High capacity Mg2Ni-type hydrogen storing alloy amorphous band and preparation method thereof

A technology of hydrogen storage alloy and amorphous strip, which is applied in the field of hydrogen storage alloy materials, can solve the problem that the powder particle size does not meet the requirements of Ni-MH battery use, the alloy composition design and spraying process are not well matched, and the alloy electrochemical Poor cycle stability and other problems, to achieve the effects of good cycle hydrogen storage and release stability, high electrochemical cycle stability, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

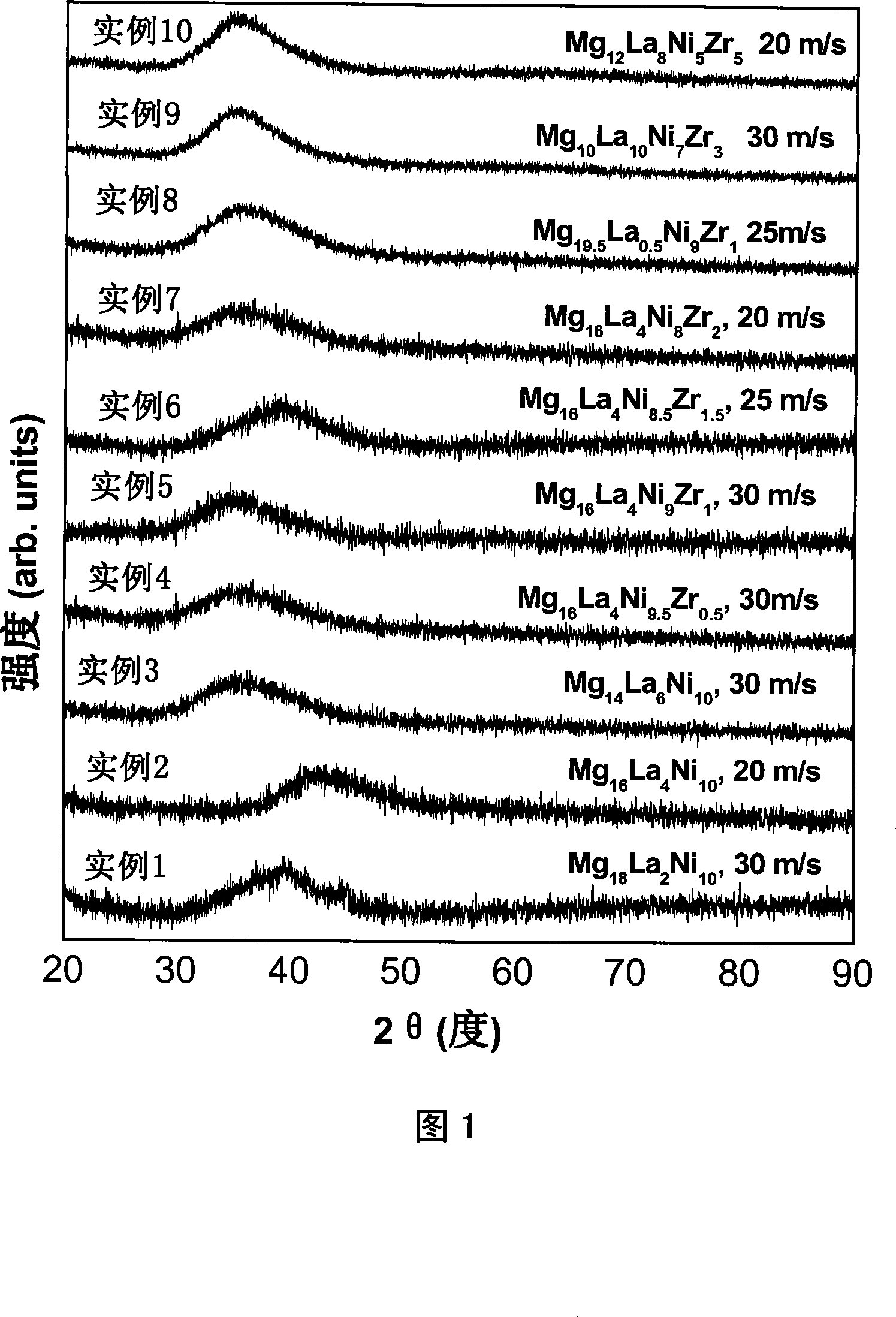

Examples

Embodiment 1

[0022] Select bulk metal magnesium, metal nickel and metal lanthanum with a purity ≥ 99.8%. According to the chemical formula Mg 18 La 2 Ni 10 Chemical dose ratio weighing. Weigh 369.6g of metal magnesium, 405.8g of metal nickel, and 224g of metal lanthanum, place them in a magnesium oxide crucible equipped with an intermediate frequency induction furnace, then cover the furnace cover, and vacuumize for about 40 minutes to a vacuum degree of 5×10 -3 Above Pa, then fill helium protective gas until the air pressure reaches 0.04MPa negative pressure, adjust the power to 4.5kw, control the temperature at 650°C to melt the metal Mg, then adjust the power to 25kw, and control the temperature at 1000°C to make the metal nickel and lanthanum melting. After the metal is melted, keep it under the melting condition for 5 minutes, and finally pour the melt into the ingot mould, and when pouring into the ingot mould, adjust the power to 8.2kw. After cooling for 20 minutes under a heli...

Embodiment 2

[0025] The preparation composition is: Mg 16 La 4 Ni 10 Mg 2 Ni-type hydrogen storage alloy amorphous strip; Weigh 279.4g of metal magnesium, 383.2g of metal nickel, and 380.8g of metal lanthanum, place them in a magnesia crucible equipped with an intermediate frequency induction furnace, then cover the furnace cover, and vacuumize for about 40 minutes to vacuum 5×10 -3 Above Pa, then fill helium protective gas until the air pressure reaches 0.04MPa negative pressure, adjust the power to 4.5kw, control the temperature at 650°C to melt the metal Mg, then adjust the power to 25kw, and control the temperature at 1000°C to make the metal nickel and lanthanum melting. After the metal is melted, keep it under the melting condition for 5 minutes, and finally pour the melt into the ingot mould, and when pouring into the ingot mould, adjust the power to 8.2kw. After cooling for 20 minutes under a helium protective atmosphere, it is released from the oven

[0026] Put about 100g o...

Embodiment 3

[0028] The preparation composition is: Mg 14 La 6 Ni 10 Mg 2 Ni-type hydrogen storage alloy amorphous strip; Weigh 212.6g of metal magnesium, 333.4g of metal nickel, and 569g of metal lanthanum, place them in a magnesia crucible equipped with an intermediate frequency induction furnace, then cover the furnace cover, and vacuumize for about 40 minute to vacuum 5×10 -3 Above Pa, then fill helium protective gas until the air pressure reaches 0.04MPa negative pressure, adjust the power to 4.5kw, control the temperature at 650°C to melt the metal Mg, then adjust the power to 25kw, and control the temperature at 1000°C to make the metal nickel and lanthanum melting. After the metal is melted, keep it under the melting condition for 5 minutes, and finally pour the melt into the ingot mould, and when pouring into the ingot mould, adjust the power to 8.2kw. After cooling for 20 minutes under a helium protective atmosphere, it is released from the oven

[0029] Put about 100g of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com