Continuous-output static-hydrogen compression, storage and filling integration system

An output, static technology, applied in pipeline systems, hydrogen technology, gas/liquid distribution and storage, etc., can solve the problems of small compression ratio range, large system volume, etc., to achieve improved practicability, low leakage risk, enhanced hydrogen The effect of compression and delivery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

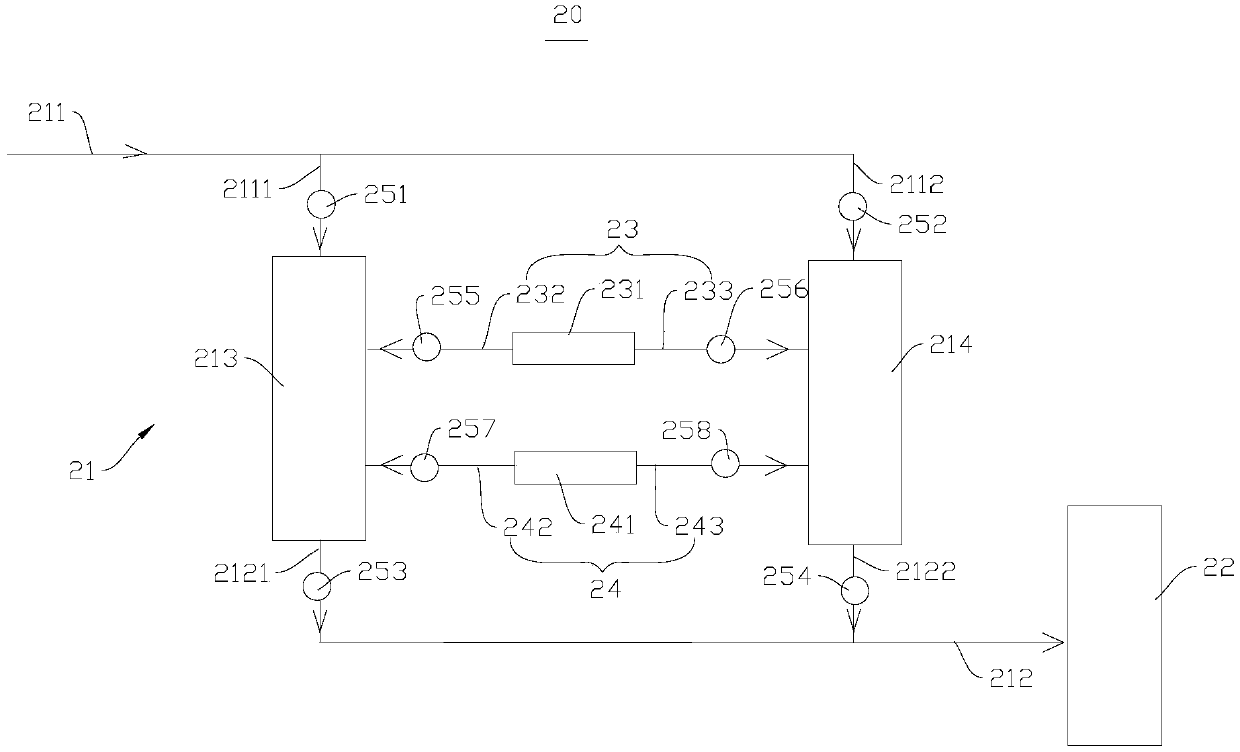

[0085] This embodiment provides a continuous output static hydrogen compression, storage, and filling integrated system 100, which includes a hydrogen source input device 10, a hydrogen pressurization and storage unit 20, and a filling device 30. Among them, the hydrogen pressurization and storage unit 20 includes a static hydrogen compression device 21 (the device contains two compression tanks, namely the first hydrogen compression tank 213 and the second hydrogen compression tank 214) and a pressurized hydrogen storage device 22 (1 pressure storage tank included).

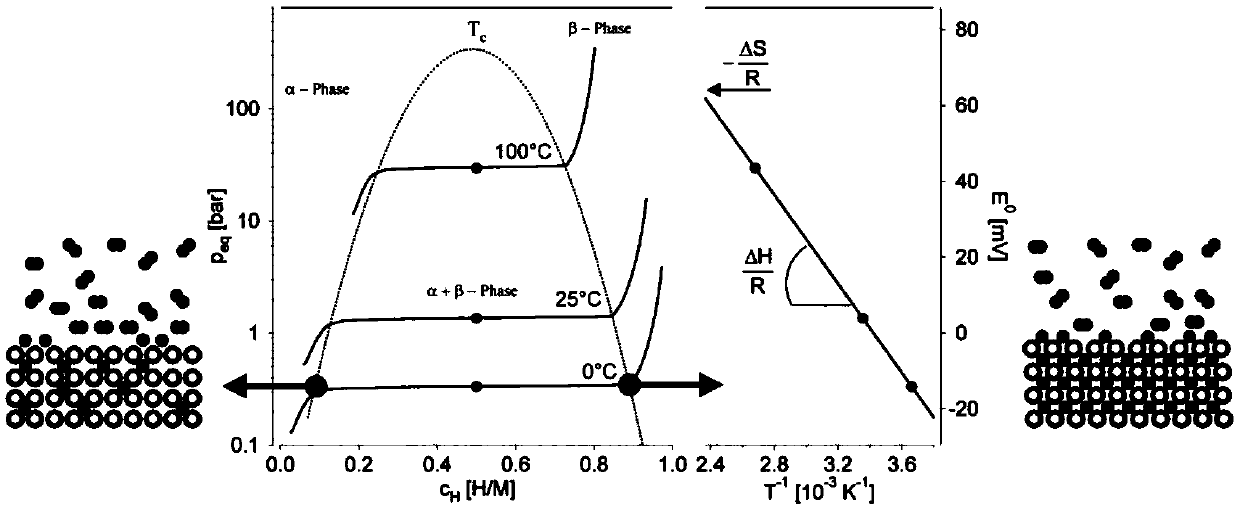

[0086] The input hydrogen source of the system is the hydrogen produced by the electrolytic water hydrogen production device, and the input pressure is 4MPa. Both the first hydrogen compression tank 213 and the second hydrogen compression tank 214 are filled with a rare earth-titanium complex phase hydrogen storage alloy. Water is used as the cold and heat medium, and the heat source comes from ordinary indust...

Embodiment 2

[0089] This embodiment provides a continuous output static hydrogen compression, storage, and filling integrated system 100, which includes a hydrogen source input device 10, two hydrogen pressurization and storage units 20, and a filling device 30. Wherein, each hydrogen pressurization and storage unit 20 includes a static hydrogen compression device 21 (each static hydrogen compression device 21 contains two compression tanks, i.e. the first hydrogen compression tank 213 and the second hydrogen compression tank 214 ) and a pressurized hydrogen storage device 22 (each pressurized hydrogen storage device 22 contains a pressure storage tank). The two static hydrogen compression devices 21 are respectively low pressure stage (output pressure 25MPa) and high pressure stage (output pressure 42MPa). Two pressurized hydrogen storage devices 22 are used to store compressed hydrogen in each stage.

[0090] The input hydrogen source of the system is hydrogen transported by tank truck...

Embodiment 3

[0099] This embodiment provides a continuous output static hydrogen compression, storage, and filling integrated system 100, the integrated system includes a hydrogen source input device 10, 3 arrays of hydrogen pressurization and storage units 20, and 3 sets of filling device 30. Wherein, each hydrogen pressurization and storage unit 20 array includes an array of static hydrogen compression devices 21 (each static hydrogen compression device 21 contains two compression tanks, i.e. the first hydrogen compression tank 213 and the second hydrogen compression tank 213). tank 214) and an array of pressurized hydrogen storage devices 22 (each pressurized hydrogen storage device 22 contains a pressure storage tank). The three arrays of static hydrogen compression devices 21 are respectively low-pressure stage (output pressure 25MPa), medium-pressure stage (output pressure 42MPa) and high-pressure stage (output pressure 90MPa). Three arrays of pressurized hydrogen storage devices 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com