LCD (Liquid Crystal Display) dispensing device

A dispensing device and dispensing technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of inability to perform automatic rotation processing, manual replacement of tooling, insufficient adaptation to displacement, etc., and achieve continuous and stable dispensing , uniform dispensing time and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

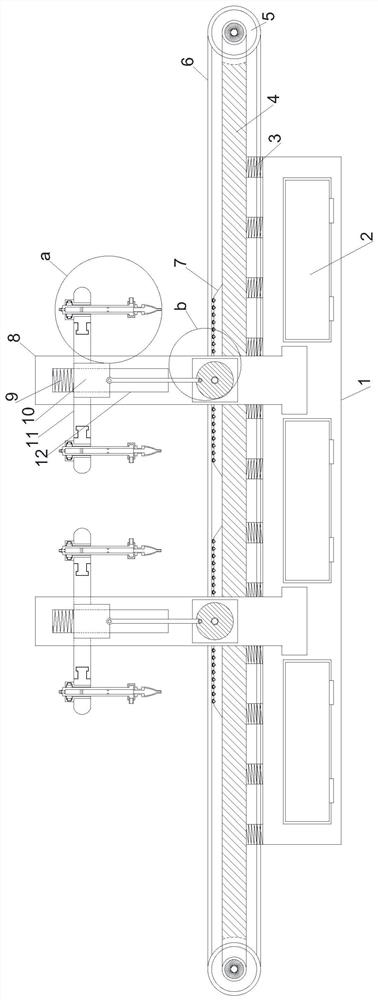

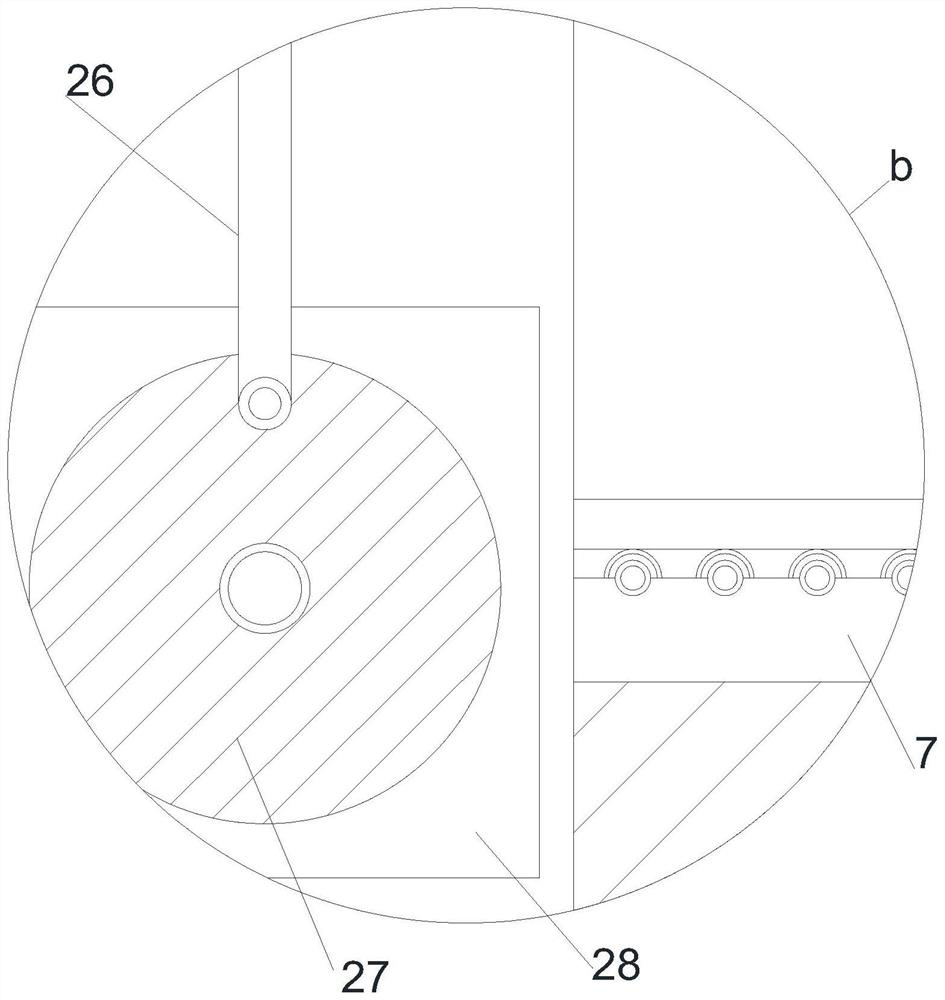

[0020] see Figure 1~3 , in an embodiment of the present invention, an LCD dispensing device includes a horizontally arranged support mounting plate 1, and the front and rear sides of the upper end of the support mounting plate 1 are horizontally provided with transmission Guide material support column 4, a stable driving material guide structure is arranged between the transmission guide material support column 4 on the front and rear sides, the front and rear ends of the middle position of the support installation plate 1 are all left and right symmetrical vertically provided with support installation columns 8, front and rear A synchronous displacement dispensing structure is provided between the support mounting columns 8 on both sides, and the stable driving material guide structure includes an electric drive roller 5 mounted on the left and right sides of the transmission material guide support column 4 through the longitudinal rotation of symmetrically arranged rotating ...

Embodiment 2

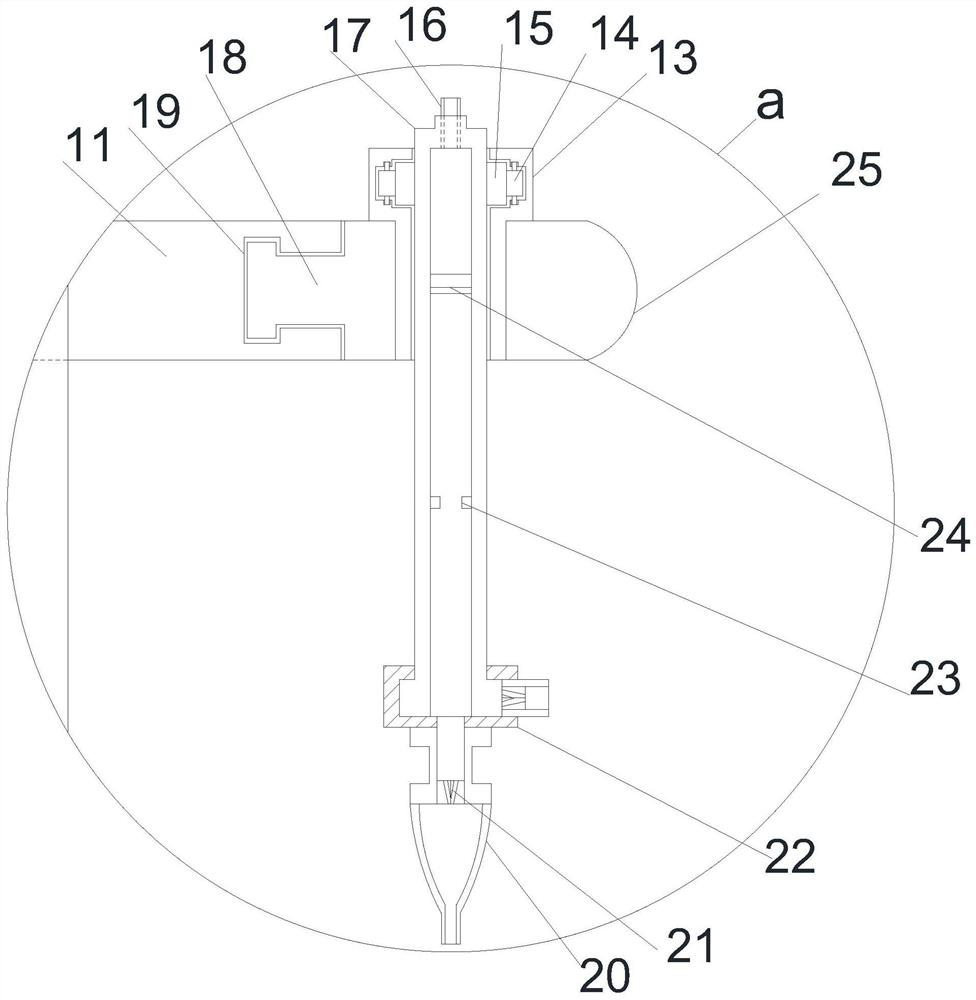

[0022] On the basis of Embodiment 1, the longitudinal guide groove 19 is horizontally provided with a mobile operation plate 25 through the limit guide column 18 outwardly, and the outer side of the guide installation cylinder 17 is provided with a rotating gear ring 15 in cooperation with the limit rotation groove, and the limit The rotation drive gear 14 is provided with the rotation drive gear 14 in the equiangular vertical engagement with the rotation gear ring 15 in the position rotation groove, and the longitudinal guide displacement is realized through the longitudinal guide groove 19 and the moving operation plate 25 in cooperation with the limit guide column 18, and the rotation gear ring 15 and the rotation The meshing transmission of the driving gear 14 realizes the twisting of the guide installation cylinder 17, so that it can be taken out smoothly for the next operation after dispensing, and the air in the guide installation cylinder 17 at the upper end of the lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com