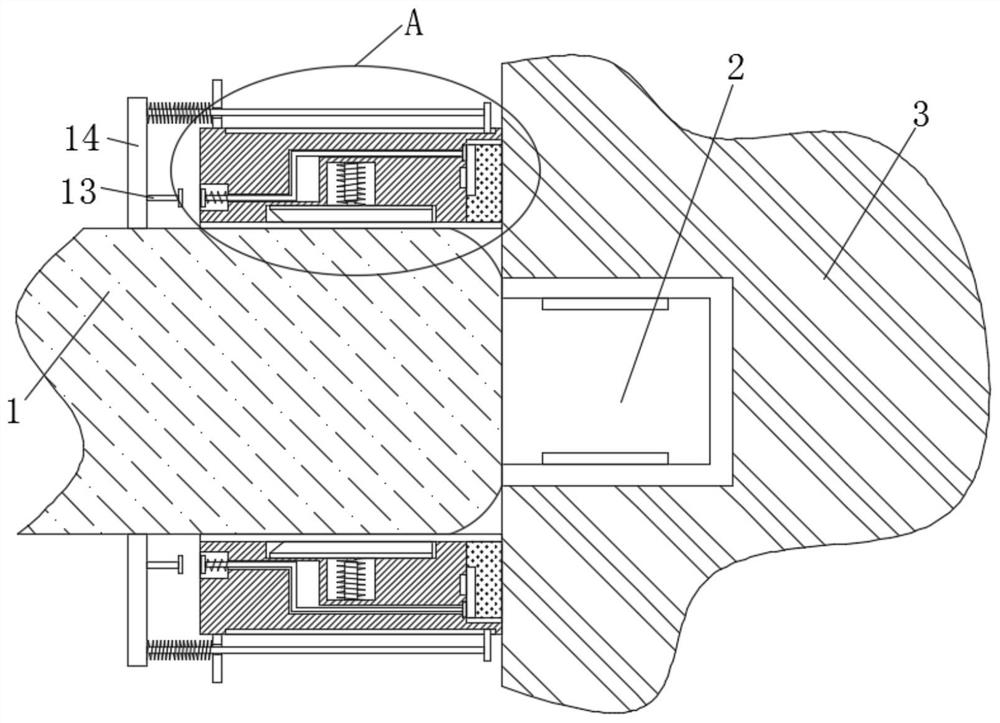

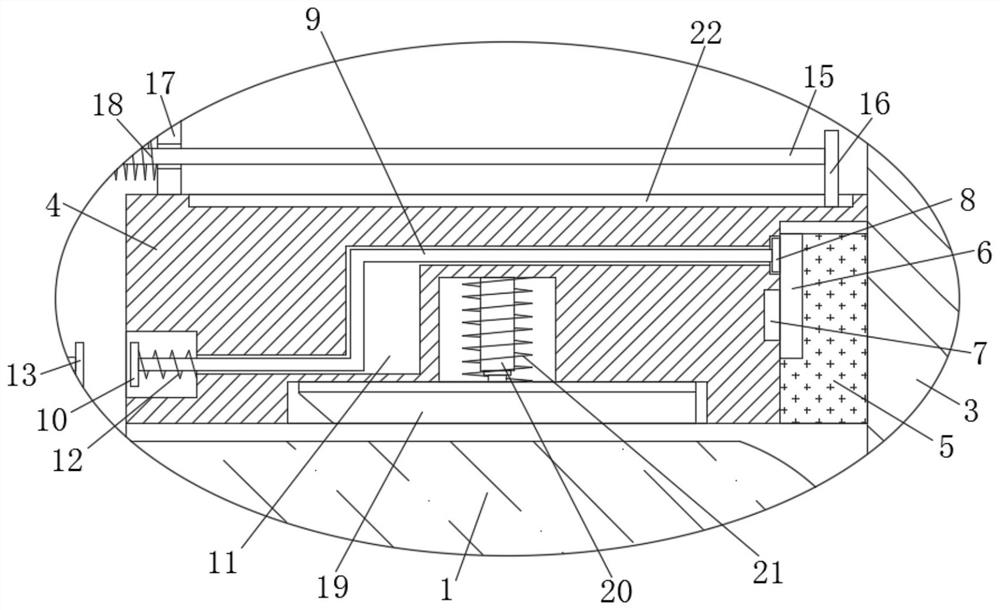

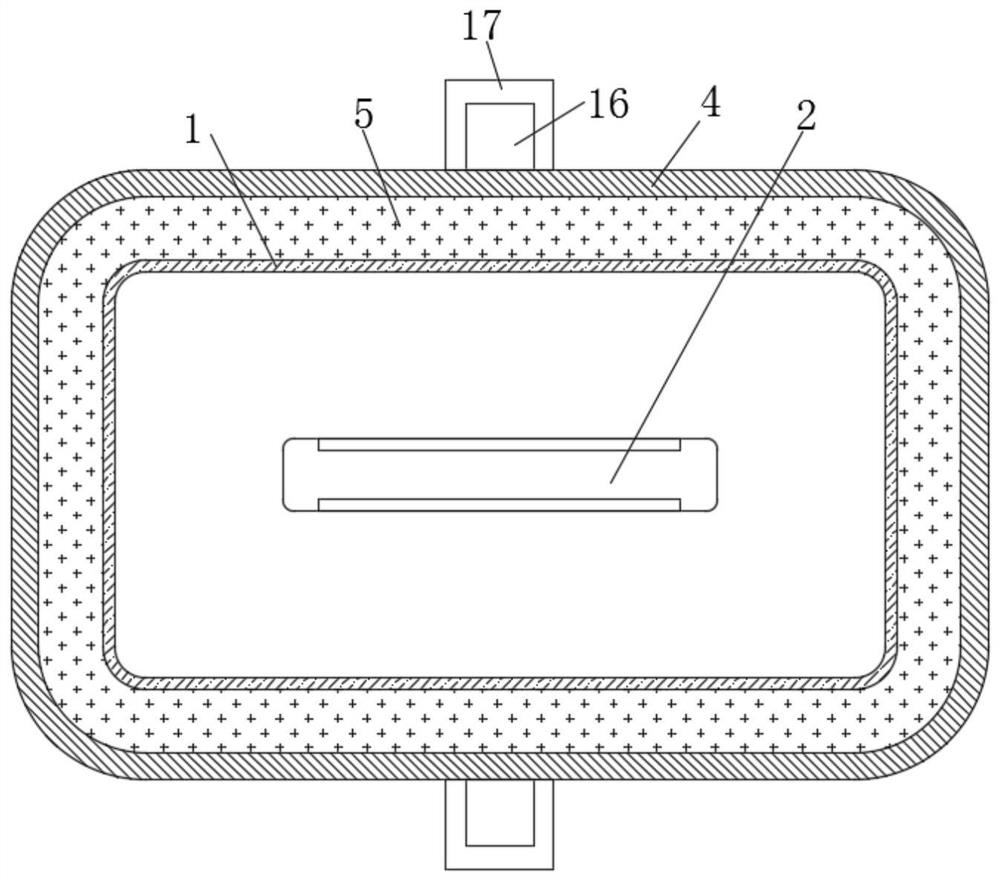

[0021] refer to Figure 1-4 , an anti-oxidation protection mechanism at a data line joint in a humid environment, comprising a data line joint housing 1, a metal joint 2 is fixedly installed on the right end of the data line joint housing 1, and an external host 3 is inserted into the right end of the metal joint 2, so that The outer cover of the data line connector shell 1 is provided with a protective cover 4, and the right end of the protective cover 4 is inserted with a drying ring 5, and the drying ring 5 is located at the connection between the protective cover 4 and the external host 3, and the right end of the drying ring 5 is closely connected to the external host 3. Fitting, the left end of the drying ring 5 is fixedly equipped with an iron sheet 6, the left side of the iron sheet 6 is provided with a magnet 7, the magnet 7 is fixedly installed inside the right end of the protective cover 4, and the iron sheet 6 is adsorbed on the magnet 7, the The side far away from...

Embodiment 2

[0023] refer to Figure 1-4 , in this embodiment, it is basically the same as Embodiment 1, and more optimally, a push plate 8 is provided on the left side of the iron sheet 6, the left end of the iron sheet 6 and the push plate 8 are attached to each other, and the left end of the push plate 8 is fixedly installed with a Connecting rod 9, the left end of connecting rod 9 is fixedly equipped with a connecting plate 10, the inside of the protective cover 4 is provided with a through groove 11 corresponding to the connecting rod 9, the connecting rod 9 is slidably connected to the protective cover 4, and the connecting rod 9 is covered with a spring One 12, the left and right ends of the spring one 12 are fixedly connected with the connecting plate 10 and the protective cover 4 respectively, the left side of the connecting plate 10 is provided with a fixed rod 13, the left end of the fixed rod 13 is fixedly connected with a riser 14, and the ends of the risers 14 are close to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com