Manufacturing method for high-precision cold-drawn inner-hole honed pipe

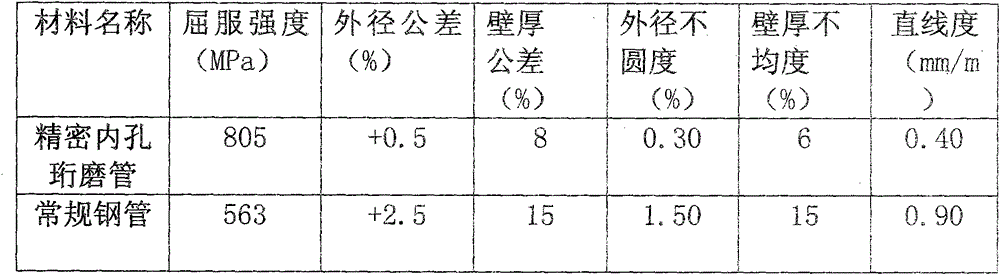

A manufacturing method and high-precision technology, applied in the field of steel pipe preparation, can solve the problems of dependence on imports of seamless steel pipes, restricting the development of cold-drawn steel pipes, yield strength, and dimensional deviation can not meet the requirements of use, etc., and achieve high rotational deformation resistance and wear resistance. good performance, low temperature impact toughness and good oil storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Taking the preparation of a 27SiMn steel pipe with a diameter of 159.3mm and a hole wall thickness of 6.3mm as an example, the following steps are included:

[0021] (1) Heating: Heat the 27SiMn tube blank to 1300°C in a ring furnace for 4 hours to ensure uniform heating of the tube blank;

[0022] (2) Perforation: The heat pipe blank is pierced by a piercer, and the temperature of the capillary tube formed after the piercing is controlled at 1250°C, and the perforation eccentricity is controlled at 4%. The tube blank is visually inspected to remove the burrs on the surface of the tube blank, Warped skin, if there are obvious pits, scratches and cracks that are visible to the naked eye on the surface of the tube blank, they should be removed to avoid flowing into the next process to control the surface quality of the tube blank;

[0023] (3) Annealing: introduce the tube blank into a continuous annealing furnace for annealing, and control the annealing temperature to 60...

Embodiment 2

[0037] Taking the preparation of a 27SiMn steel pipe with a diameter of 139.9mm and a hole wall thickness of 7.9mm as an example, the following steps are included:

[0038] (1) Heating: Heat the 27SiMn tube blank to 1380°C in a ring furnace for 5 hours to ensure uniform heating of the tube blank;

[0039] (2) Perforation: The heat pipe blank is pierced by a piercer, and the temperature of the capillary tube formed after perforation is controlled at 1350°C, and the perforation eccentricity is controlled at 5%. The tube blank is visually inspected to remove burrs, Warped skin, if there are obvious pits, scratches and cracks that are visible to the naked eye on the surface of the tube blank, they should be removed to avoid flowing into the next process to control the surface quality of the tube blank;

[0040] (3) Annealing: introduce the tube blank into a continuous annealing furnace for annealing, and control the annealing temperature to 700°C, and the annealing time to 90min, ...

Embodiment 3

[0051] Taking the preparation of a 27SiMn steel pipe with a diameter of 140.4mm and a hole wall thickness of 8.3mm as an example, the following steps are included:

[0052] (1) Heating: Heat the 27SiMn tube billet to 1350°C in a ring furnace for 4.5 hours to ensure uniform heating of the tube billet;

[0053] (2) Perforation: The heat pipe blank is pierced by a piercer, and the temperature of the capillary tube formed after perforation is controlled at 1300°C, and the perforation eccentricity rate is controlled at 4.5%. The tube blank is visually inspected to remove the burrs on the surface of the tube blank, Warped skin, if there are obvious pits, scratches and cracks that are visible to the naked eye on the surface of the tube blank, they should be removed to avoid flowing into the next process to control the surface quality of the tube blank;

[0054] (3) Annealing: introduce the tube blank into a continuous annealing furnace for annealing, and control the annealing tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com