Novel cooling method and device applied to semi-continuous casting of magnesium alloy

A cooling method and cooling device technology, applied in the field of magnesium metal smelting, can solve the problems affecting the quality and safety of magnesium metal smelting, the surface color becomes black, yellow and green, and the surface of magnesium rods is oxidized and corroded, so as to prevent combustion and explosion accidents, Low oxidation corrosion and high bar utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

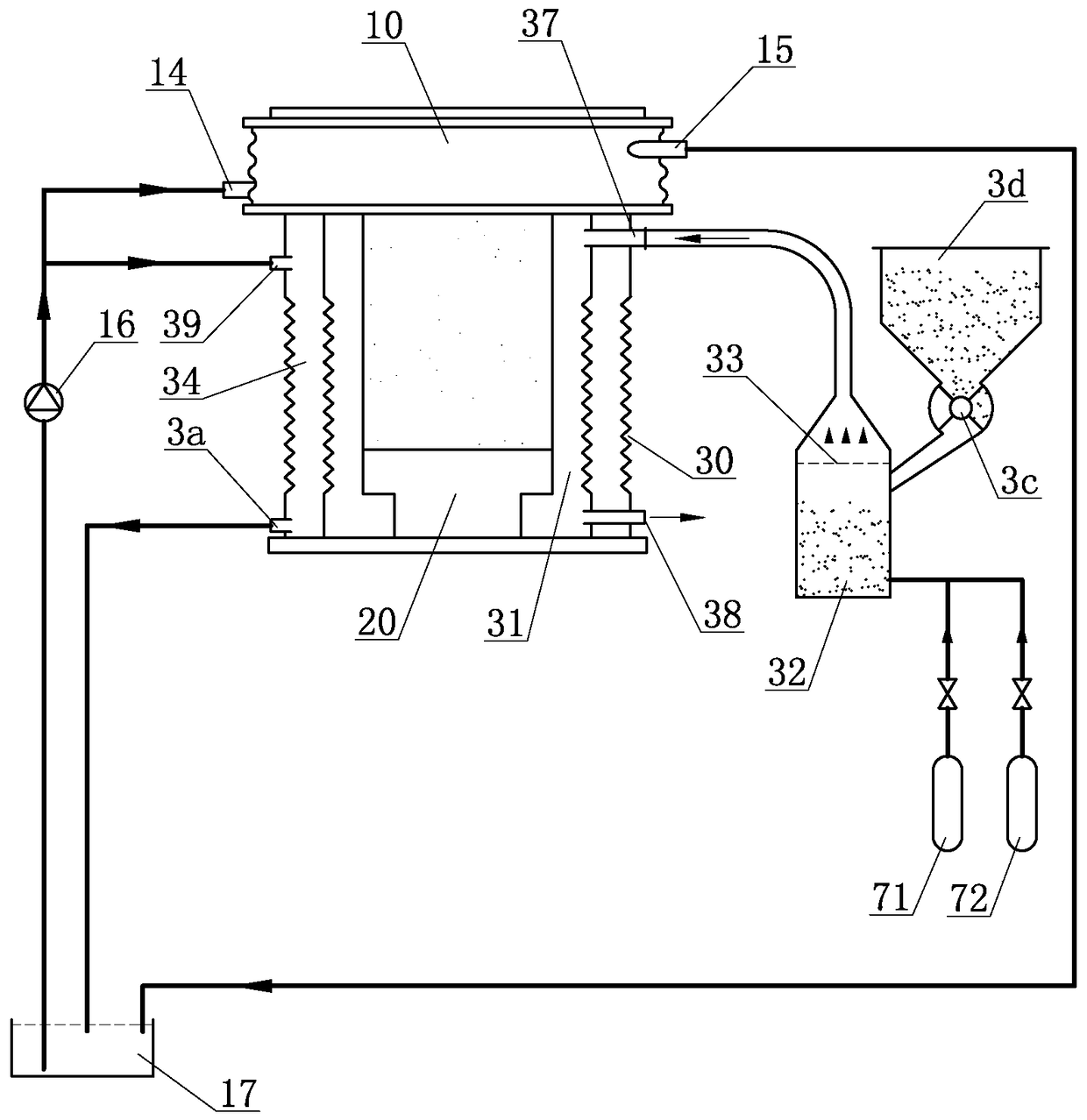

[0042] Such as figure 1 , Figure 4 , Figure 5 , Image 6 , a novel cooling device applied to semi-continuous casting of magnesium alloys, comprising a crystallizer 10 and a dummy head 20 . The crystallizer is installed on the lifting table 13 of a rod pulling machine 12 . The dummy head pulls out the magnesium alloy billet when the lifting table moves down.

[0043] The crystallizer is provided with a primary cooler 11 for primary cooling of the magnesium liquid, and the primary cooler is a primary cooling water jacket. The primary cooling water jacket is provided with an input interface 14 and an output interface 15 . The input interface 14 is connected to a water source, and the water source in this embodiment is normal temperature water extracted from a cooling water pool by a water pump 16 .

[0044] Below the crystallizer is provided a secondary cooler 30 for secondary cooling of the magnesium alloy slab. The secondary cooler is provided with a secondary cooling a...

Embodiment 2

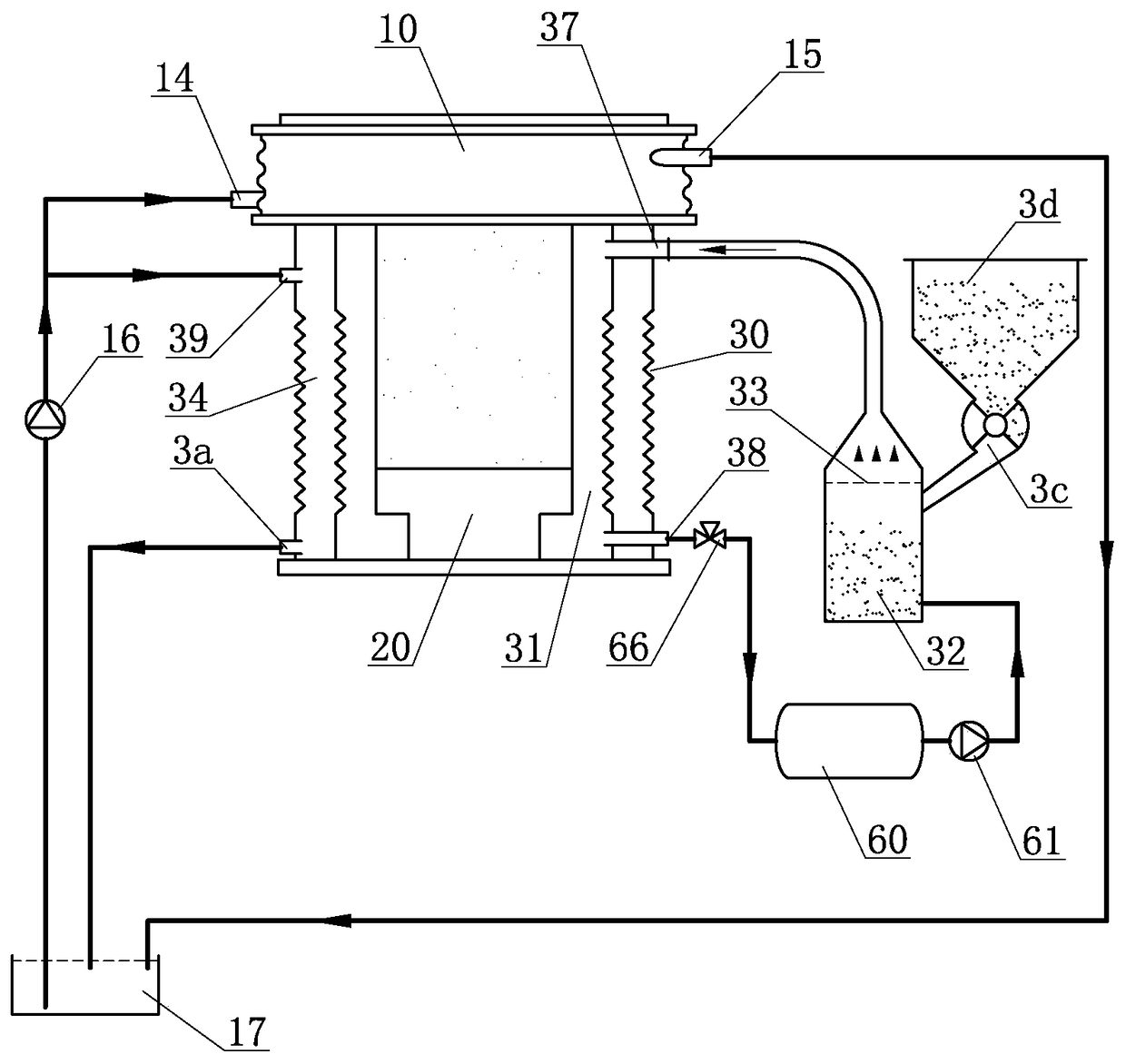

[0052] Such as figure 2 , a new cooling device applied to semi-continuous casting of magnesium alloys. This embodiment is an improvement of the first embodiment.

[0053] In this embodiment, a protective gas storage tank 60 and a protective gas circulation fan 61 are provided. Preconfigured shielding gas is stored in the shielding gas tank. The shielding gas circulation fan circulates the shielding gas through the secondary cooling chamber 31 and the shielding gas storage tank. In this embodiment, the protective gas circulation fan is installed on the pipeline connecting the dry ice cooling chamber 32 and the output port of the protective gas storage tank.

[0054] An exhaust valve 66 is provided at the outlet port 38 of the secondary cooling chamber. Before the work process starts, open the exhaust valve first, start the protective gas circulation fan, and discharge the air in the secondary cooling air chamber.

[0055] In this embodiment, the shielding gas can be recyc...

Embodiment 3

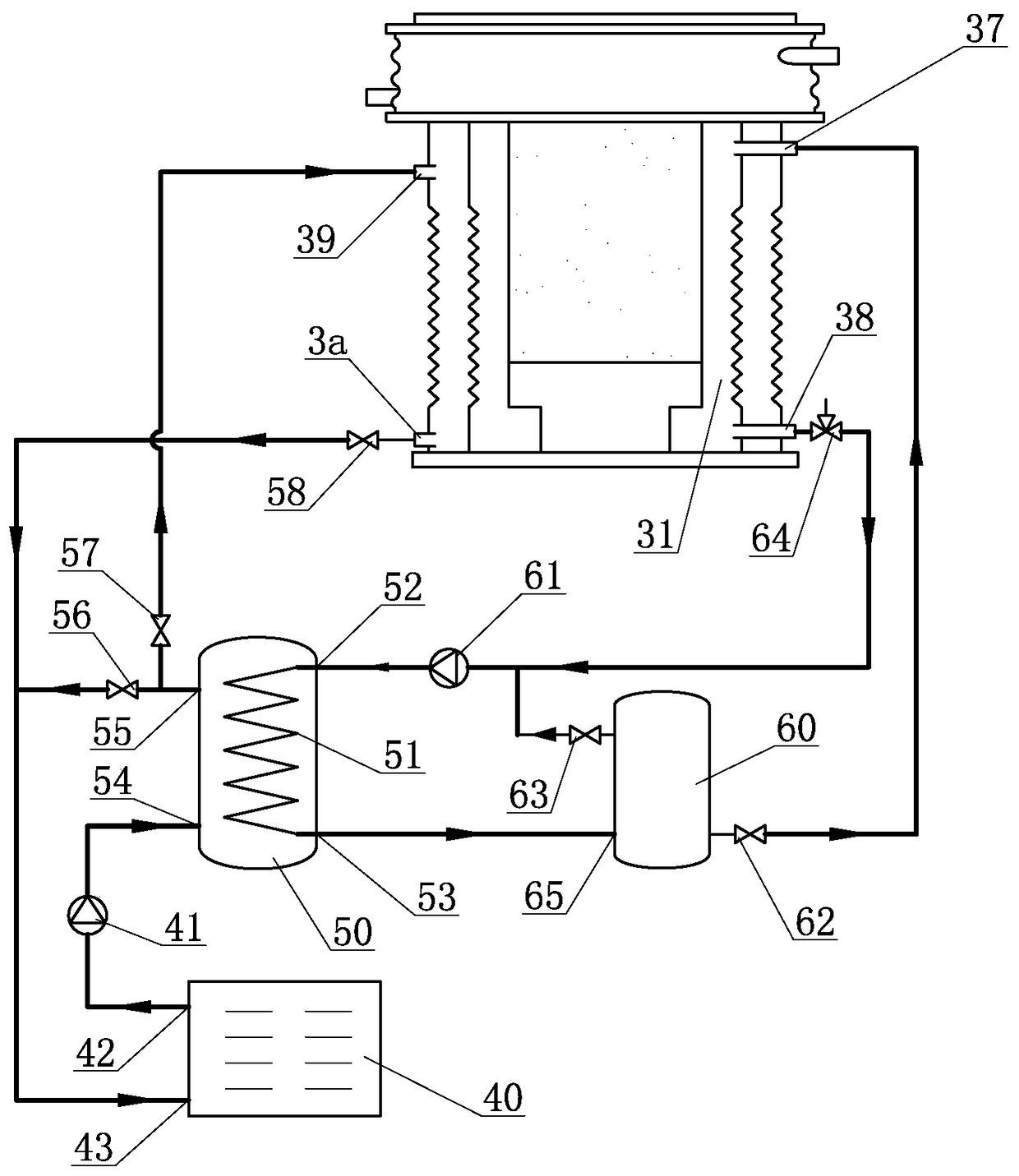

[0057] Such as image 3 , a new cooling device applied to semi-continuous casting of magnesium alloys. This embodiment is an improvement of Embodiment 1 or Embodiment 2.

[0058] In Embodiment 1 or Embodiment 2, the method of cooling the protective gas before secondary cooling is to use dry ice to cool down, but the cooling efficiency of dry ice is low, and it is difficult to greatly cool down a large flow of gas in a short period of time.

[0059] In this embodiment, cooling liquid is used to cool the protective gas, and a refrigerator 40 , a cooling tank 50 , a protective gas storage tank 60 and a protective gas circulation fan 61 are provided. The refrigerant is a liquid that does not freeze at a low temperature, and ethylene glycol solution can be used. Refrigerating equipment is installed on the refrigerator, and the refrigerator cools the refrigerant liquid. After being cooled by the refrigerator, the temperature of the refrigerant can reach -25°C to -20°C. The chill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com