Patents

Literature

67results about How to "No pause" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

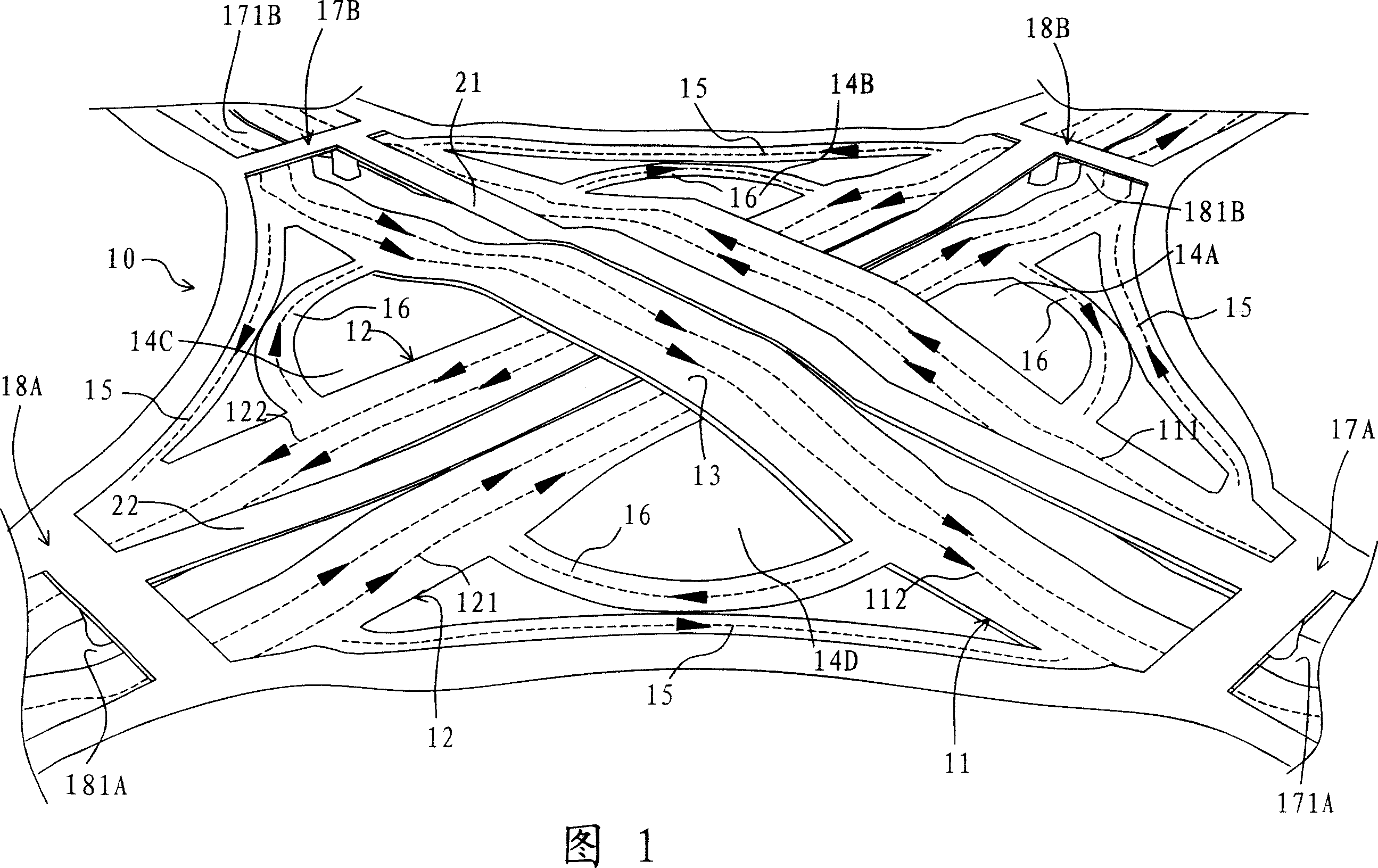

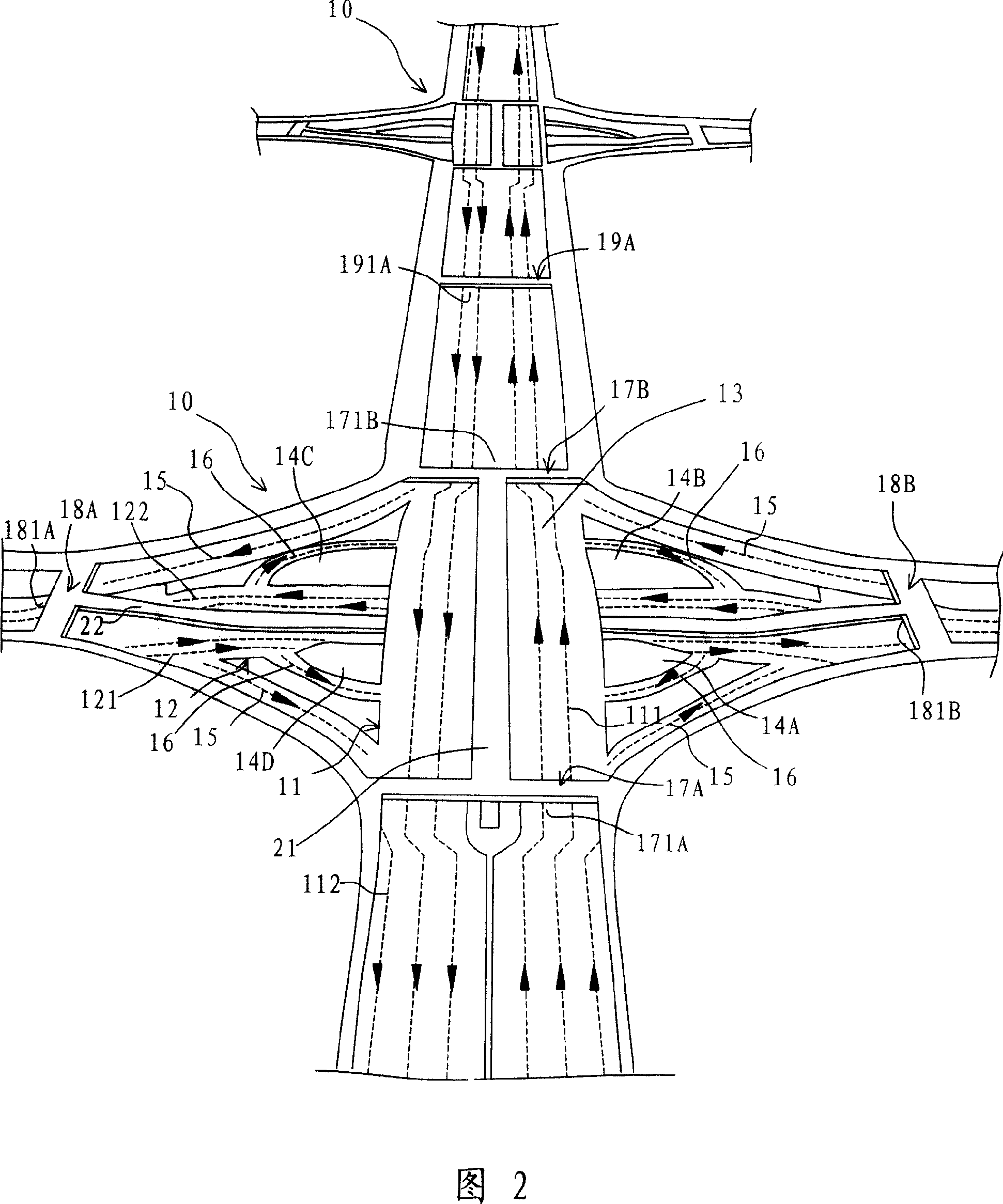

Non-traffic light non-barrier urban multi-level fast traffic road structure

A city solid quick traffic road without traffic light and obstacle is characterized in that a, the cross between longitudinal and transverse roads are solid designed, b, one of longitudinal and transverse roads extends over the horizontal road before the cross to span the vertical road to be transitioned to following horizontal road, c, the part of longitudinal or transverse road outside the cross is disposed with a right steering road connected to the vertical road, d, the longitudinal and transverse roads near the outer side of cross are respectively arranged with a walk bridge along the horizontal road, e, tow sides and under the walk bridge of longitudinal and transverse roads are arranged with concave vehicle roads, f, two side walk bridges at the cross of longitudinal and transverse roads are arranged with a walk channel between, while the walk channel is communicated with two end walk bridges. The invention can eliminate traffic light at cross, to travel people and vehicle independently, to improve traffic efficiency and safety.

Owner:彭振华

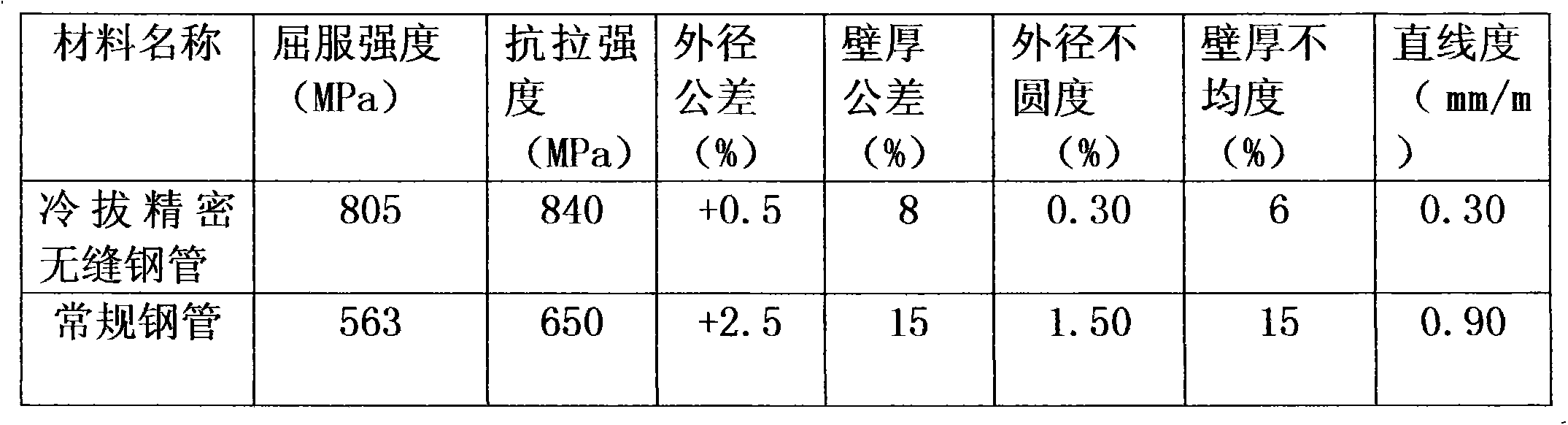

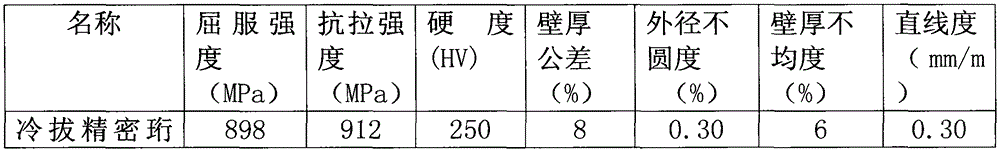

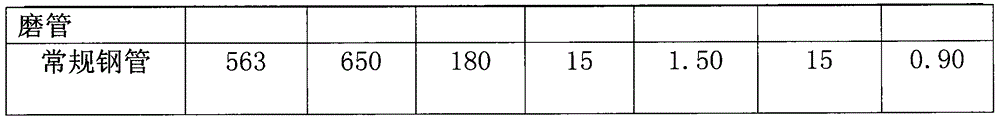

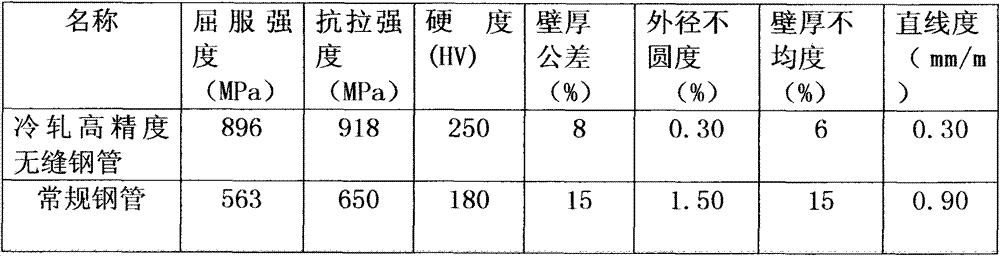

Production method of cold-drawn precision seamless steel pipes

InactiveCN104338777AImprove performanceImprove low temperature impact toughnessAcid washingLubrication

The invention relates to a production method of cold-drawn precision seamless steel pipes. The production method comprises the steps of: heating: pipe blanks are heated in an annular furnace; perforation: the heat pipe blanks are perforated by a perforation machine; annealing: the pipe blanks are annealed; cold rolling: the annealed pipe blanks are leaded into a pipe rolling machine for cold rolling to obtain rolled pipes; stress relieving: the rolled pipes are leaded into a heating furnace for heating to obtain annealed pipe blanks; acid washing treatment: the acid washing is performed for the annealed pipe blanks to remove scales on the surfaces; phosphating treatment: zinc phosphate chemical generation films are formed on the surfaces of the pipe blanks; saponification treatment: such lubrication films as metallic soaps are formed on the films; cold drawing: the cold drawing is performed for the pipe blanks to be cold drawn to obtain cold-drawn pipes; normalization air-cooling treatment; first straightening treatment; induction furnace quenching treatment; box furnace tempering treatment; honing; thermal straightening treatment; and obtaining of the cold-drawn precision seamless steel pipes. The production method obtains the cold-drawn precision seamless steel pipes with high yield strength, high tensile strength, precise sizes and smooth surfaces.

Owner:WUXI DAJIN HIGH PRECISION COLD DRAWN STEEL TUBE

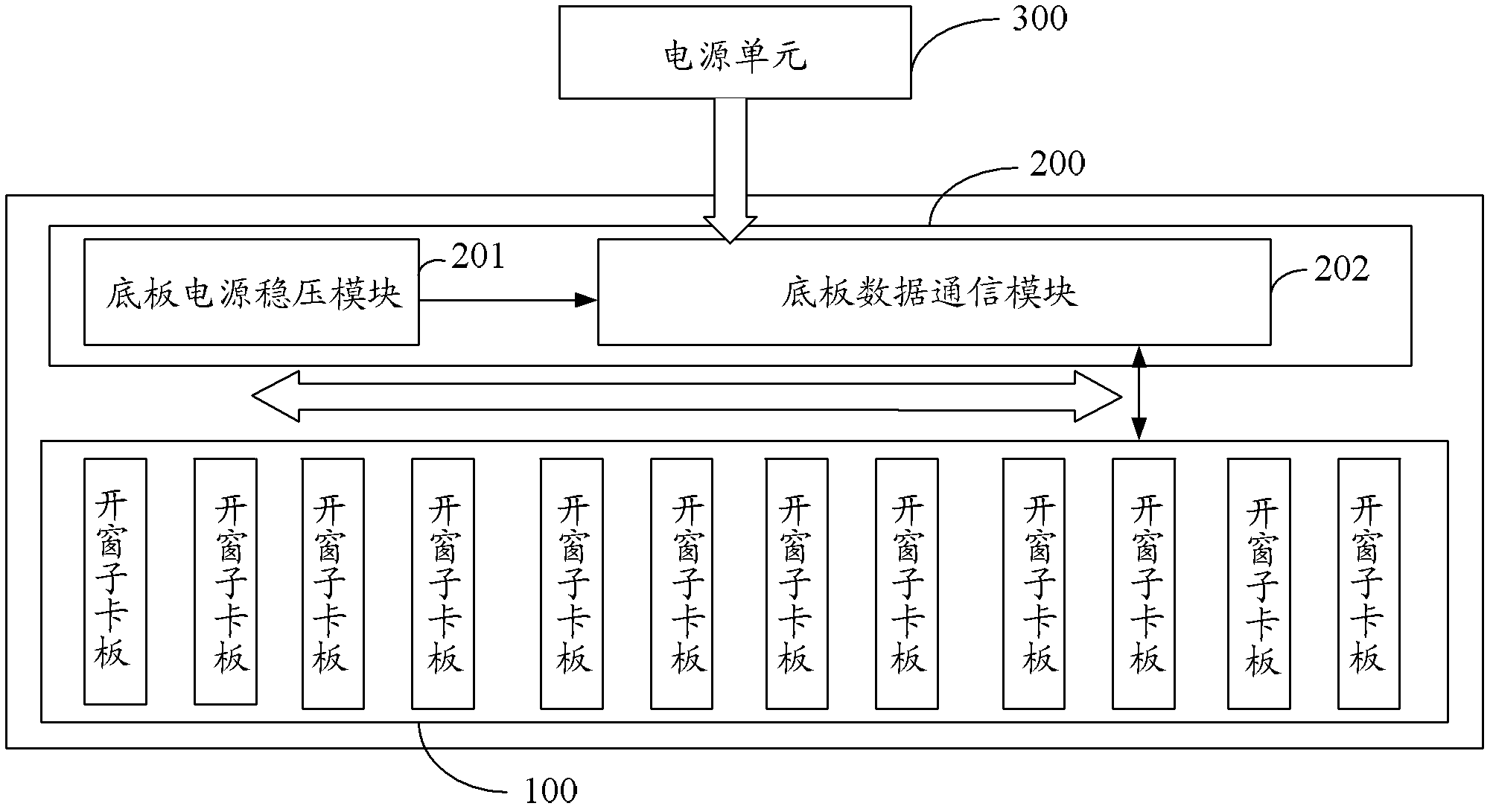

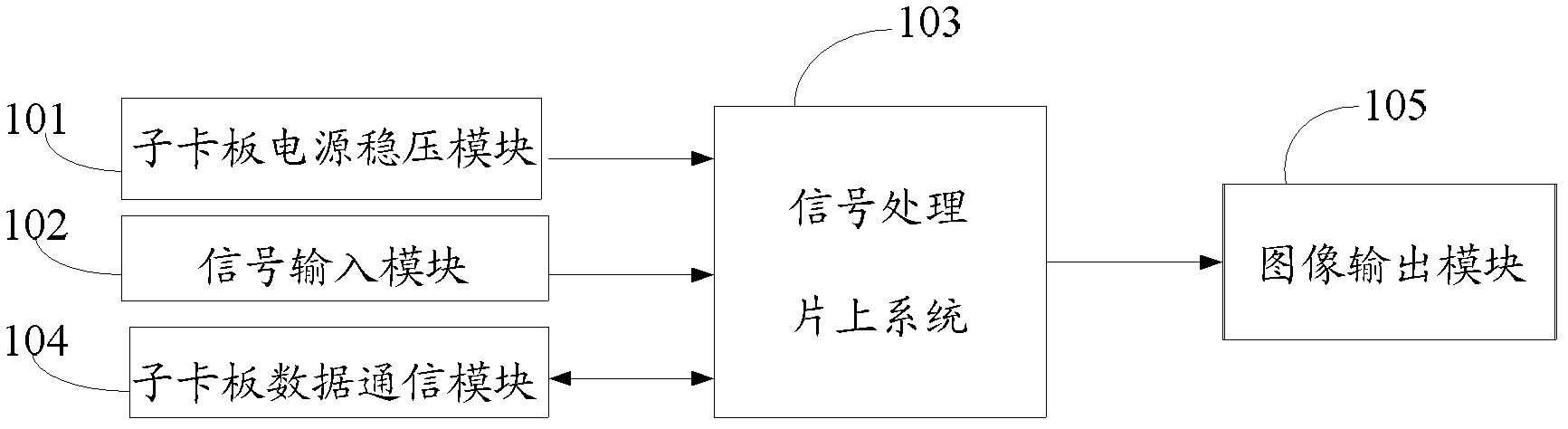

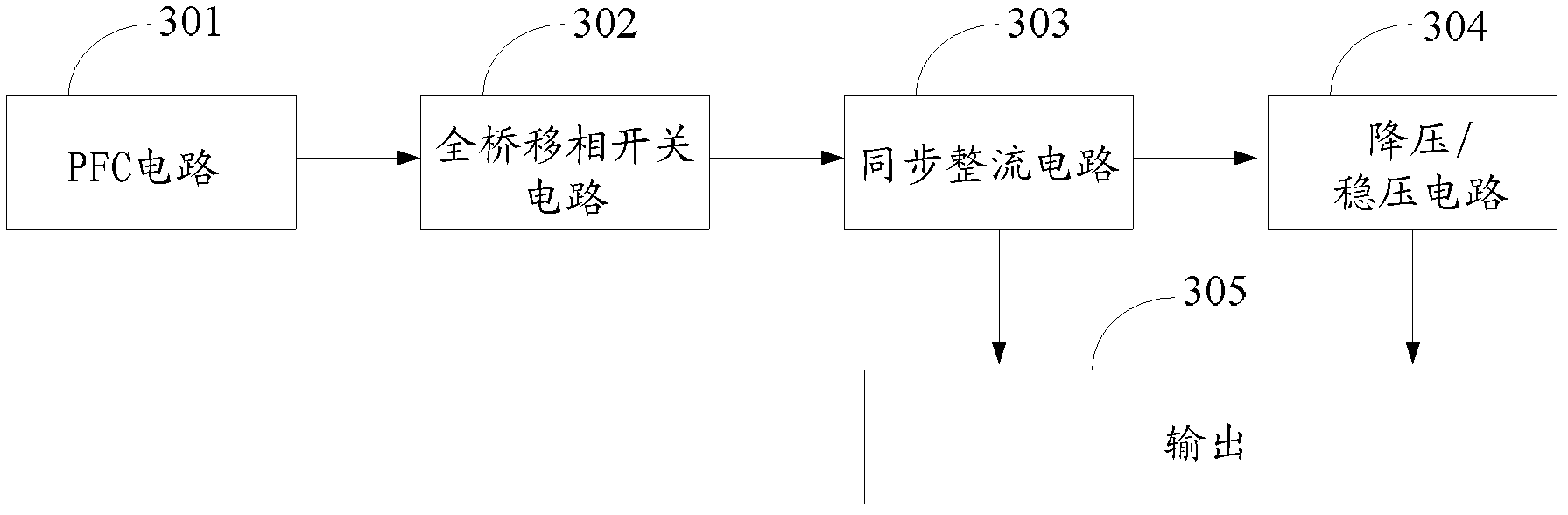

Windowing controller based on large screen liquid crystal splicing display

The invention relates to the large screen liquid crystal splicing display field, in particular relates to a windowing controller based on large screen liquid crystal splicing display. In the windowing controller, one or more image windows can be provided on a large screen; image overlapping is realized on the basis of a liquid crystal splicing function, i.e. one signal can be overlapped on other signals and displayed in the whole screen or through a single screen, and adjacent screens can be spliced randomly; and meanwhile, functions such as dragging the window randomly to change the size, screen-crossing roaming, window switching signal and the like can be achieved through control software, and images with super high resolution can be supported.

Owner:SHENZHEN SKYWORTH QUNXIN SECURITY TECH

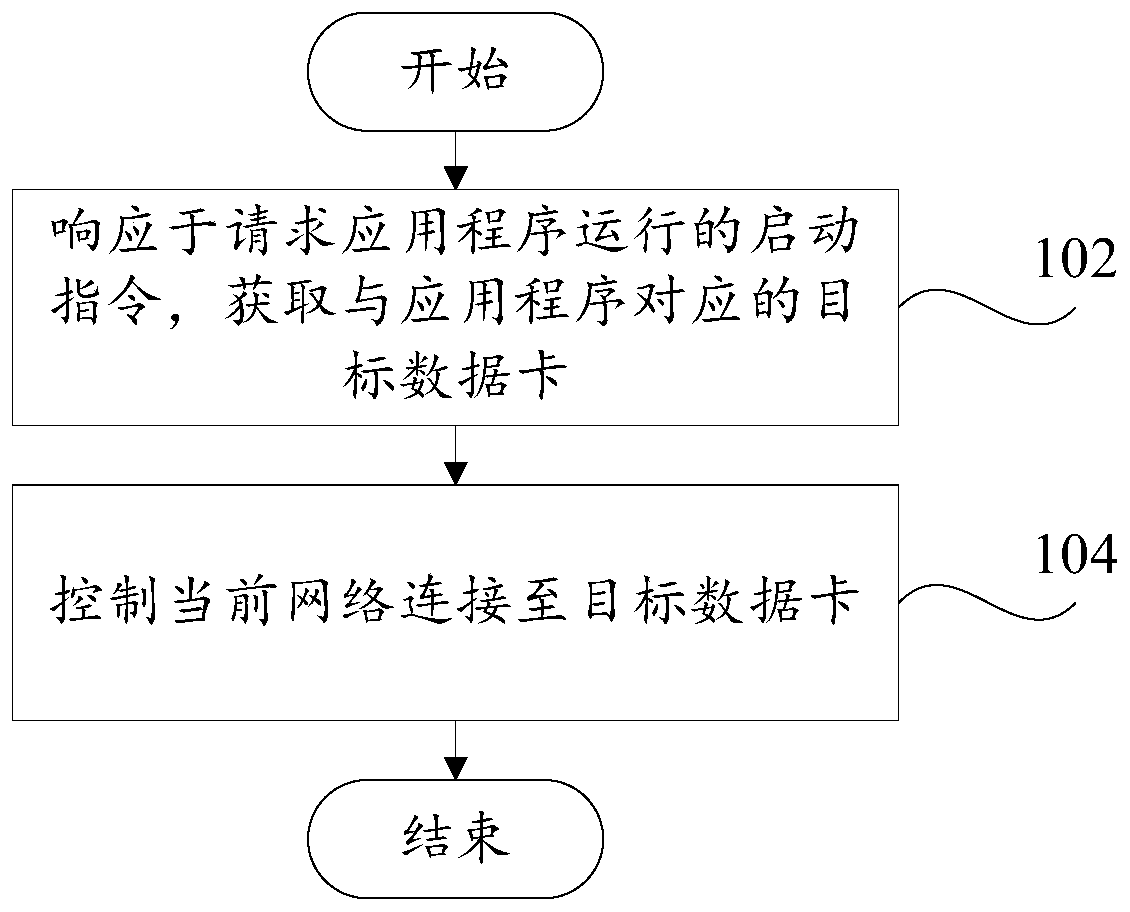

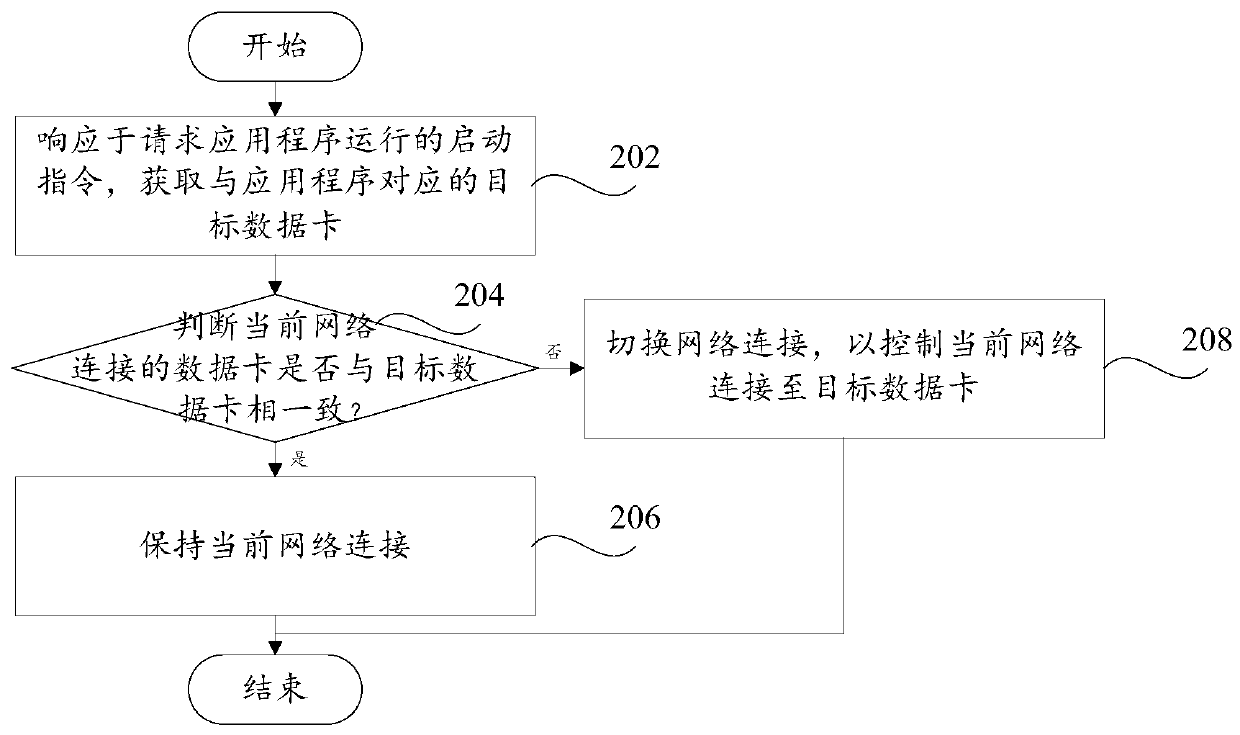

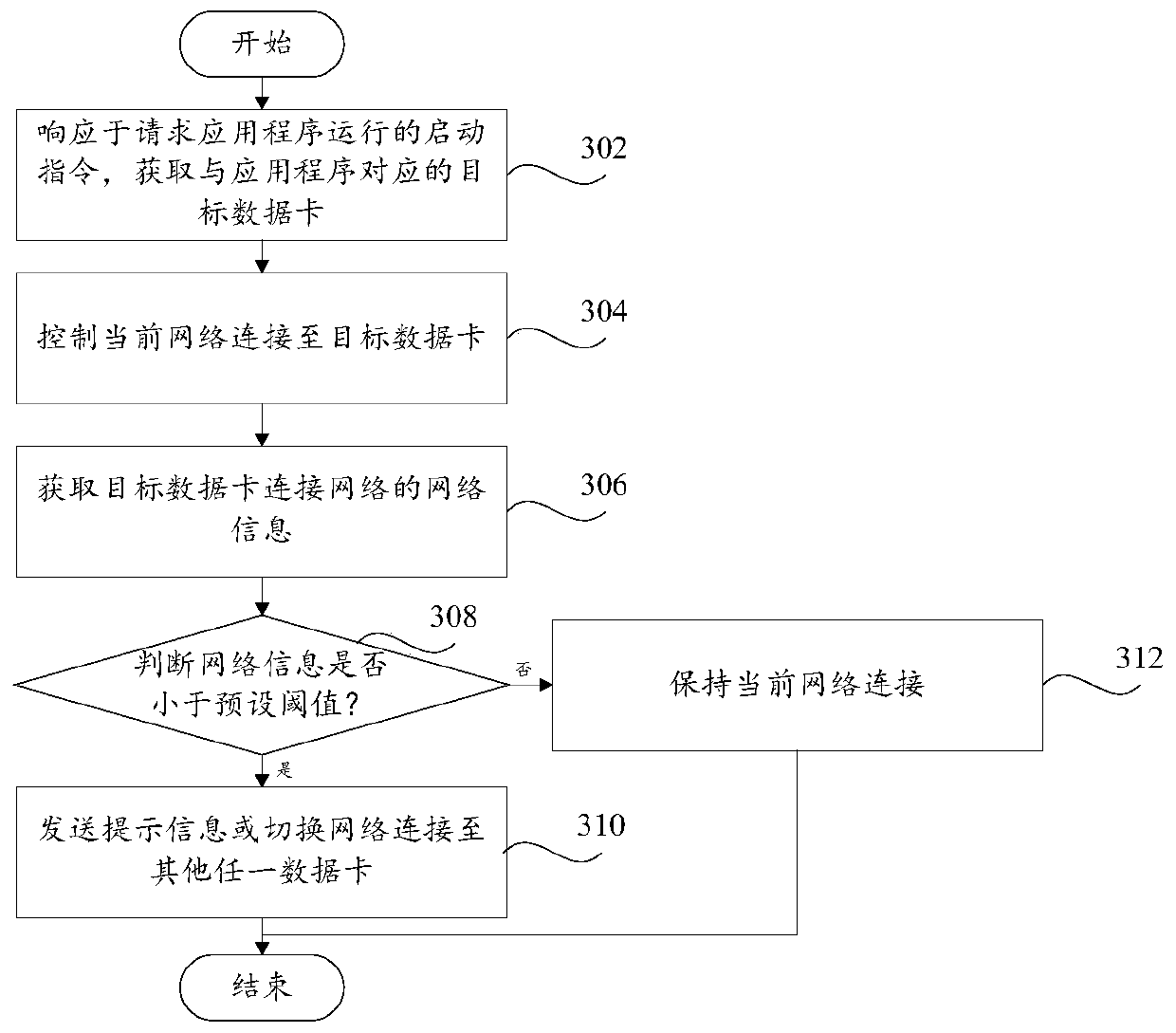

Network switching method, terminal and computer readable storage medium

InactiveCN110072228ANo pauseSave on data traffic chargesNetwork data managementTraffic volumeTraffic capacity

The invention relates to a network switching method, a terminal and a computer readable storage medium. The network switching method is suitable for a terminal with at least two data cards. The methodcomprises the following steps: obtaining a target data card corresponding to an application program in response to a starting instruction for requesting the operation of the application program; andcontrolling the current network to be connected to the target data card so as to supply the flow-free service of the target data card to the program. According to the network switching method providedby the invention, when the user uses the application program, the terminal can automatically carry out network switching. On one hand, manual operation of the user is not needed, the switching efficiency is improved, and the user does not generate a pause feeling, and on the other hand, it is guaranteed that the application program can use the traffic-free service of the target data card, the data traffic of the user is effectively and reasonably used, meanwhile, certain data traffic cost can be saved for the user, and therefore the use experience of the user is improved.

Owner:NUBIA TECHNOLOGY CO LTD

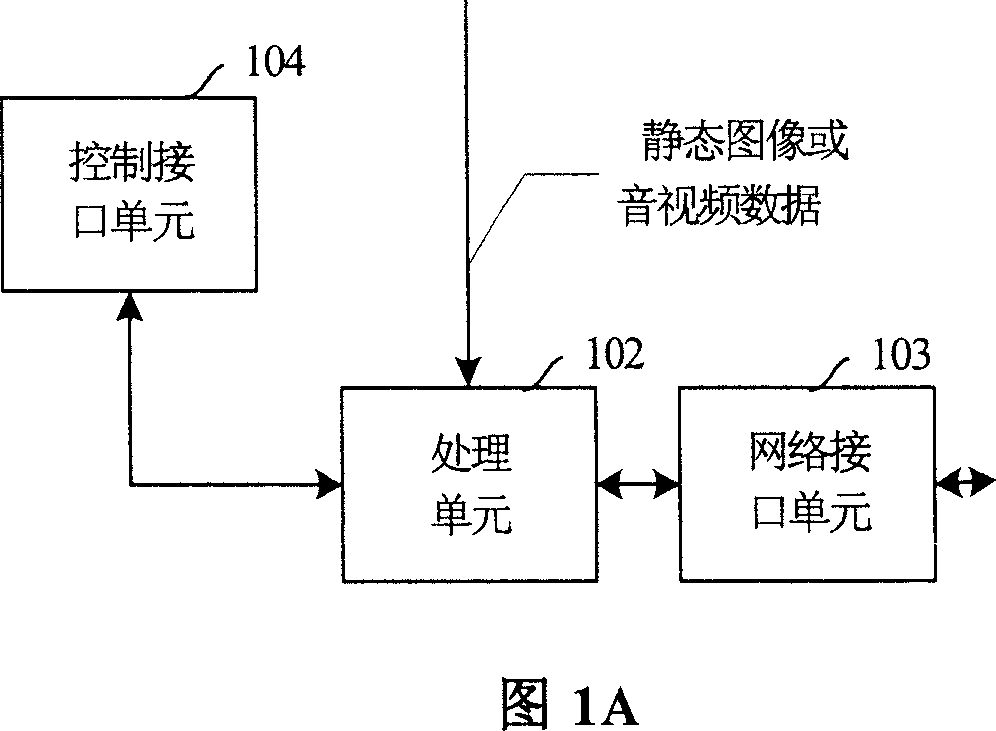

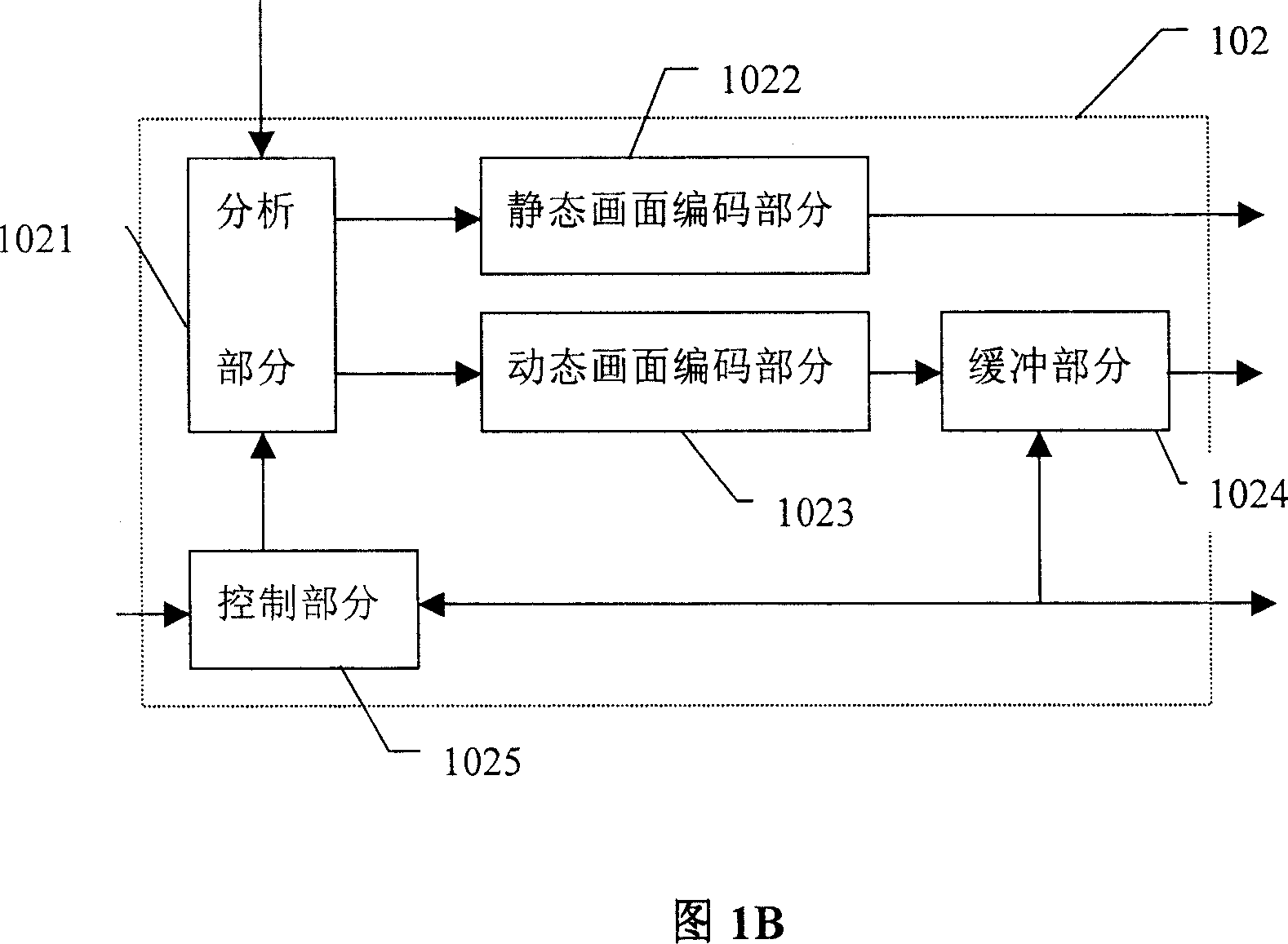

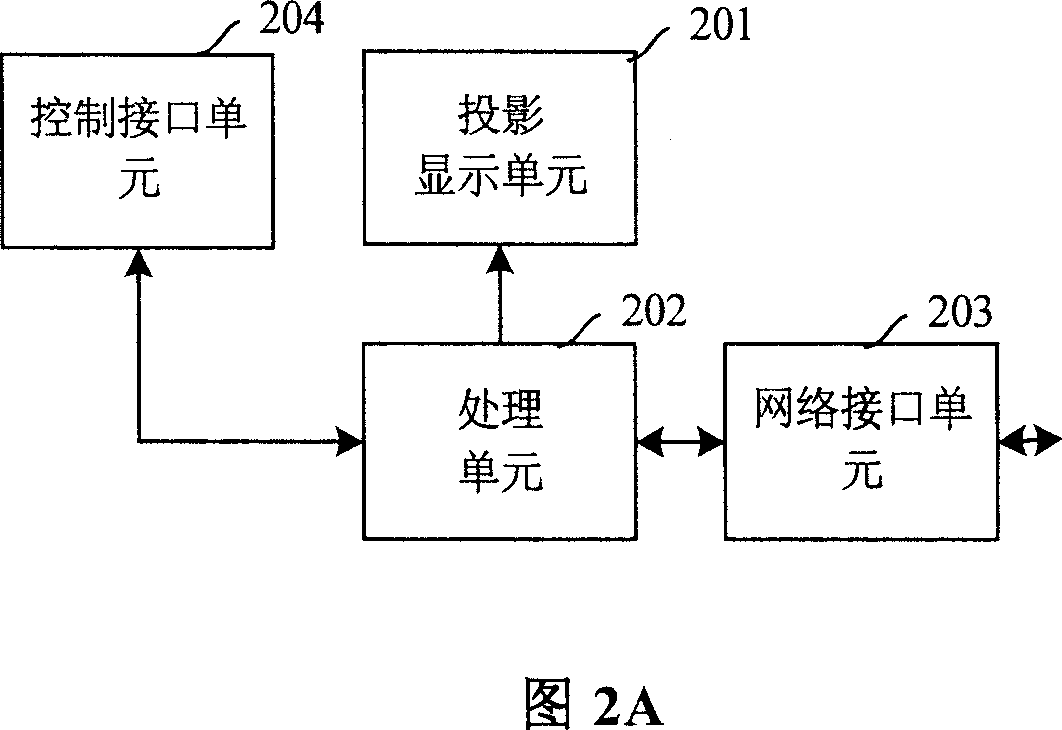

Method and system for projecting dynamic static hybrid picture

InactiveCN1949872AMeet dynamic requirementsNo pauseProjectorsData switching by path configurationComputer graphics (images)Projection system

The inventin discloses a protecting method in a projecting system comprising projection information transmitting end and projecting end, able to achieve static image and dynamic video display effect on the condition of limited transmission bandwidth. And it comprises the steps of: at the projection information transmitting end, analyzing the projection information to generate static picture information and dynamic picture information; transmitting them as data to the projecting end; at the projecting end, extracting them from the received data; and displaying them in the respective windows. And the invention can assure projected picture performance and effectively reduce CPU processing ability requirements.

Owner:LENOVO (BEIJING) LTD

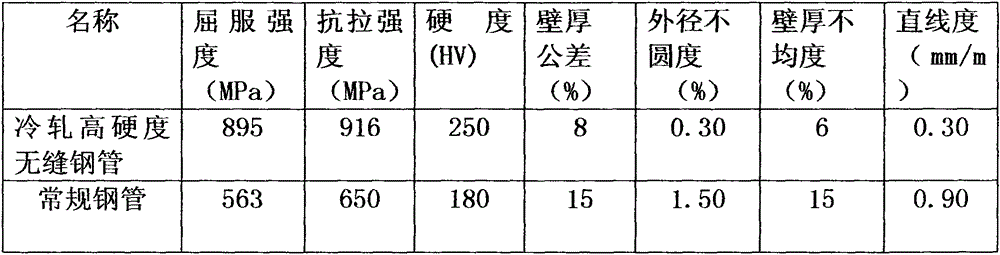

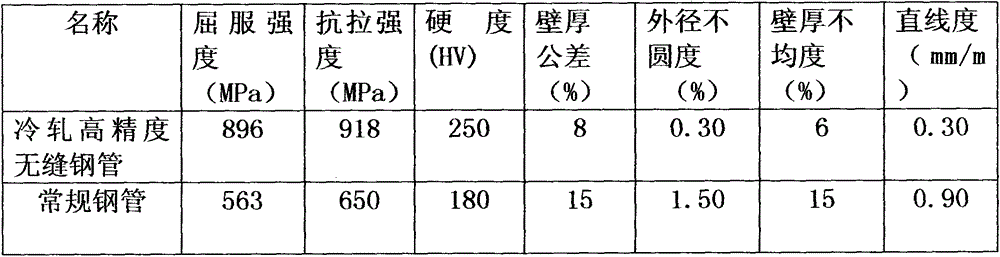

Cold-rolled high-hardness seamless steel pipe manufacturing method

InactiveCN104551667AExtended service lifeImprove wear resistanceOther manufacturing equipments/toolsZinc phosphateAcid washing

The invention relates to a cold-rolled high-hardness seamless steel pipe manufacturing method. The manufacturing method includes the steps of heating a pipe billet in a circular furnace; punching the heated pipe billet by a puncher; annealing the pipe billet; spraying borax to descale; placing the annealed pipe billet in a pipe mill for hot rolling; performing pipe separation by separating a hot-rolled pipe from a mandrel; performing stress relief annealing, namely, heating the hot-rolled pipe in the heating furnace to obtain the annealed pipe billet; performing acid washing treatment to remove rust scale on the surface; phosphating to enable the surface to form a zinc phosphate chemical film; performing saponification treatment to form a metallic soap lubricating film and the like; performing cold rolling on the obtained pipe billet to be subjected to cold rolling to obtain a cold-rolled pipe; performing heat treatment to reduce residual stress; performing pre-straightening treatment to reduce residual stress; performing induction furnace quenching treatment; tempering in a box-type furnace; honing; performing hot straightening to obtain a high-precision steel pipe. The steel pipe obtained by the method is high in hardness and precise in size.

Owner:WUXI JIANGNAN HIGH PRECISION COLD DRAWN PIPE

Intelligent television control method based on local area network

ActiveCN102523508AImprove experience and satisfactionEasy to implementData switching by path configurationSelective content distributionLocal area networkInput device

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Production method of cold-drawn high-precision seamless steel tube

InactiveCN104551669AImprove performanceImprove low temperature impact toughnessOther manufacturing equipments/toolsMetal rolling arrangementsZinc phosphateStress relieving

The invention relates to a production method of a cold-drawn high-precision seamless steel tube. The production method includes heating a tube blank in a circular furnace; punching a heat tube by the aid of a puncher; subjecting the tube blank to annealing; spraying the tube blank with sodium borate to remove oxide skin; leading the annealed tube blank into a tube mill for hot milling; tensioning the milled tube after tandem milling by a tensioning machine for sizing; performing stress relieving, to be specific, heating the milled tube in a heating furnace to obtain an annealed tube blank; performing acid dipping on the tube blank to remove scale of the surface; subjecting the tube blank to parkerizing, and accordingly a chemical coating of zinc phosphate is generated on the surface of the tube blank; performing saponification to form lubricating coatings such as metallic soap; subjecting the tube blank to be cold drawn to cold drawing, and the cold-drawn tube is achieved; heating the cold-drawn tube to decrease residual stress; pre-straightening the cold-drawn tube to further decrease the residual stress; quenching the cold-drawn tube in an induction furnace; tempering the cold-drawn tube in a box-type furnace; honing the cold-drawn tube; subjecting the cold-drawn tube to heat straightening. In this way, the high-precision steel tube is obtained and high in yield strength and precise in size.

Owner:WUXI JIANGNAN HIGH PRECISION COLD DRAWN PIPE

Driving gear for stepless speed change device for motor cycle

InactiveCN1418794AHigh transmission efficiencyRide comfortChain/belt transmissionEngineeringDrive wheel

The stepless speed change driving wheel for motorcycle includes engine main shaft, on the engine main shaft a fixed wheel, a moving wheel and a slop board are set, in the moving wheel a centrifugal roller conduit and centrifugal roller are set, the moving wheel can be axially moved mo the sliding bush of engine main shaft, the fixed wheel and engine main shaft can be synchronsouly rotated, between the moving wheel and engine main shaft a driving mechanism is set, and between the moving wheel and slop board an elastic component, said elastric component adopts spreader spring perfectly, so thatthe rotating speed and torque of driven wheel can obtain more reasonable distribution. As compared with existent motorcycle it can save fuel by about 20%.

Owner:程吾

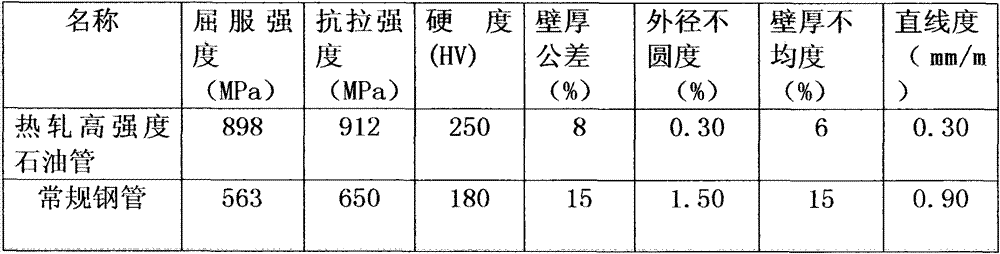

Hot-rolled high-strength oil pipe manufacturing method

The invention relates to a hot-rolled high-strength oil pipe manufacturing method, which comprises the following steps: heating: heating a pipe blank in an annular furnace; punching: punching holes in the heated pipe blank through a puncher; annealing: annealing the pipe blank; spraying borax; removing oxide skin; hot-rolling: feeding the annealed pipe into a pipe mill for hot-rolling; separating the pipe: separating the rolled pipe from a core rod; removing stress and annealing: feeding the rolled pipe into the heating furnace for heating, so as to obtain the annealed pipe blank; pickling: removing rust scale on the surface; phosphating: forming a zinc phosphate chemically-generated covering membrane on the surface; saponifying: forming metal soap and lubrication covering membranes: cold-drawing: cold-drawing the pipe blank to be cold-drawn, so as to obtain a cold-drawn pipe; performing heat treatment: reducing residual stress; honing; and performing hot straightening treatment, so as to obtain a cold-drawn precise inner-hole honed pipe, wherein a numerically-controlled honing machine is adopted in honing. The cold-drawn precise inner hole-honed pipe obtained through the method is good in comprehensive performance, good in low-temperature impact toughness, precise in dimension, smooth in surface, and excellent oil storage property.

Owner:WUXI OULONG SPECIAL STEEL PIPE

Manufacturing method for high-precision cold-drawn inner-hole honed pipe

InactiveCN105880934AImprove performanceImprove low temperature impact toughnessZinc phosphateStress relief

The invention relates to a manufacturing method for a high-precision cold-drawn inner-hole honed pipe. The manufacturing method includes the following steps of heating, i.e., heating a tube blank in a circular furnace; perforation, i.e., perforating the hot tube blank through a perforating machine; annealing, i.e., annealing the tube blank; cold rolling, i.e., leading the annealed tube blank into a tube rolling mill for cold rolling to obtain a rolled tube; stress relief annealing, i.e., leading the rolled tube into a heating furnace for heating to obtain an annealed tube blank; acid pickling, i.e., carrying out acid pickling on the annealed tube blank to remove rust scale on the surface; phosphating, i.e., forming a chemically-generated zinc phosphate covering film on the surface of the tube blank; saponification, i.e., forming metallic soap and the like on the covering film to lubricate the covering film; cold drawing, i.e., carrying out cold drawing on the tube blank to be cold-drawn to obtain a cold-drawn tube; heat treatment, i.e., reducing residual stress of the cold-drawn tube through the quenching-tempering heat treatment process; honing, i.e., carrying out honing with a numerically controlled honing machine; and hot straightening treatment, i.e., carrying out hot straightening treatment to obtain a high-precision cold-drawn steel tube. The precision inner-hole honed tube which is high in yield strength, precise in dimension and smooth in surface is obtained by means of the method.

Owner:WUXI SHENLU HYDRAULIC PARTS

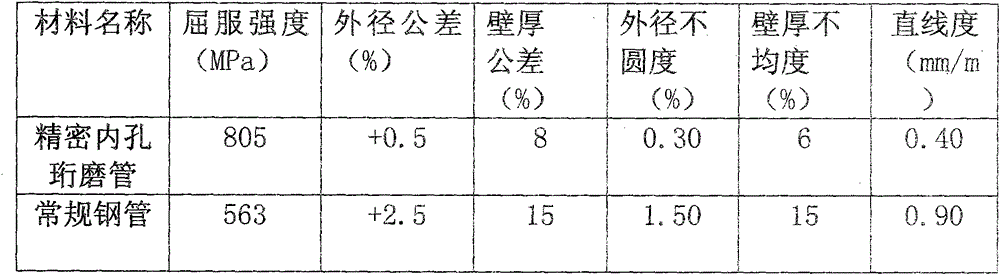

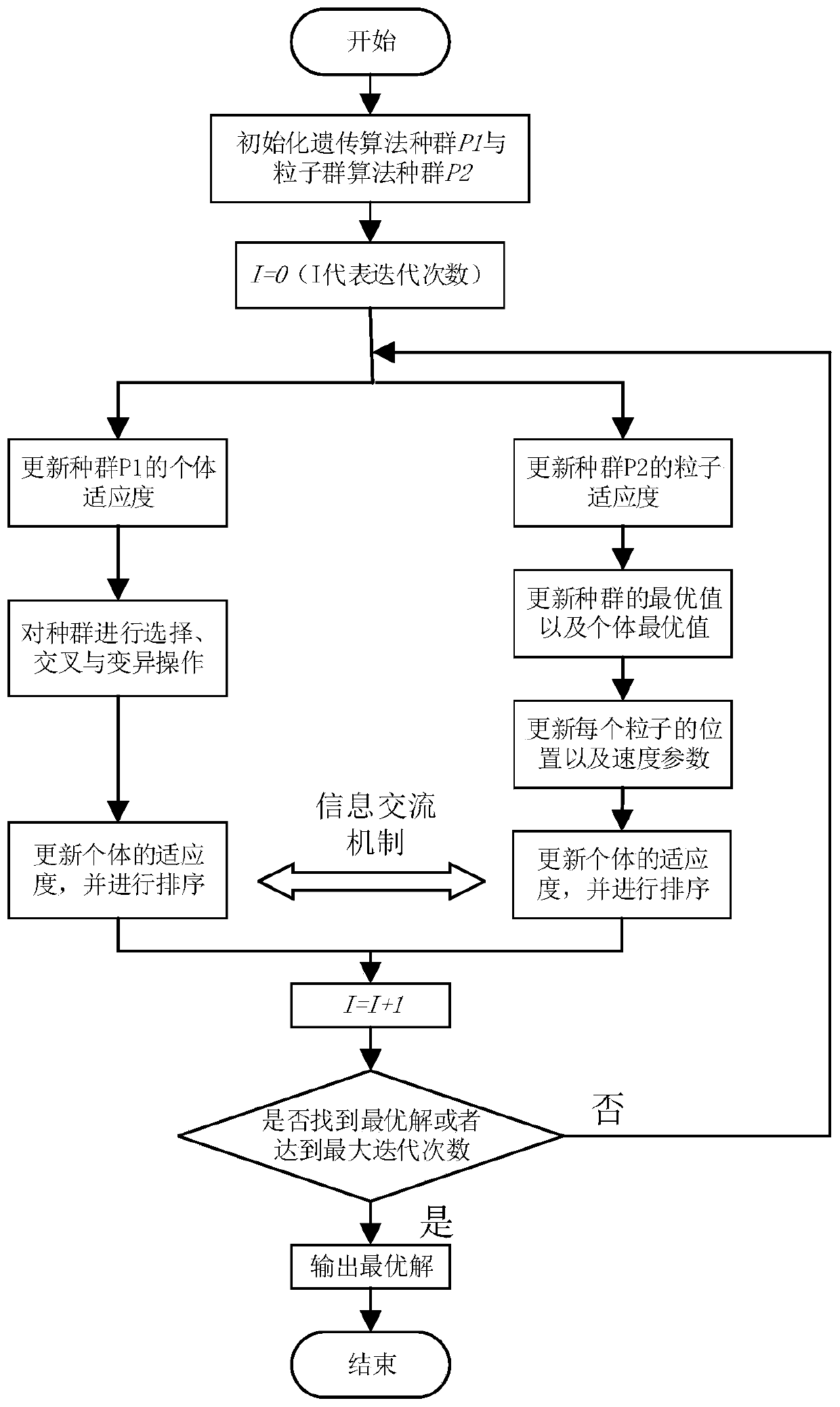

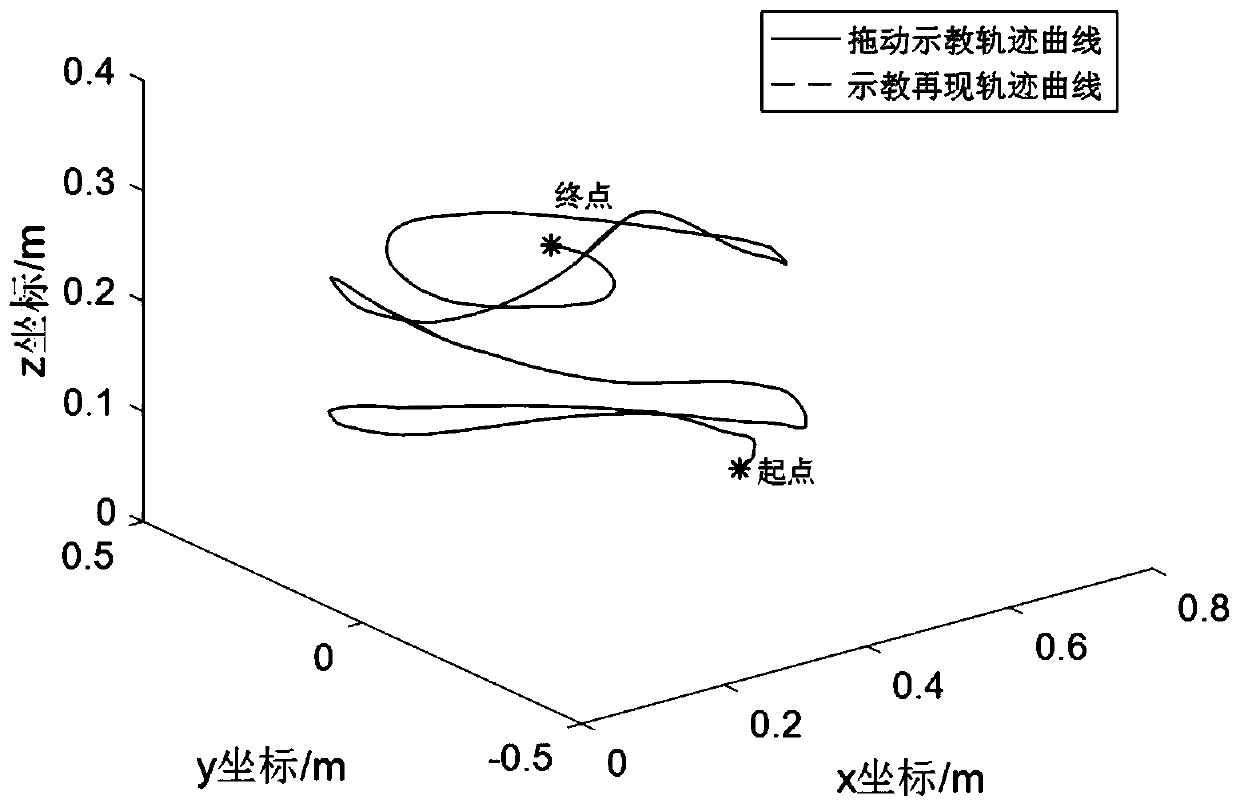

Teaching regenerated trajectory optimizing method based on GA-PSO

ActiveCN109895103AEfficient removalEliminate high frequency jitterProgramme-controlled manipulatorSimulationTrajectory optimization

The invention relates to a teaching regenerated trajectory optimizing method based on GA-PSO. The method comprises the steps that 1), when direct teaching is conducted, sampling is conducted on the trajectory of a robot according to a set sampling period, and the angular value of each joint of the robot is recorded in real time; 2), a GA-PSO algorithm is adopted as an optimization algorithm to obtain the optimal trajectory point time interval sequence; 3), spline interpolation is conducted three times according to the optimized time interval sequence and corresponding sampling trajectory pointto obtain an optimized teaching trajectory; 4), when teaching trajectory regeneration is conducted, the optimized teaching trajectory is discretized according to the controlling period to be transmitted to the robot controller, and the whole teaching trajectory is completely regenerated. Compared with the prior art, the method has the advantages of redundant trajectory information removing, stable operation, halt and abrupt acceleration nonexistence and the like.

Owner:TONGJI UNIV

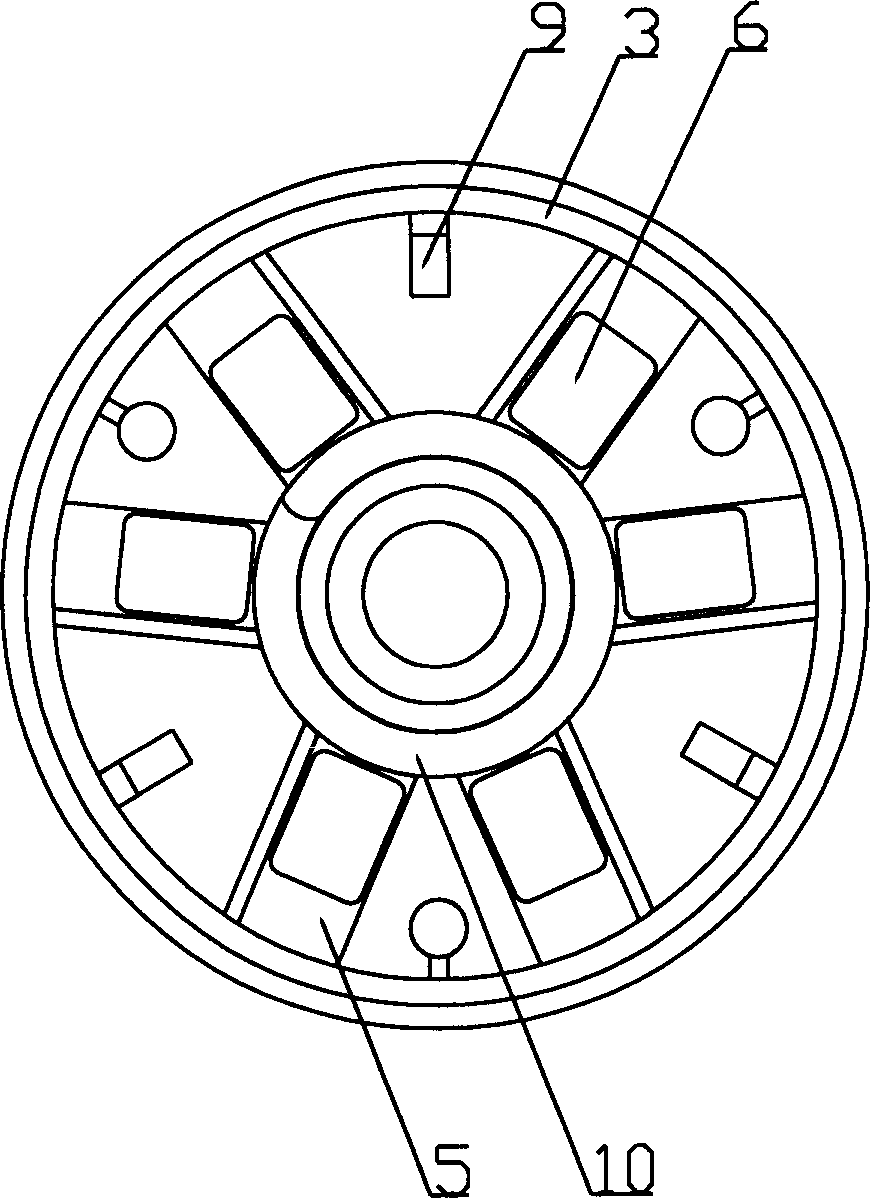

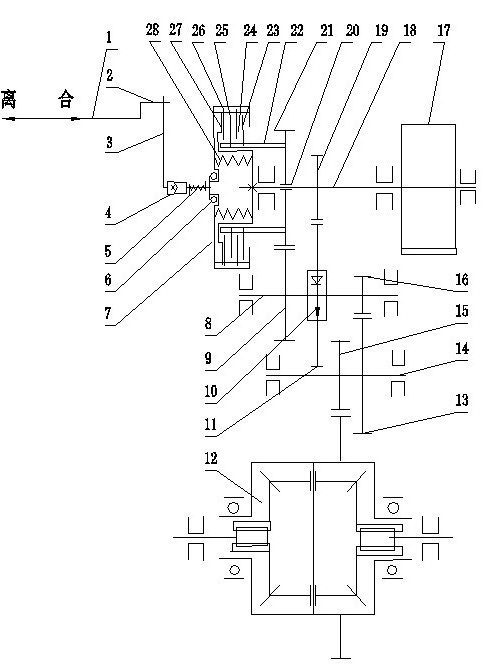

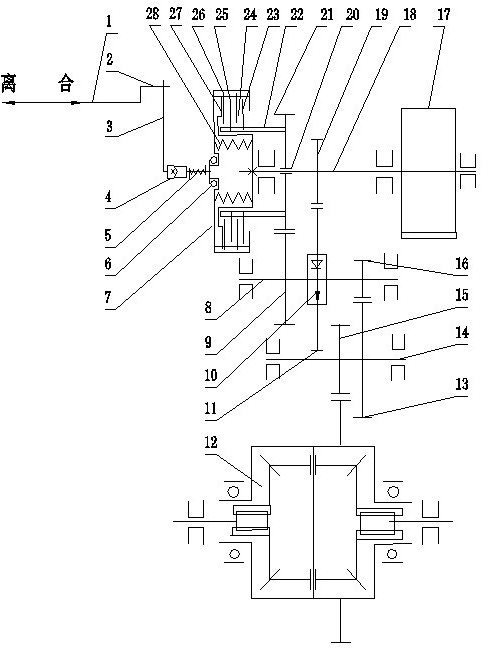

Two-gear speed-changing driving device of electric vehicle

ActiveCN102642595AIngenious structural designEasy to manufacture and installWheel based transmissionEngineeringElectric vehicle

The invention discloses a two-gear speed-changing driving device of an electric vehicle, comprising a motor (17), a power transmission mechanism and a differential mechanism (12), and further comprising a friction clutch, wherein the motor (17) is respectively connected with the friction clutch and the differential mechanism (12) through the power transmission mechanism; and the power transmission mechanism is provided with an isolator (10). The two-gear speed-changing driving device of the electric vehicle has the advantages of ingenious structure design and convenience for manufacturing andinstallation; with the adoption of a two-gear speed-changing system formed by the friction clutch and the power transmission mechanism, gear shifting is flexible and reliable, the power conversion istable, no impacts or pauses exist, the reliability is high and the safety performance is improved; and meanwhile, the requirements of climbing and driving with a load are met.

Owner:CHONGQING ZONGSHEN INTEGRATED RES TECH CO LTD

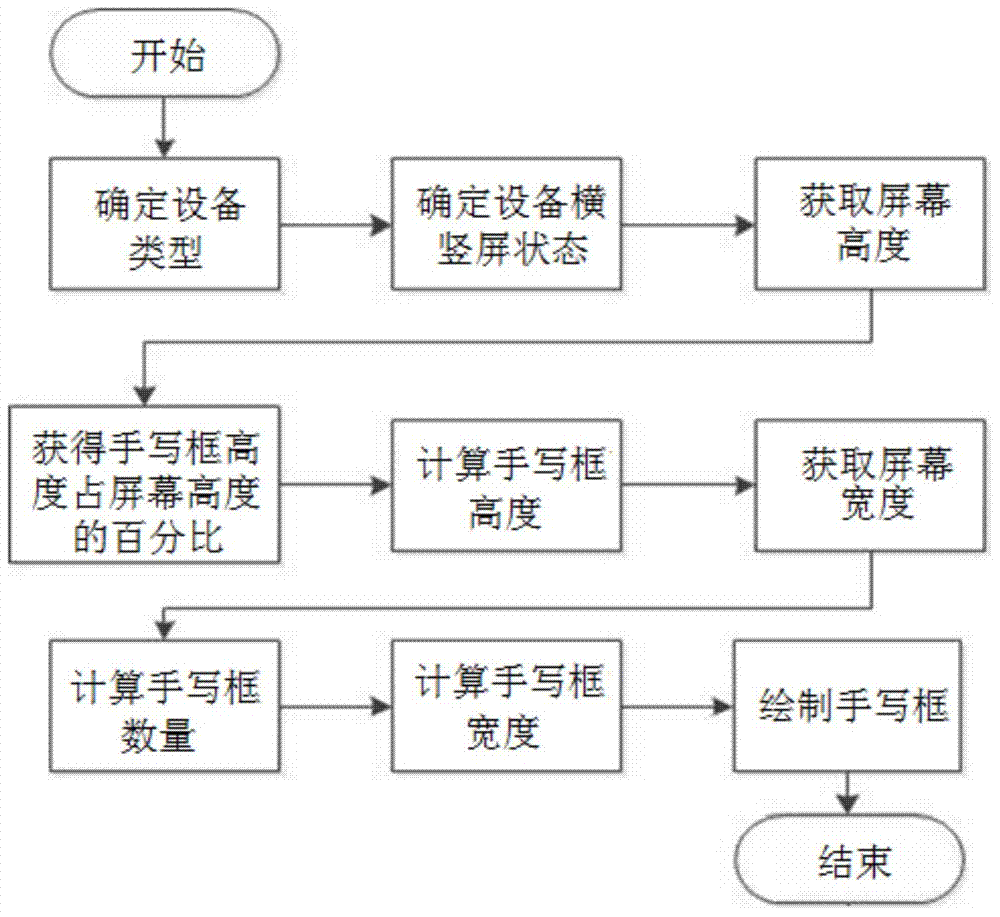

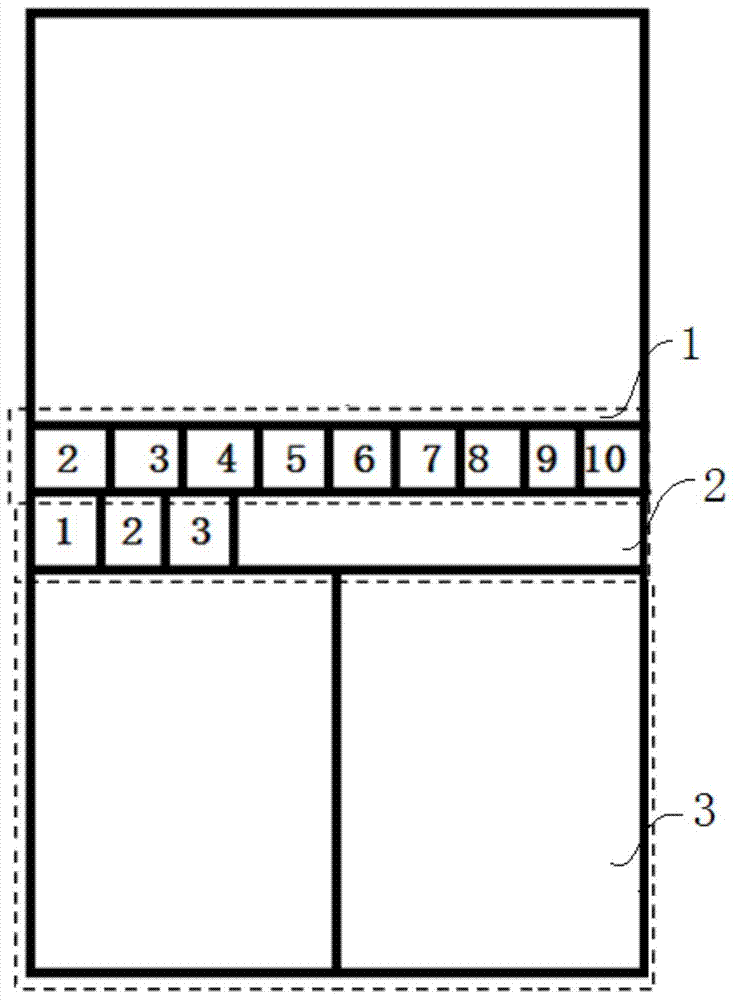

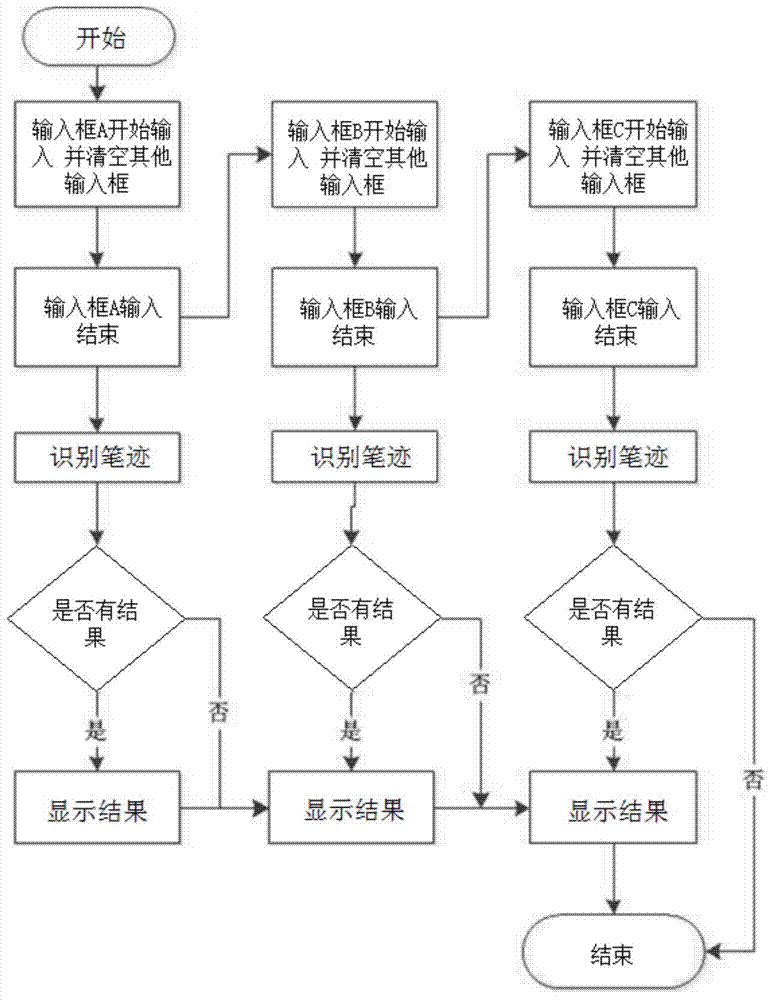

Handwriting input method for inputting characters into multiple handwriting frames

InactiveCN103616974AReduced waiting time for text recognitionNo pauseInput/output processes for data processingHandwritingText recognition

The invention discloses a handwriting input method for inputting characters into multiple handwriting frames, and belongs to the technical field of input methods. The handwriting input method comprises the steps that firstly, the heights of the handwriting frames are determined; secondly, the number of the handwriting frames is determined; thirdly, the characters are input into the Nth handwriting input frame, and whether disengaging time of a finger or a touch pen exceeds preset time is judged, or whether the finger or the touch pen starts to input handwriting in the N+1th handwriting input frame is judged; if either of two conditions is met or both of the two conditions are met, a recognition thread is started for the Nth handwriting input frame, and the characters in the handwriting input frame are recognized; after the recognition is finished, a recognition result is displayed if obtained, and no recognition result is displayed if no recognition result is obtained; if neither of the two conditions is met, the recognition thread is not started; fourthly, the processes in the third step are executed again on the N+1th handwriting input frame until the input process is over. The handwriting input method for inputting the characters into the multiple handwriting frames does not need to wait character recognition, and improves the handwriting input speed exponentially.

Owner:NANJING FUJITSU NANDA SOFTWARE TECH

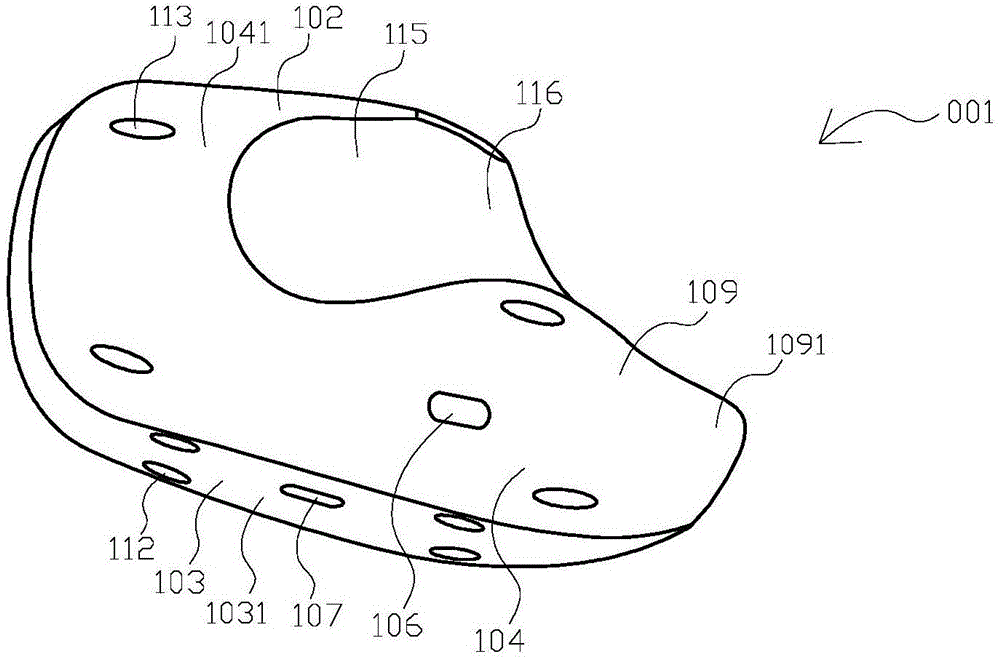

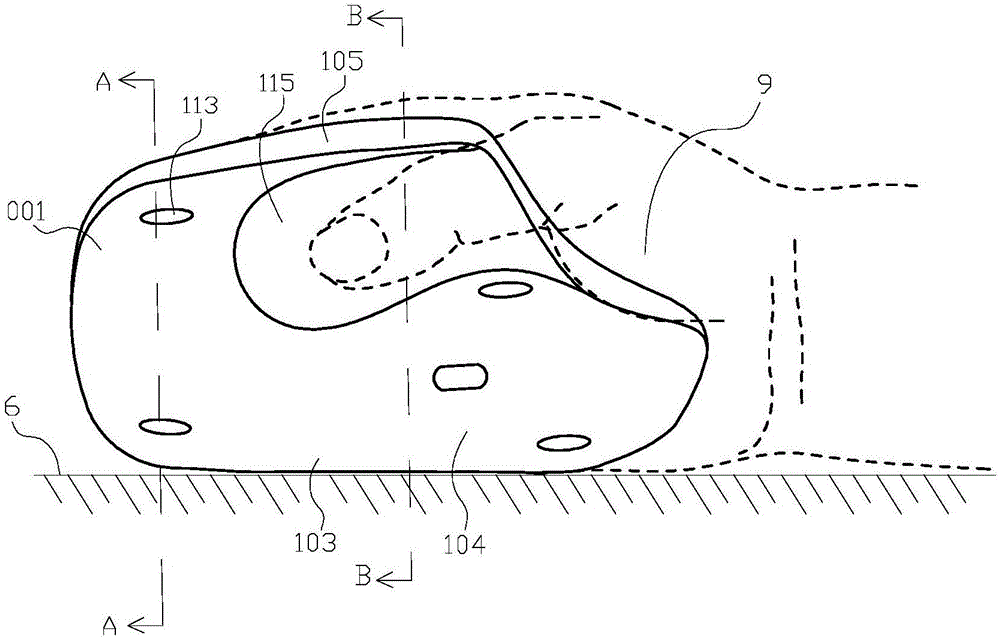

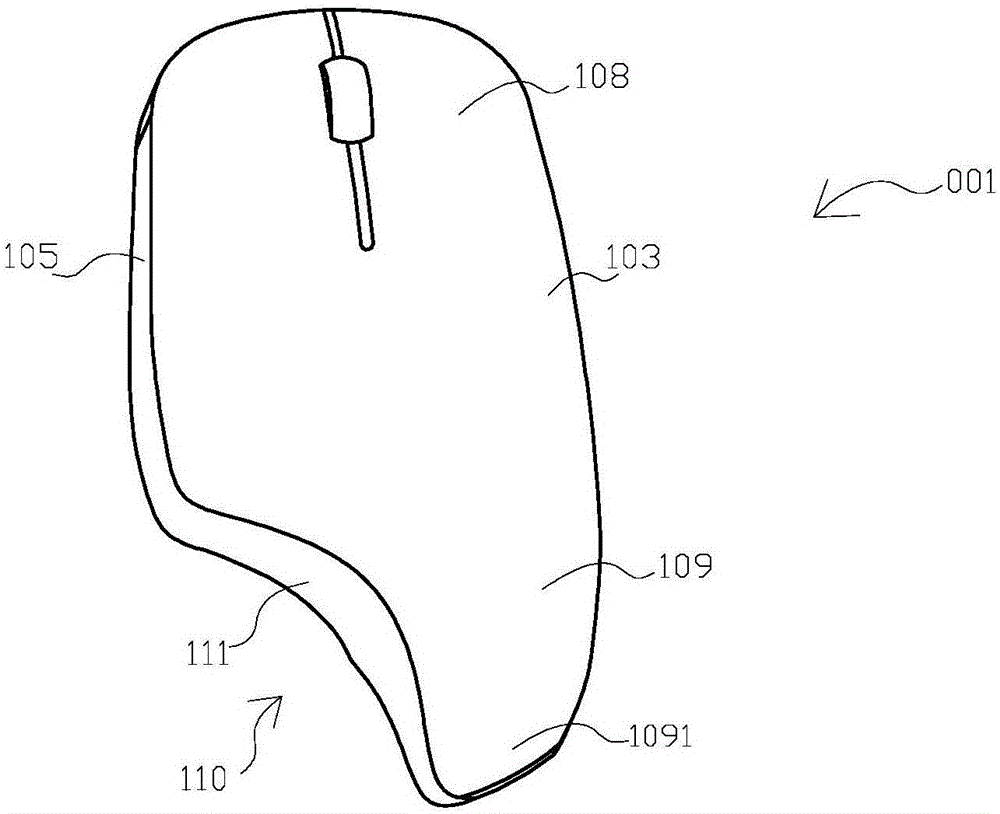

Mouse

ActiveCN106055132ANo pauseAvoid erraticInput/output processes for data processingAdjustment ActionComputer science

Provided is a mouse. According to the mouse, cursor movement can be sensed when the bottom of a shell is arranged on a working surface for slipping, and cursor movement can also be sensed when the outer side of the shell is arranged on the working surface for slipping. A notch is formed in the inner side of the latter half portion of the shell and used for containing the thenar muscle part, swelling downwards due to the fact that the thumb holds the bottom of the shell, of the palm when the state of cursor movement is sensed when the outer side of the shell is arranged on the working surface for slipping; or from the position in front of a point which is 1 / 3 of the longitudinal length of the shell away from the rear end to the front end to the tail end of the rear end of the shell, the inner side of the shell is deflected to the outer side of the shell in a rectilinearly inclined or concave-arc inclined or concave-arc-containing inclined mode, therefore, the tail end of the rear end of the shell is deflected on the side, passing through the thickness center line of a rolling wheel and perpendicular to the axial longitudinal section of the rolling wheel, of the outer side of the shell. By means of the advantages of the mouse, the wrist and the palm can change operation postures at two operation states conveniently, adverse adjustment action is avoided, operation on a key and the rolling wheel does not need to be stopped, and cursor pause and cursor drift cannot occur.

Owner:蒋新东

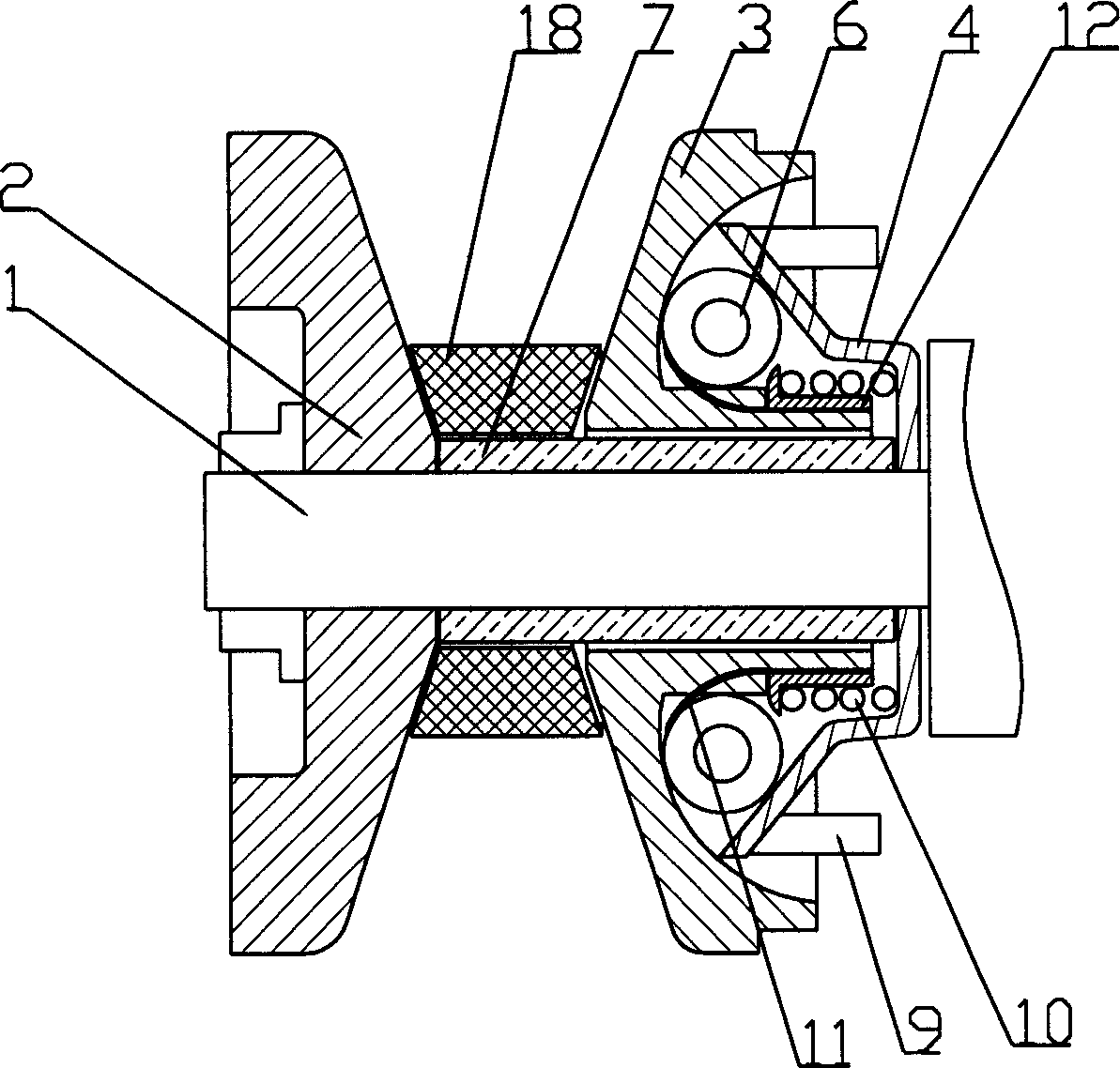

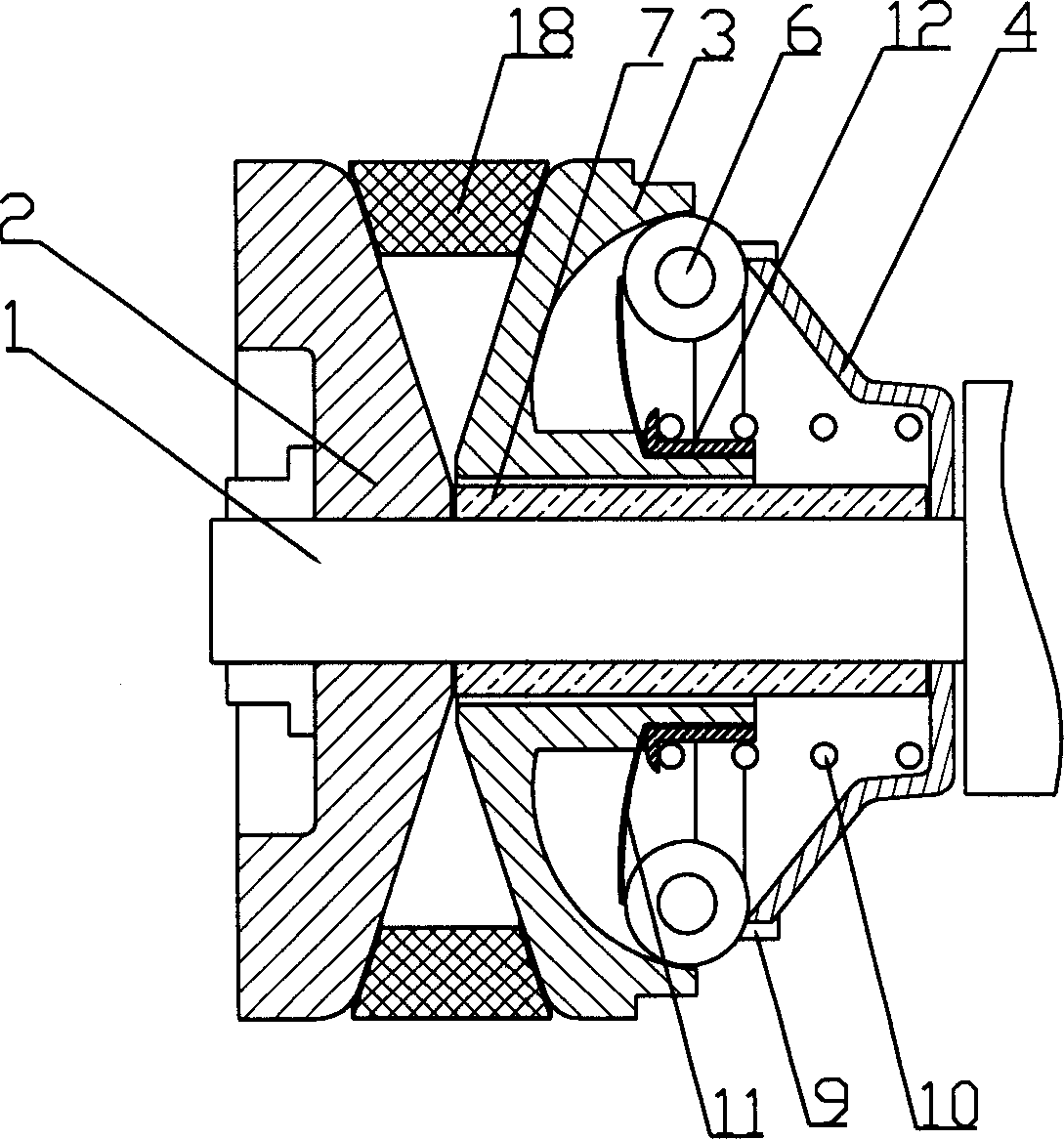

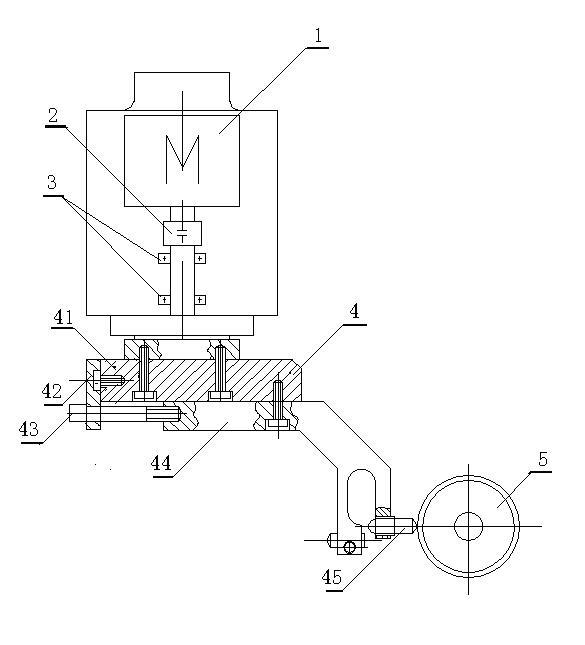

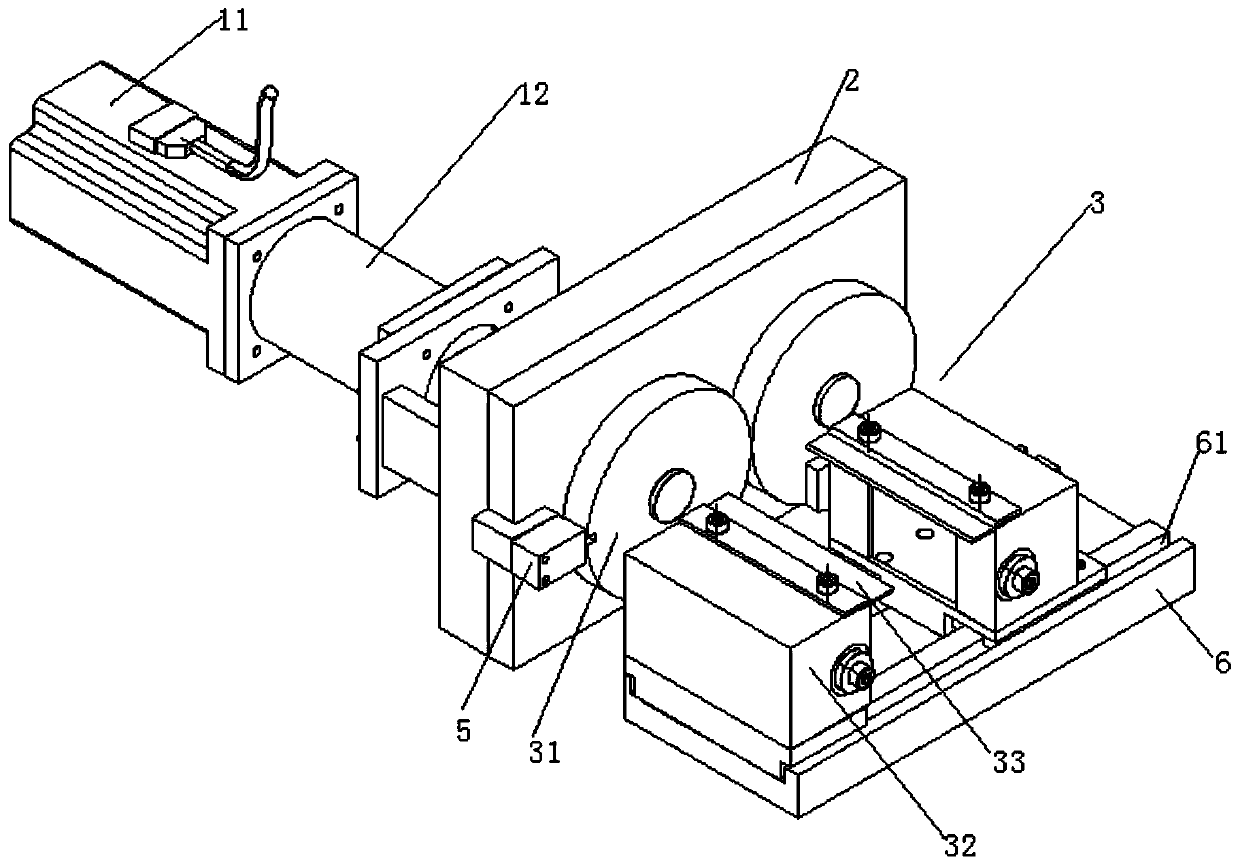

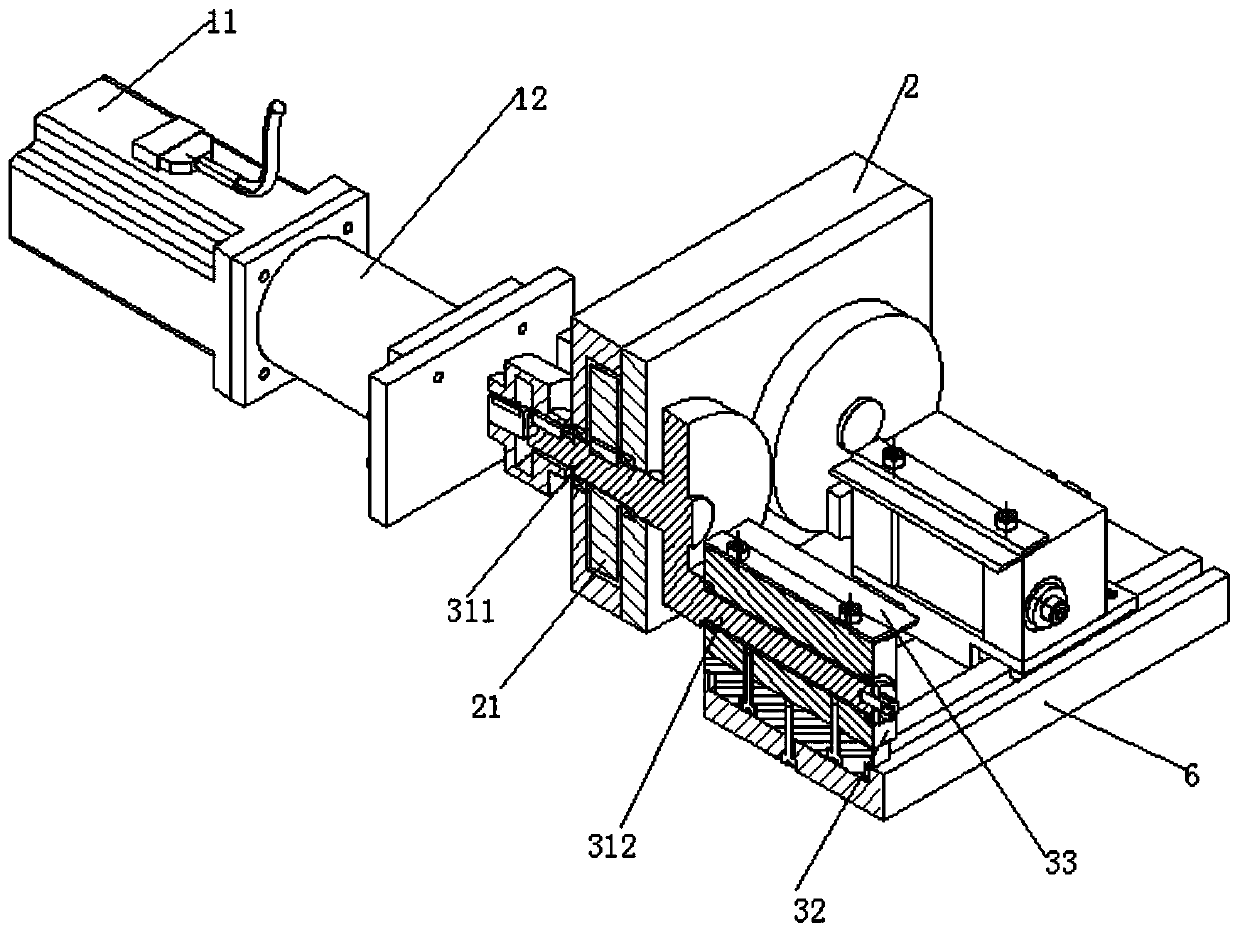

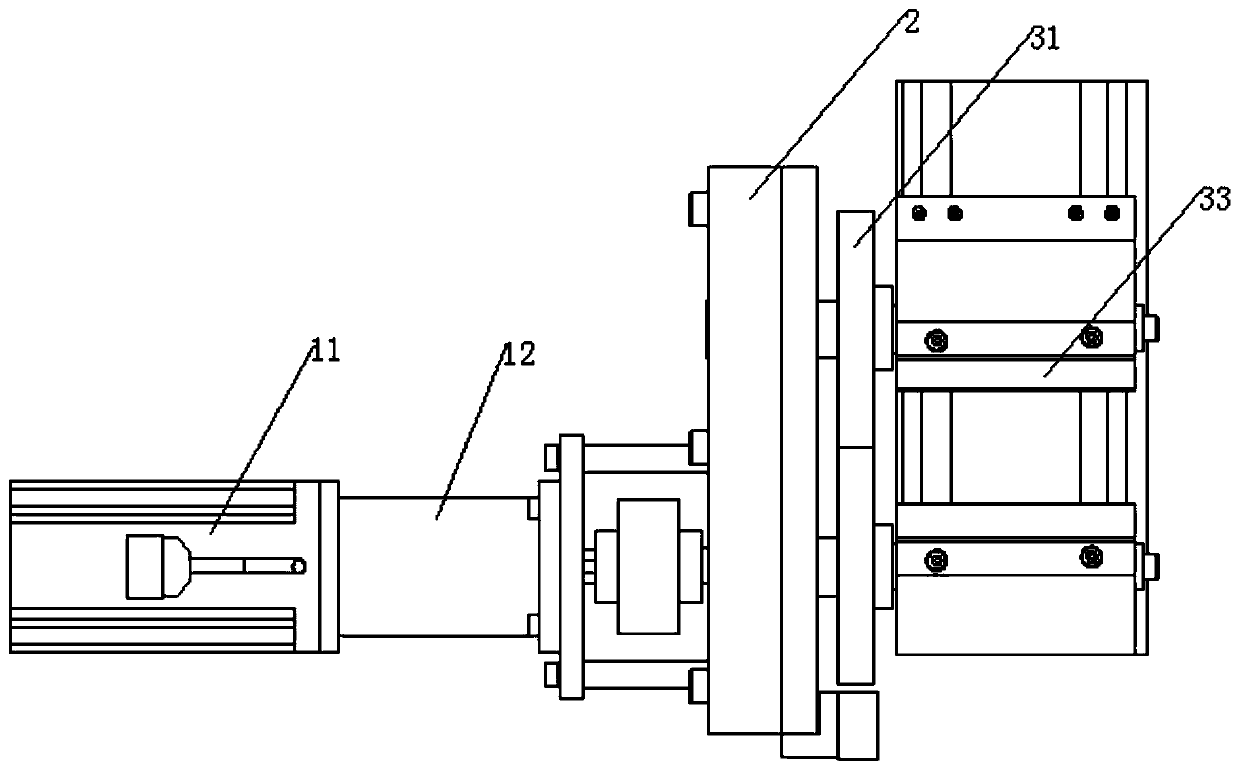

Arc dresser for dressing grinding wheels of groove grinders for deep-groove balls

InactiveCN102554786AEasy to adjustGood profile of grinding wheelAbrasive surface conditioning devicesSingle phaseEngineering

The invention discloses an arc dresser for dressing grinding wheels of groove grinders for deep-groove balls. The particular implementation scheme includes that a driving shaft of a single-phase speed regulating motor (1) is connected with a bearing (3) by a coupler (2), an eccentric gear (4) is connected to the lower end of the bearing (3) and provided with an eccentric seat (41), the left side of the eccentric seat (41) is connected with a fixing pat (42), the lower portion of the fixing part (42) is connected with an adjusting part (43), the right end of the adjusting part (43) is connected with an eccentric part (44), the eccentric part (44) is connected with a grinding head (45) by a transmission oscillating plate (46), the grinding head (45) contacts with a grinding wheel (5), and the single-phase speed regulating motor (1) drives the transmission oscillating plate (46) to rotate in a reciprocating manner by the aid of shaft connection. The arc dresser has the advantages that adjustment is convenient and speedy when the arc dresser is used for trimming the grinding wheel, retardation and stop are avoided during rotation, forming profile of the grinding wheel is excellent, and roughness is low. In addition, the arc dresser is favorable for guaranteeing the quality of products, production efficiency is greatly improved, and production cost is lowered.

Owner:JIANGSU DIBANG SANXING BEARING

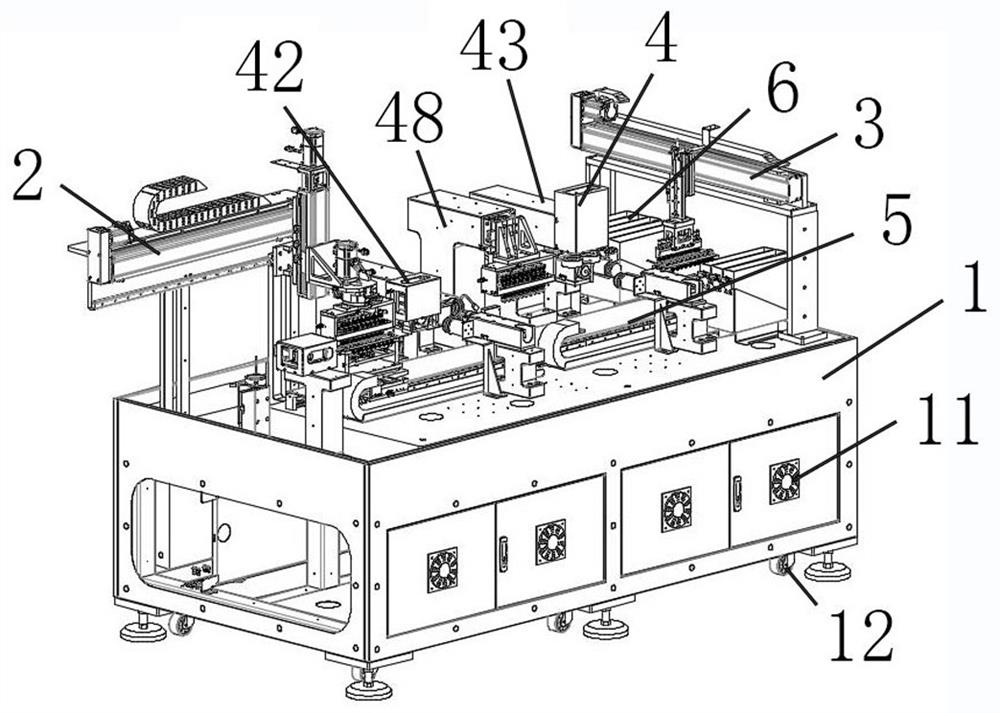

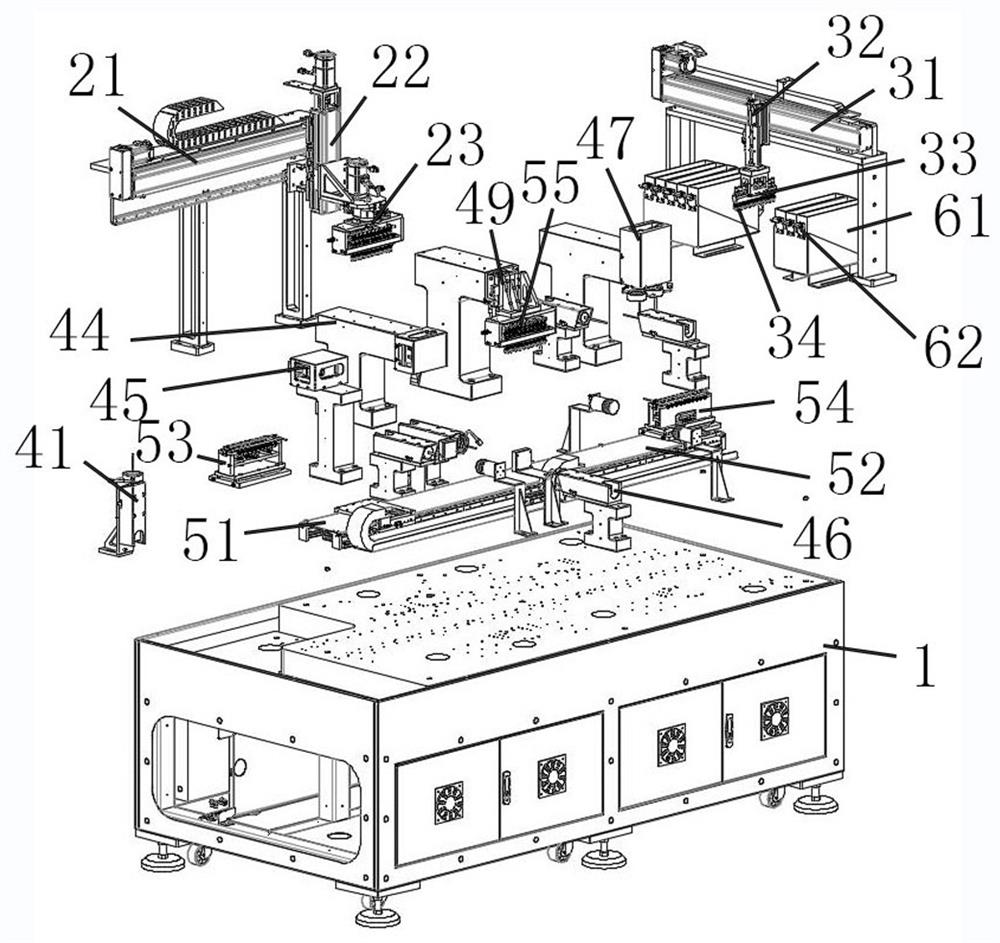

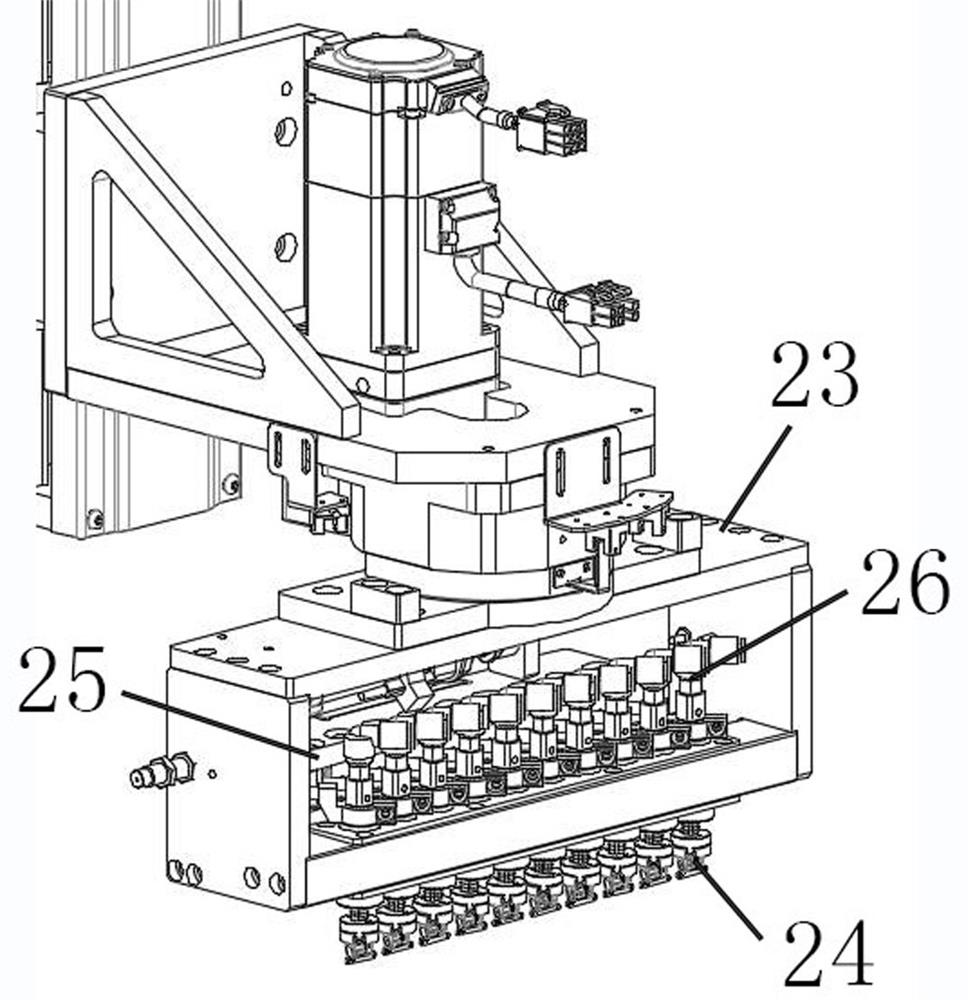

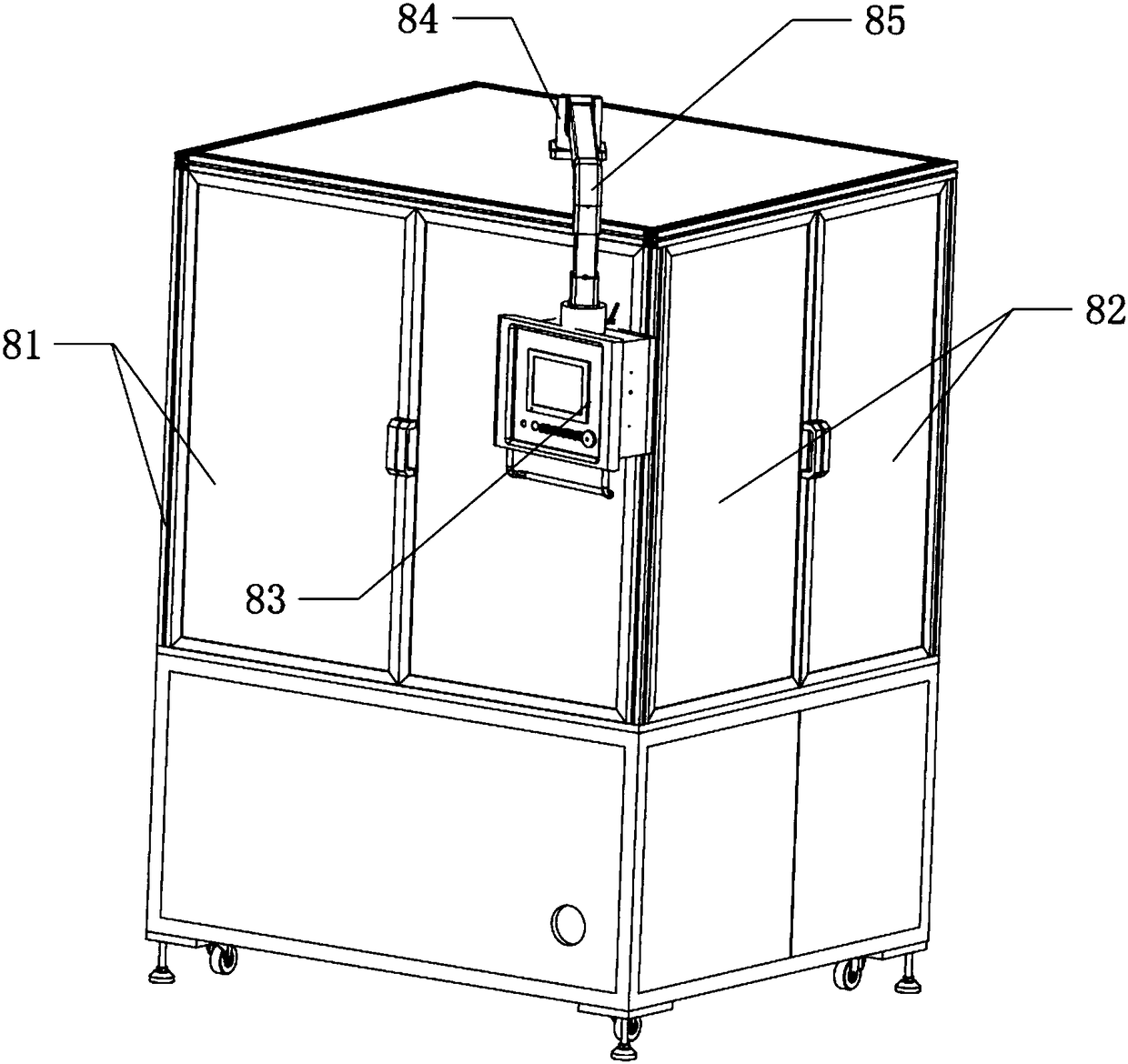

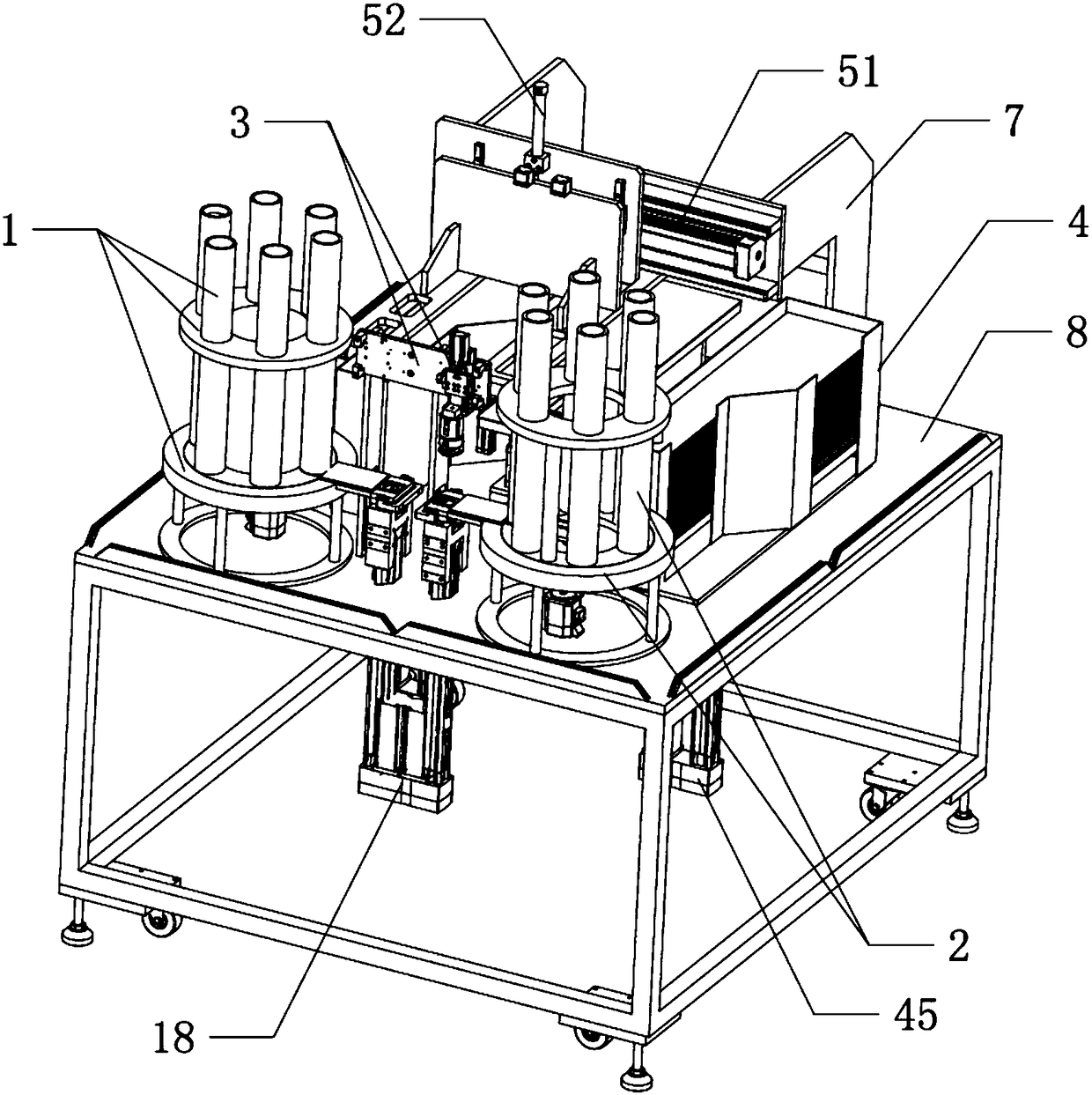

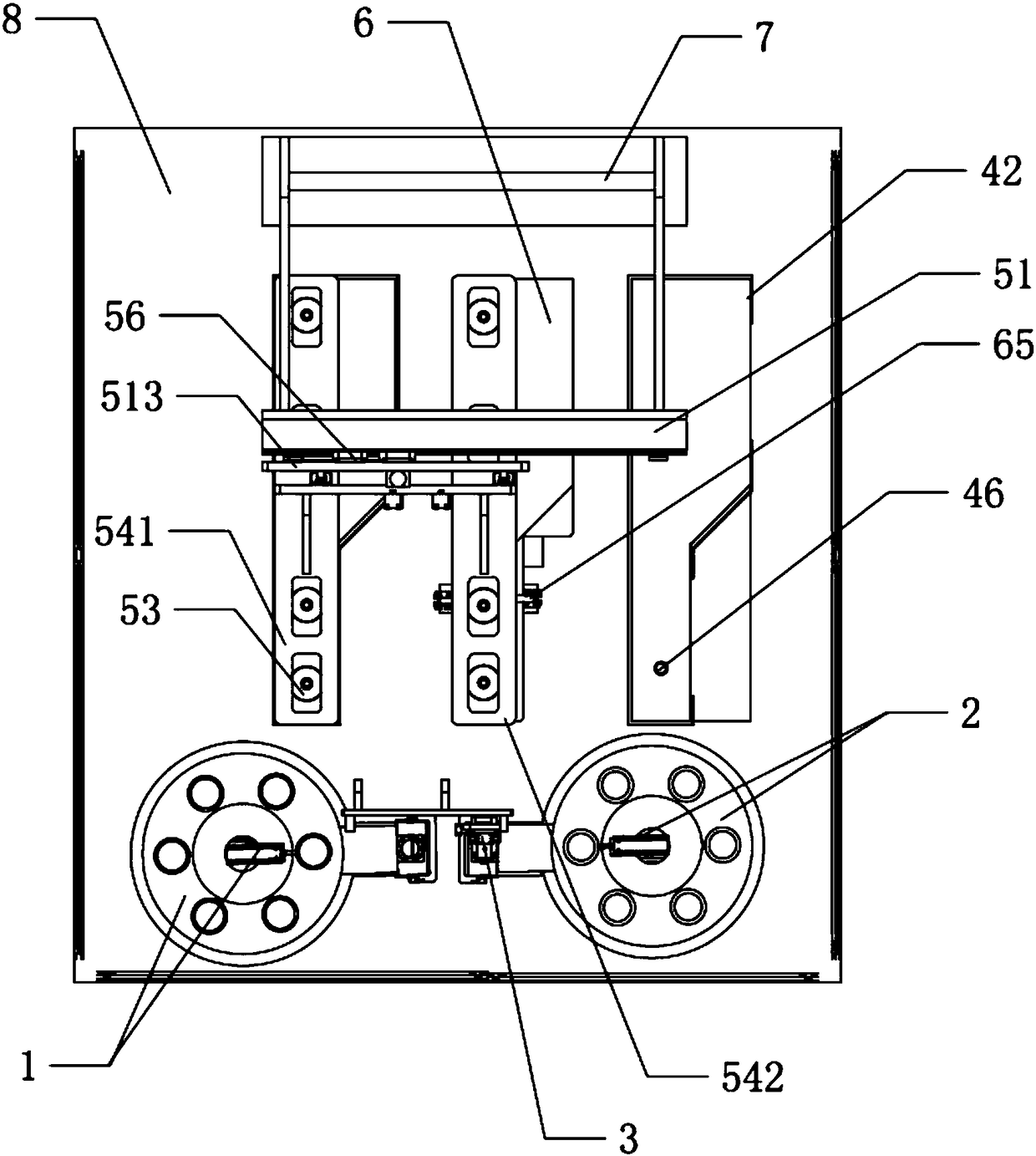

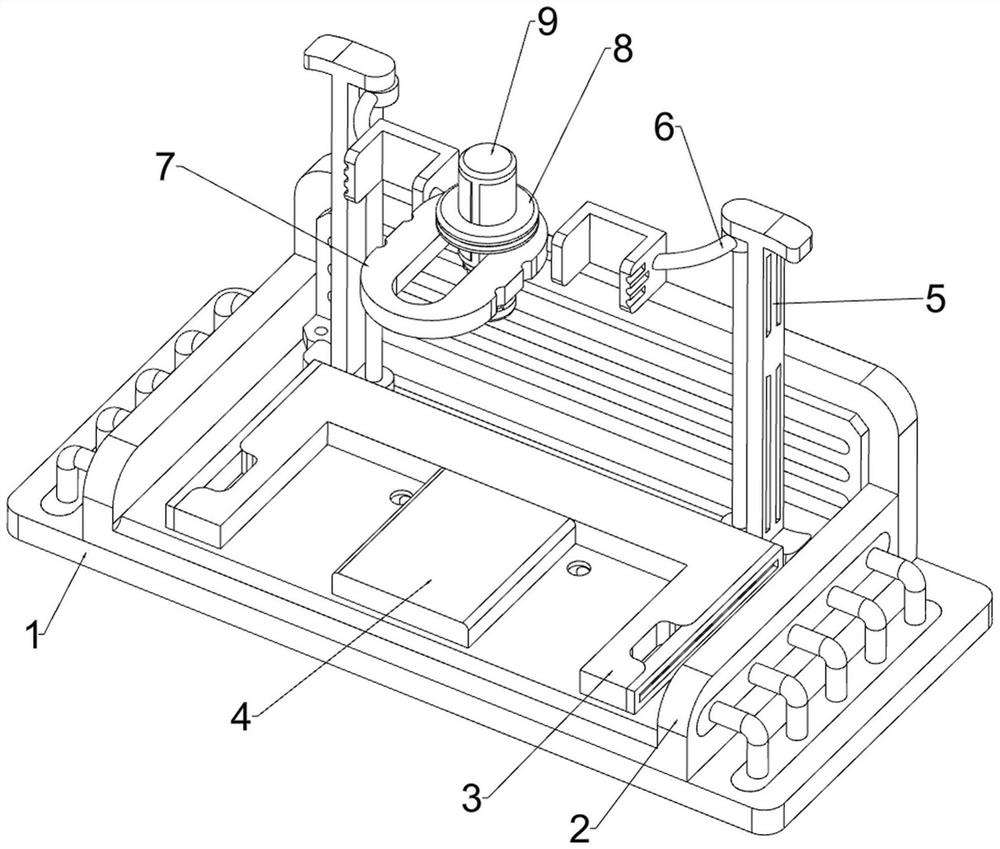

Multi-surface detection equipment

The invention discloses multi-surface detection equipment which comprises a case, a first carrying module, a second carrying module, a detection device, a transfer module, a material distribution box and a control system. The first carrying module comprises a first material suction device, the second carrying module comprises a second material suction device, the transfer module comprises a first transferring device and a second transferring device, the first transferring device is provided with a first bearing seat, the second transferring device is provided with a second bearing seat, a third material suction device is arranged between the first transferring device and the second transferring device, and the detection device comprises a bottom face camera, a first detection assembly and a second detection assembly. The whole operation process of the multi-surface detection equipment is smooth without pause, and the automation degree is high; the bottom camera, the first detection assembly and the second detection assembly are arranged to carry out 2D and 3D detection on multiple aspects and multiple sizes of products, and the detection degree is higher; and the multiple products can be transferred and detected at the same time, and the detecting and transferring efficiency is higher.

Owner:SUZHOU DINNAR TECH FOR AUTOMATION CO LTD

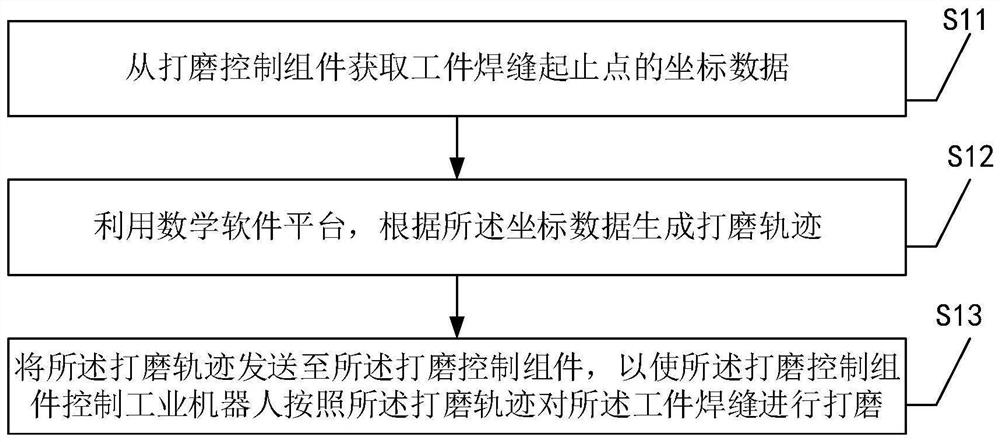

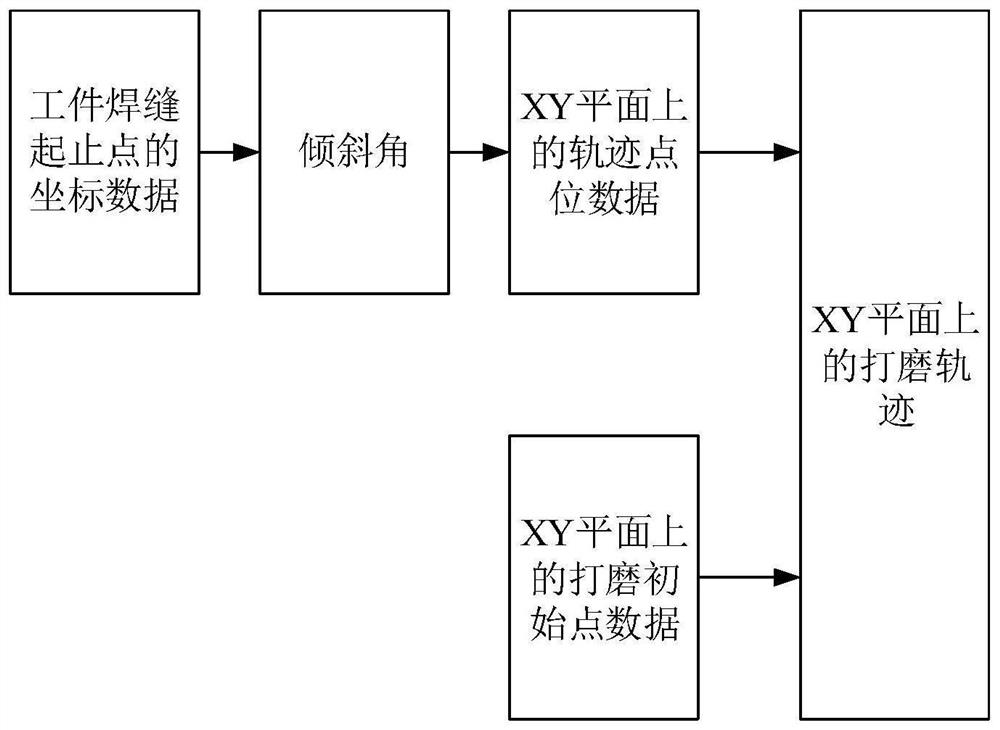

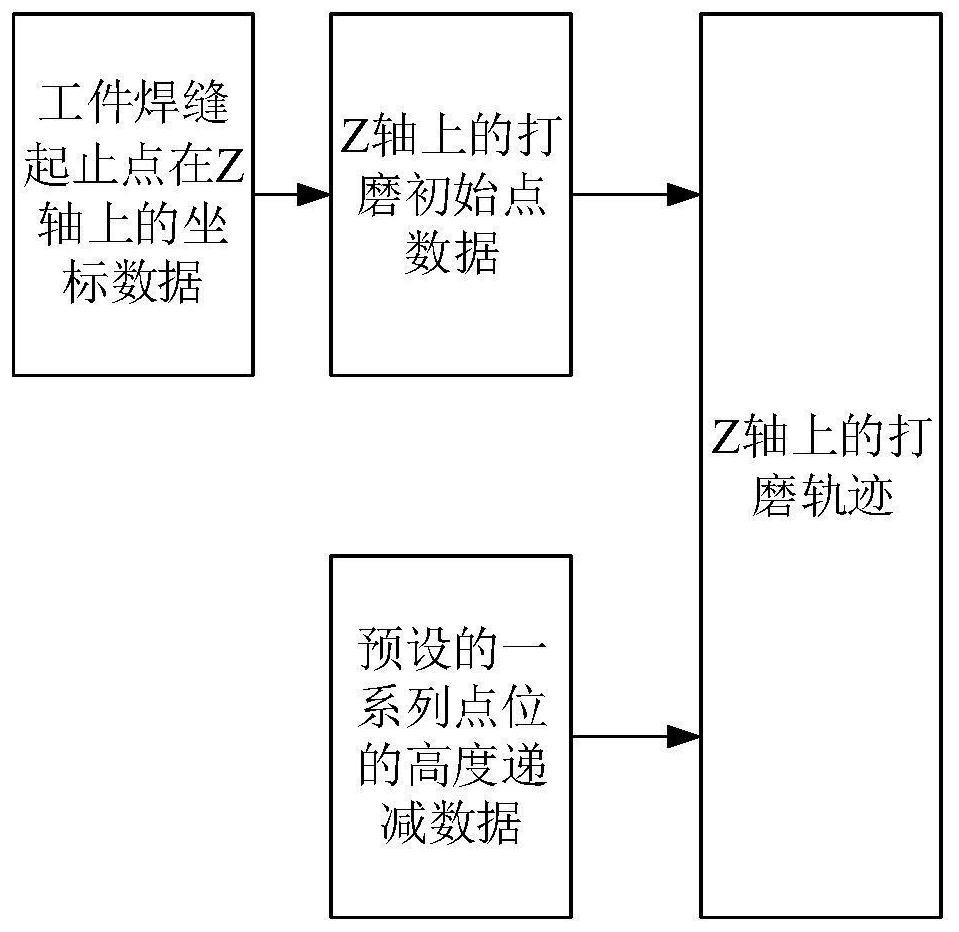

Workpiece welding seam polishing method, terminal equipment and polishing control assembly

PendingCN113275949ANo pauseDoes not cause oversanding issuesEdge grinding machinesDesign optimisation/simulationPolishingTerminal equipment

The invention discloses a workpiece welding seam polishing method applied to terminal equipment. According to the method, when a workpiece is polished, a polishing track is generated according to coordinate data of a workpiece welding seam of a polishing control assembly through a mathematical software platform, and finally a robot is controlled to polish the workpiece welding seam according to the polishing track. Firstly, the polishing track is generated according to the coordinate data of the actual polished workpiece welding seam, and therefore, the adaptability of the whole scheme to different workpiece welding seams is guaranteed; furthermore, the polishing track generated by the mathematical software platform is very smooth, so that pause of the robot in the polishing process is avoided; and finally, the polishing track is automatically generated, the robot is controlled to execute polishing operation, and therefore, manual participation is not needed, and the polishing efficiency is remarkably improved. In addition, the invention further provides the terminal equipment, a workpiece welding seam polishing method applied to the polishing control assembly and the polishing control assembly. The technical effects of the terminal equipment, the workpiece welding seam polishing method applied to the polishing control assembly and the polishing control assembly correspond to the technical effects of the method.

Owner:SHANDONG YINGXIN COMP TECH CO LTD

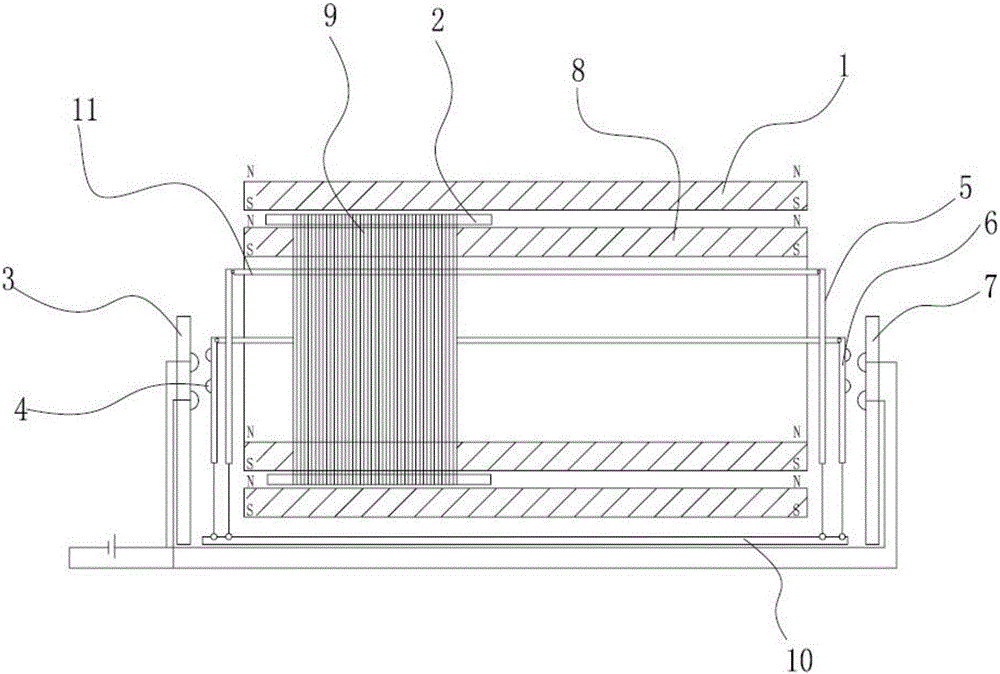

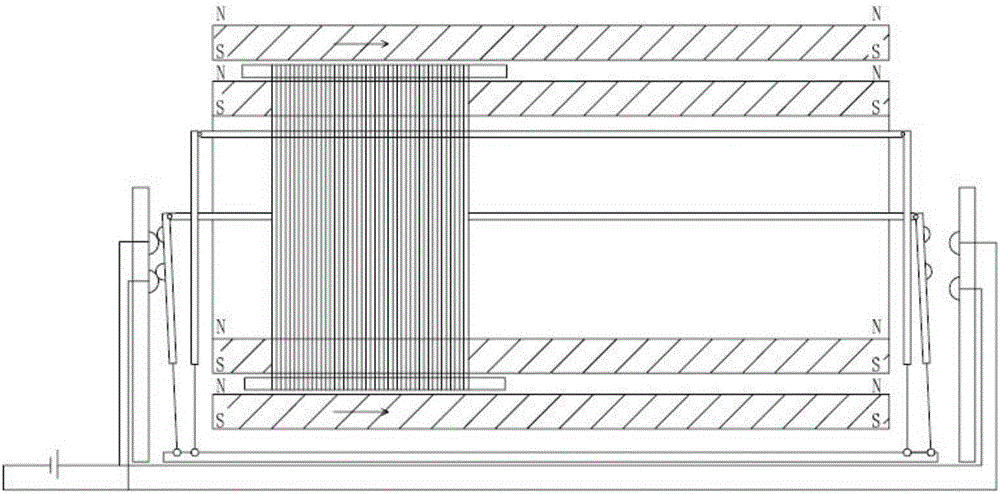

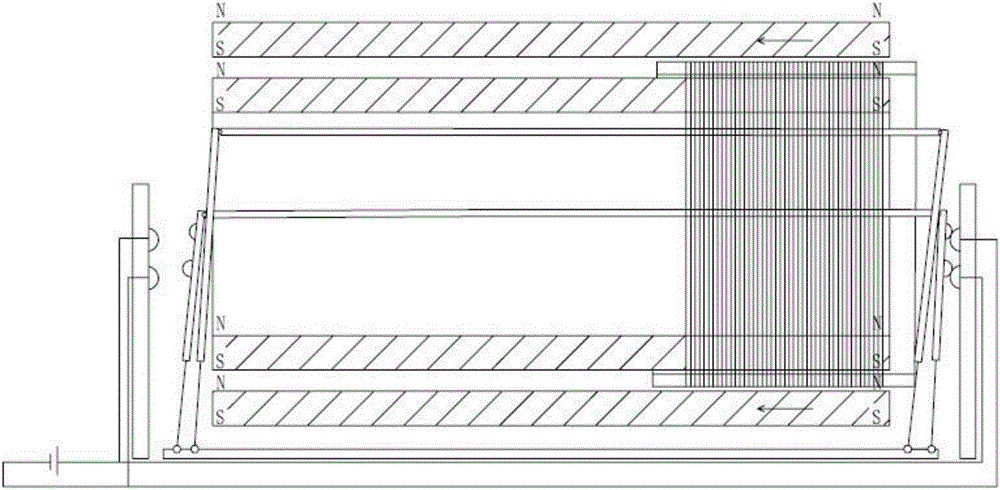

DC reciprocating thruster

InactiveCN106849591ANo pauseSolve unsolvable technical problemsDynamo-electric machinesSwitched currentPower flow

The invention relates to a DC reciprocating thruster comprising a magnet group and a movable coil frame. The magnet group comprises an outer and an inner magnet which are concentrically arranged. The outer magnet and the inner magnet have the same cross section in a closed shape. The movable coil frame is arranged axially between the outer magnet and the inner magnet in a sliding way. The two ends of the magnet group are provided with a forward current switch frame and a reverse current switch frame respectively. Linked power swing switches are arranged symmetrically on both ends of the magnet group. Linked position swing switches are installed between the power swing switches and the forward current switch frame or between the power swing switches and the reverse current switch frame. The side surfaces, opposite to the forward current switch frame or the reverse current switch frame, of the position swing switches are provided with corresponding contacts. The DC reciprocating thruster enables the movable coil frame to perform horizontal reciprocating motion by switching current directions by means of an electromagnetic principle, can generate mechanical energy by efficiently utilizing direct current, and solves a technical problem that cannot be solved by a motor.

Owner:赵德连

Cold drawing precision honing tube manufacture method

InactiveCN105880920AImprove performanceImprove low temperature impact toughnessNumerical controlZinc phosphate

The invention relates to a cold drawing precision honing tube manufacture method comprising the following steps: heating, heating a tube blank in an annular furnace; perforation, using a perforator to perforate the hot tube blank; annealing, annealing the tube blank; spraying borax, descaling; hot rolling, guiding the annealing tube into a tube grimper for hot rolling; detaching tube, detaching the rolled tube from a core rod; stress relieving, guiding the rolled tube into the heating furnace so as to obtain an annealing tube blank; pickling processing, removing surface rust scale; phosphatization processing, forming a zinc phosphate chemical generation overlay film on the surface; saponification processing, forming a metallic soap lubrication overlay film; primary cold drawing, cold drawing a to-be-cold drawn tube blank; secondary cold drawing, secondarily cold drawing the cold drawing tube after the primary cold drawing, thus obtaining a cold drawn tube; heat treatment, reducing residual stress; honing, using a numerical control honing machine; hot straightening processing; obtaining the cold drawing precision honing tube. The cold drawing precision honing tube obtained by the method is good in integration performance, precise in sizes, and excellent in oil storage performance.

Owner:WUXI SHENLU HYDRAULIC PARTS

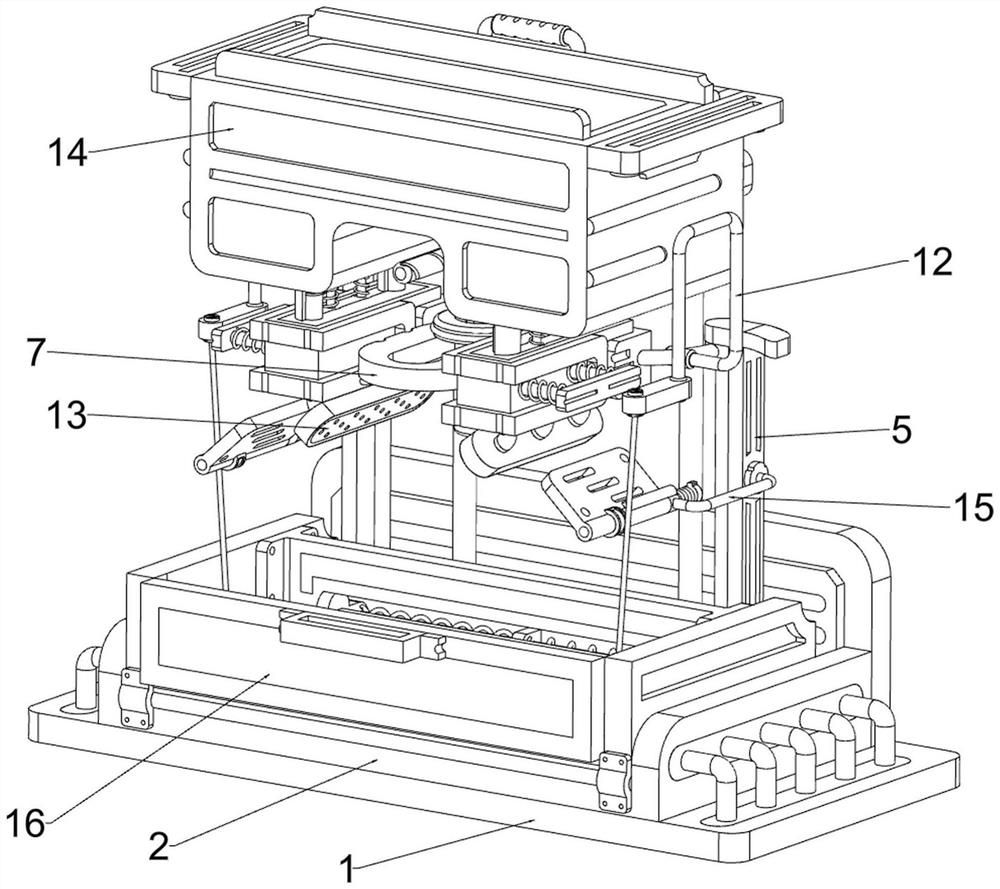

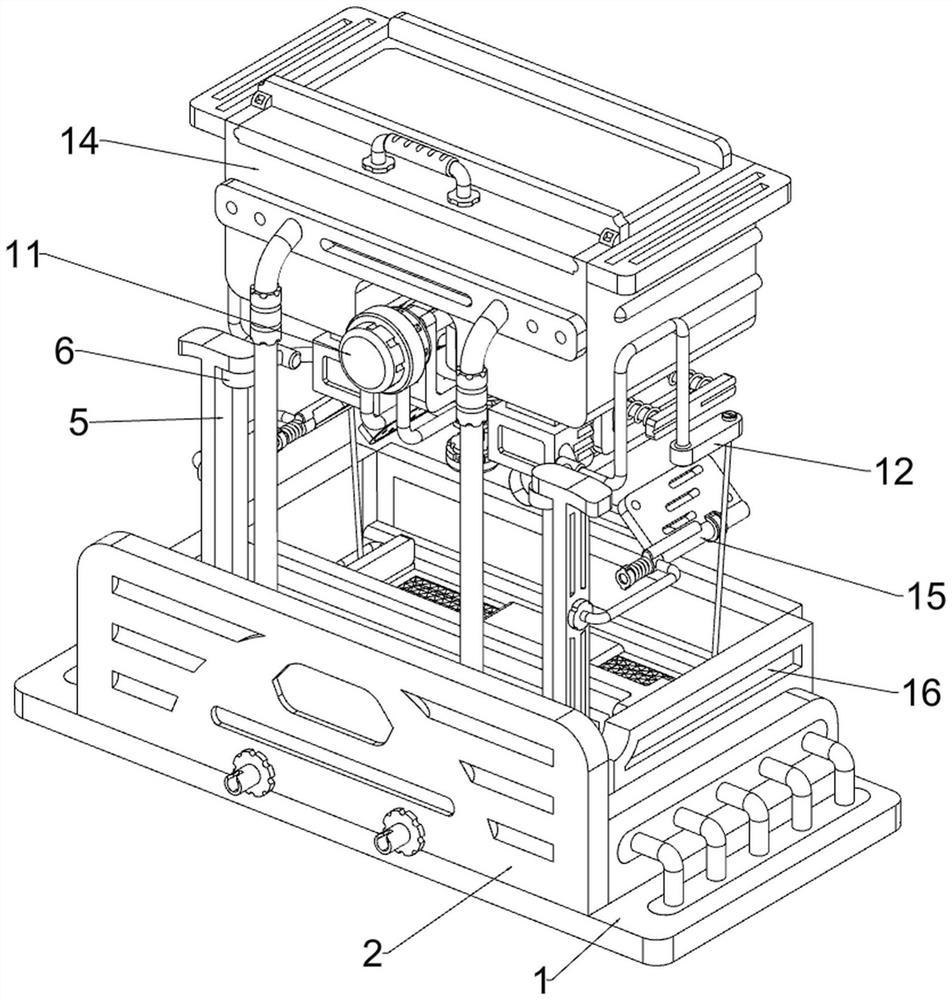

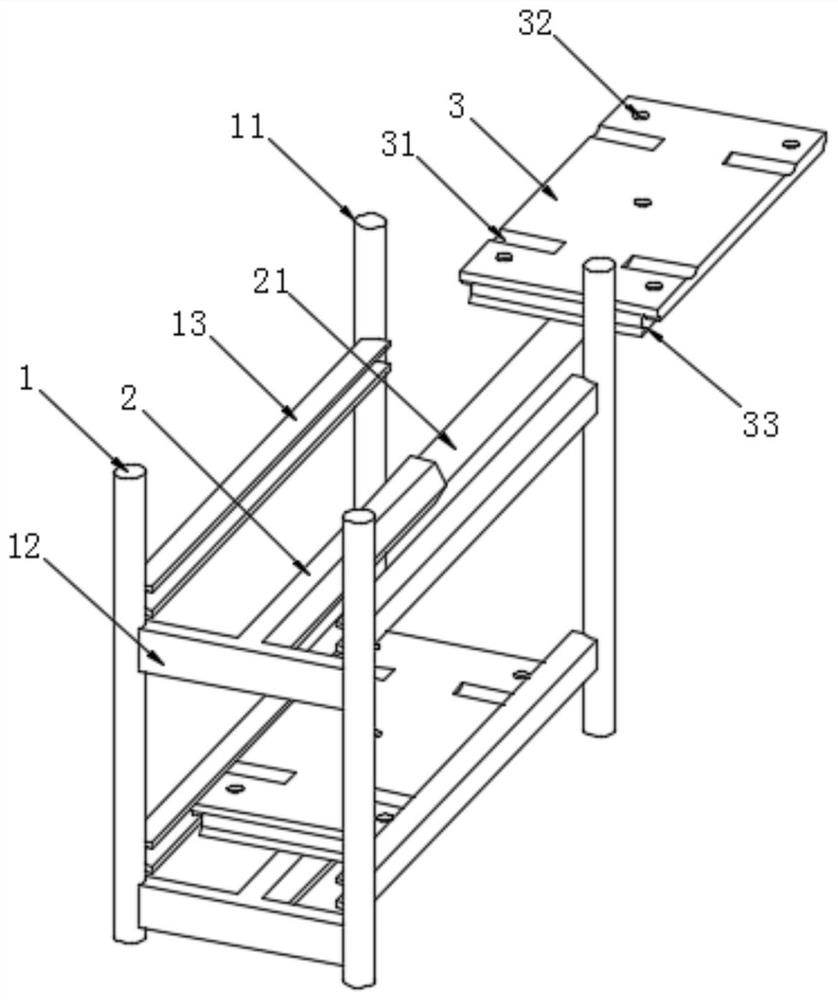

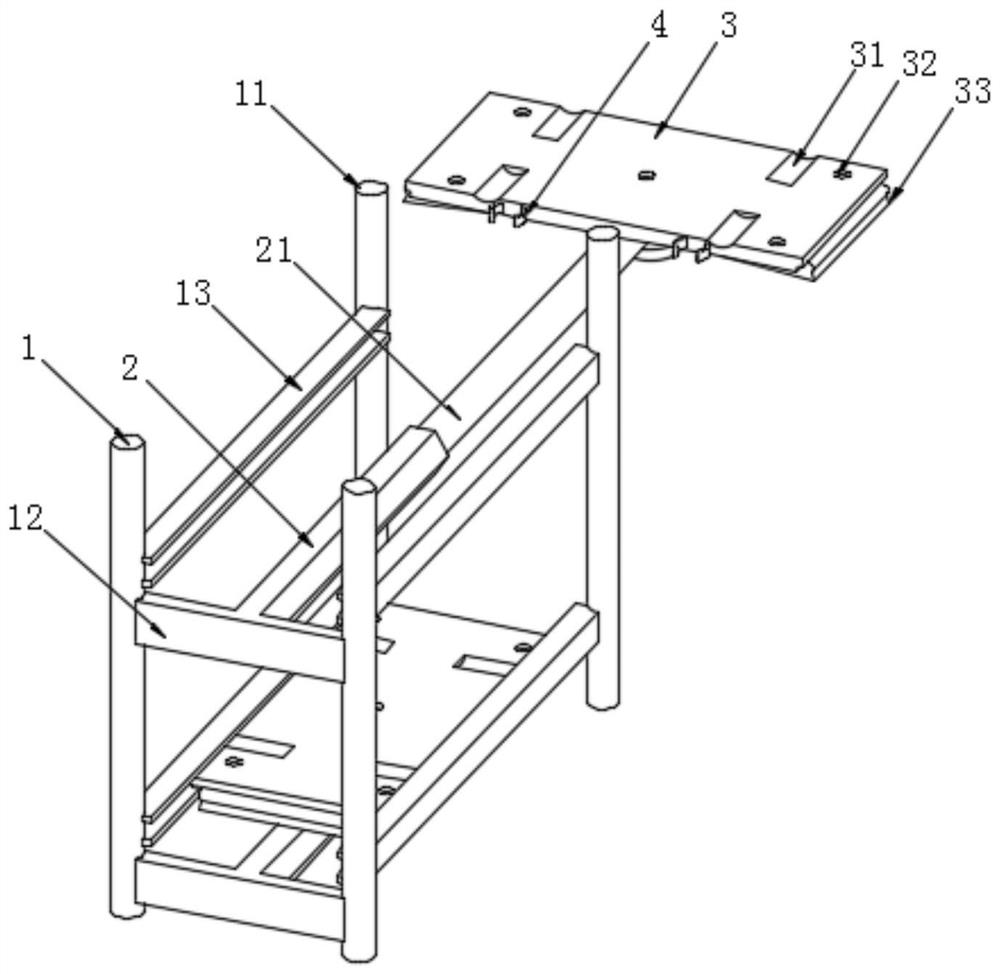

Automatic assembling device for upper and lower couplers

ActiveCN108381141AAssembly is slowImprove assembly efficiencyFinal product manufactureMetal working apparatusEngineeringMechanical engineering

Owner:CHANGCHUN FAWAY ADIENT AUTOMOTIVE SYETEMS CO LTD

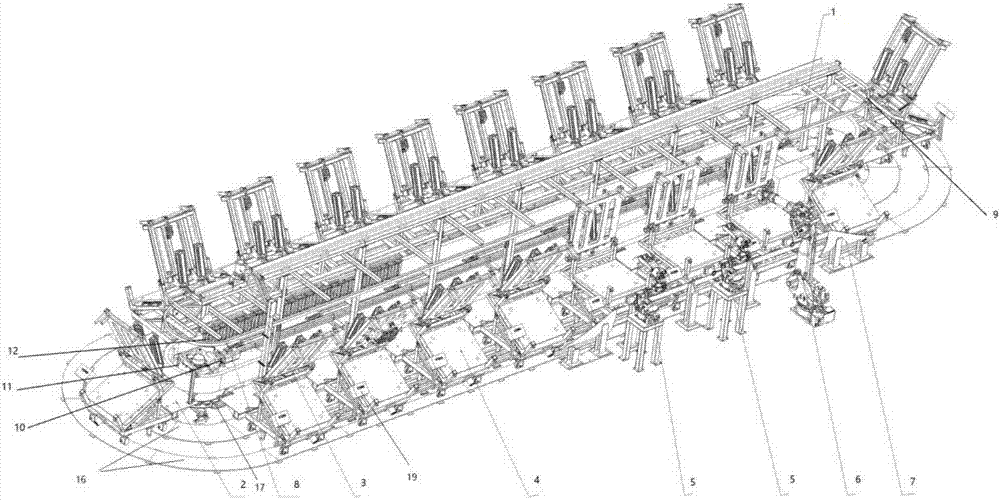

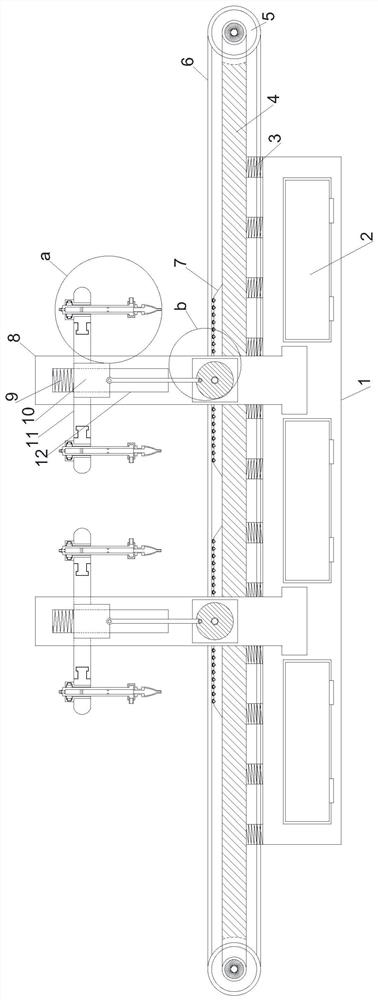

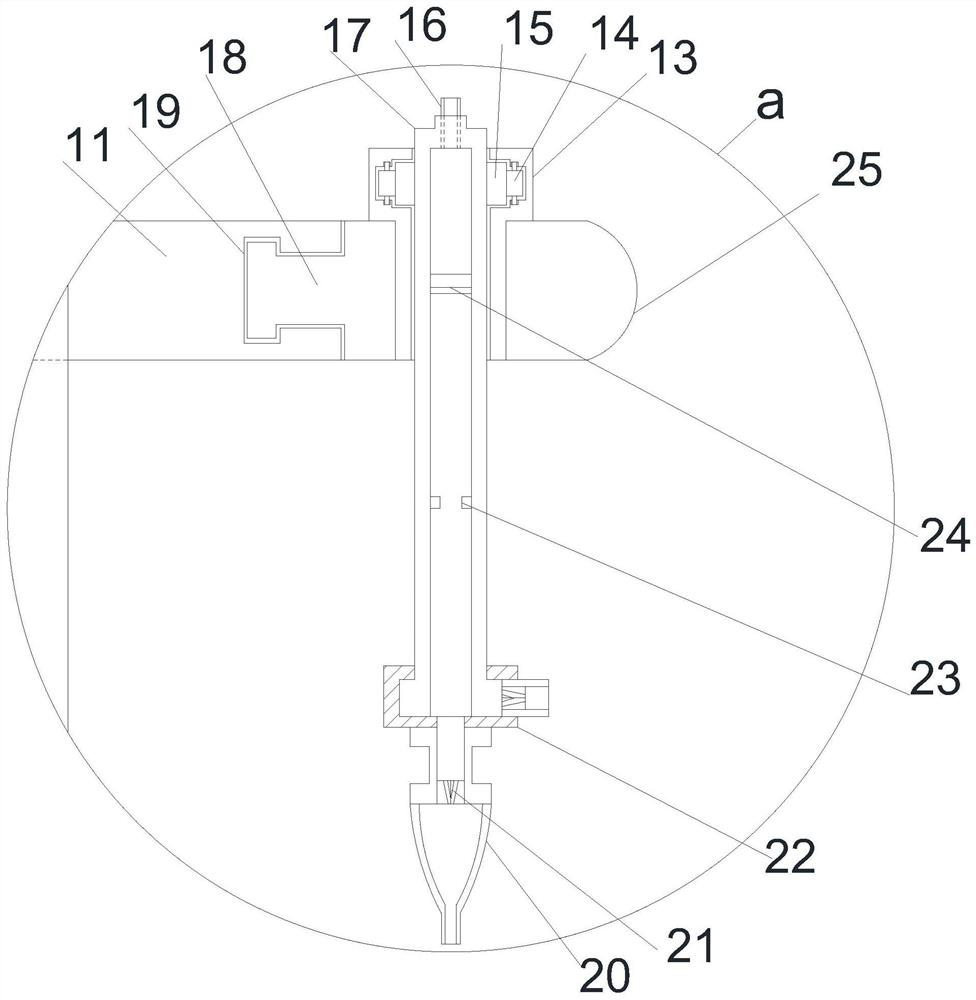

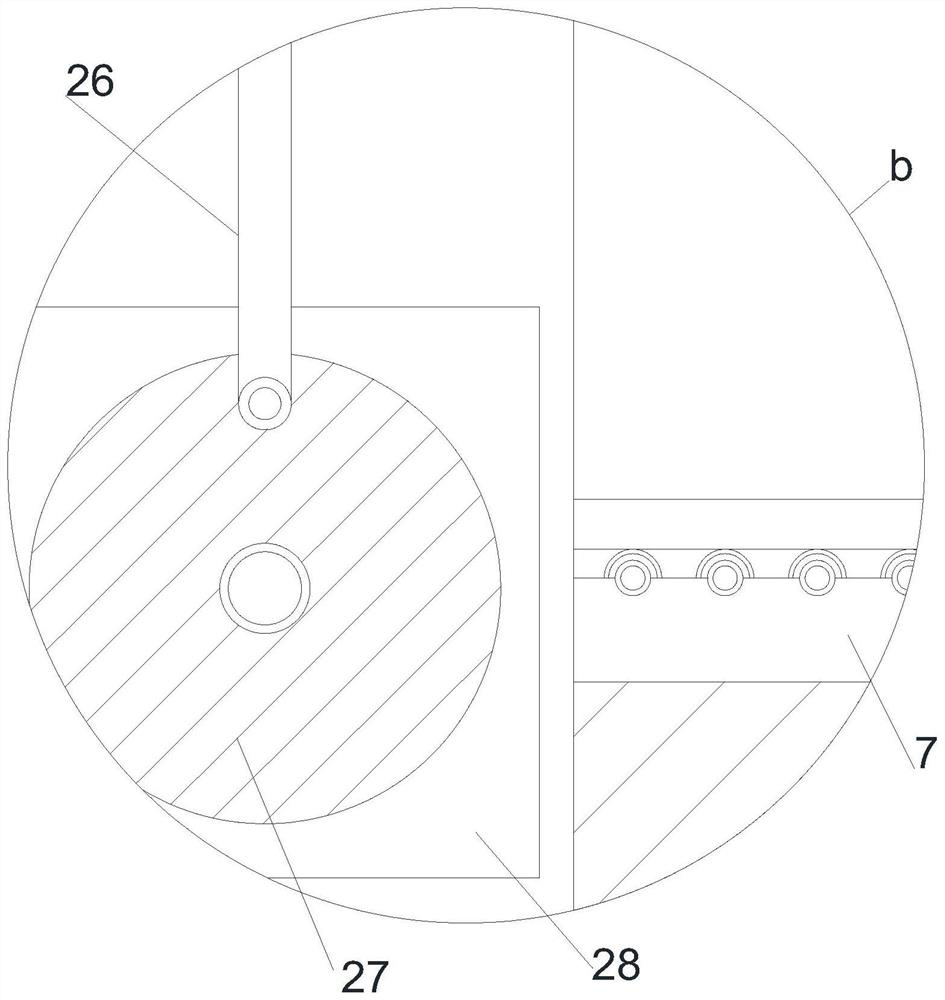

Elliptic annular foaming line for automotive soundproofing mat

PendingCN107283708APromote repairEasy to meet process requirementsCoatingsElectric machineryEngineering

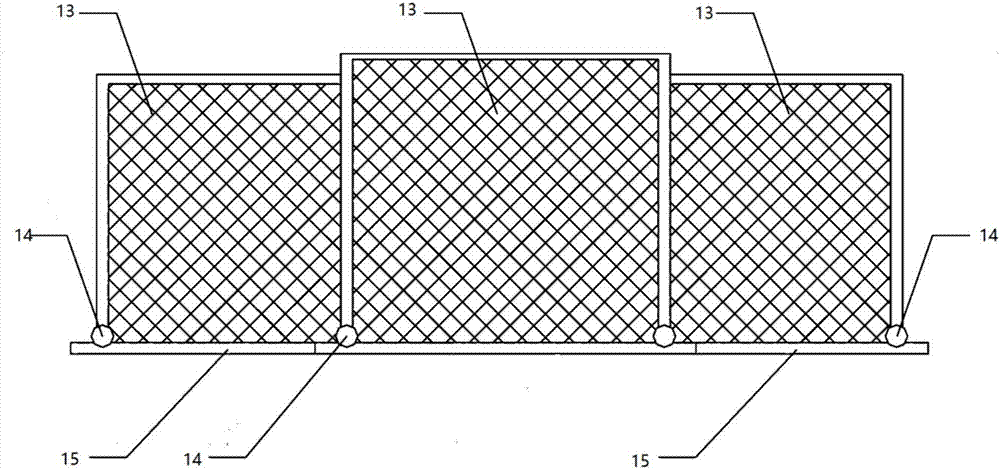

The invention discloses an elliptic annular foaming line for an automotive soundproofing mat. The elliptic annular foaming line comprises an annular line body, a fixture traction trolley, fixture automatic gas connecting devices, foaming fixture trolleys, a mould release agent and in-mould coating spraying robot, a charging robot, mould frame lower lifting guide rails and a movable protection net, wherein the annular line body comprises an elliptic support, a speed reduction motor, a driving chain wheel and a chain; the fixture traction trolley is driven by the chain to be connected with the foaming fixture trolley to do a continuous annular motion; the elliptic support is designed into an annular form that two ends are circular arc sections and the middle is a straight line section; the mould release agent and in-mould coating spraying robot, the mould frame lower lifting guide rails, the charging robot and the fixture automatic gas connecting devices are arranged on the straight line section positioned on one end of the support; the movable protection net is arranged on an outermost side of the annular line body without a machining device; and roller wheels and the rails which are slid in match with the roller wheels are arranged on the movable protection net. The elliptic annular foaming line disclosed by the invention is simple to operate and high in automation, and manual operation is reduced.

Owner:ANHUI XINMENG EQUIP CO LTD

Cellosilk cutting device

The invention discloses a cellosilk cutting device. The cellosilk cutting device comprises a power source, a gear box, two pendulum tool mechanisms, a reset sensor and a pendulum tool bottom plate. Each pendulum tool mechanism is composed of a pendulum tool wheel, a pendulum tool frame and a silk cutting blade, and rotating shafts extending backward are formed on the pendulum tool wheels. The pendulum tool mechanisms are mounted on the gear box through the rotating shafts, and the rotating shafts of the two pendulum tool mechanisms correspond to two gears meshing with each other in the gear box. One of the rotating shafts extends rearward out of the gear box and is connected to the power source, and connecting rods extending forward are formed at the eccentric positions of the pendulum tool wheels. The pendulum tool frames are mounted on the connecting rods through bearings, and the silk cutting blades are horizontally mounted at the tops of the pendulum tool frames. The bottoms of thetwo pendulum tool frames are both mounted on the pendulum tool bottom plate, and the reset sensor is mounted on the gear box. The cellosilk cutting device solves the problems of striking a tool and being stuck when multiple cellosilk is transported and cut continuously at a high speed.

Owner:ZHONGSHAN ZHENDEMEI PRECISION MASCH CO LTD

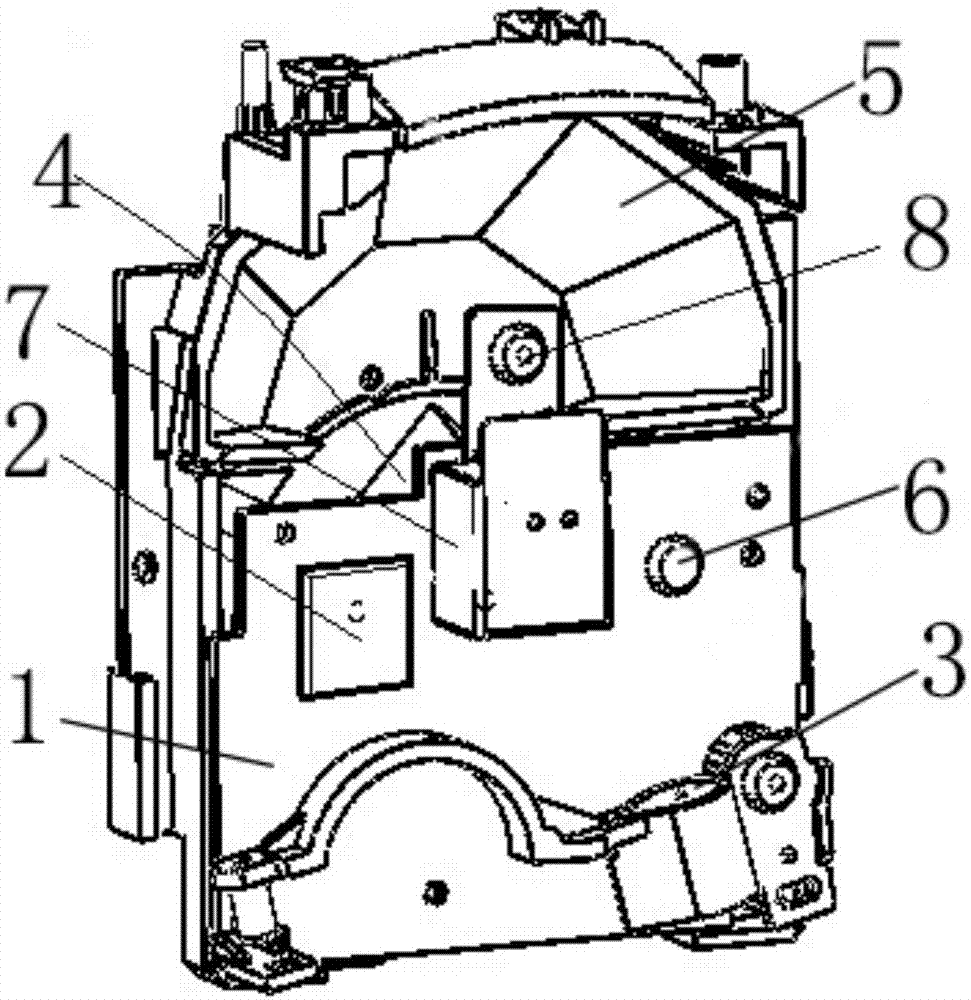

LCD (Liquid Crystal Display) dispensing device

InactiveCN111715472ATime unityUnified dispensing effectLiquid surface applicatorsCoatingsLiquid-crystal displayElectric machinery

The invention relates to the field of display screen production, in particular to an LCD dispensing device. The LCD dispensing device comprises a support mounting plate which is arranged horizontally,wherein transmission guide support columns are horizontally arranged on the front and back sides of the upper end of the support mounting plate through spring mounting columns which are arranged vertically at horizontal equal intervals; and a stable driving guide structure is arranged between the transmission guide support columns on the front and back sides. Periodical lifting driving is realized through cooperation of periodical driving motors, so that the device is continuous and stable in dispensing, unified in dispensing time, consistent in dispensing effect, and stable and efficient indispensing operation. Air in a guide mounting barrel at the upper end of a lifting piston is pumped pneumatically like an injector, and a guide mounting barrel at the lower end of the lifting piston is matched with a one-way valve to realize pumping and injection dispensing in order to finish operation. Diverse dispensing positions are realized through rotation displacement and guide movement, sothat the application range is wide. Moreover, the LCD dispensing device is high in injection dispensing speed, free from pause, and high in efficiency.

Owner:HEFEI PRECISE DISPLAY CO LTD

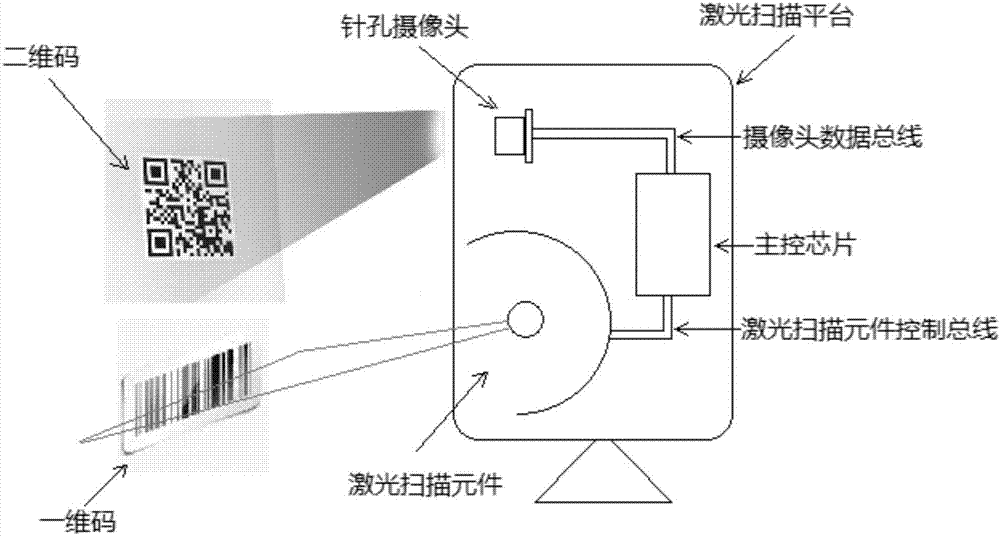

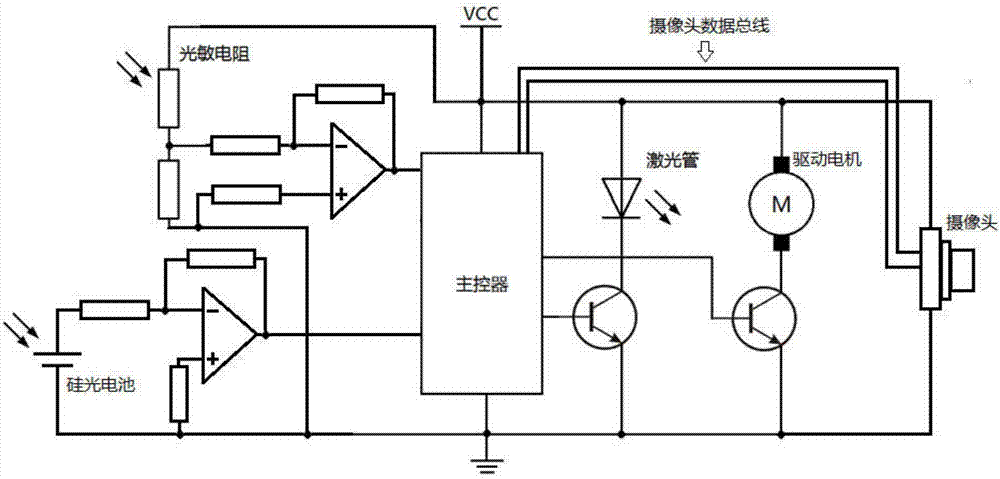

Laser barcode scanning platform supporting one-dimensional code and two-dimensional code recognition

InactiveCN107451506ARealize identificationSeamless switchingSensing by electromagnetic radiationLaser scanningControl line

The invention provides a laser barcode scanning platform supporting one-dimensional code and two-dimensional code recognition, a working circuit and a working method. The laser barcode scanning platform comprises a PCB (printed circuit board), a main controller, a one-dimensional code scanning mechanism and a two-dimensional code scanning mechanism; the one-dimensional code scanning mechanism comprises a laser tube, a driving motor, a four-sided mirror and a reflecting mirror, wherein the laser tube is arranged on the PCB and is connected with the main controller through a laser scanning element control line; and the two-dimensional code scanning mechanism comprises a camera connected with main controller through a camera data bus. The camera of the laser barcode scanning platform of the invention can record a working range outside a transparent window through the transparent window of the laser barcode scanning platform; the main controller allocates the working flows of one-dimensional scanning decoding and two-dimensional scanning decoding according to a preset one-dimensional proportion and a preset two-dimensional proportion; and therefore, the recognition of one-dimensional codes and two-dimensional codes can be realized, and the recognition work of the one-dimensional codes and the two-dimensional codes can be seamlessly switched without stagnancy.

Owner:广州微光信源物联科技有限公司

Miniature grinding device for mechanical manufacturing design

ActiveCN114654344AAvoid errorsImprove grinding efficiencyGrinding drivesGrinding machinesPhysicsGrinding

The invention relates to a grinding device, in particular to a miniature grinding device for mechanical manufacturing design. According to the micro grinding device for mechanical manufacturing and design, clamping work of mechanical parts can be automatically completed, and then it is guaranteed that grinding work is conducted orderly. A miniature grinding device for mechanical manufacturing design comprises a base, a supporting seat, a connecting seat, a workbench, electric sliding rails and the like, the supporting seat is arranged at the top of the base, the connecting seat is arranged in the supporting seat, the workbench is arranged in the middle in the supporting seat, and the electric sliding rails are arranged on the left side and the right side of the rear portion in the supporting seat. When the mechanical part is polished, the polishing block and the sliding block gradually move downwards, the pull rope is loosened, the sliding frame moves inwards under the action of the return spring to clamp the mechanical part, the polishing block makes contact with the mechanical part to conduct polishing work, in this way, clamping of the mechanical part is completed without manual operation, and errors caused by manual operation can be avoided.

Owner:NANTONG VOCATIONAL COLLEGE

Manufacturing method of hot-rolled high-precision petroleum pipe

InactiveCN104759835AImprove performanceImprove low temperature impact toughnessAcid washingStress relief

The invention relates to a manufacturing method of a hot-rolled high-precision petroleum pipe. The manufacturing method comprises the following steps: heating: a pipe blank is heated in an annular furnace; perforation: the heated pipe blank is perforated by a perforator; annealing: the pipe blank is annealed; spraying of boron sand: oxide scales are removed; hot rolling: the annealed pipe blank is led into a pipe rolling machine for hot rolling; sizing: the rolled pipe formed by continuous rolling is sized by a sizing machine; stress relief annealing: the rolled pipe is led into a heating furnace for heating so that the annealed pipe blank is obtained; acid washing: rust scales on the surface are removed; parkerizing: a chemical coating film of zinc phosphate is formed on the surface; saponification: such lubricating coating films as a metallic soap are formed; cold rolling: the pipe blank to be cold rolled is cold rolled to obtain a cold-rolled pipe; heat treatment: residual stress is reduced; pre-straightening: the residual stress is reduced; quenching in an induction furnace; tempering in a chamber furnace; honing; hot straightening; and obtaining of the high-precision steel pipe. The method is used for manufacturing the high-precision steel pipe with high yield strength and size precision.

Owner:WUXI OULONG SPECIAL STEEL PIPE

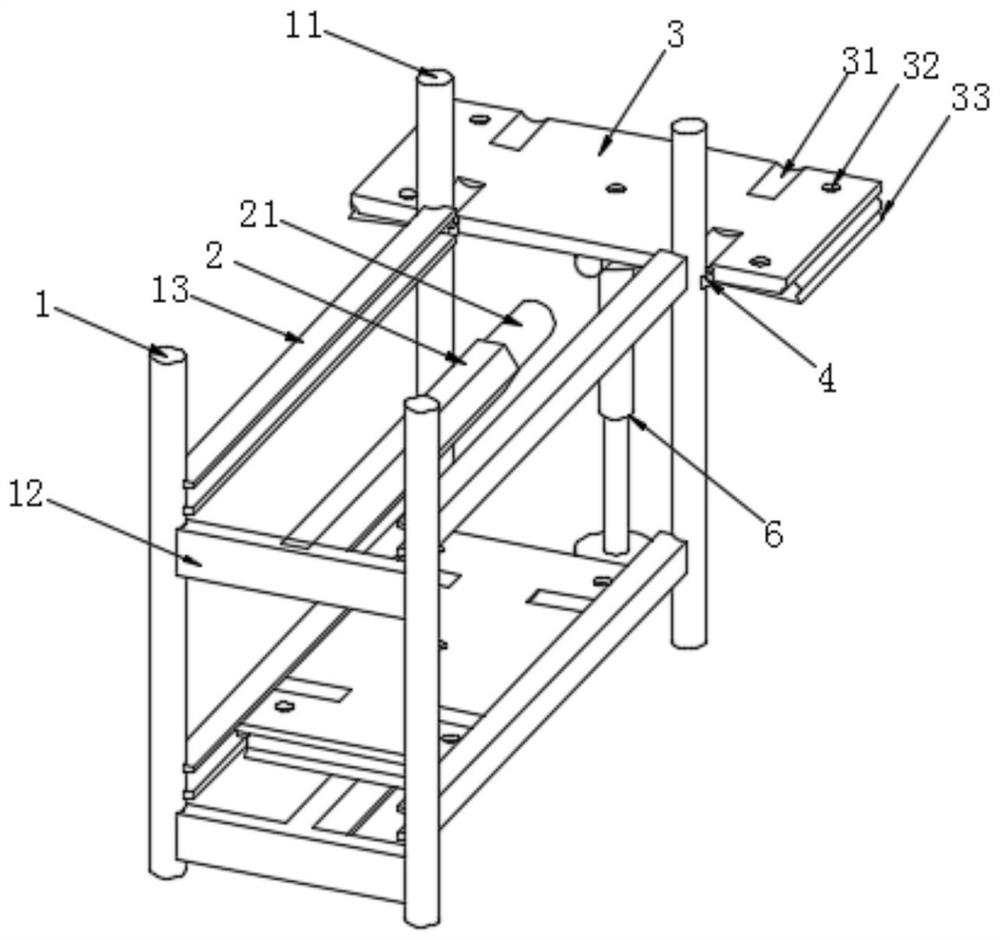

Mechanical three-dimensional garage

Owner:日照市科技中等专业学校

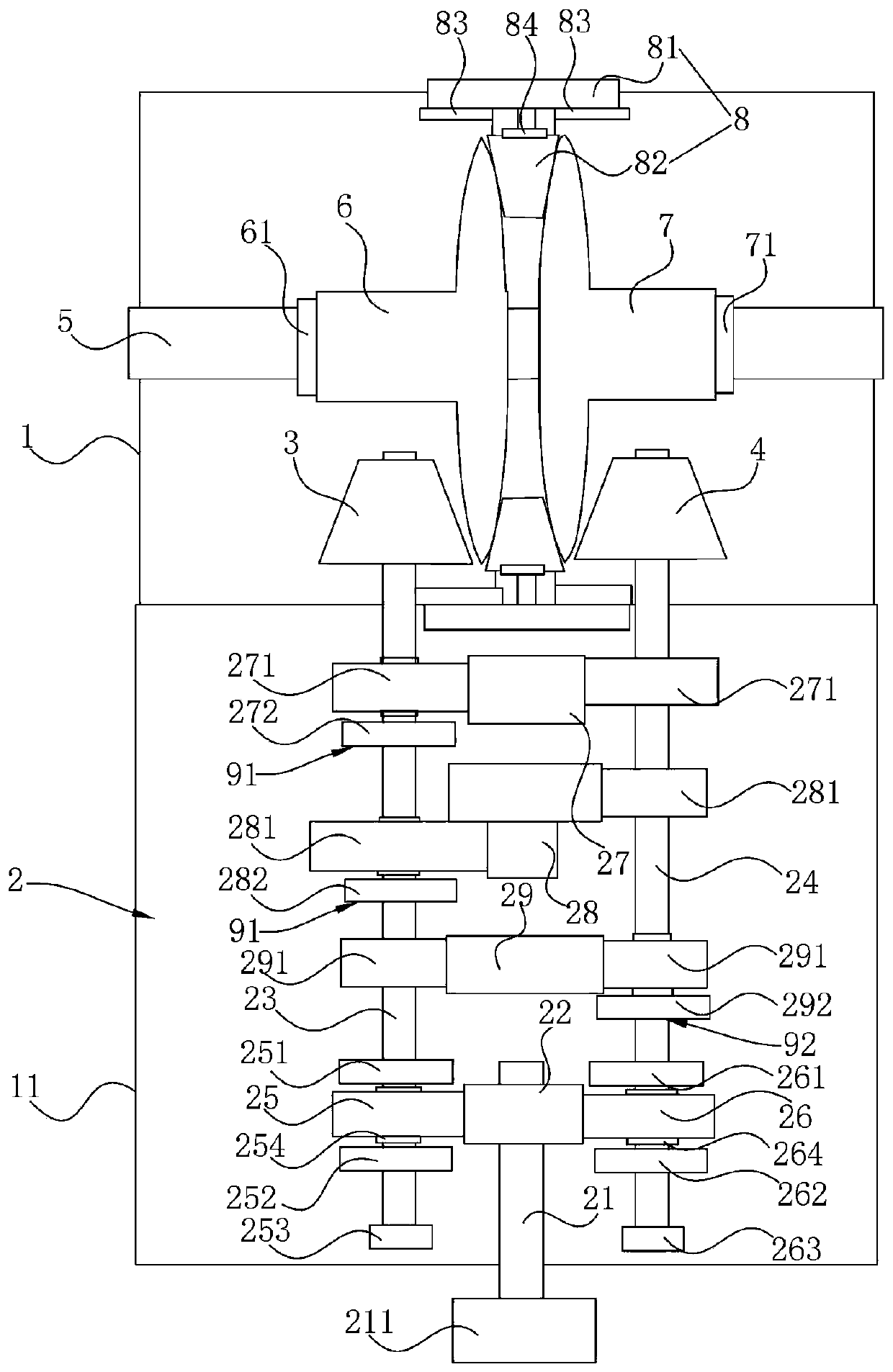

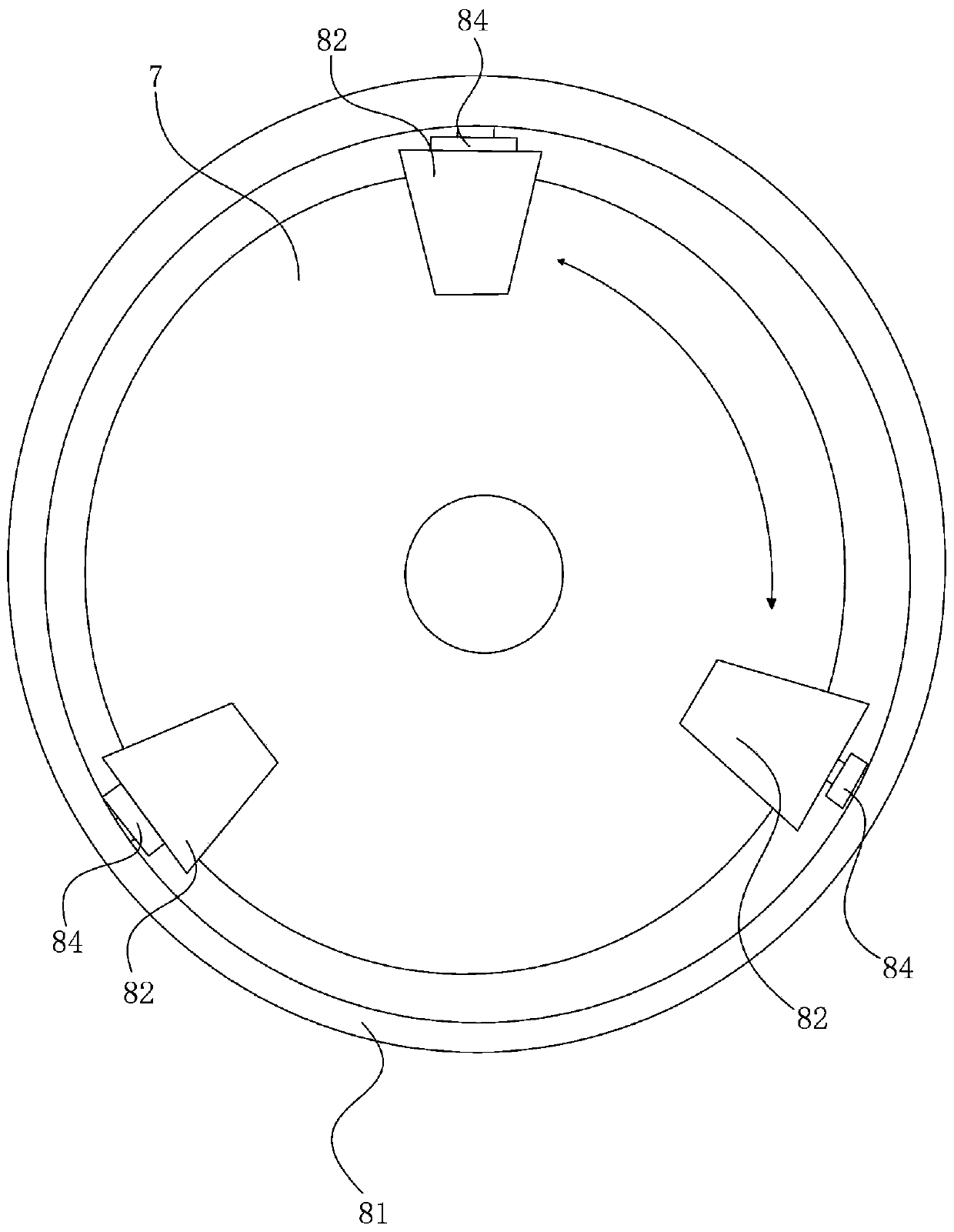

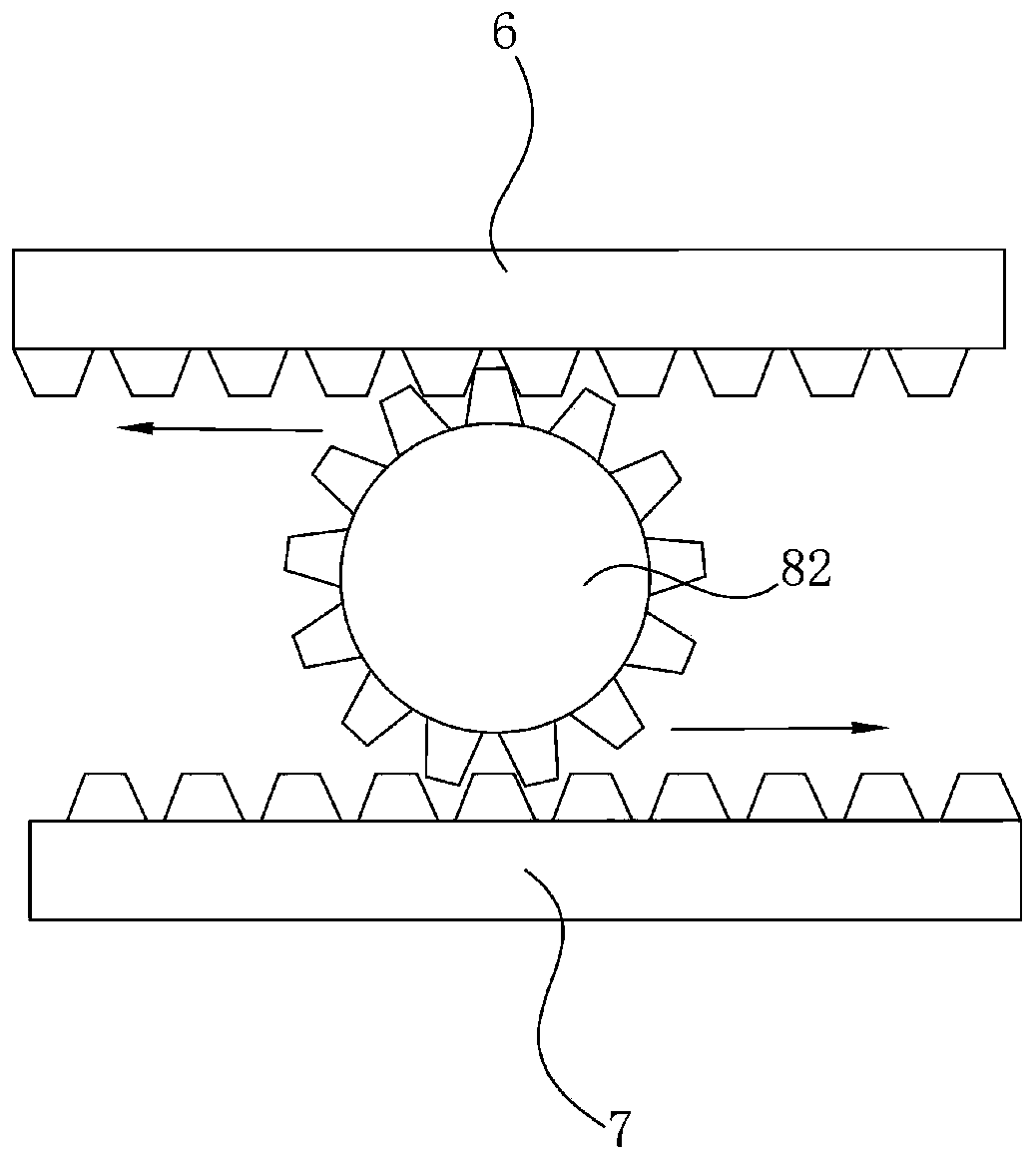

Dual-drive differential positive and reverse rotation transmission and multi-speed change device

PendingCN110805677AQuick responseReduce output torqueDifferential gearingsGearing detailsControl theoryBevel gear

The invention discloses a dual-drive differential positive and reverse rotation transmission and multi-speed change device comprising a shell, a power mechanism, a first bevel gear, a second bevel gear, a locating shaft fixedly arranged in the shell, a first differential wheel, a second differential wheel and a planet wheel, wherein the first bevel gear and the second bevel gear are driven by thepower mechanism, the first differential wheel and the second differential wheel are rotationally connected to the locating shaft, the planet wheel is arranged between the first differential wheel andthe second differential wheel, the side, far away from the planet wheel, of the first differential wheel is meshed with the first bevel gear, the side, far away from the planet wheel, of the second differential wheel is meshed with the second bevel gear, the planet wheel comprises a power rotation ring on the outer side and three rolling bevel gears located inside the power rotation ring and rotationally connected with the power rotation ring, and the three rolling bevel gears are evenly distributed along the inner circumference face of the power rotation ring. The dual-drive differential positive and reverse rotation transmission and multi-speed change device has the effects of improving reversing speed of a positive and reverse rotation transmission device, solving the reversing pause problem existing during brake starting and improving the accelerating speed after reversing.

Owner:陈藕生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com