Arc dresser for dressing grinding wheels of groove grinders for deep-groove balls

A technology for correcting grinding wheels and deep groove balls, which is applied to the parts of grinding machine tools, grinding/polishing equipment, abrasive surface adjustment devices, etc., and can solve the loss of accuracy of correctors correcting grinding wheels, wear and roughness of pendulum plates and cylinders In order to achieve the effect of good grinding wheel forming profile, ensure product quality and low roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawings and embodiments.

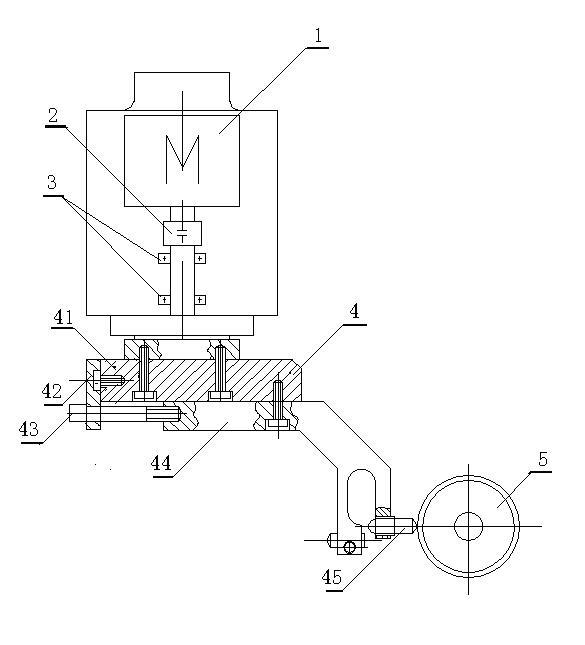

[0010] See attached figure 1 , this figure is a simplified assembly diagram of the present invention, the driving shaft of the single-phase speed-regulating motor 1 is connected with the bearing 3 through the coupling 2, the lower end of the bearing 3 is connected with an eccentric device 4, the eccentric device 4 is equipped with an eccentric seat 41, and the eccentric The left side of the seat 41 is connected with the fixed part 42, the lower part of the fixed part 42 is connected with the adjustment part 43, the right end of the adjustment part 43 is connected with the eccentric part 44, and the eccentric part 44 is connected with the grinding head 45 through the transmission pendulum piece 46, and the grinding head 45 is connected with the The grinding wheel 5 is in contact, and the single-phase speed-regulating motor 1 is connected through the shaft to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com