Isolating valve of oil pump

An isolation valve and oil pump technology, applied in multi-way valves, valve devices, engine components, etc., can solve problems such as being unsuitable for large-scale applications, slow response speed, power interruption, etc., to achieve low cost, fast response speed and reliability. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

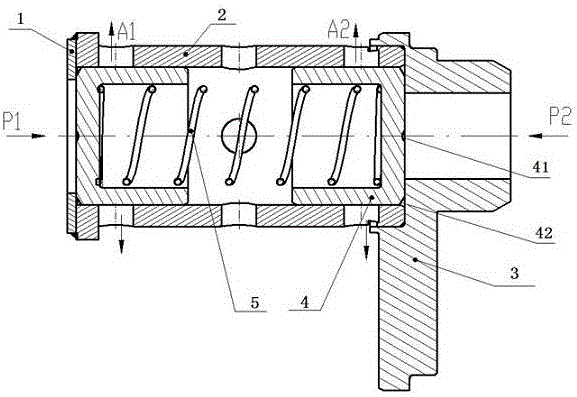

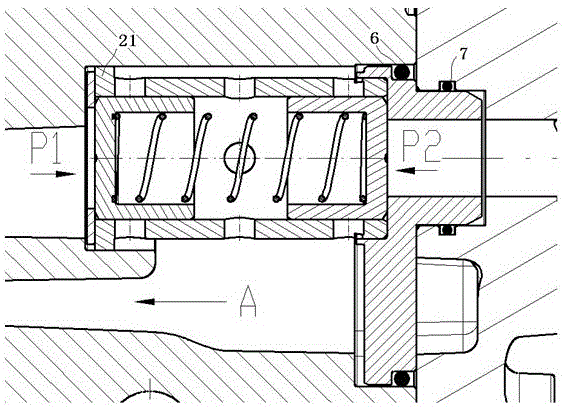

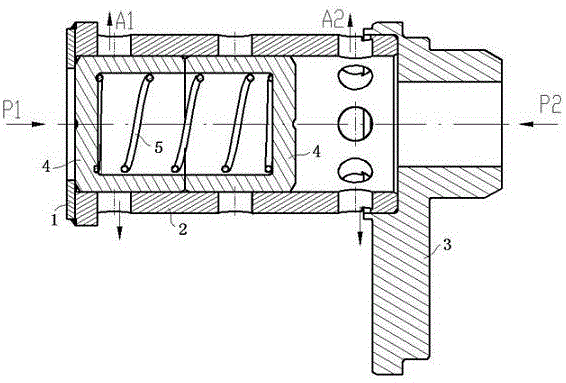

[0027] Below in conjunction with accompanying drawing, the present invention will be further described:

[0028] Figure 1 to Figure 5 An oil pump isolation valve is shown, including a lower valve seat 1 , a valve sleeve 2 , an upper valve seat 3 , a valve core 4 and a spring 5 . Such as figure 1 As shown, the upper valve seat 3 and the valve sleeve 2 are fixed together by riveting, the lower valve seat 1 and the valve sleeve 2 are fixed together by laser welding; there are two valve cores 4, the valve core 4 is installed in the valve sleeve 2, and the spring 5 is set between two spools 4, when the spool 4 is subjected to an external force, it can move and rotate freely in the valve sleeve 2; when not subjected to an external force, the spool 4 is kept in the reset position under the thrust of the spring 5 . The present invention is a double-spool type oil pump isolation valve structure. The lower valve seat 1 and the upper valve seat 3 are respectively arranged at both end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com