Elliptic annular foaming line for automotive soundproofing mat

A technology for automotive sound insulation pads and foaming lines, which can be applied to coatings and other directions, can solve the problems of high labor intensity and low production efficiency, and achieve the effects of high degree of automation, improved efficiency and good overall strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific embodiments and drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

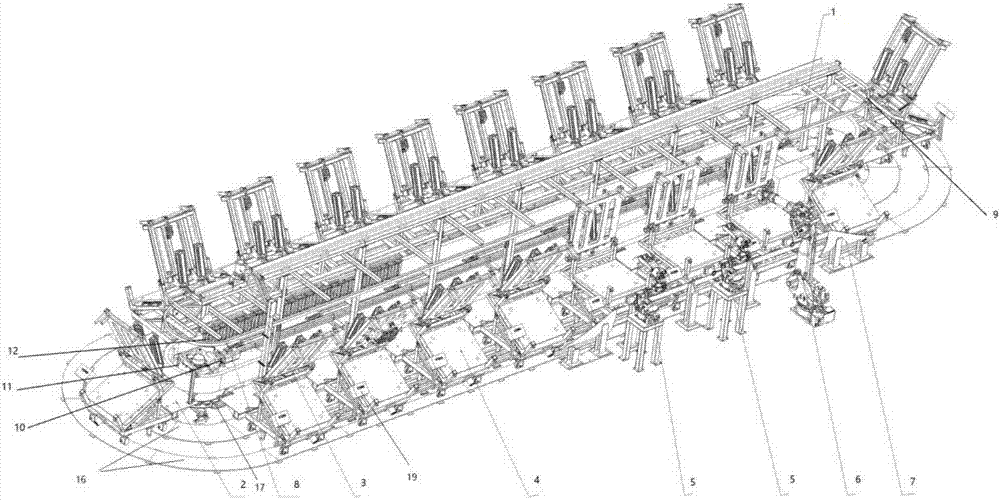

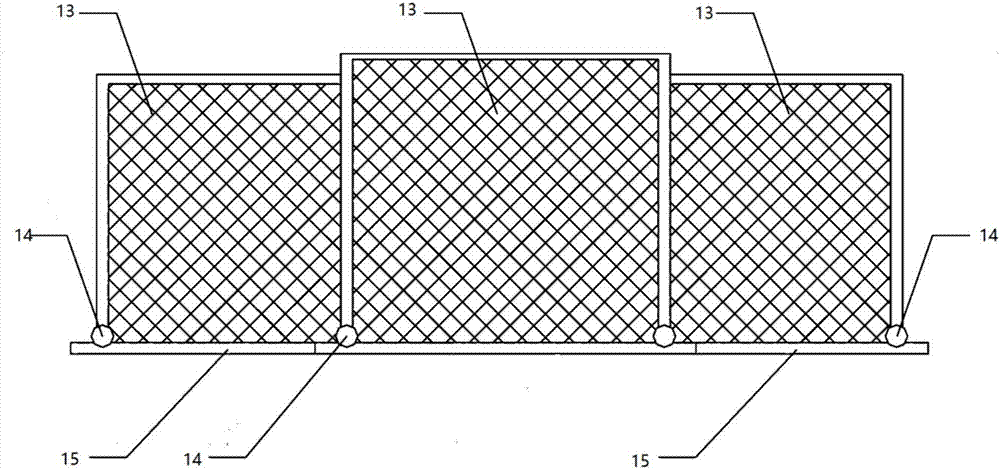

[0020] Such as figure 1 , 2 As shown, an elliptical annular foaming line for automobile sound insulation pads includes an annular wire body 1, a fixture traction trolley 2, an automatic fixture air connection device 3, a foam fixture trolley 4, a spraying release agent and an in-mold paint robot 5, Filling robot 6, lifting guide rail 7, movable protective net 13 under the mold base; the ring-shaped wire body 1 includes an elliptical support 9, a reduction motor 10, a driving sprocket 11, and a chain 12; the chain 12 drives the fixture to pull The trolley 2 is connected to the foam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com