High-wear-resisting long-service-life four-shaft forging robot

A highly wear-resistant, robotic technology, used in forging/pressing/hammering machinery, forging/pressing/hammer devices, manufacturing tools, etc., can solve the problem that the friction interface does not have a self-storage function, the impact of positioning accuracy, and the impact of applications, etc. problems, to achieve the effect of long maintenance interval, reduced area and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

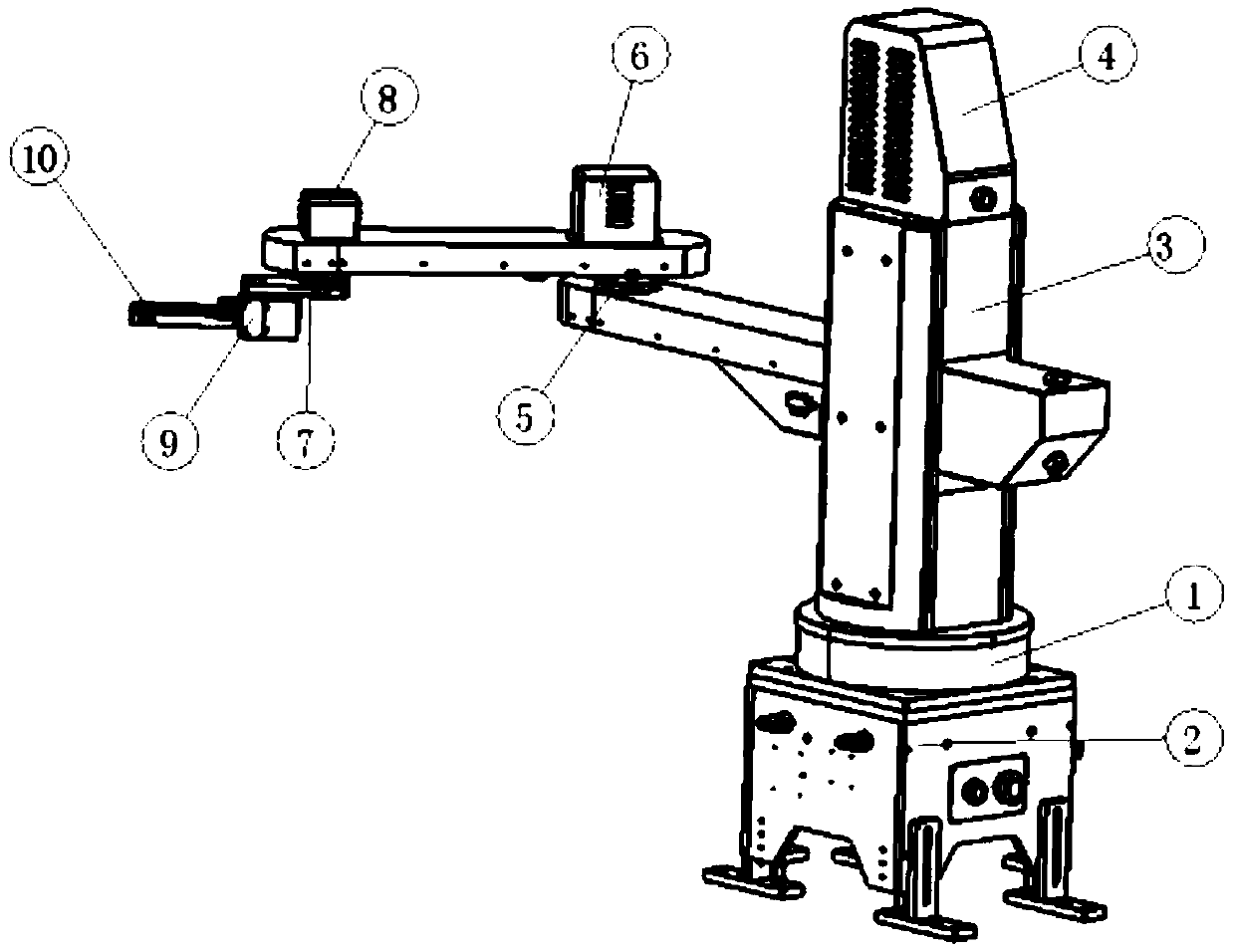

[0025] Such as figure 1 A four-axis forging robot with high wear resistance and long life is shown, which is composed of an actuator, a control system and a position detection mechanism. It is characterized in that: the actuator consists of a base, a first axis body 1, a first axis servo motor 2, Column, second axis body 3, second axis servo motor 4, swing arm, third axis body 5, third axis servo motor 6, correction arm, fourth axis body 7, fourth axis servo motor 8, gripper 9 , collet 10; the first axis body 1 is fixed on the upper surface of the base, used to connect the upper surface of the base and the lower surface of the column, the first axis body 1 is controlled by the first axis servo motor 2 arranged inside the base Coarse adjustment and rotation on the XY plane; the second axis body 3 is fixed in the middle of the column, and is controlled by the second axis servo motor 4 arranged at the upper end of the column to move up and down along the Z axis of the column axis...

Embodiment 2

[0037] The whole is consistent with Example 1, the difference is:

[0038] The first axis servo motor 2, the third axis servo motor 6, and the fourth axis servo motor 8 are all connected to their respective shaft bodies through a worm reducer; the second axis servo motor 4 controls the second axis through a worm reducer and a screw The body 3 moves on the linear guide rail; the jaw 9 is made of medium carbon alloy steel; the chuck 10 is made of high carbon alloy steel;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com