Patents

Literature

33results about How to "Good oil storage performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

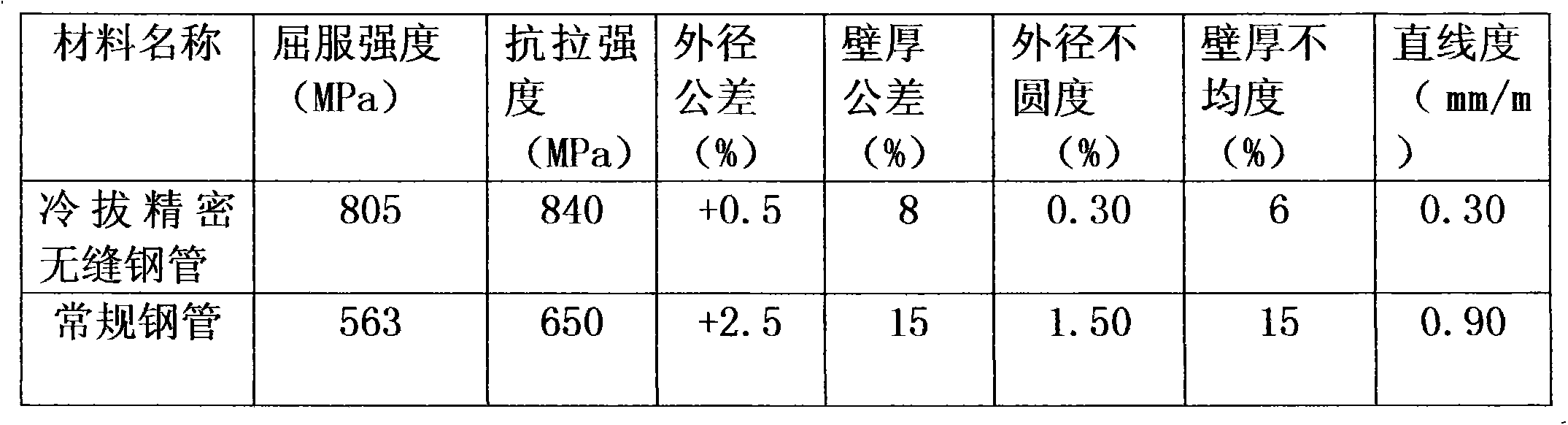

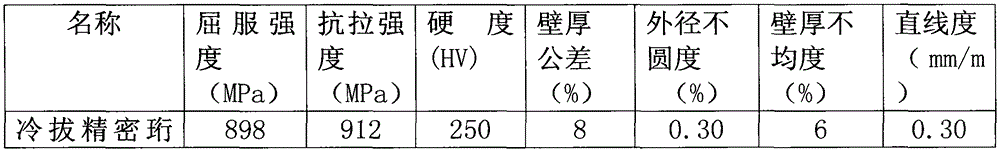

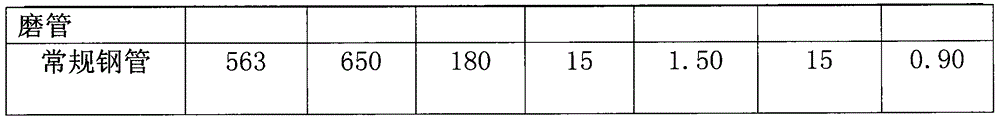

Production method of cold-drawn precision seamless steel pipes

InactiveCN104338777AImprove performanceImprove low temperature impact toughnessAcid washingLubrication

The invention relates to a production method of cold-drawn precision seamless steel pipes. The production method comprises the steps of: heating: pipe blanks are heated in an annular furnace; perforation: the heat pipe blanks are perforated by a perforation machine; annealing: the pipe blanks are annealed; cold rolling: the annealed pipe blanks are leaded into a pipe rolling machine for cold rolling to obtain rolled pipes; stress relieving: the rolled pipes are leaded into a heating furnace for heating to obtain annealed pipe blanks; acid washing treatment: the acid washing is performed for the annealed pipe blanks to remove scales on the surfaces; phosphating treatment: zinc phosphate chemical generation films are formed on the surfaces of the pipe blanks; saponification treatment: such lubrication films as metallic soaps are formed on the films; cold drawing: the cold drawing is performed for the pipe blanks to be cold drawn to obtain cold-drawn pipes; normalization air-cooling treatment; first straightening treatment; induction furnace quenching treatment; box furnace tempering treatment; honing; thermal straightening treatment; and obtaining of the cold-drawn precision seamless steel pipes. The production method obtains the cold-drawn precision seamless steel pipes with high yield strength, high tensile strength, precise sizes and smooth surfaces.

Owner:WUXI DAJIN HIGH PRECISION COLD DRAWN STEEL TUBE

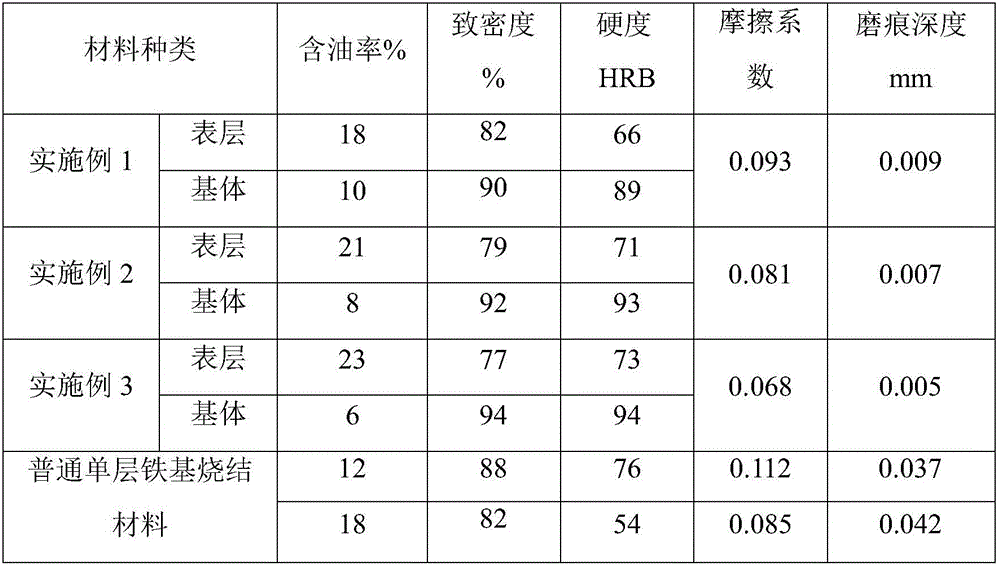

High-strength antifriction double-layered iron base powder metallurgy material and preparation method thereof

ActiveCN106041099AImprove carrying capacitySpeed up the flowTransportation and packagingMetal-working apparatusSurface layerHardness

The invention discloses a high-strength antifriction double-layered iron base powder metallurgy material and a preparation method thereof. The preparation method comprises the following steps that a densification enhancer is mixed in a matrix, so that a matrix material is dense and high in strength; a compound pore-forming agent is mixed in a surface layer to enable a surface layer material to be porous and oil-bearing, and besides, the requirements on the hardness and the wear resistance of the surface layer are met, and the contact interface and the lubricating condition of a friction pair are kept stable, so that the novel high-strength antifriction double-layered iron base powder metallurgy material is prepared. The bearing property, the wear resistance and the antifriction anti-seizing property of the iron base powder metallurgy material are improved remarkably, and high strength and a high lubricating property are effectively combined.

Owner:HEFEI UNIV OF TECH

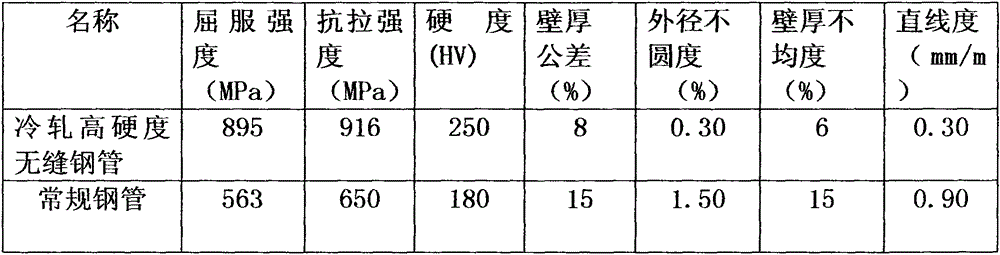

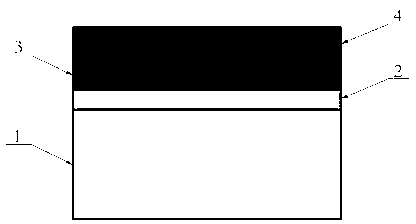

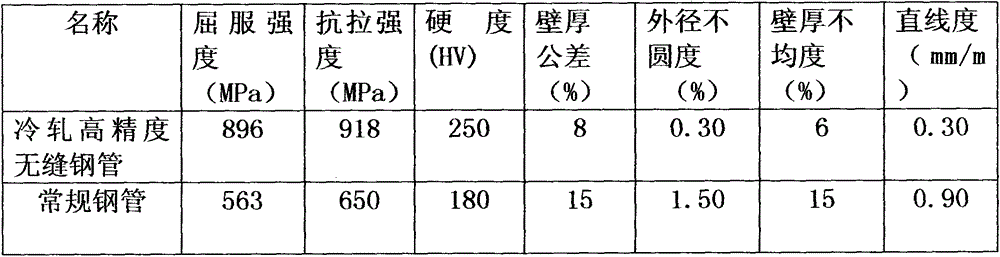

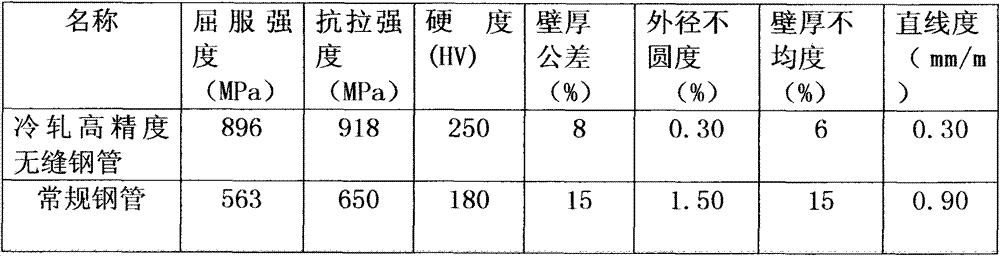

Cold-rolled high-hardness seamless steel pipe manufacturing method

InactiveCN104551667AExtended service lifeImprove wear resistanceOther manufacturing equipments/toolsZinc phosphateAcid washing

The invention relates to a cold-rolled high-hardness seamless steel pipe manufacturing method. The manufacturing method includes the steps of heating a pipe billet in a circular furnace; punching the heated pipe billet by a puncher; annealing the pipe billet; spraying borax to descale; placing the annealed pipe billet in a pipe mill for hot rolling; performing pipe separation by separating a hot-rolled pipe from a mandrel; performing stress relief annealing, namely, heating the hot-rolled pipe in the heating furnace to obtain the annealed pipe billet; performing acid washing treatment to remove rust scale on the surface; phosphating to enable the surface to form a zinc phosphate chemical film; performing saponification treatment to form a metallic soap lubricating film and the like; performing cold rolling on the obtained pipe billet to be subjected to cold rolling to obtain a cold-rolled pipe; performing heat treatment to reduce residual stress; performing pre-straightening treatment to reduce residual stress; performing induction furnace quenching treatment; tempering in a box-type furnace; honing; performing hot straightening to obtain a high-precision steel pipe. The steel pipe obtained by the method is high in hardness and precise in size.

Owner:WUXI JIANGNAN HIGH PRECISION COLD DRAWN PIPE

Fuel-saving type Cr-O-N nanocrystalline composite ceramic coated piston ring of diesel engine and preparation method thereof

InactiveCN103256142AHigh hardnessImprove oil storage capacityPiston ringsVacuum evaporation coatingPiston ringComposite ceramic

The invention discloses a fuel-saving Cr-O-N nanocrystalline composite ceramic coated piston ring of a diesel engine and a preparation method of the fuel-saving Cr-O-N nanocrystalline composite ceramic coated piston ring of the diesel engine. The nanocrystalline composite ceramic coated piston ring which is composed of Cr, CrN and a Cr-O-N nanometer crystal layer in sequence is generated by means of the technology of arc ion plating. The fuel-saving type Cr-O-N nanocrystalline composite ceramic coated piston ring of the diesel engine and the preparation method of the fuel-saving Cr-O-N nanocrystalline composite ceramic coated piston ring are reasonable in structural design and achieve gradual change of components and the hardness gradient. In addition, the prepared Cr-O-N nanocrystalline composite ceramic coating layer and the piston ring have the advantages that good binding force, good wear-resistant property and corrosion-resistent property are provided, higher oil storage capability and hardness are provided, the defects that existing piston rings are poor in wear-resistant property and insufficient in oil storage capacity are overcome, long-term stable work of the piston ring is ensured, and the using performance of the piston ring is enabled to be greatly improved. Moreover, the fuel-saving type Cr-O-N nanocrystalline composite ceramic coated piston ring of the diesel engine has the advantages of being stable in quality in the process of coating, high in processing efficiency, and capable of reducing production cost of factories and having good industrial application prospect.

Owner:WUHAN UNIV

Production method of cold-drawn high-precision seamless steel tube

InactiveCN104551669AImprove performanceImprove low temperature impact toughnessOther manufacturing equipments/toolsMetal rolling arrangementsZinc phosphateStress relieving

The invention relates to a production method of a cold-drawn high-precision seamless steel tube. The production method includes heating a tube blank in a circular furnace; punching a heat tube by the aid of a puncher; subjecting the tube blank to annealing; spraying the tube blank with sodium borate to remove oxide skin; leading the annealed tube blank into a tube mill for hot milling; tensioning the milled tube after tandem milling by a tensioning machine for sizing; performing stress relieving, to be specific, heating the milled tube in a heating furnace to obtain an annealed tube blank; performing acid dipping on the tube blank to remove scale of the surface; subjecting the tube blank to parkerizing, and accordingly a chemical coating of zinc phosphate is generated on the surface of the tube blank; performing saponification to form lubricating coatings such as metallic soap; subjecting the tube blank to be cold drawn to cold drawing, and the cold-drawn tube is achieved; heating the cold-drawn tube to decrease residual stress; pre-straightening the cold-drawn tube to further decrease the residual stress; quenching the cold-drawn tube in an induction furnace; tempering the cold-drawn tube in a box-type furnace; honing the cold-drawn tube; subjecting the cold-drawn tube to heat straightening. In this way, the high-precision steel tube is obtained and high in yield strength and precise in size.

Owner:WUXI JIANGNAN HIGH PRECISION COLD DRAWN PIPE

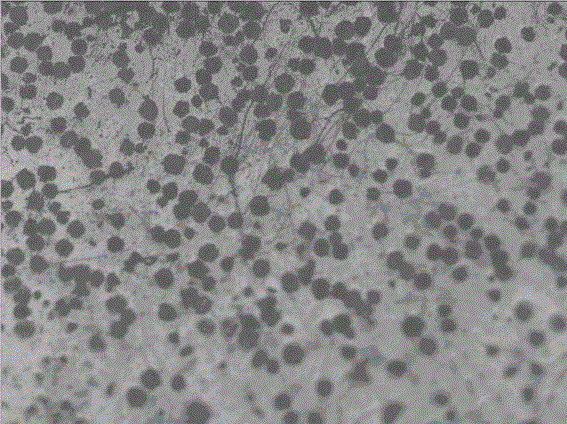

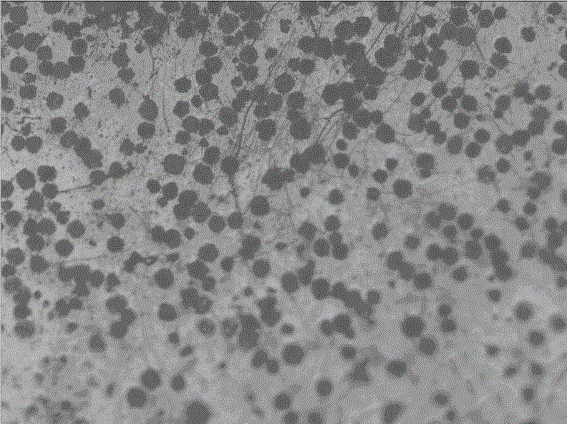

Piebald cylinder sleeve for centrifugal casting production and production technology of piebald cylinder sleeve

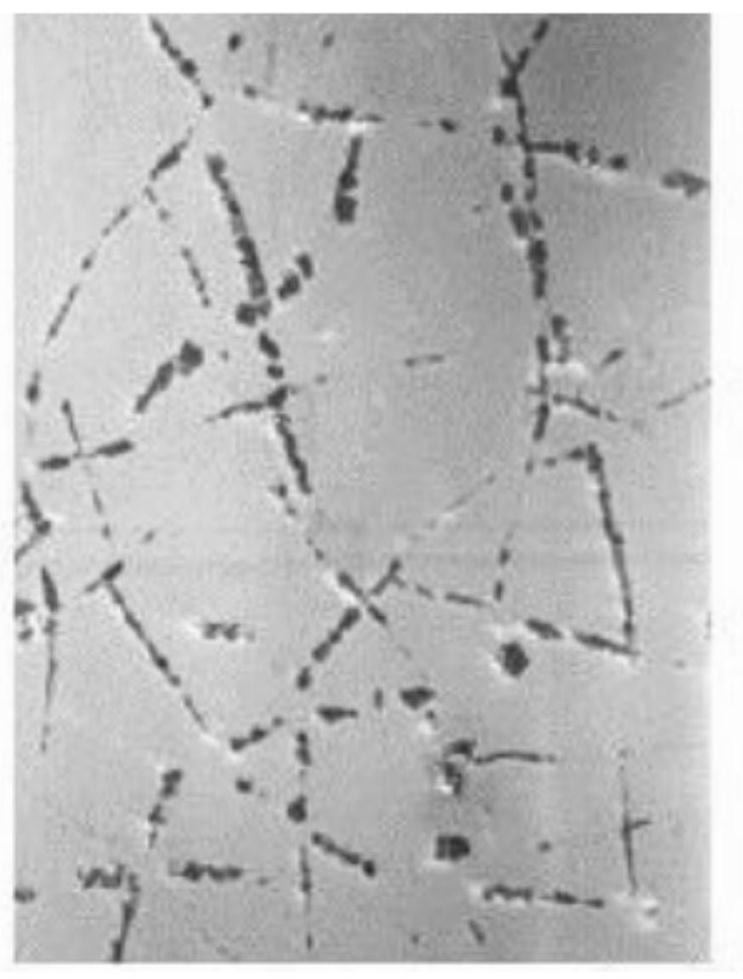

ActiveCN105369116AGood anti-friction performanceOvercome poor oil storageFurnace typesHeat treatment furnacesPearlitePiston

The invention discloses a piebald cylinder sleeve for centrifugal casting production and a production technology of the piebald cylinder sleeve. The piebald cylinder sleeve comprises, by weight percent, 3.5-3.9% of C, 2.6-3.0% of Si, smaller than 0.02% of P, 0.7-0.9% of Cu, 0.2-0.4% of Ni, 0.04-0.08% of Bi, 0.1-0.3% of Nb, 0.03-0.06% of Mg, 0.02-0.04% of Ce and the balance Fe. According to the high-performance spheroidal graphite cast iron cylinder sleeve, the amount of spheroidal graphite (the field diameter is 70 mm) is not smaller than 200, and the matrix structure is granular pearlite. Compared with the prior art, after finish grinding and polishing processes are sequentially conducted on inner holes of the cylinder sleeve obtained through the formula and the production technology, piebald-similar surface graphite and a WS2 alloy layer are formed on the surface layer, thus, honing of net stripes is not needed for the inner holes of the cylinder sleeve, oil storage performance, the lubricating property and the abrasion reducing performance are better, and the defects that a gray cast iron cylinder sleeve is poor in oil storage performance, long in run-in period with a piston, low in strength and poor in plasticity are overcome.

Owner:ZYNP GRP

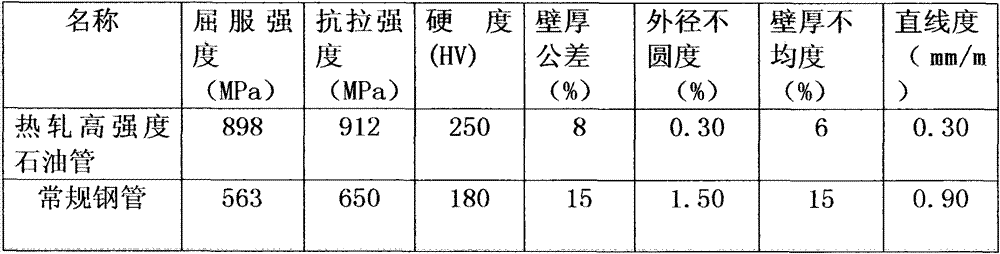

Hot-rolled high-strength oil pipe manufacturing method

The invention relates to a hot-rolled high-strength oil pipe manufacturing method, which comprises the following steps: heating: heating a pipe blank in an annular furnace; punching: punching holes in the heated pipe blank through a puncher; annealing: annealing the pipe blank; spraying borax; removing oxide skin; hot-rolling: feeding the annealed pipe into a pipe mill for hot-rolling; separating the pipe: separating the rolled pipe from a core rod; removing stress and annealing: feeding the rolled pipe into the heating furnace for heating, so as to obtain the annealed pipe blank; pickling: removing rust scale on the surface; phosphating: forming a zinc phosphate chemically-generated covering membrane on the surface; saponifying: forming metal soap and lubrication covering membranes: cold-drawing: cold-drawing the pipe blank to be cold-drawn, so as to obtain a cold-drawn pipe; performing heat treatment: reducing residual stress; honing; and performing hot straightening treatment, so as to obtain a cold-drawn precise inner-hole honed pipe, wherein a numerically-controlled honing machine is adopted in honing. The cold-drawn precise inner hole-honed pipe obtained through the method is good in comprehensive performance, good in low-temperature impact toughness, precise in dimension, smooth in surface, and excellent oil storage property.

Owner:WUXI OULONG SPECIAL STEEL PIPE

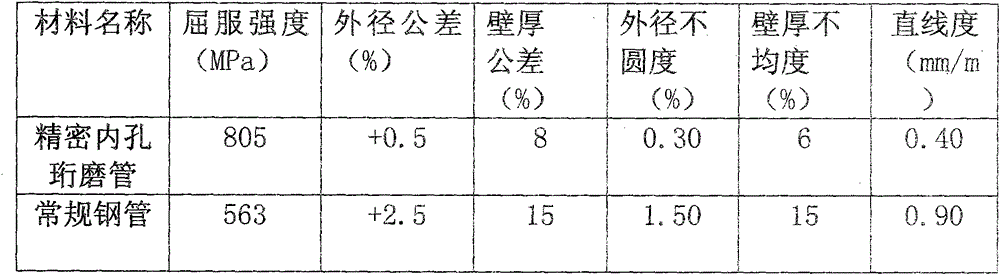

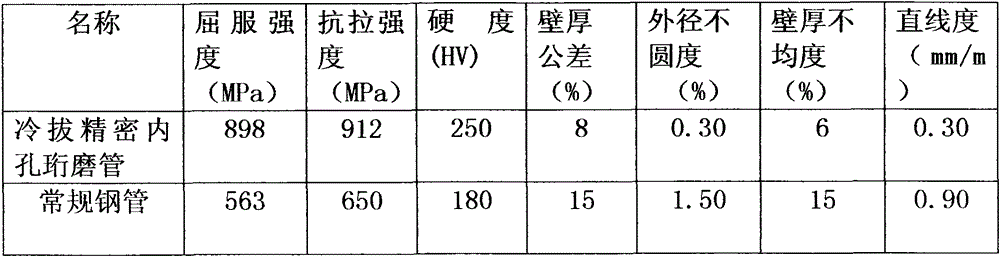

Manufacturing method for high-precision cold-drawn inner-hole honed pipe

InactiveCN105880934AImprove performanceImprove low temperature impact toughnessZinc phosphateStress relief

The invention relates to a manufacturing method for a high-precision cold-drawn inner-hole honed pipe. The manufacturing method includes the following steps of heating, i.e., heating a tube blank in a circular furnace; perforation, i.e., perforating the hot tube blank through a perforating machine; annealing, i.e., annealing the tube blank; cold rolling, i.e., leading the annealed tube blank into a tube rolling mill for cold rolling to obtain a rolled tube; stress relief annealing, i.e., leading the rolled tube into a heating furnace for heating to obtain an annealed tube blank; acid pickling, i.e., carrying out acid pickling on the annealed tube blank to remove rust scale on the surface; phosphating, i.e., forming a chemically-generated zinc phosphate covering film on the surface of the tube blank; saponification, i.e., forming metallic soap and the like on the covering film to lubricate the covering film; cold drawing, i.e., carrying out cold drawing on the tube blank to be cold-drawn to obtain a cold-drawn tube; heat treatment, i.e., reducing residual stress of the cold-drawn tube through the quenching-tempering heat treatment process; honing, i.e., carrying out honing with a numerically controlled honing machine; and hot straightening treatment, i.e., carrying out hot straightening treatment to obtain a high-precision cold-drawn steel tube. The precision inner-hole honed tube which is high in yield strength, precise in dimension and smooth in surface is obtained by means of the method.

Owner:WUXI SHENLU HYDRAULIC PARTS

Novel technology for producing fluorine-free chromium-based composite ceramic material coating

InactiveCN102418134AWeak elasticityReduce toughnessElectrolytic coatingsOil retentionComposite ceramic

The invention discloses a novel method for producing a fluorine-free chromium-based composite ceramic material coating. The coating comprises components of: 150-350g / l of chromic anhydride, 1.5-3.5g / l of sulfuric acid, 3-8ml / l of an FHD additive, and 2-10g / l of trivalent chromium. The production method comprises steps that: a chromium layer is pre-deposited for 10-40min on the surface of a workpiece; an electrode is switched, such that the mesh of the chromium layer is deepened and thickened; ceramic powder is filled in the mesh slits; the electrode is switched again, chromium is electrically deposited on the surface of the workpiece, such that the mesh is sealed, and the ceramic powder is fixed, until the thickness of the coating satisfies the technological requirements of products. Finally, a chromium-based composite ceramic coating with a ceramic powder content of 1-6Wt%, and properties such as excellent oil retention property, excellent lubricity, excellent wear resistance, excellent corrosion resistance, excellent oxidation resistance, and excellent thermal shock resistance can be obtained. The composite ceramic coating can be widely applied in industries such as automobiles, national defense, aeronautics, astronautics, vehicles, ships, engineering machineries, steel, and the like.

Owner:苏晴 +1

Preparation method of high efficient oil storage type oil absorbent felt material

InactiveCN110124621AEasy to manufactureImprove oil storage capacityOther chemical processesNon-miscible liquid separationOysterResin-Based Composite

The invention discloses a preparation method of a high efficient oil storage type oil absorbent felt material, and belongs to the field of oil pollution treatment. Oyster mushroom bran is processed byplasma to increase the content of polar groups on the surface so as to improve the lipophilic property and oil adsorption performance; methyl methacrylate and butyl acrylate are used to prepare composite resin, which can increase the oil absorption amount and has good mechanical stability and lipophilic-hydrophobic properties; processed chitosan is added to enhance the oil absorbing performance of the oil absorbent felt material, moreover, chitosan has excellent thermal stability and a good solid-solid phase change performance; when the oil absorbent felt material is used in an environment with a large temperature difference, during the solid-solid phase change process, the chitosan can maintain a relatively stable volume in the oil absorbent felt material, and thus other components can well exert their functions. The problem that the oil absorbing performance and oil storage performance of a conventional oil absorbent felt are not good is solved.

Owner:陈文涛

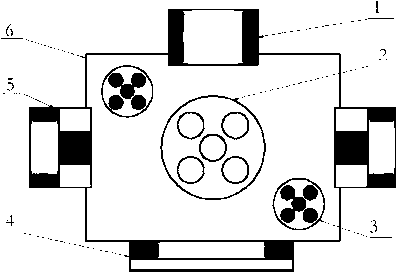

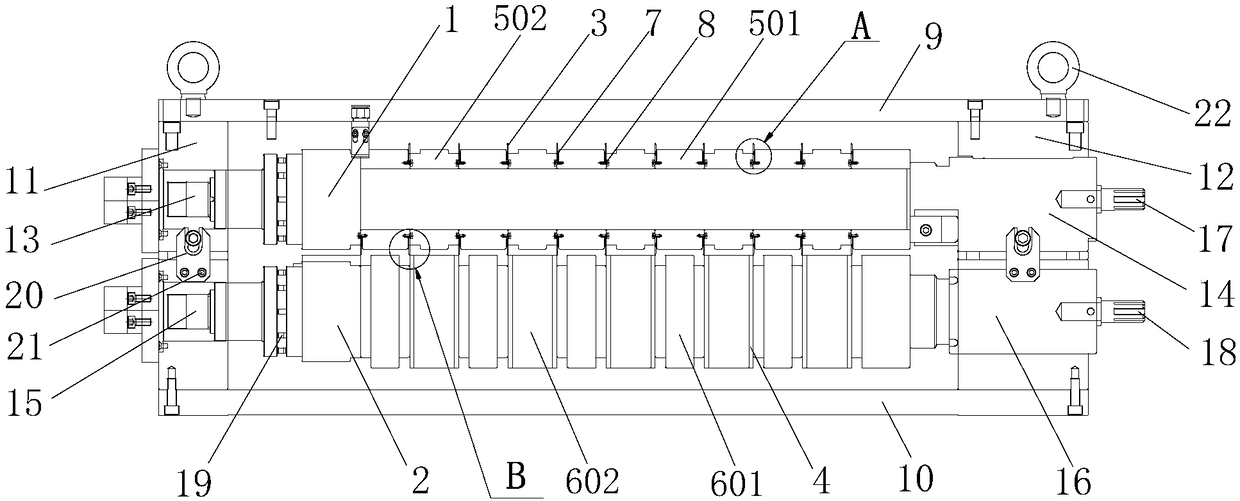

Electrode slice slitting device

InactiveCN108405962ARealize the goal of slitting operationHigh precisionShearing machinesMaintainance and safety accessoriesEngineeringKnife holder

The invention discloses an electrode slice slitting device. The slitting device comprises a frame, a first slitting mechanism, a second slitting mechanism, a connecting mechanism and an oil coating mechanism; multiple first cutters of the first slitting mechanism are arranged on a first cutter frame at intervals; first clamping sleeves are arranged between every two adjacent first cutters; secondcutters of the second slitting mechanism are arranged on a second cutter frame at intervals; second clamping sleeves are arranged between every two adjacent second cutters; the connecting mechanism isused for fixedly connecting the first slitting mechanism with the second slitting mechanism, so that edges of the first cutters are bonded with edges of the second cutters; a felt of the oil coatingmechanism is connected with a switch through an oil pipe; the switch is used for controlling an oil content on the felt; and the felt can lubricate and clean the first cutters and the second cutters.The slitting device is stable and reliable in structure, high in slitting precision, excellent in product consistency and long in service life of the cutters.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD +1

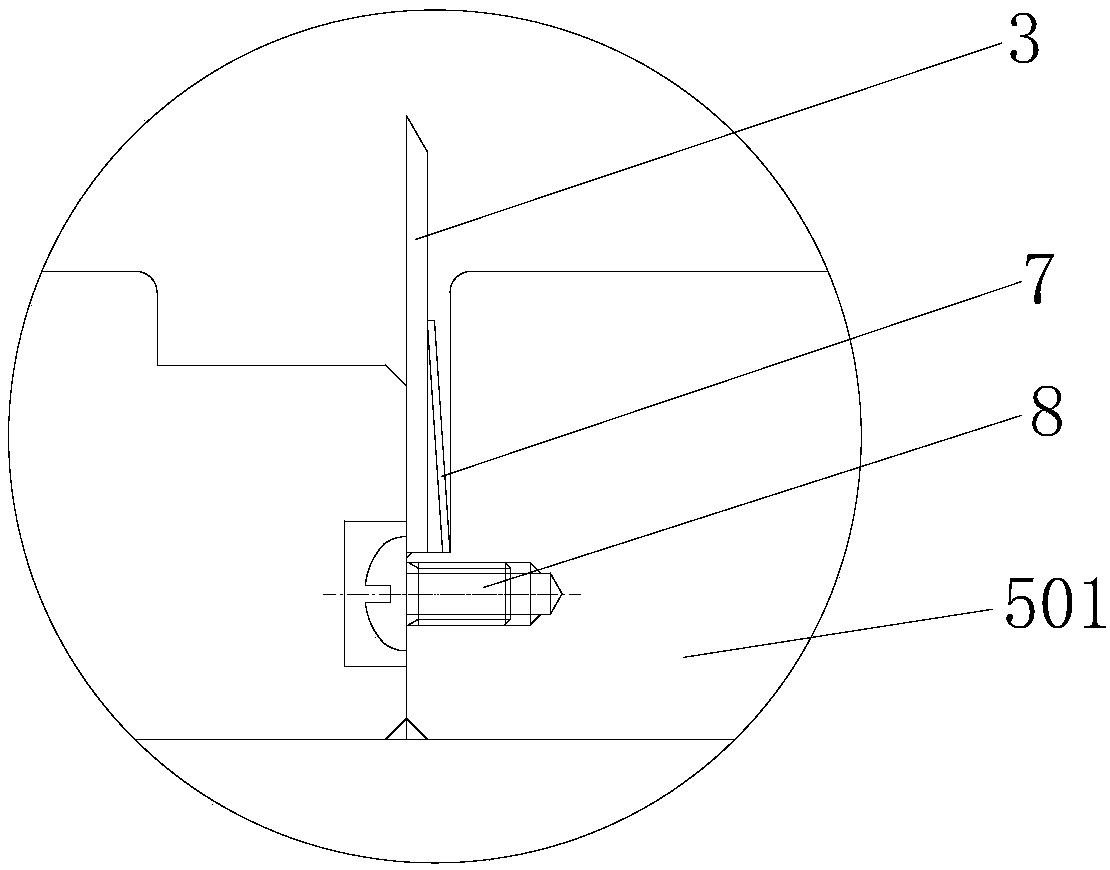

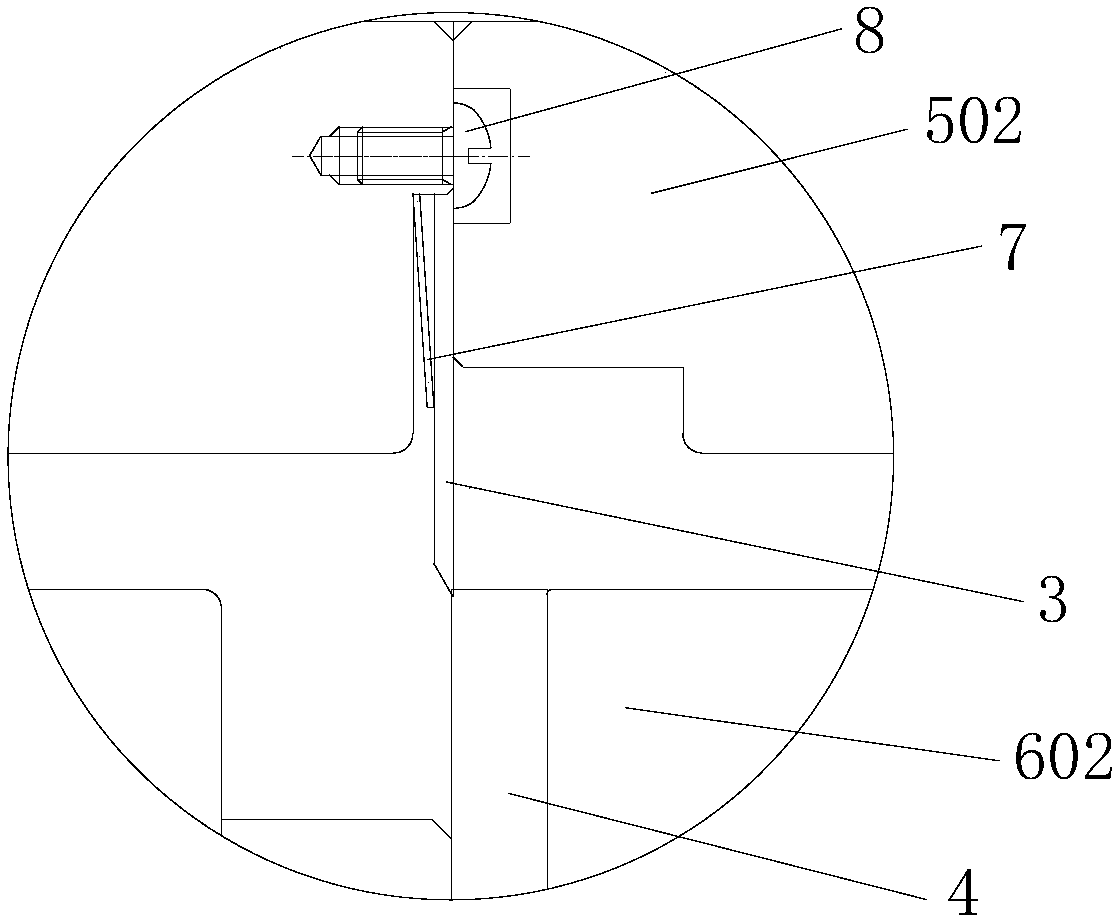

Cold drawing precision honing tube manufacture method

InactiveCN105880920AImprove performanceImprove low temperature impact toughnessNumerical controlZinc phosphate

The invention relates to a cold drawing precision honing tube manufacture method comprising the following steps: heating, heating a tube blank in an annular furnace; perforation, using a perforator to perforate the hot tube blank; annealing, annealing the tube blank; spraying borax, descaling; hot rolling, guiding the annealing tube into a tube grimper for hot rolling; detaching tube, detaching the rolled tube from a core rod; stress relieving, guiding the rolled tube into the heating furnace so as to obtain an annealing tube blank; pickling processing, removing surface rust scale; phosphatization processing, forming a zinc phosphate chemical generation overlay film on the surface; saponification processing, forming a metallic soap lubrication overlay film; primary cold drawing, cold drawing a to-be-cold drawn tube blank; secondary cold drawing, secondarily cold drawing the cold drawing tube after the primary cold drawing, thus obtaining a cold drawn tube; heat treatment, reducing residual stress; honing, using a numerical control honing machine; hot straightening processing; obtaining the cold drawing precision honing tube. The cold drawing precision honing tube obtained by the method is good in integration performance, precise in sizes, and excellent in oil storage performance.

Owner:WUXI SHENLU HYDRAULIC PARTS

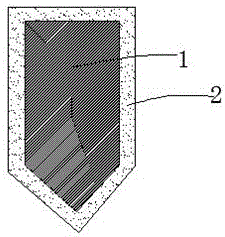

Valve guide pipe coated with ion nitriding layer

InactiveCN106121761AReasonable structureIncrease profitMachines/enginesLift valveManganeseTemperature resistance

The invention discloses a valve guide pipe coated with an ion nitriding layer. The valve guide pipe comprises an iron-based powder matrix and the ion nitriding layer, wherein the iron-based powder matrix comprises cobalt, nickel, manganese disulfide, phosphorus, sulfur, iron and other matter; and the iron-based powder matrix is coated with the ion nitriding layer. The iron-based powder matrix is prepared through powder metallurgy pressing and sintering, the sintering temperature is low, and the utilization rate of materials is high. The cobalt, the nickel, the manganese disulfide, the phosphorus and the sulfur contained in the iron-based powder matrix achieve the good oil storage effect and good self-lubrication performance. Meanwhile, the ion nitriding layer coating the iron-based powder matrix achieves the abrasion resistance and high temperature resistance, and prolongs the service life. More importantly, the valve guide pipe coated with the ion nitriding layer has the excellent performance and can meet the higher and higher requirements for engines on the market.

Owner:SUZHOU GENFU MACHINERY SCI & TECH

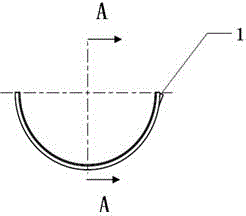

Mute holder of bearing

PendingCN107588103ASolve the problem of abnormal soundReduce use costBearing componentsEngineeringOil storage

The invention belongs to the technical field of bearings, relating to a mute holder of a bearing. The mute holder comprises a round holder body on which a plurality of isolation blocks are uniformly arranged, a pocket hole is formed between every two adjacent isolation blocks, the bottom surface of the pocket hole is a first cambered surface, the side surface of the pocket hole is a cylindrical surface, two sides of an upper end opening of the pocket hole are respectively provided with a fore shaft part, and a second cambered surface is formed on the inner side surface of the fore shaft part.By improving the design of the structure of the holder, the abnormal noise problem of the bearing is effectively solved, the bearing adopted by the bearing provided by the invention can be used for effectively replacing imported bearings, and the use cost of enterprises is reduced; meanwhile, the roller path guide manner and oil storage effect of the bearing are relatively greatly improved.

Owner:WUXI NO 2 BEARING

Manufacturing method of hot-rolled high-precision petroleum pipe

InactiveCN104759835AImprove performanceImprove low temperature impact toughnessAcid washingStress relief

The invention relates to a manufacturing method of a hot-rolled high-precision petroleum pipe. The manufacturing method comprises the following steps: heating: a pipe blank is heated in an annular furnace; perforation: the heated pipe blank is perforated by a perforator; annealing: the pipe blank is annealed; spraying of boron sand: oxide scales are removed; hot rolling: the annealed pipe blank is led into a pipe rolling machine for hot rolling; sizing: the rolled pipe formed by continuous rolling is sized by a sizing machine; stress relief annealing: the rolled pipe is led into a heating furnace for heating so that the annealed pipe blank is obtained; acid washing: rust scales on the surface are removed; parkerizing: a chemical coating film of zinc phosphate is formed on the surface; saponification: such lubricating coating films as a metallic soap are formed; cold rolling: the pipe blank to be cold rolled is cold rolled to obtain a cold-rolled pipe; heat treatment: residual stress is reduced; pre-straightening: the residual stress is reduced; quenching in an induction furnace; tempering in a chamber furnace; honing; hot straightening; and obtaining of the high-precision steel pipe. The method is used for manufacturing the high-precision steel pipe with high yield strength and size precision.

Owner:WUXI OULONG SPECIAL STEEL PIPE

Application technology of novel release agent in centrifugal casting of cylinder liner

InactiveCN102039367AImprove mechanical propertiesImprove the lubrication effectFoundry mouldsMoulding machinesFerrosiliconGraphite

The invention relates to an application technology of a novel release agent in the centrifugal casting of a cylinder liner. The release agent has the following material tissue components in percentage by weight: 70-80% of 200-mesh artificial graphite powder, 3-5% of 200-mesh aluminide, 1-3% of 220-mesh ferrosilicon powder, 4-8% of 200-mesh quartz powder and 2-4% of 75 Si powder.

Owner:韦加伟

Production method of cold-drawn precise-inner hole honed tube

InactiveCN104551539AImprove performanceImprove low temperature impact toughnessRigid pipesZinc phosphateStress relieving

The invention relates to a production method of a cold-drawn precise-inner hole honed tube. The production method includes heating a tube blank in a circular furnace; punching a heat tube by the aid of a puncher; subjecting the tube blank to annealing; spraying the tube blank with sodium borate to remove oxide skin; leading the annealed tube blank into a tube mill for hot milling; separating the milled tube and a mandrel; performing stress relieving, to be specific, leading the milled tube into a heating furnace to obtain an annealed tube blank; performing acid dipping on the tube blank to remove scale of the surface; subjecting the tube blank to parkerizing, and accordingly a chemical coating of zinc phosphate is generated on the surface of the tube blank; performing saponification to form lubricating coatings such as metallic soap; subjecting the tube blank to be cold drawn to cold drawing, and the cold-drawn tube is achieved; performing heating on the cold-drawn tube to decrease residual stress; adopting a CNC honing machine to hone the cold-drawn tube; subjecting the cold-drawn tube to heat straightening, and the cold-drawn precise-inner hole honed tube is achieved. The cold-drawn precise-inner hole honed tube made in the way is good in comprehensive performance and low-temperature impact toughness, has precise size and smooth surface and is good in oil storage effect.

Owner:WUXI JIANGNAN HIGH PRECISION COLD DRAWN PIPE

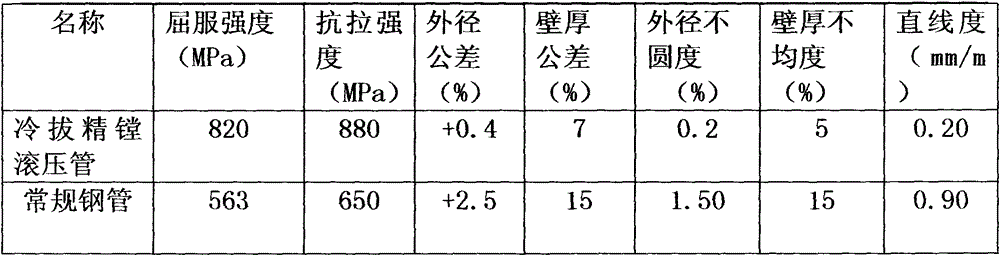

Production method of cold-drawn fine-bored rolled tube

InactiveCN104551668AHigh surface hardnessImprove surface strengthOther manufacturing equipments/toolsRigid pipesInduction furnaceSaponification

The invention relates to a production method of a cold-drawn fine-bored roller tube. The production method includes heating a tube blank in a circular furnace; punching a heat tube by the aid of a puncher; subjecting the tube blank to annealing; spraying the tube blank with sodium borate to remove oxide skin; leading the annealed tube blank into a tube mill for hot milling; tensioning the milled tube after tandem milling by a tensioning machine for sizing; performing stress relieving, to be specific, heating the milled tube in a heating furnace to obtain an annealed tube blank; performing acid dipping on the tube blank to remove scale of the surface; subjecting the tube blank to parkerizing, and accordingly a chemical coating of zinc phosphate is generated on the surface of the tube blank; performing saponification to form lubricating coatings such as metallic soap; subjecting the tube blank to be cold drawn to cold drawing, and the cold-drawn tube is achieved; performing normalizing air cooling; straightening the cold-drawn tube; quenching the cold-drawn tube in an induction furnace; tempering the cold-drawn tube in a box-type furnace; performing fine-boring rolling to obtain the cold-drawn fine-bored rolled tube. The cold-drawn fine-bored rolled tube made in the way is good in comprehensive performance and low-temperature impact toughness, has precise size and smooth surface and is good in oil storage effect.

Owner:WUXI JIANGNAN HIGH PRECISION COLD DRAWN PIPE

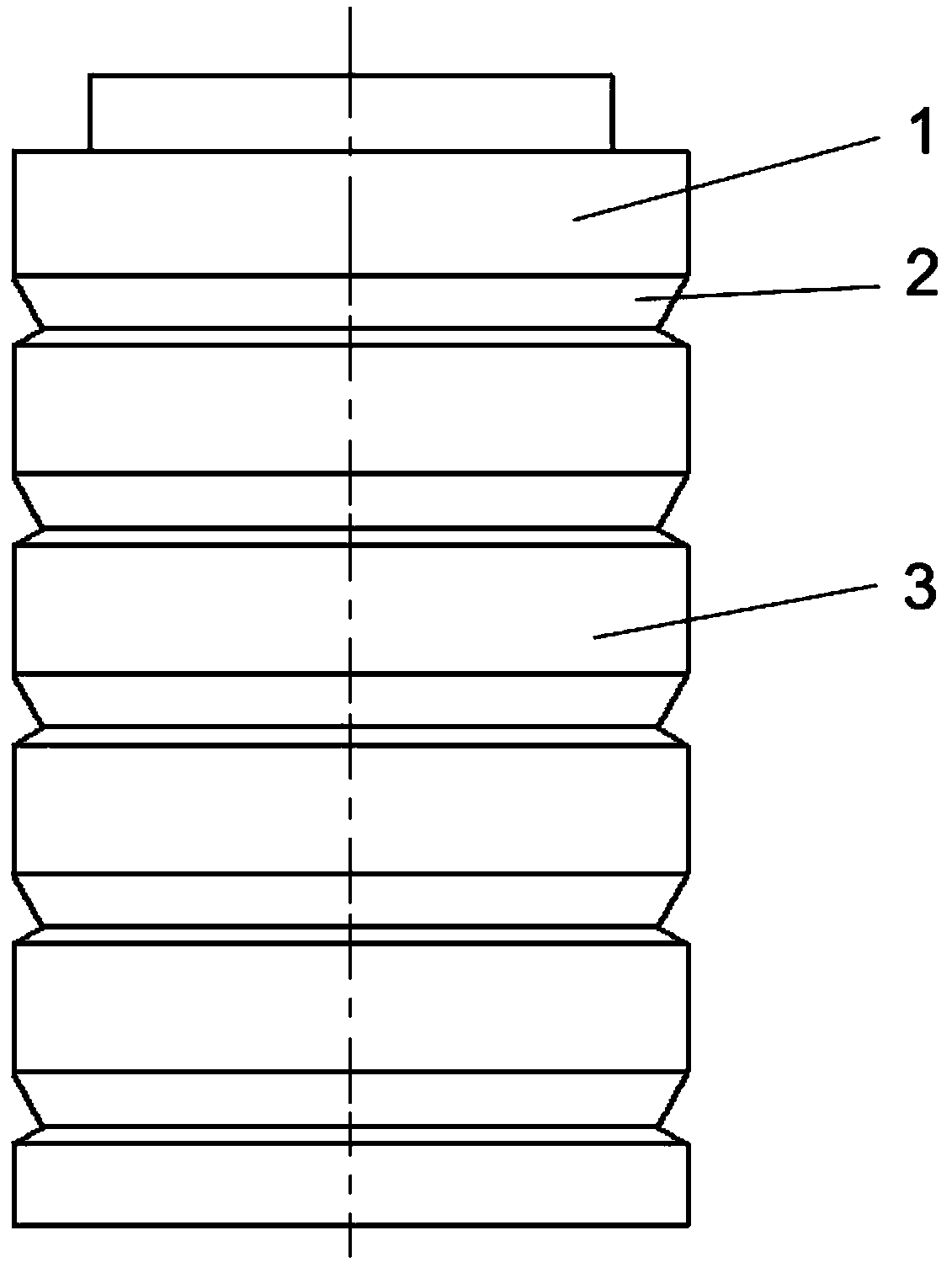

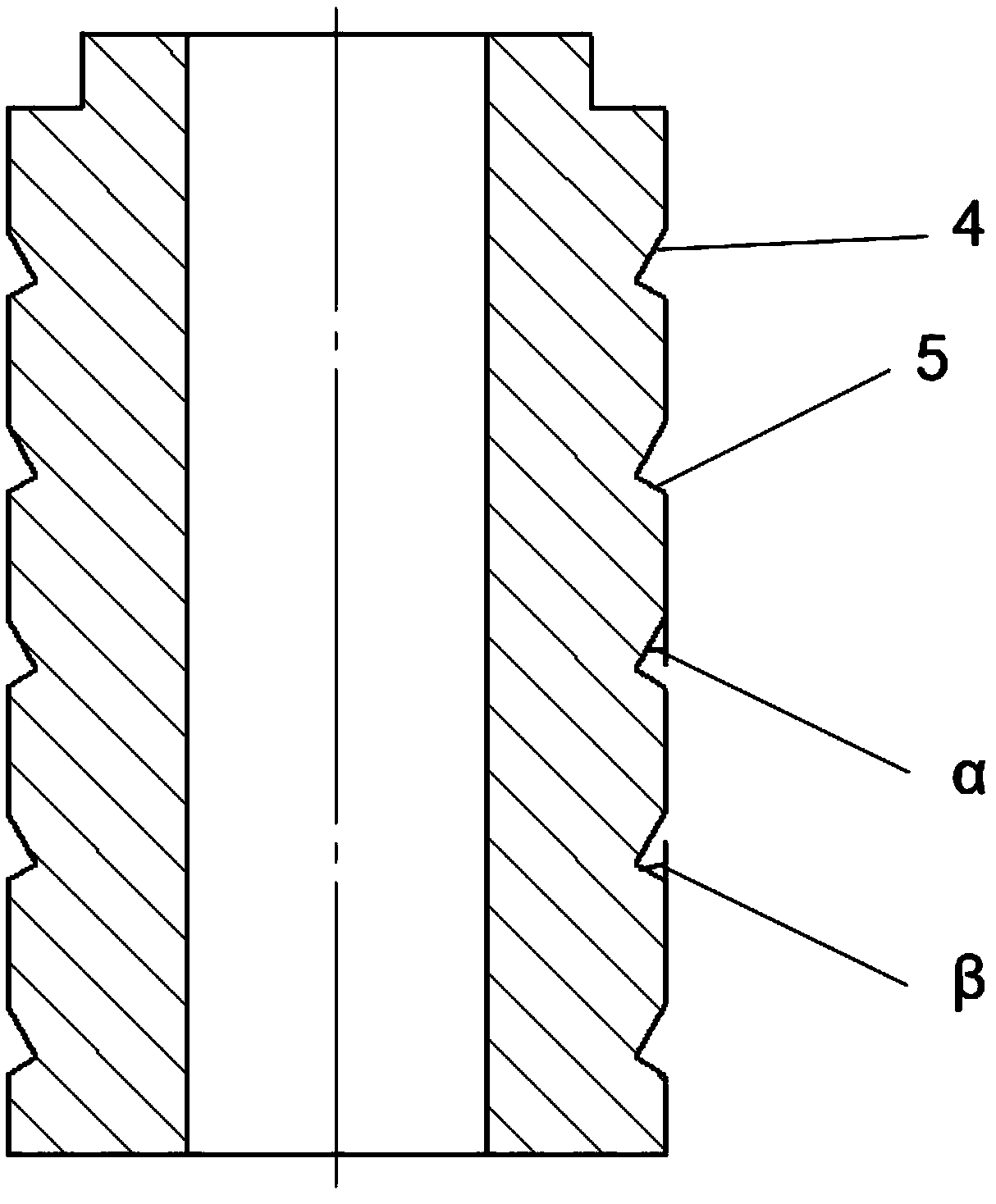

Asymmetric groove type sand storage wear-resistant oil well pump plunger

PendingCN109611327AReduce resistanceExtended duty cyclePositive displacement pump componentsLiquid fuel engine componentsWork periodWear resistant

The invention discloses an asymmetric groove type sand storage wear-resistant oil well pump plunger, belongs to the field of oil field oil production equipment. Annular grooves coaxial with a plungerbody are formed in the surface of the plunger body, and the annular grooves are arranged at equal intervals along the axial direction of the plunger body; and an axial inclination included angle between the upper wall surface of each annular groove and the plunger body is alpha, the axial inclination included angle between the lower wall surface of each annular groove and the plunger body is beta,wherein the alpha is larger than the beta. According to the plunger, the outer surface of the plunger body is arranged to be of an asymmetric groove structure, so that the oil storage capacity and the sand storage capacity of a plunger-pump cylinder ring space is improved, the resistance to reciprocating motion of the plunger in a pump cylinder is reduced, the working period of a plunger-pump cylinder is prolonged, the single well productivity is increased, and the single-well oil production cost is continuously reduced.

Owner:JILIN UNIV

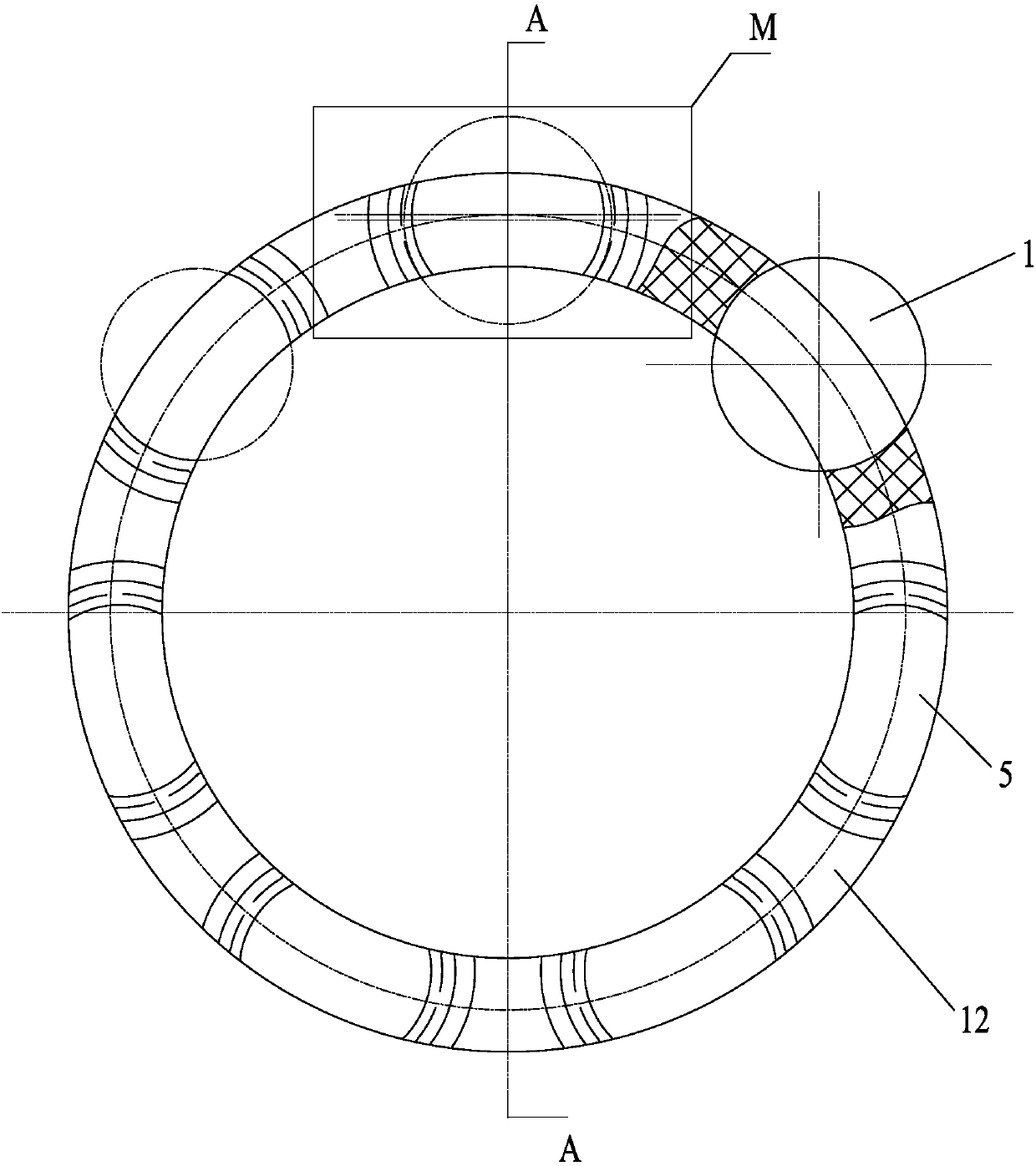

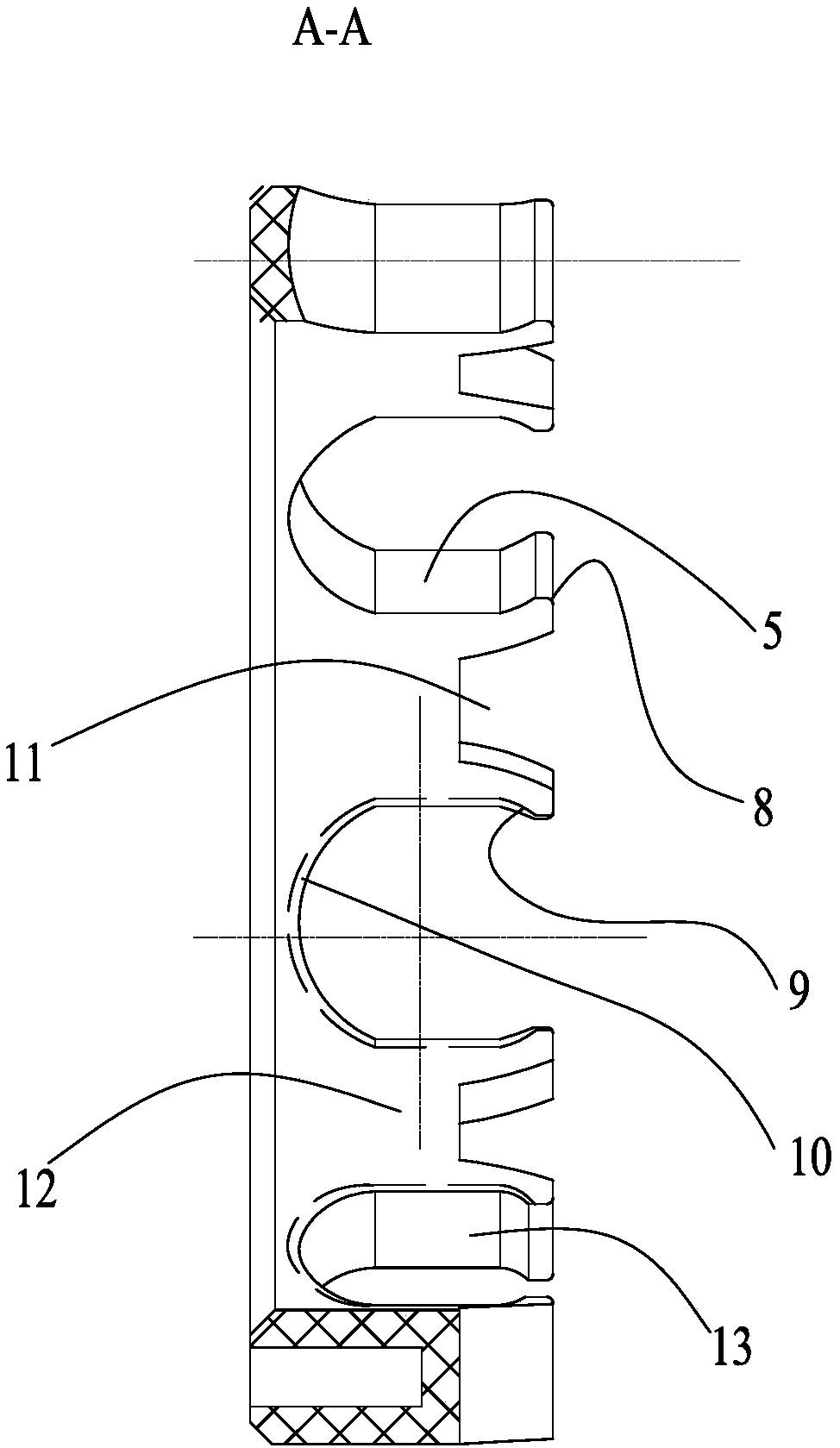

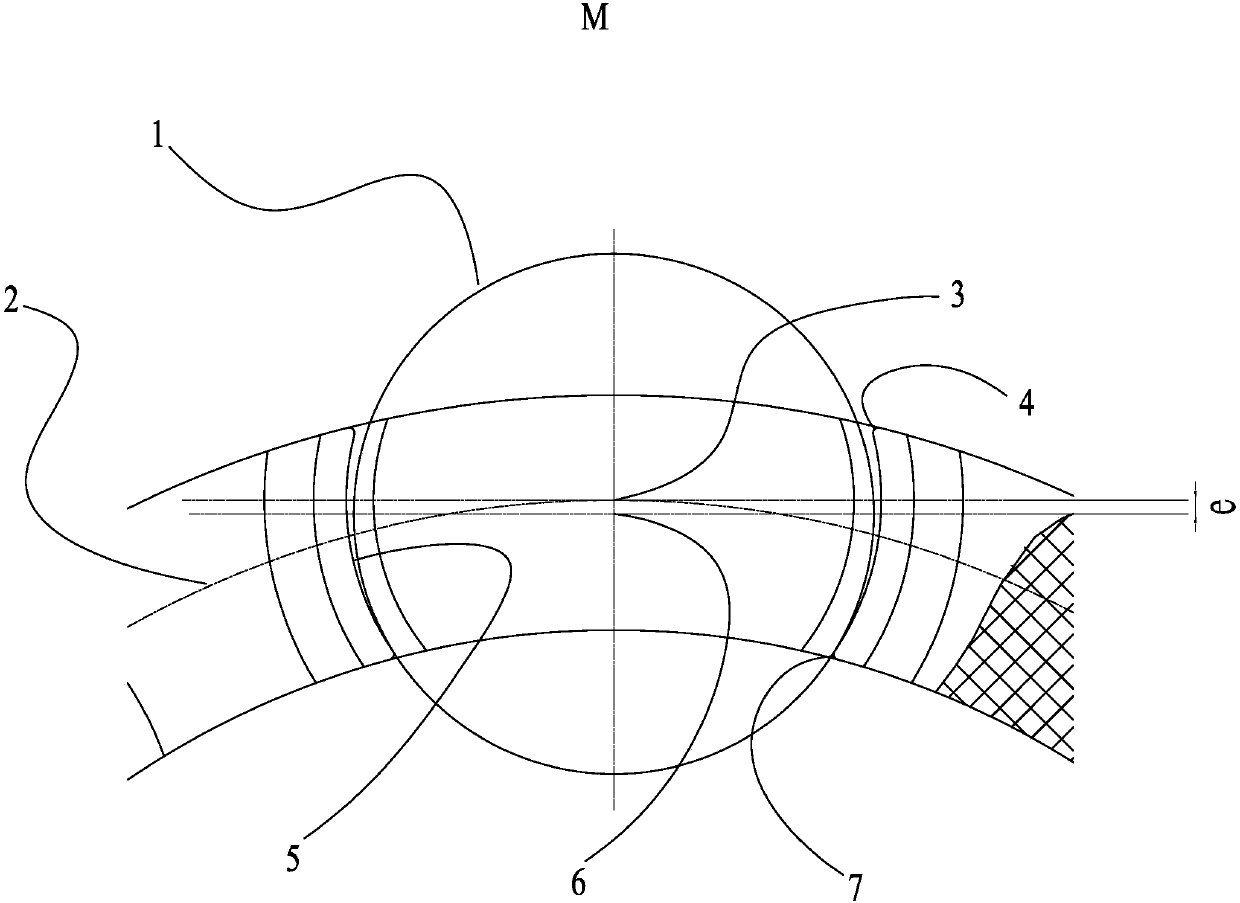

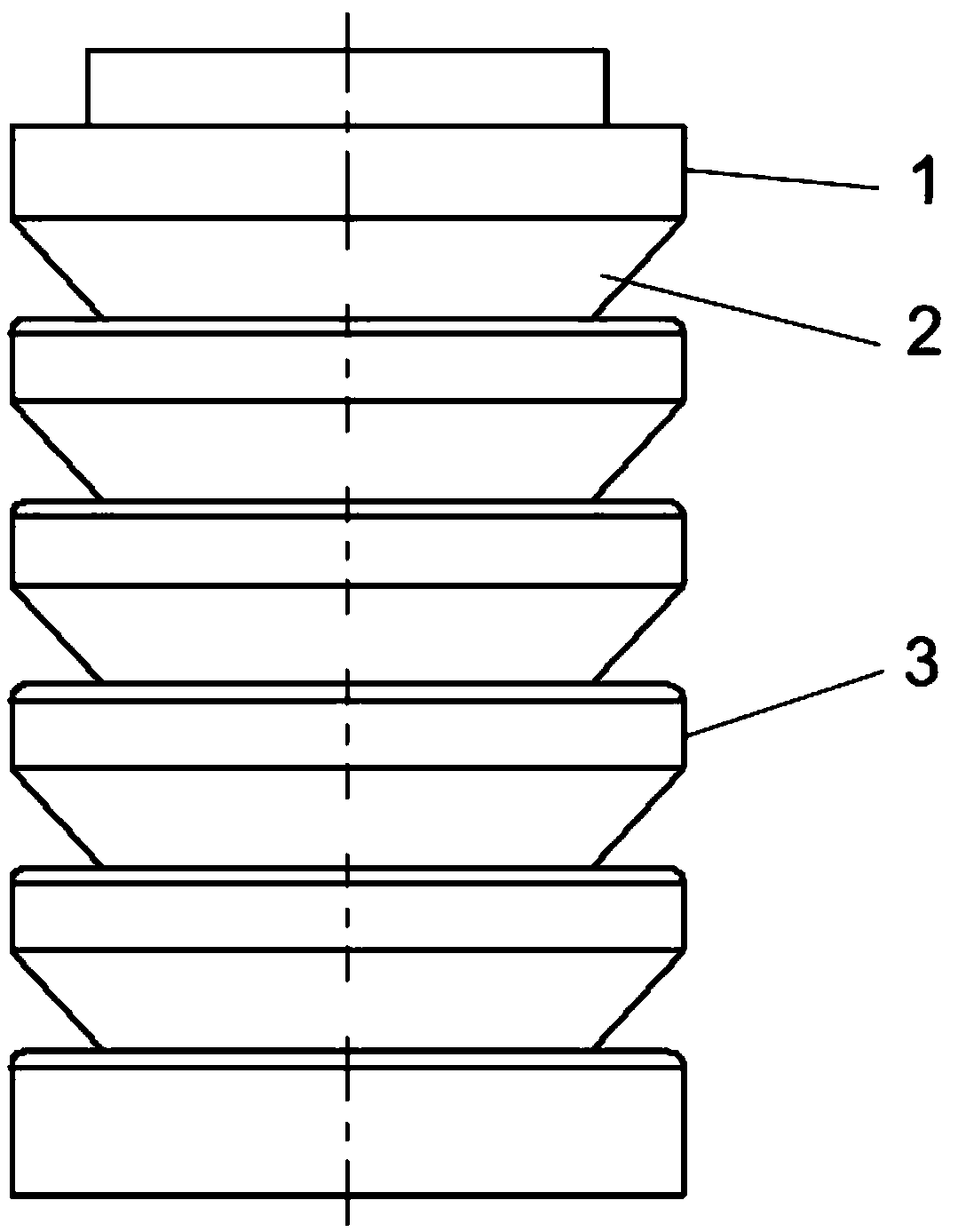

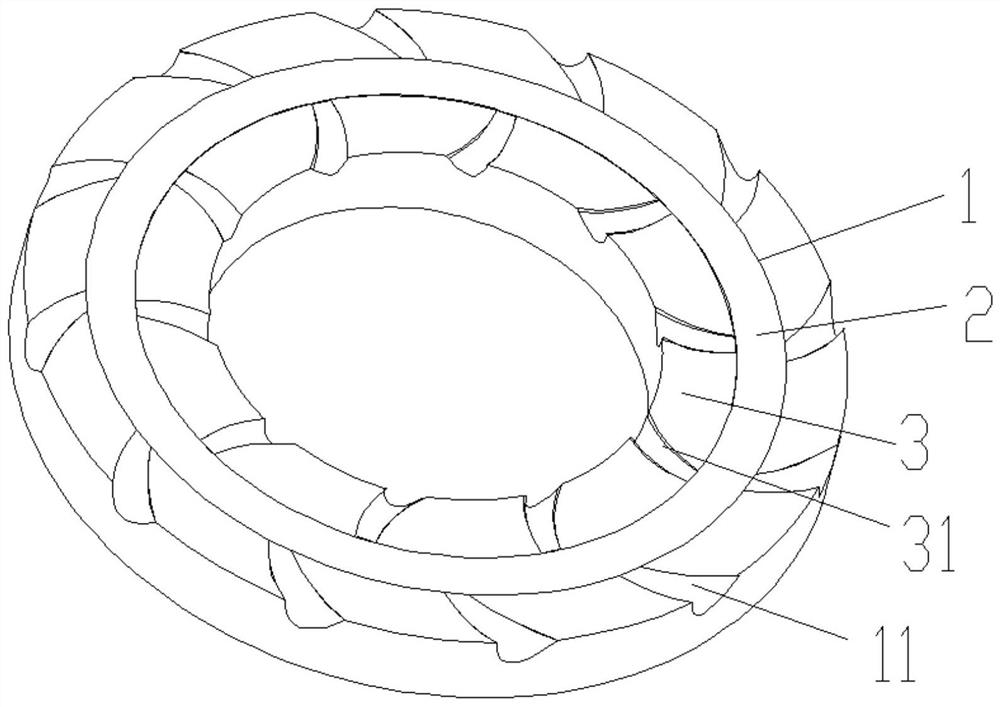

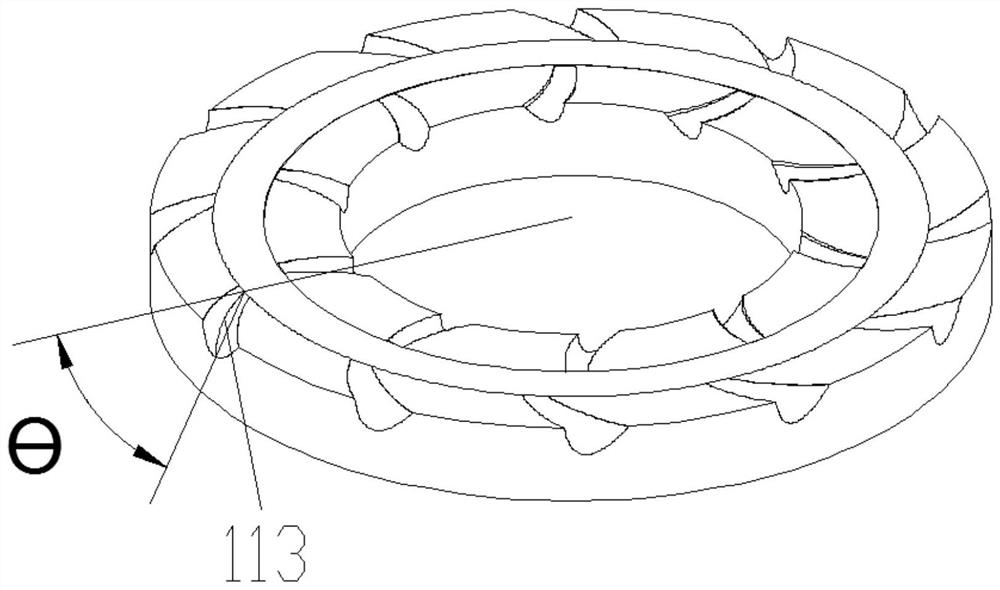

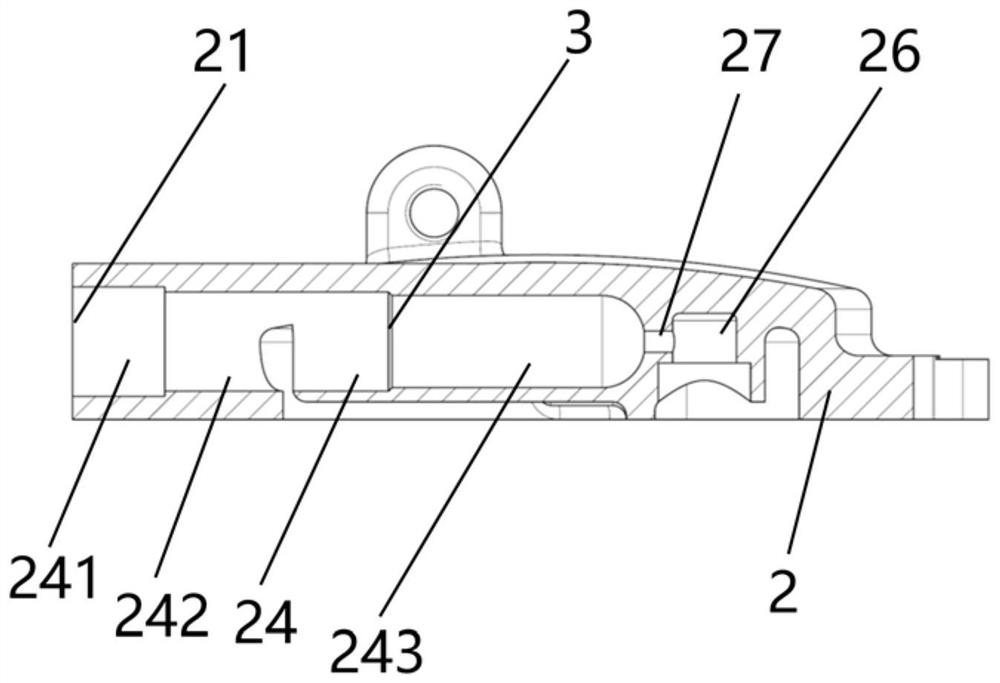

Lubricating structure and mechanical lubricating device having same

ActiveCN110566794BReduce direct contactExtended service lifeEngine lubricationFriction reductionStructural engineering

The invention provides a lubricating structure and a sealing structure with the same. The lubricating structure comprises an annular lubricating end face. The annular lubricating end face comprises acircular first converging area, a circular dam area and a circular second converging area in sequence in the direction towards the center. The first converging area and the second converging area areeach circumferentially arranged around the central point of the lubricating end face. The first converging area is provided with a plurality of first spiral grooves extending from the inner circumferential side of the first converging area to the outer circumferential side, and the first spiral grooves are circumferentially arranged around the center of the first converging area; and / or, the second converging area is provided with a plurality of second spiral grooves extending from the outer circumferential side of the second converging area to the inner circumferential side, and the second spiral grooves are circumferentially arranged around the center of the second converging area. According to the lubricating structure, under the high load, high speed or extreme once oiling and oil lacking conditions, the high oil storage capacity can be kept, and the direct contact between the end faces of a friction pair is reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

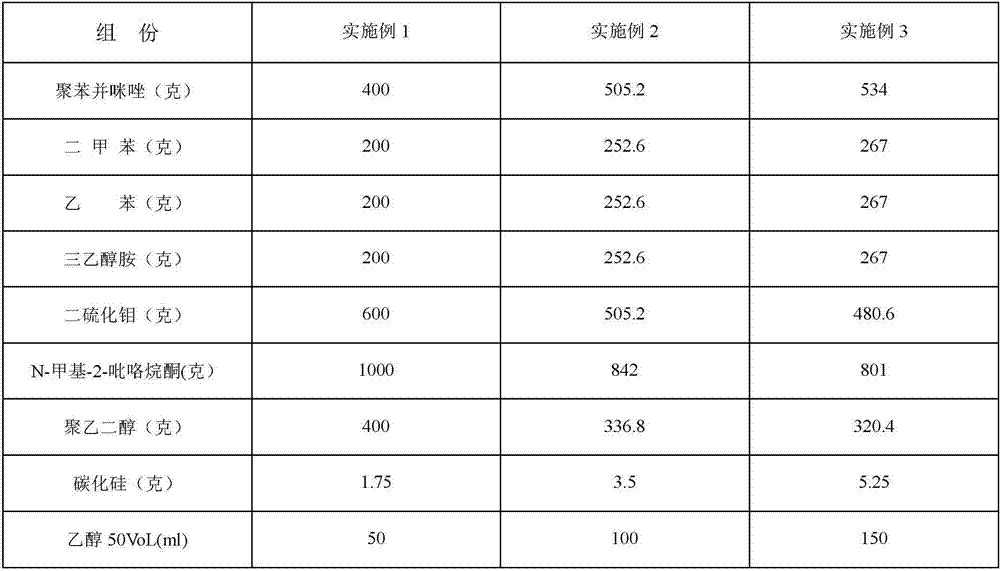

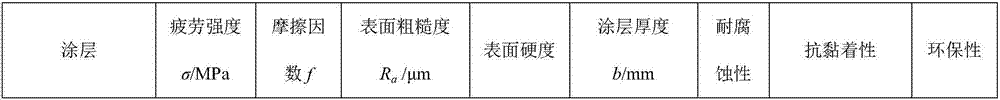

Printing solution for forming friction-reducing layer of sliding bearing, preparation method and application thereof

ActiveCN104693996BStir wellImprove corrosion resistanceBearing componentsAnti-corrosive paintsPolyethylene glycolInternal combustion engine

The invention relates to a printing solution for forming the antifriction layer of a sliding bearing. The printing solution is prepared from the following components in parts by weight: 10-50 parts of a polybenzimidazole resin solution, 20-60 parts of a molybdenum disulfide solution and 0.5-6 part of a silicon carbide ceramic solution, wherein the polybenzimidazole resin solution is prepared by mixing and stirring polybenzimidazole resin, dimethylbenzene, ethylbenzen, and triethanolamine according to the weight ratio of 2:1:1:1, the molybdenum disulfide solution is prepared by mixing and stirring molybdenum disulfide powder, N-methyl-2-pyrrolidone and polyethylene glycol according to the weight ratio of 3:5:2, the silicon carbide ceramic solution is prepared by adding the 50VOL% ethanol solution into silicon carbide ceramic powder, and the pH value of the silicon carbide ceramic solution is between 9 and 10. The invention further provides a preparation method of the printing solution and the antifriction layer of the sliding bearing for an internal combustion engine, which is prepared by using the printing solution.

Owner:广东韶配动力机械有限公司

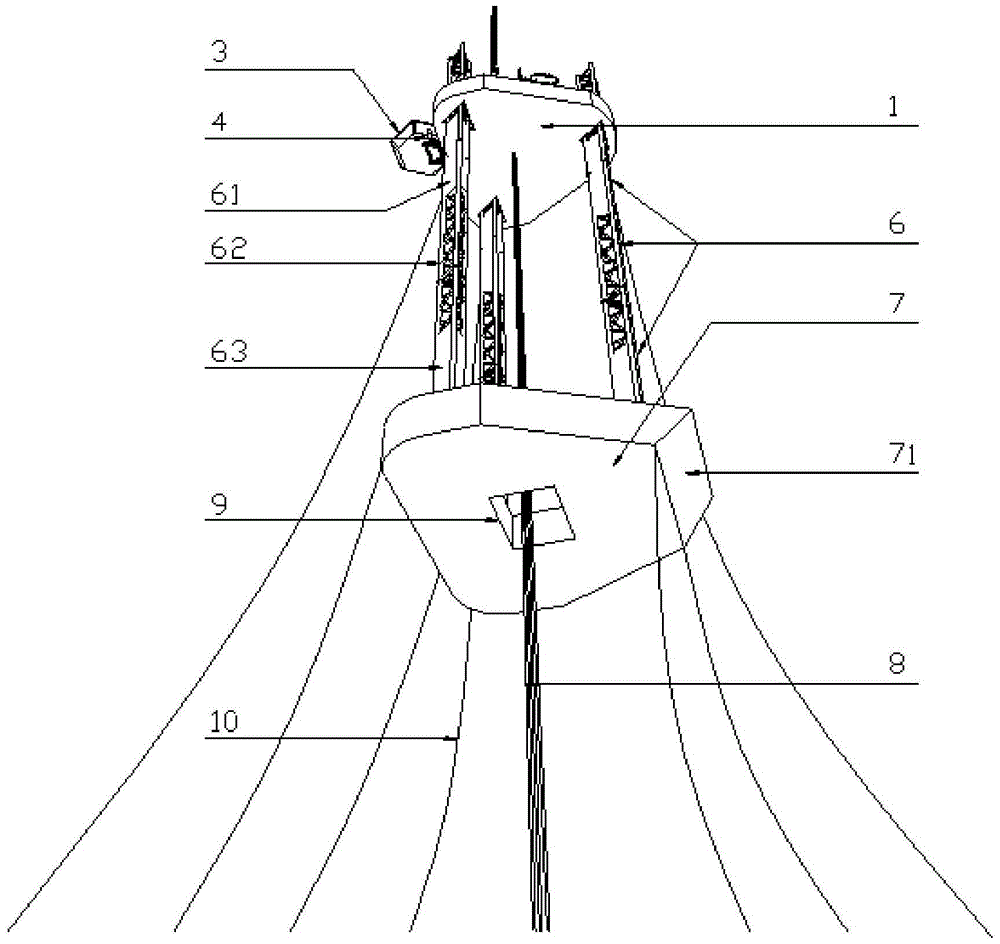

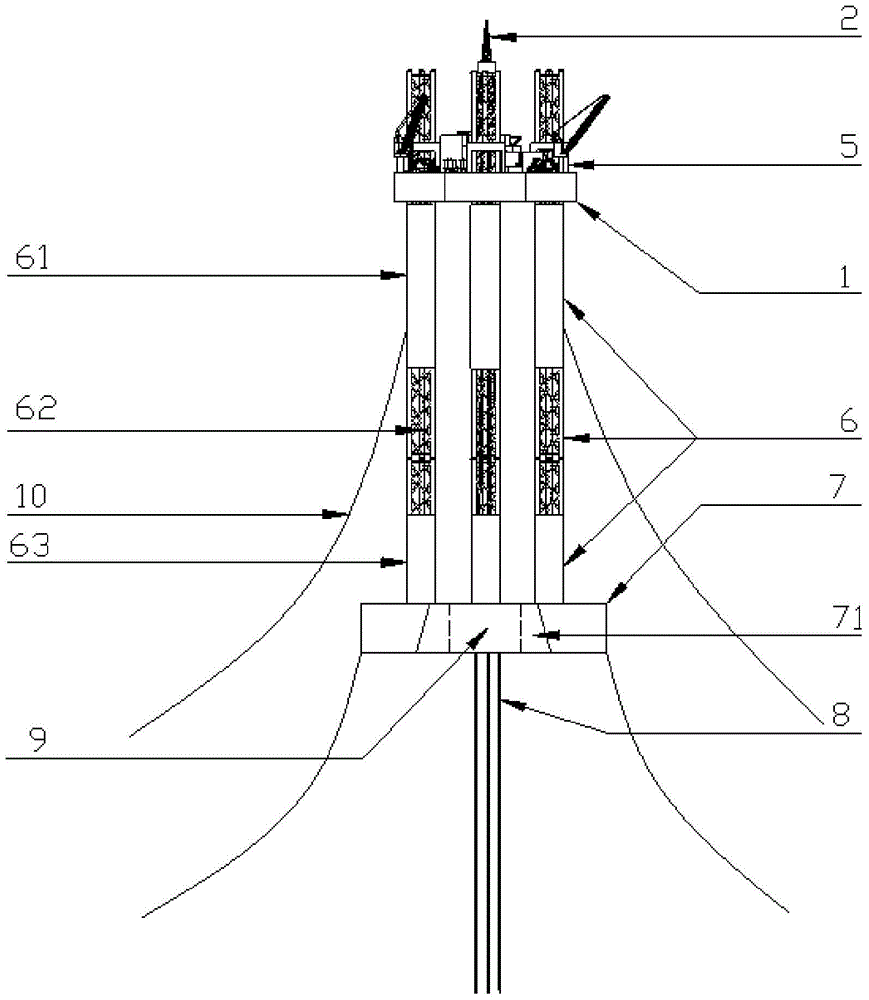

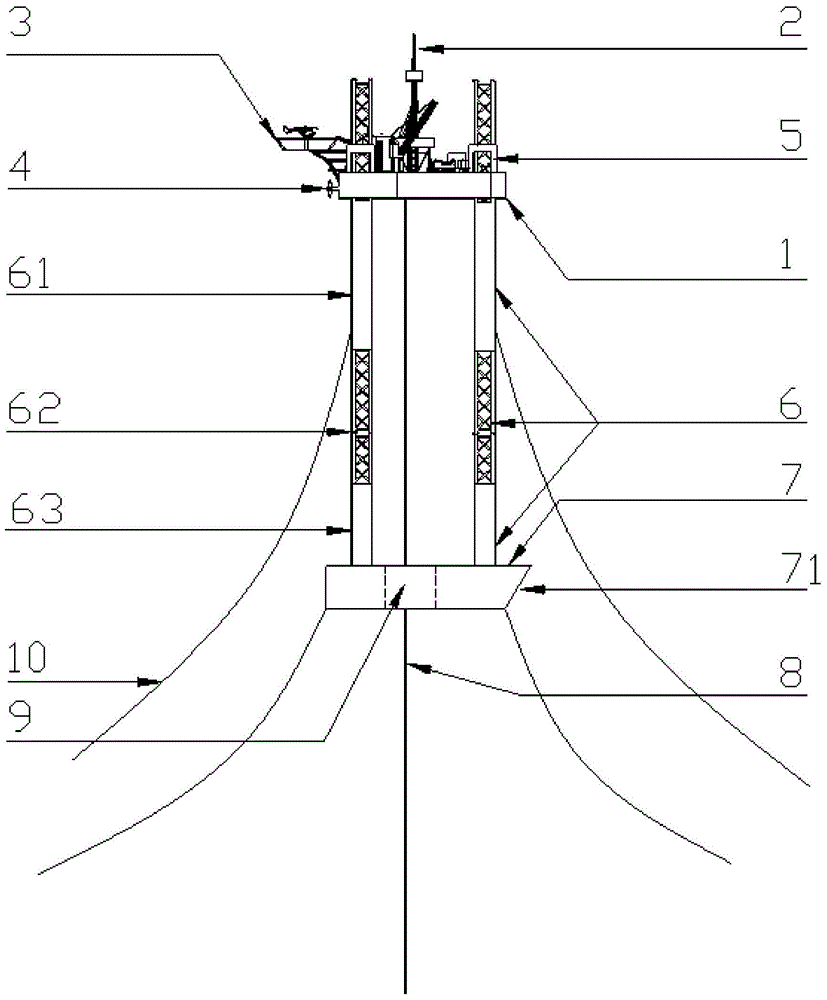

A floating jack-up drilling platform

ActiveCN104627332BImprove oil storage capacityGood oil storage performanceFloating buildingsMooring systemWell drilling

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

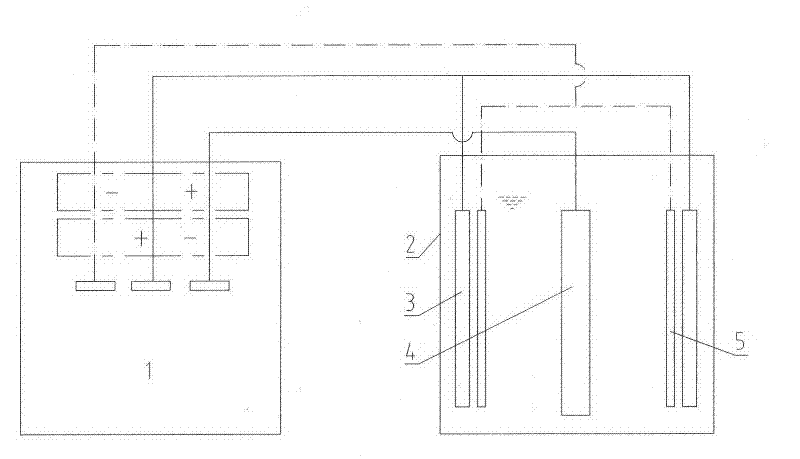

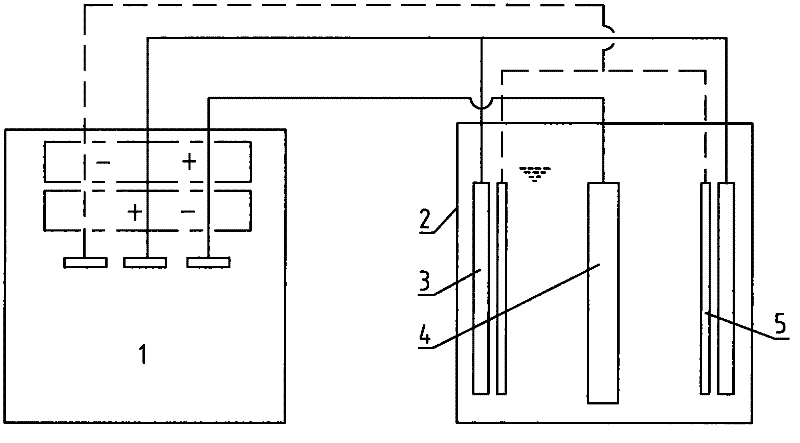

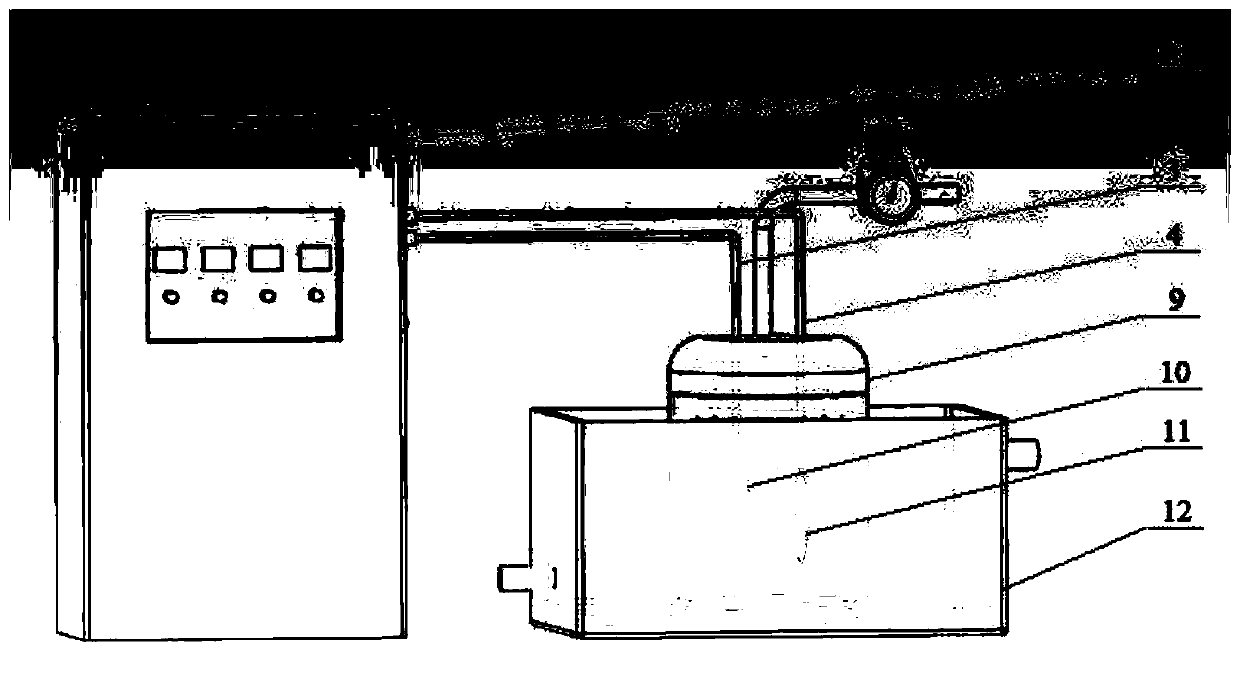

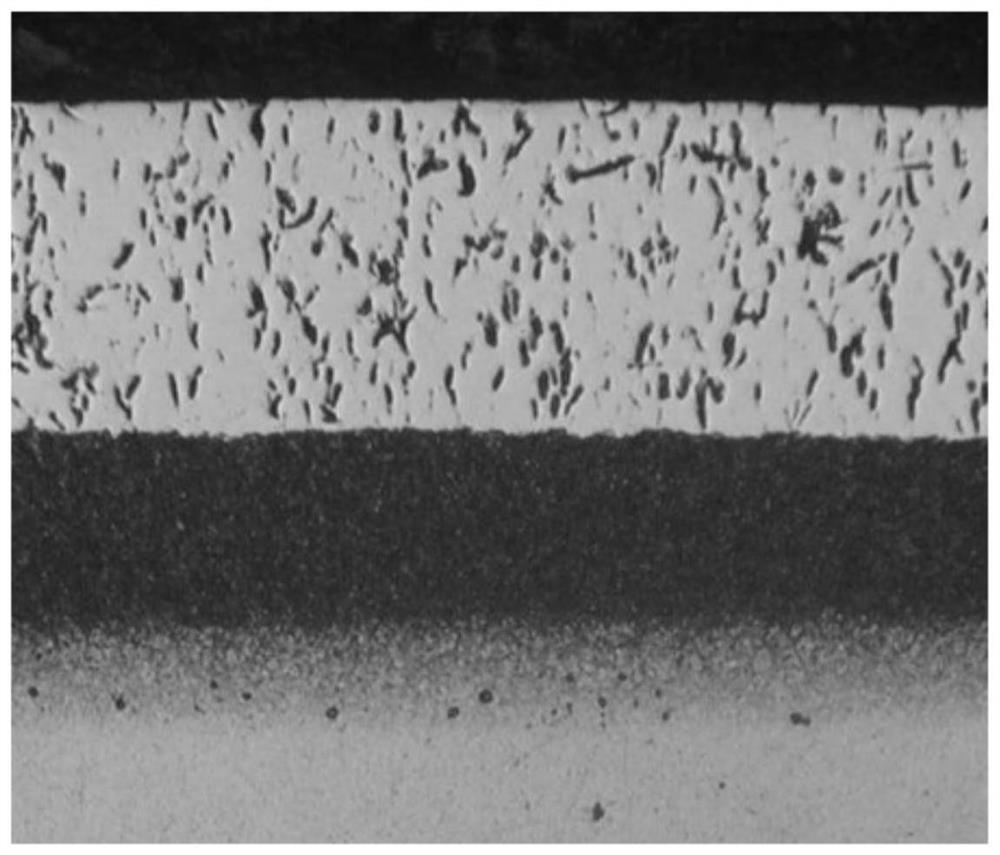

A carbonitriding surface treatment method for piston rings using liquid-phase arc discharge

ActiveCN108517486BReduce pollutionGood oil storage performanceSolid state diffusion coatingMaterials sciencePlasma bubble

The invention discloses a piston ring carbonitriding surface treatment method adopting liquid phase arc discharge. The method includes the steps that in a pressure-adjustable vessel containing solutions with specific compositions and concentrations, a piston ring to be treated serves as a cathode, an inert electrode material serves as an anode, direct-current impulse voltages are applied between the cathode and the anode, arc discharge is formed on the contact interface of the solutions and the piston ring, the solutions are ionized to produce plasmas containing carbon and nitrogen ions, the plasmas bears a combination reaction with the piston ring and diffuse into a workpiece, and carbonitriding is realized. Pressure waves produced by rupture of plasma bubbles are used for shaping rough and uneven micro-modelling on the surface of the piston ring. The pressure in the vessel is adjuted to control the formation amount and the critical rupture pressure of the plasma bubbles to improve the quality of surface treatment. The method is good in environment suitability, high in treatment speed and production efficiency, low in cost, energy-saving and environment-friendly. The piston ring treated by adopting the method has the advantages of being high in abrasion resistance, corrosion resistance, good in lubricating performance, high in fatigue strength and the like.

Owner:YIZHENG RUNYANG MACHINERY

Bearing bush with surface microporous structure and processing method thereof

ActiveCN102537066BIncreasing the thicknessImprove the extrusion effectBearing componentsMicrometerAlloy

The invention provides a bearing bush with surface microporous structures and a processing method. The bearing bush includes a bearing bush body, and the body comprises a metal bearing bush back and an antifriction alloy layer, wherein the antifriction alloy layer is a friction layer between the bearing bush and a journal. The bearing bush is characterized in that microporous structures are formed on the inner surface of the antifriction alloy layer through machining. The microporous structures are micropores formed by adopting the laser micromachining technique for machining, the micro-pores are arranged regularly, the diameters range from 150 micrometers to 200 micrometers, and the depths range from 35 micrometers to 50 micrometers. The bearing bush is provided with the microporous structures on the inner surface, can effectively improve the oil film bearing capability, and remarkably improves the lubrication effect.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

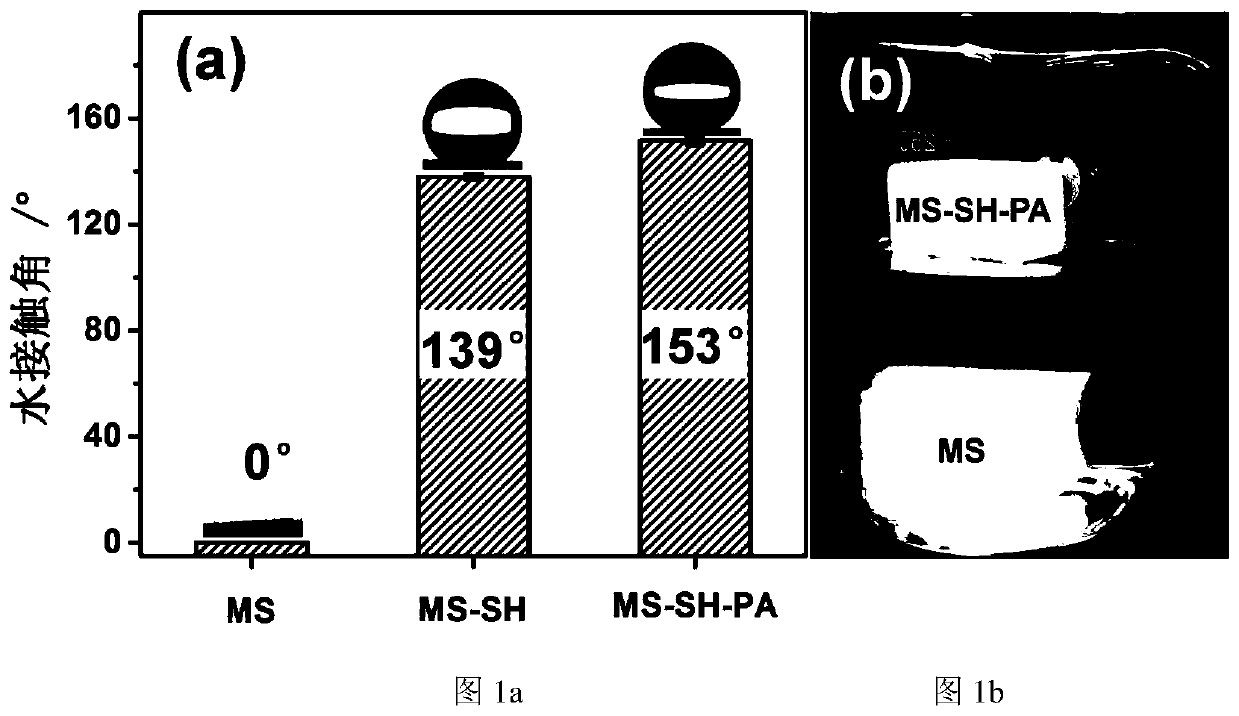

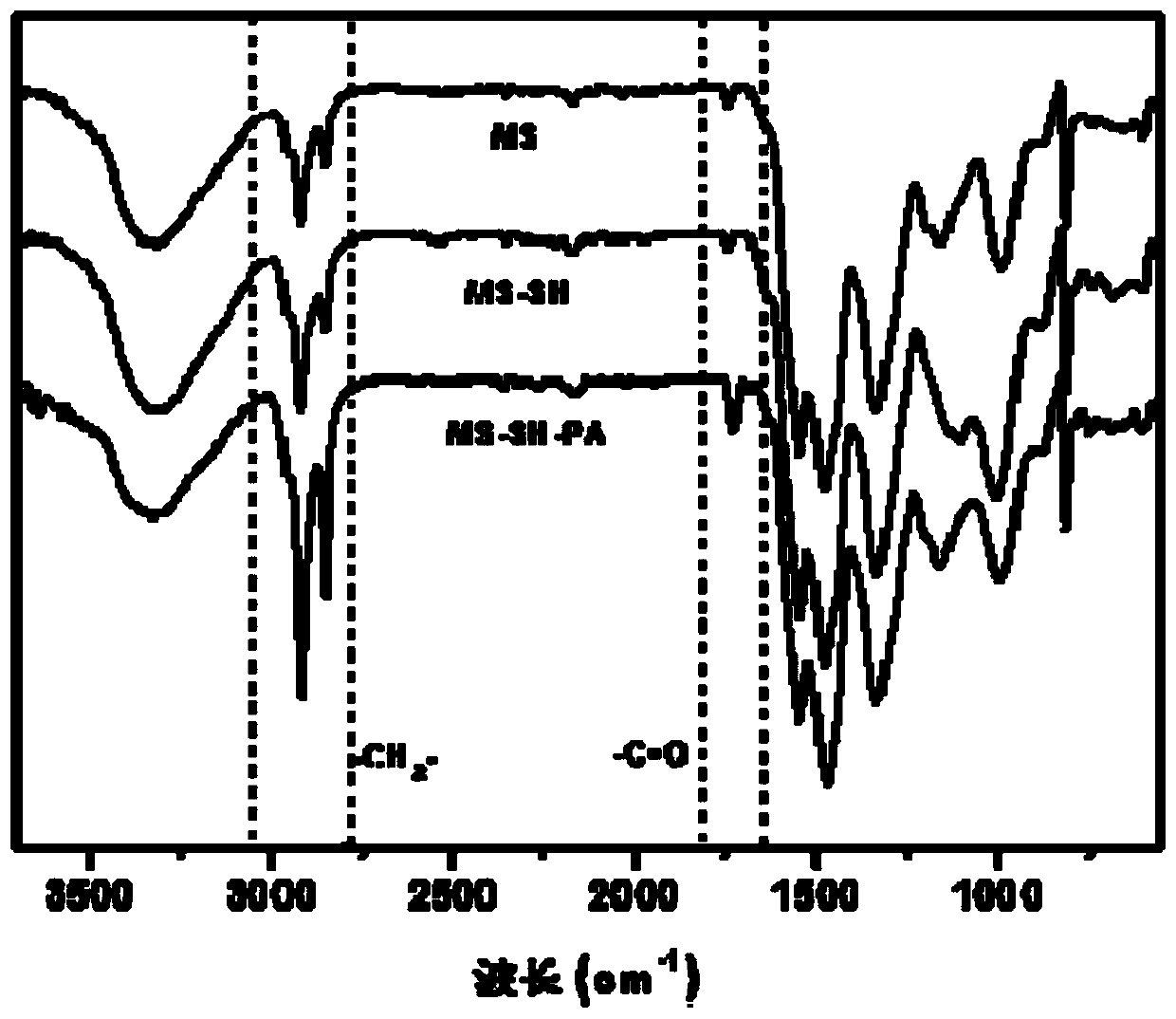

A kind of superhydrophobic superoleophilic melamine foam and its preparation method and application

ActiveCN107011534BHigh utility valueExtrusion resistantOther chemical processesAlkali metal oxides/hydroxidesAlkaneChemical reaction

The invention discloses super-hydrophobic and super-oleophylic melamine foam and a preparation method and application thereof. The super-hydrophobic and super-oleophylic melamine foam is prepared by the following steps of using porous melamine foam as a substrate; chemically grafting the substrate with a substance of one or a mixture of trimethoxysilylpropanethiol and 3-mercaptopropyltriethoxysilane to activate the substrate; under the existence of ultraviolet light and light initiator, enabling the thiol and the vinyl of long-chain alkane acrylic ester to generate clicking chemical reaction, so as to enrich C-C long chains on the substrate, so that the surface energy of the substrate is reduced, the roughness is improved, the hydrophobic property is greatly improved, and the oil and water selectivity is obviously improved. The preparation method has the advantages that the hydrophobic modification on the melamine foam is precise, the efficiency is high, the operation is simple and convenient, the implementing is easy, the consumption time is short, the cost is low, and the method is suitable for large-scale production. The super-hydrophobic and super-oleophylic melamine foam can be directly applied to the sea oil overflow, recycling of leaked chemicals, separation of oil and water mixture, and the like.

Owner:SOUTH CHINA UNIV OF TECH

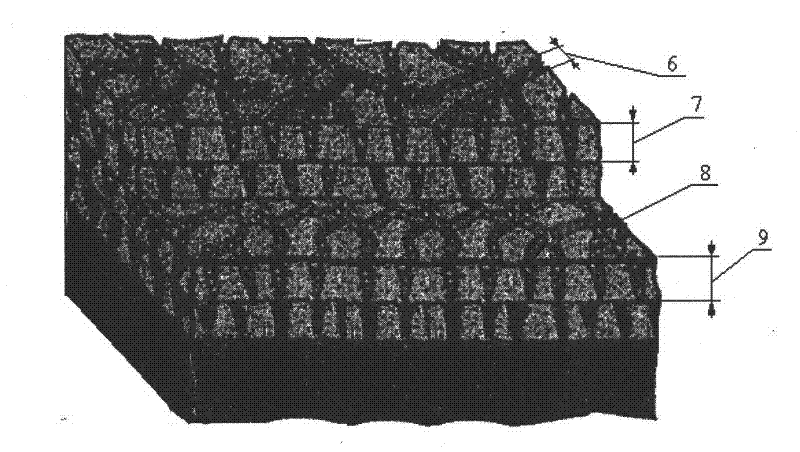

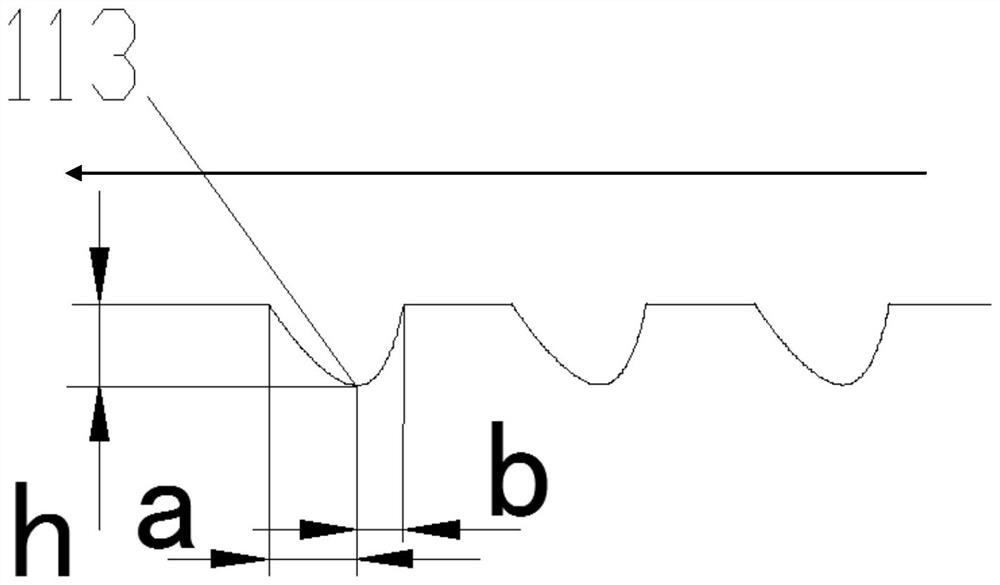

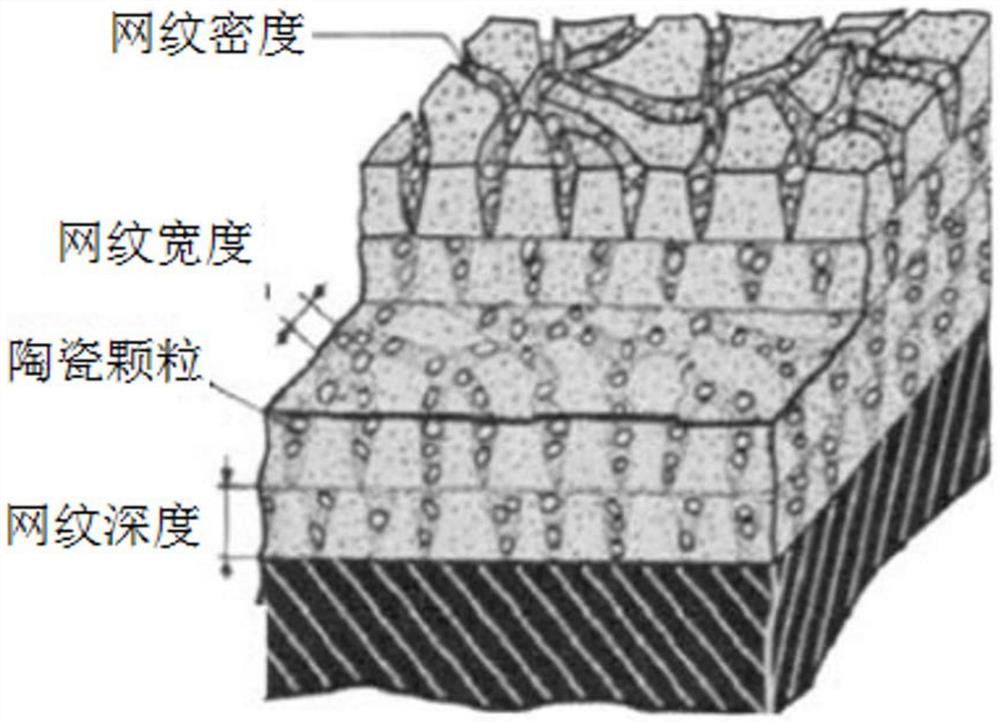

Chromium-based ceramic composite plating process for piston ring

InactiveCN113584548AHigh hardnessGood oil storage performanceElectrolysis componentsElectrolytic inorganic material coatingCeramic compositePiston ring

The invention relates to the technical field of piston ring coatings, in particular to a chromium-based ceramic composite plating process for a piston ring. The process aims to solve the problem that a traditional piston ring is prone to cylinder scoring, and specifically comprises eight steps. A chromium-based ceramic composite coating contains 2% to 6% (volume) of ceramic particles (Al2O3) and 40 to 100 microcracks / mm, a hardness of the coating is as high as 800 HV0.1 to 1200 HV0.1, the microcracks are good in oil storage performance, a lubricating condition is improved, friction loss is reduced, the coating has high wear resistance, service life of the piston ring with the coating is more than 5 times service life of a common chromium-plated piston ring, and the problems that a traditional piston ring is prone to wear and cylinder scoring are effectively solved.

Owner:长沙正圆动力科技有限责任公司

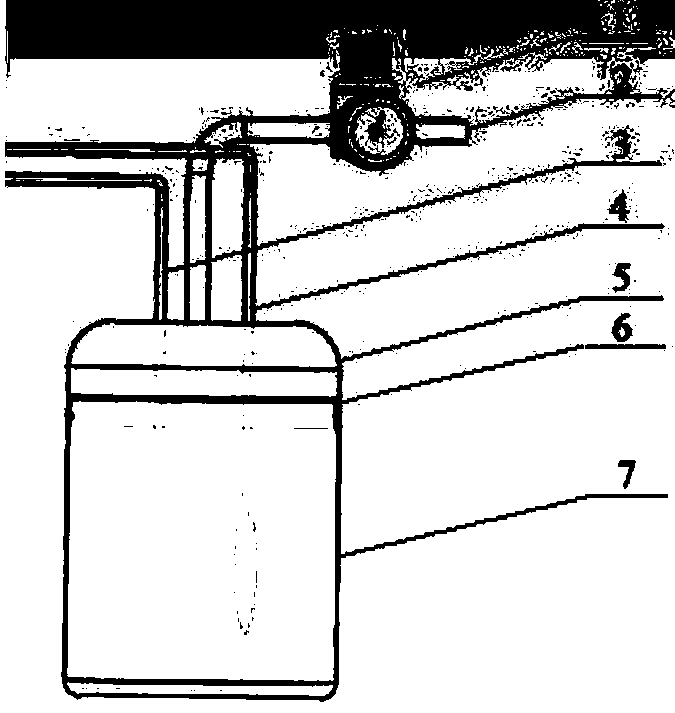

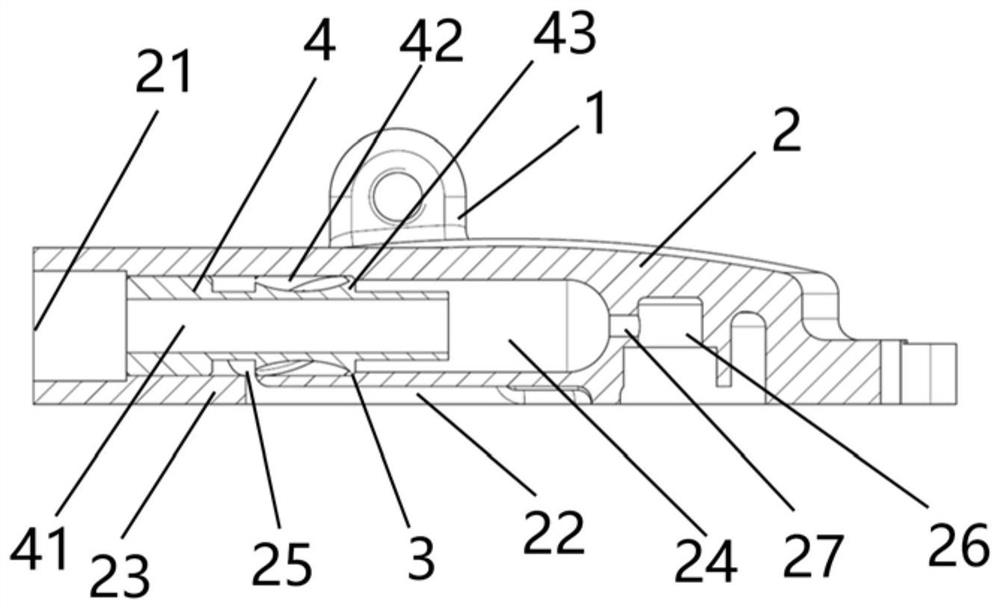

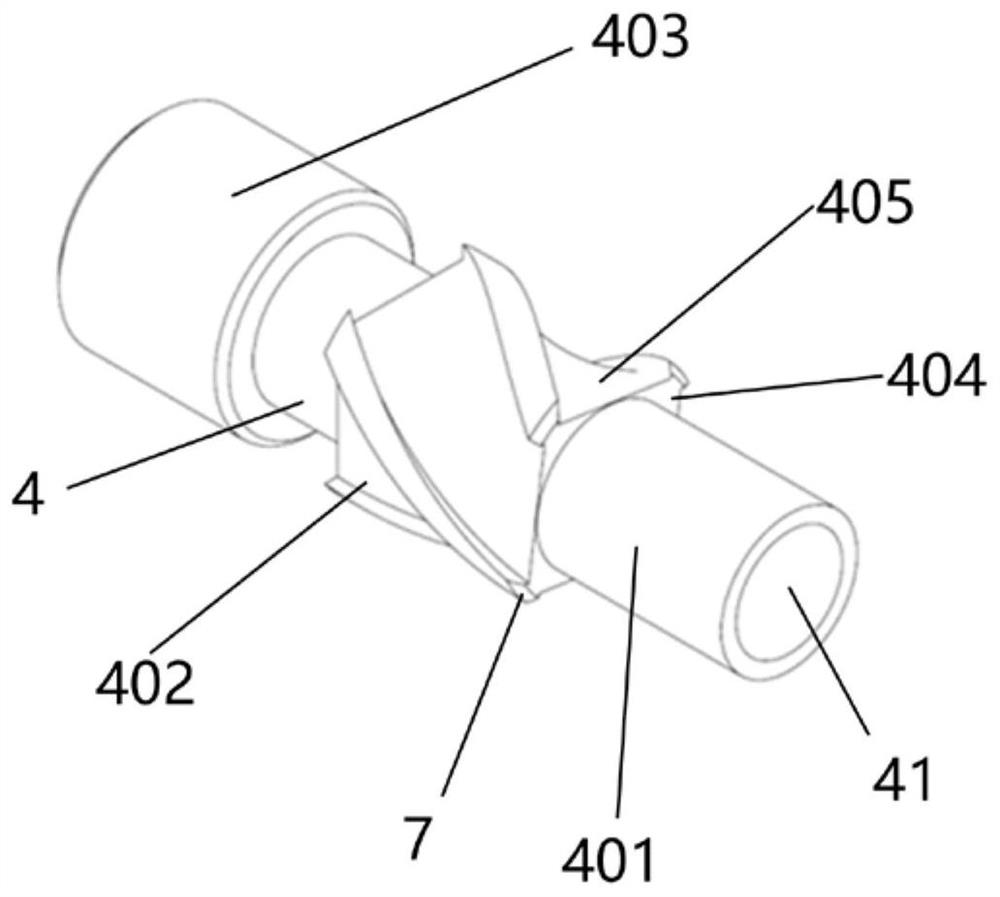

Compressor with built-in oil separator

PendingCN113294340AGood oil storage performanceReasonable use of internal spaceRotary/oscillating piston pump componentsLiquid fuel engine componentsThermodynamicsEngineering

The invention discloses a compressor with a built-in oil separator. The compressor comprises a compressor body; a shell provided with a front shell part, wherein the front shell part is provided with an exhaust port, and an exhaust cavity is formed between the front shell part and a static vortex; an oil separator shell arranged on the front shell part, wherein an oil separator channel is formed between the oil separator shell and the front shell part, the oil separator channel communicates with the exhaust port, the oil separator channel is provided with a stop part, an oil separator inlet is formed in the oil separator shell, and the oil separator inlet communicates with the oil separator channel and the exhaust cavity; and an oil separator core rod which is arranged in the oil separator channel, wherein an exhaust channel is arranged in the oil separator core rod, the exhaust channel communicates with the oil separator channel and the exhaust port, a spiral channel is formed between the oil separator core rod and the oil separator channel, the spiral channel communicates with the oil separator channel, the spiral channel communicates with the oil separator inlet, and a contact part is arranged on the oil separator core rod. Through the application of the compressor, the oil storage capacity of the compressor is improved, impurities are prevented from being generated in the installation process, and the safety and reliability of the compressor are further improved.

Owner:SHANGHAI HIGHLY NEW ENERGY TECH CO LTD

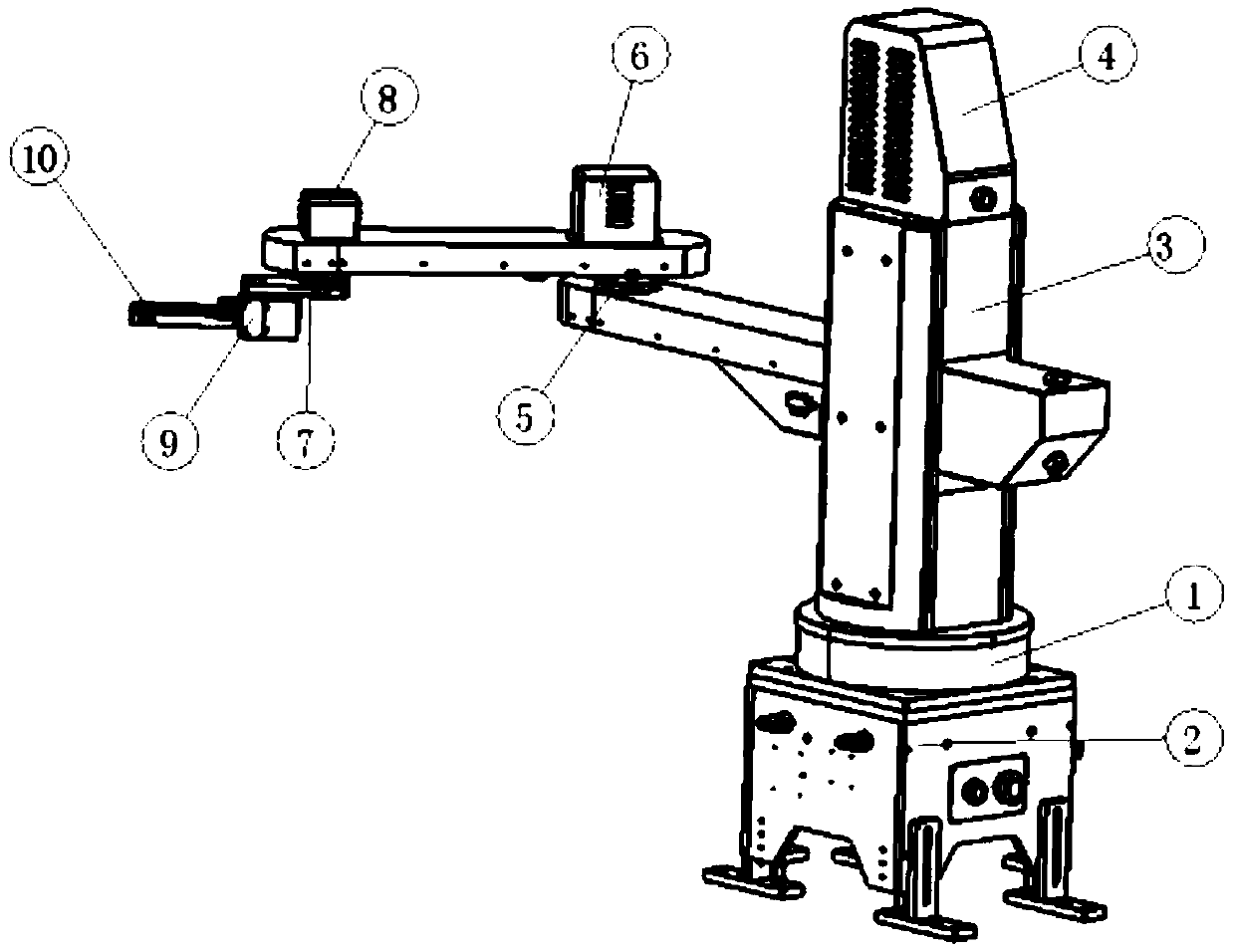

High-wear-resisting long-service-life four-shaft forging robot

InactiveCN110788266AImprove wear resistanceExcellent oil storage and lubrication abilityForging/hammering/pressing machinesCoatingsControl systemControl engineering

The invention discloses a high-wear-resisting long-service-life four-shaft forging robot. The robot is composed of an execution mechanism, a control system and a position detection mechanism. The execution mechanism is composed of a base, a first shaft body, a first shaft servo motor, a stand column, a second shaft body, a second shaft servo motor, a swing arm, a third shaft body, a third shaft servo motor, a correction arm, a fourth shaft body, a fourth shaft servo motor, a clamping jaw and a chuck. High-wear-resisting perforated coatings are arranged on output end friction surfaces of all absolute value servo motors. A rotating joint is good in surface wear resistance, good in oil storage, long in service life and long in maintaining interval period.

Owner:青岛嘉乐智能自动化科技有限公司

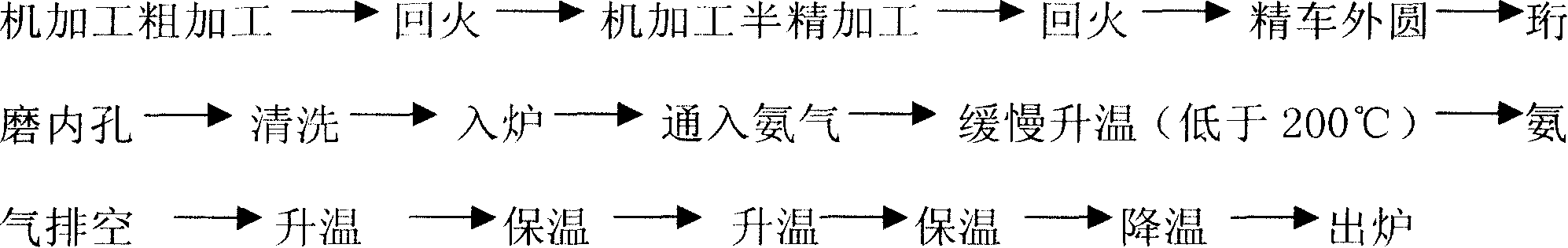

Technique for nitrogen treatment of diesel cylinder cover

InactiveCN101173363ANitriding less pittingGood oil storage performanceSolid state diffusion coatingWarming rateEngineering

The invention provides a nitrogen treatment technique of ship firewood cylinder sleeve, which is characterized in that a tempering working procedure is added after rough machining and semifinishing of machining before nitrogen treatment respectively. Due to the scientific control of technique parameters such as warming rate, heat insulation time, cooling rate and dissolution rate of alkaline air, the nitrogen process is under strict control so that the nitrogen deformation is small and the nitrogen layers are even. The invention has advantages that a silvered nitrogen layer evenly coated on the nitrogen-treated surface of the cylinder sleeve has a good quality of rust protection and high resistibility of cavitating corruption; after being polished a few nitrogen pocking marks are left on the nitrogen layer of inner hole, and the reticulate pattern is clear; the cylinder sleeve has a good oil-store performance, high abrasion resistibility and low engine oil consumption.

Owner:严方

A piebald cylinder liner produced by centrifugal casting and its production process

ActiveCN105369116BGood oil storage performanceImprove the lubrication effectFurnace typesHeat treatment furnacesSurface layerAlloy

The invention discloses a piebald cylinder sleeve for centrifugal casting production and a production technology of the piebald cylinder sleeve. The piebald cylinder sleeve comprises, by weight percent, 3.5-3.9% of C, 2.6-3.0% of Si, smaller than 0.02% of P, 0.7-0.9% of Cu, 0.2-0.4% of Ni, 0.04-0.08% of Bi, 0.1-0.3% of Nb, 0.03-0.06% of Mg, 0.02-0.04% of Ce and the balance Fe. According to the high-performance spheroidal graphite cast iron cylinder sleeve, the amount of spheroidal graphite (the field diameter is 70 mm) is not smaller than 200, and the matrix structure is granular pearlite. Compared with the prior art, after finish grinding and polishing processes are sequentially conducted on inner holes of the cylinder sleeve obtained through the formula and the production technology, piebald-similar surface graphite and a WS2 alloy layer are formed on the surface layer, thus, honing of net stripes is not needed for the inner holes of the cylinder sleeve, oil storage performance, the lubricating property and the abrasion reducing performance are better, and the defects that a gray cast iron cylinder sleeve is poor in oil storage performance, long in run-in period with a piston, low in strength and poor in plasticity are overcome.

Owner:ZYNP GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com