Driving gear for stepless speed change device for motor cycle

A continuously variable speed, driving wheel technology, applied in the direction of vehicle gearbox, vehicle components, chain/belt transmission, etc., can solve the problems of large change in speed ratio, low transmission efficiency, poor riding comfort and sliding performance, etc. The effect of reducing noise and wear, improving transmission efficiency and driving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

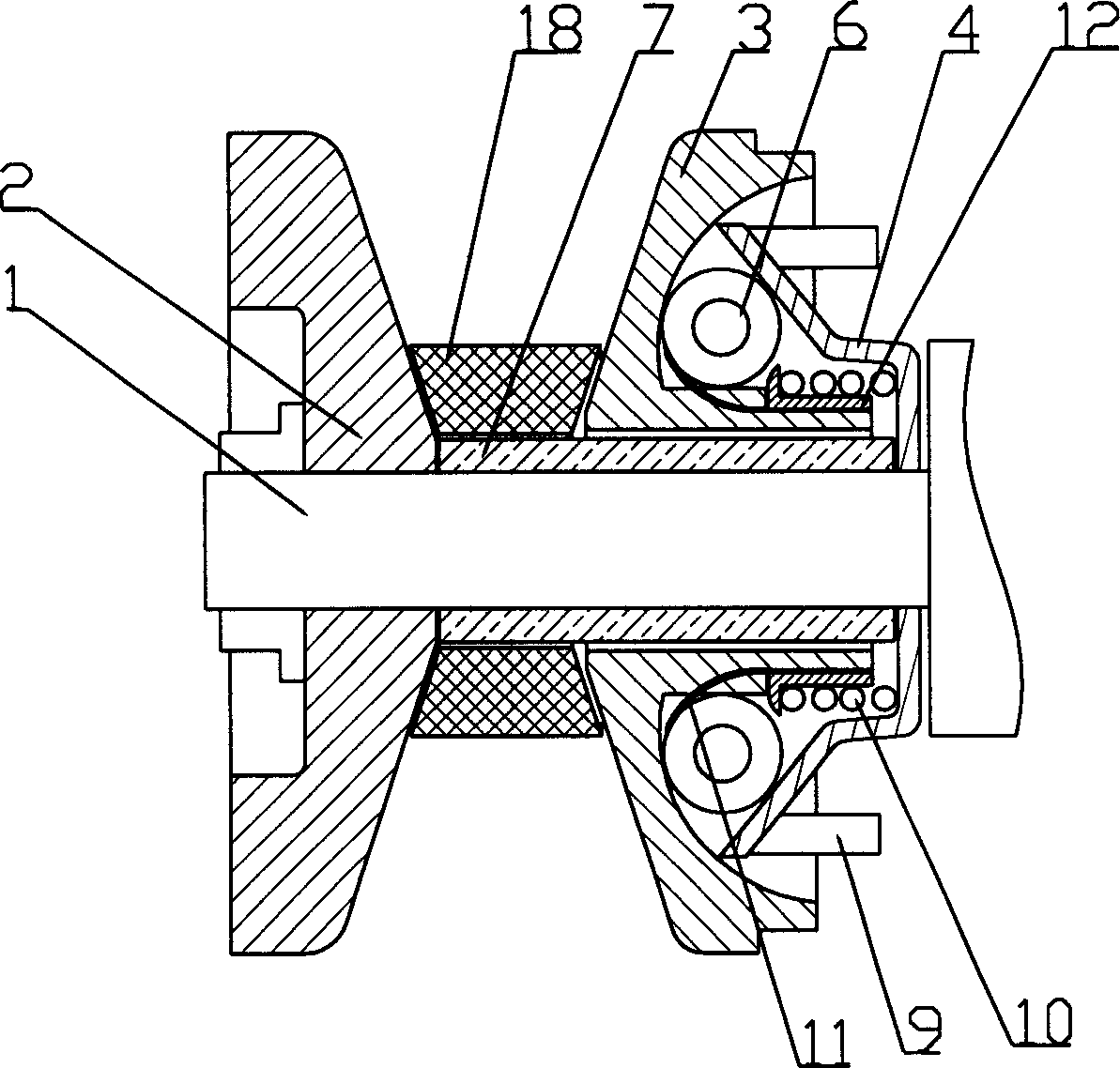

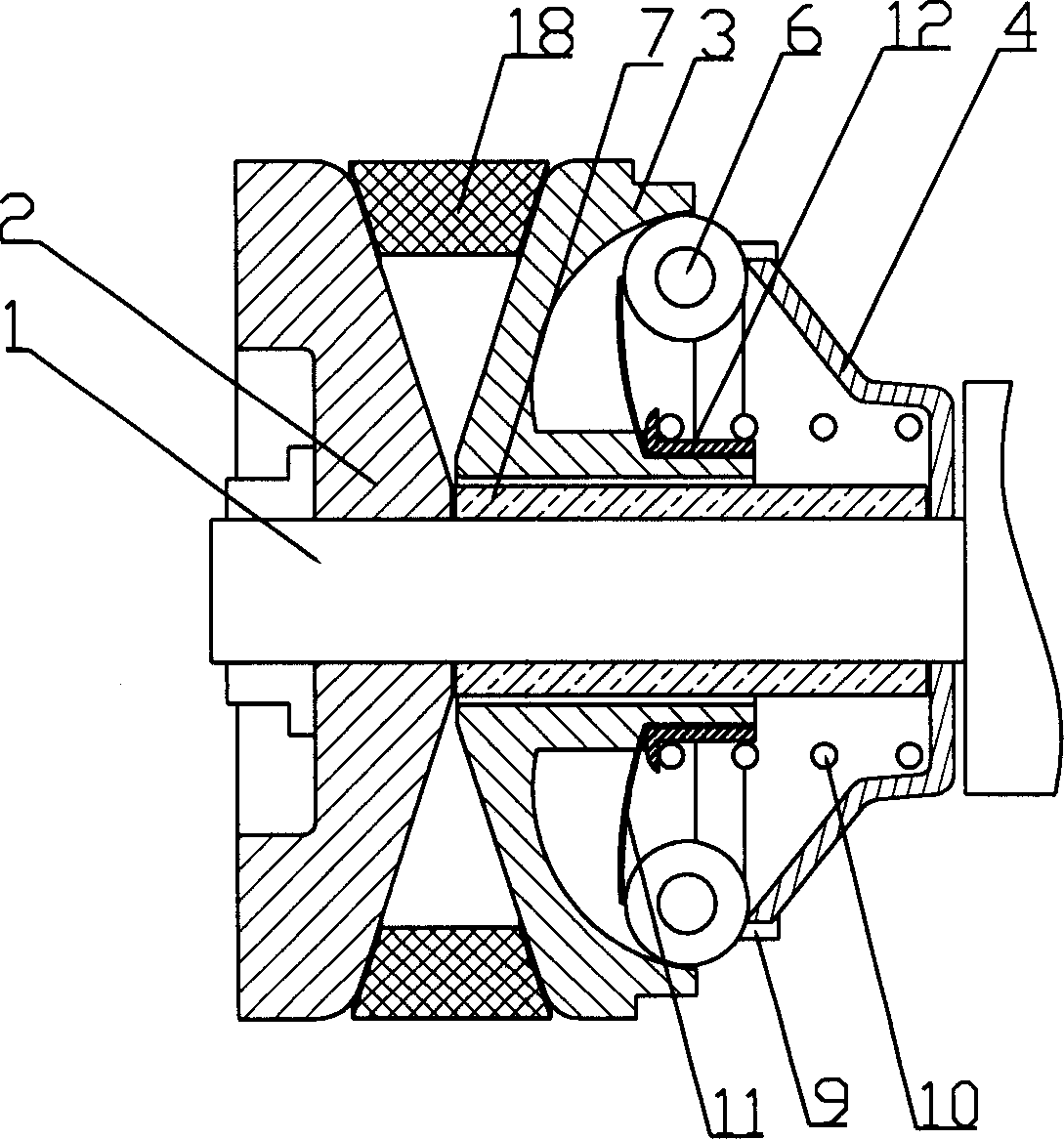

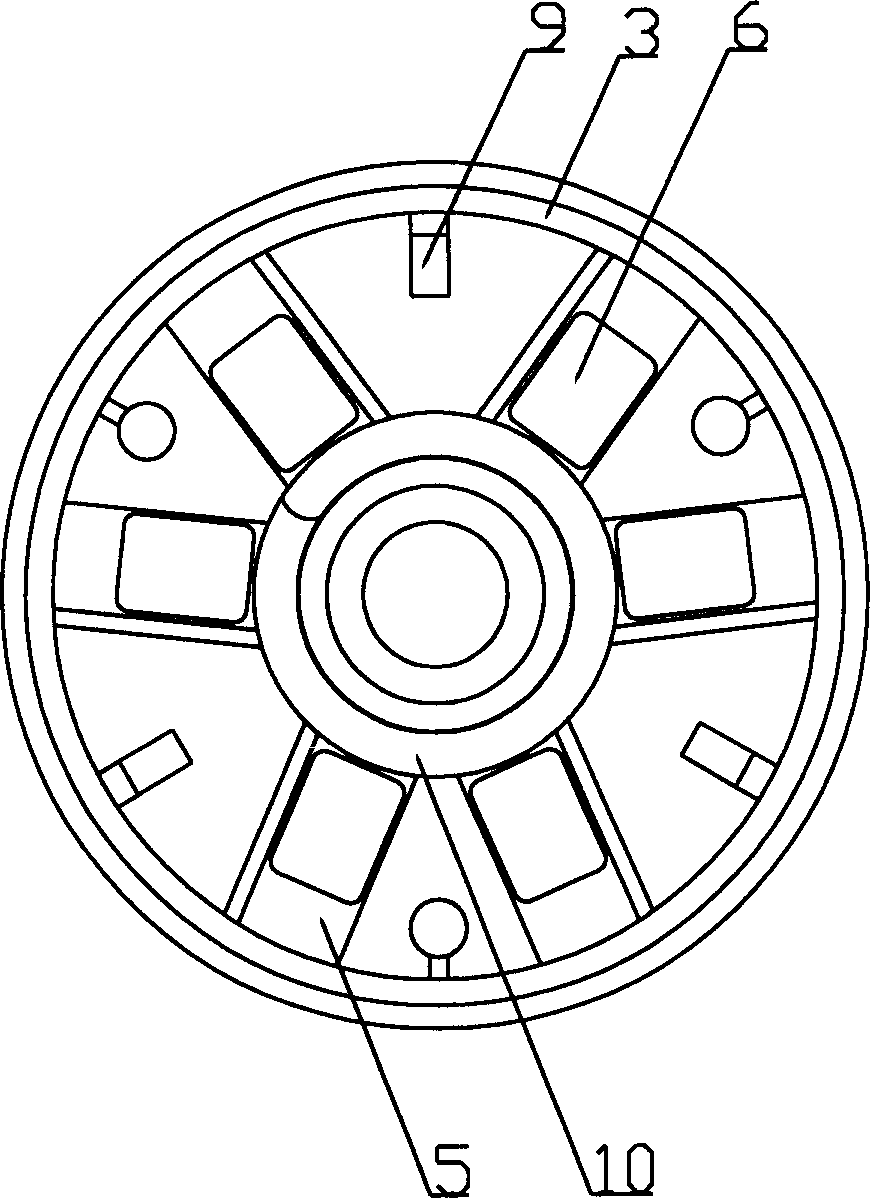

[0025] figure 1 , figure 2 , image 3 , Pic 4-1 , Figure 4-2 Example 1 of the present invention is given. The continuously variable transmission driving wheel of the motorcycle of the present embodiment comprises: an engine main shaft 1, which is provided with a fixed wheel 2, a moving wheel 3 and a slope plate 4, and a belt 18 is provided between the fixed wheel and the moving wheel. The moving wheel is provided with a centrifugal roller groove 5 and a centrifugal roller 6, and the moving wheel 3 can move axially on the sliding sleeve 7 of the engine main shaft. The fixed wheel 2, the moving wheel 3, the ramp plate 4 and the engine main shaft 1 rotate synchronously; the ramp plate 4 is provided with a driving groove 8, and the moving wheel is provided with a driving guide post 9 corresponding to the driving groove. Stage clip 10 is provided between moving wheel and ramp plate. An elastic dial 11 is arranged in the centrifugal roller channel. Stage clip is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com