Waste lubricating oil hydrogenation recycling method

A waste lubricating oil and hydrogen recycling technology, applied in the directions of lubricating compositions, hydrotreating processes, chemical instruments and methods, etc., can solve the problems of detachment from the outer surface of the catalyst, slow diffusion, and increased bed pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

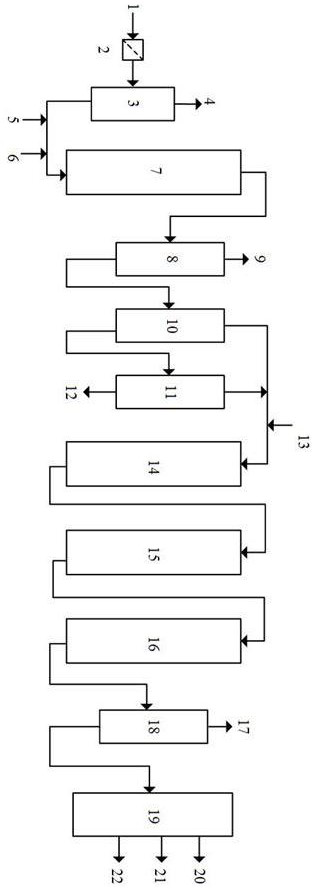

Method used

Image

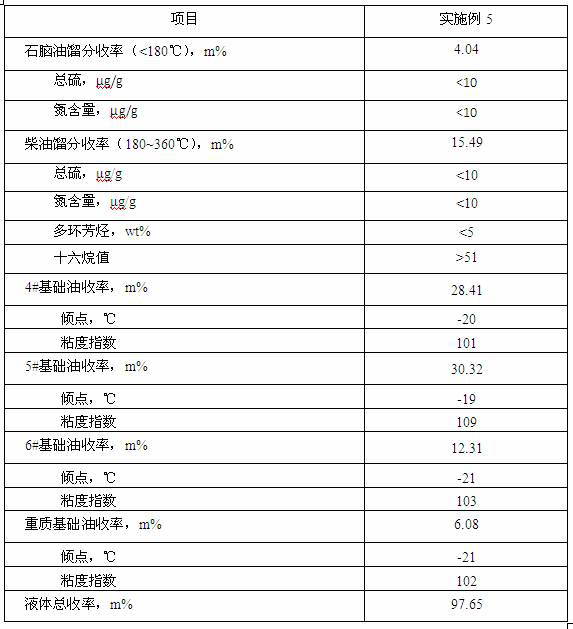

Examples

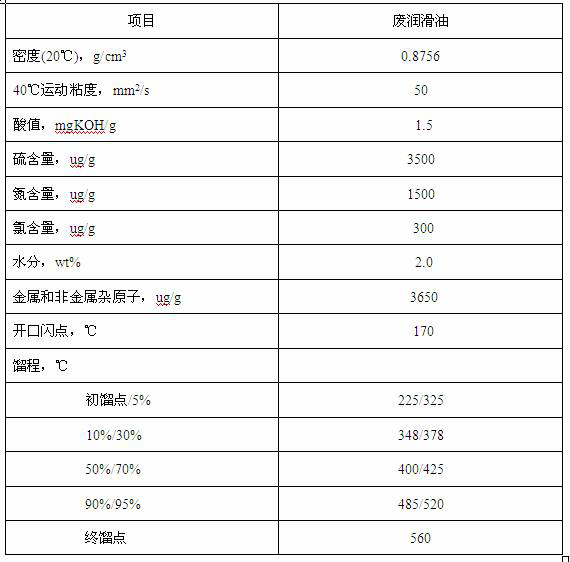

Embodiment 1

[0102] The waste lubricating oil is processed according to the step of hydrogen pretreatment in the slurry bed in the method of the present invention, and the self-sulfiding oil-soluble molybdenum catalyst developed by the State Key Laboratory of Heavy Oil is used. The reaction conditions and reaction results are shown in Table 2 and Table 3. The preparation method of self-sulfurized oil-soluble molybdenum catalyst is as follows:

[0103] Weigh 30g of molybdenum trioxide, add 200mL of distilled water, then add 60mL of ammonia water (concentration: 17%), stir and heat to 40°C to dissolve. Add 360 mL of ammonium sulfide solution with a sulfur content of 8% to the solution under stirring, raise the temperature to 80° C., and stir for 2 hours to react. The liquid containing crystals was suction-filtered with a Buchner funnel, washed with distilled water, and dried at room temperature for 12 hours to obtain ammonium tetrathiomolybdate. Weigh 15g of ammonium tetrathiomolybdate and...

Embodiment 2

[0106] The waste lubricating oil is processed according to the slurry bed hydrogen pretreatment step in the method of the invention, and the self-sulfiding oil-soluble molybdenum and nickel composite catalyst developed by the State Key Laboratory of Heavy Oil is used. The reaction conditions and reaction results are shown in Table 2 and Table 3. The self-sulfurized oil-soluble molybdenum and nickel composite catalyst can choose the product obtained by any of the following preparation methods.

Embodiment 21

[0108] Weigh 30g of molybdenum trioxide, add 200mL of distilled water, then add 60mL of ammonia water (concentration: 17%), stir and heat to 40°C to dissolve. Add 360 mL of ammonium sulfide solution with a sulfur content of 8% to the solution under stirring, raise the temperature to 80° C., and stir for 2 hours to react. The liquid containing crystals was suction-filtered with a Buchner funnel, washed with distilled water, and dried at room temperature for 12 hours to obtain ammonium tetrathiomolybdate. Weigh 15g of ammonium tetrathiomolybdate and add it to dodecamonium, the molar ratio of dodecamonium / molybdenum=2.5 / 1, the reaction temperature is 60°C, and the reaction time is 1 hour to obtain the oil-soluble molybdenum-based catalyst. Precursor.

[0109] Weigh 37g of n-butanol, heat up to 80°C, add 20g of sodium hydroxide, keep the reaction temperature at 80°C, and react for 0.5 hours to obtain sodium butoxide; weigh 80g of carbon disulfide, add sodium n-butoxide to carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com