Mute holder of bearing

A cage, mute technology, applied in bearing components, shafts and bearings, mechanical equipment and other directions, can solve the problems of large difference distance, gap in mute effect, affecting the mute effect of motor bearing cage, etc., to solve the problem of abnormal noise, reduce The effect of using cost, raceway guiding method and oil storage effect improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

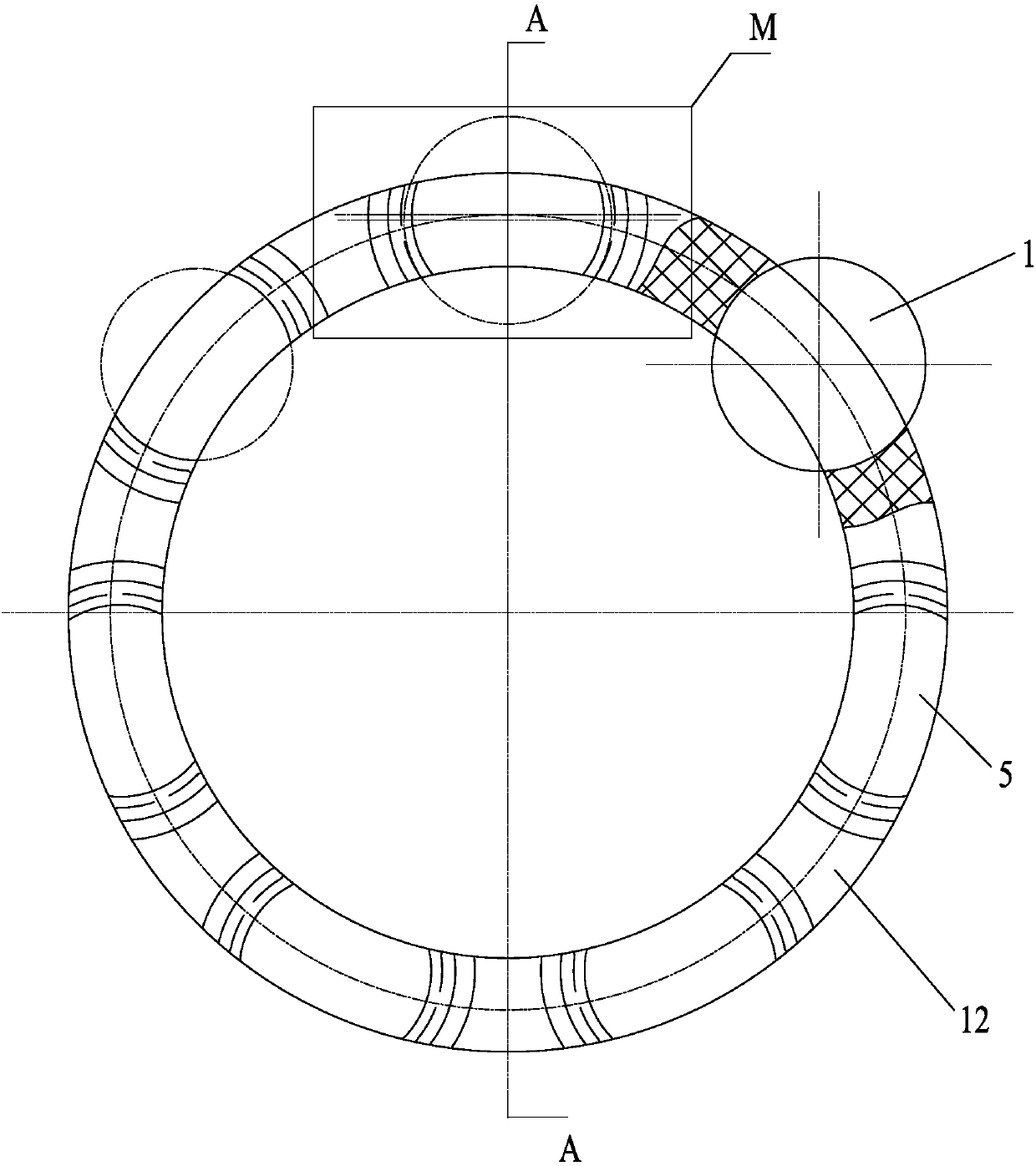

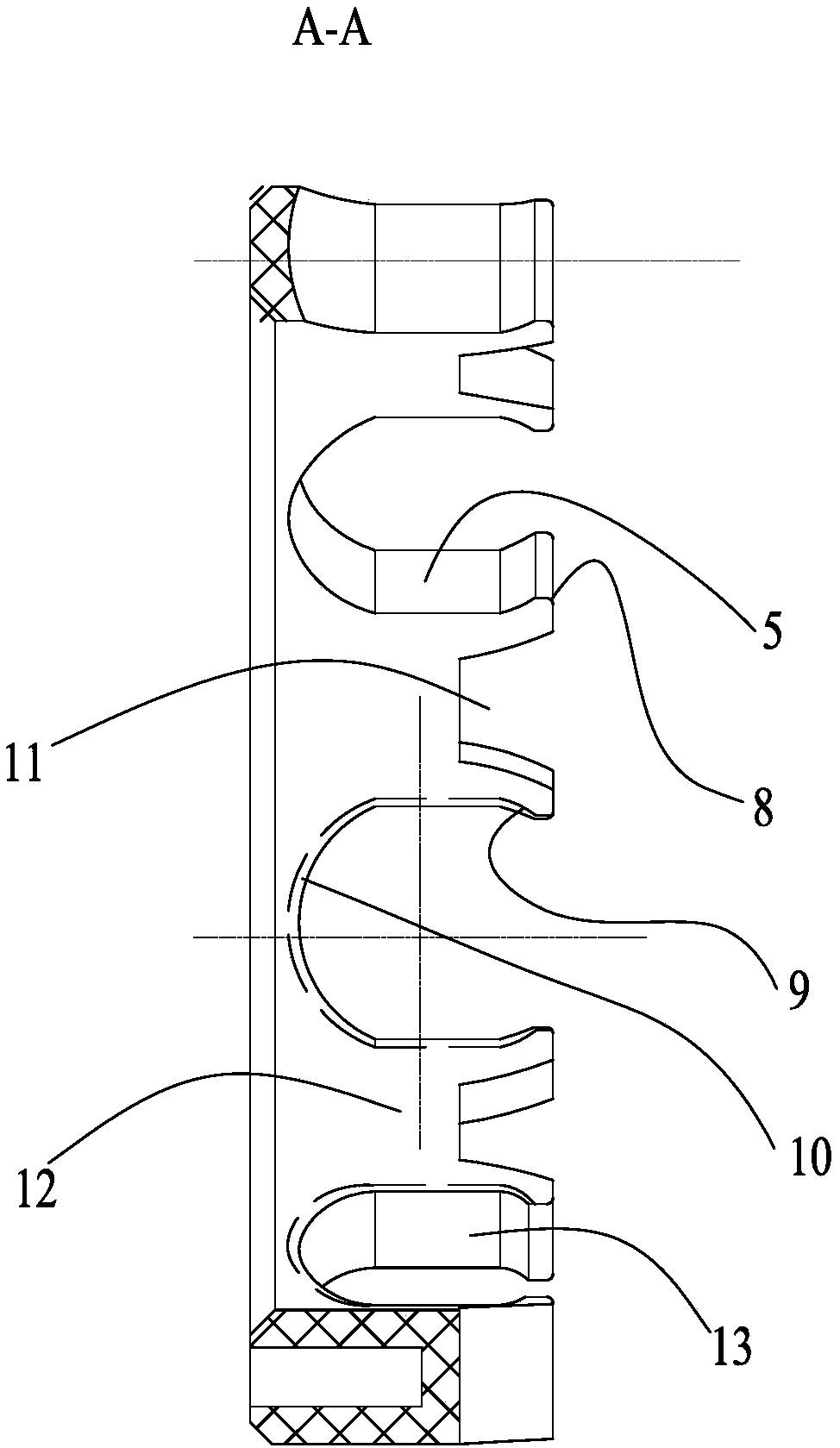

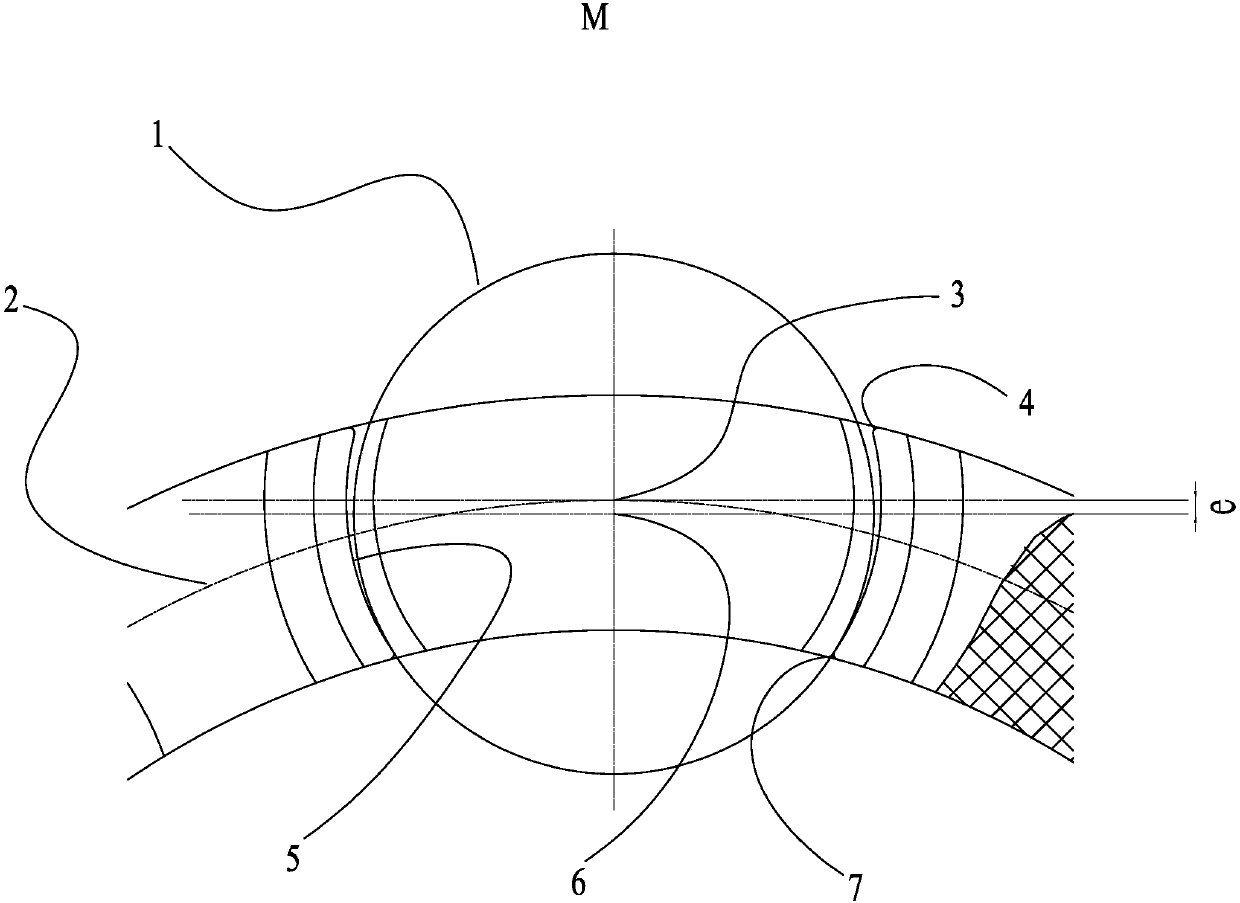

[0013] Figure 1~3 , including steel ball 1, cage body 2, center of circle 3, first chamfer 4, pocket 5, center point 6, second chamfer 7, locking part 8, second arc surface 9, first arc surface 10. Groove 11, spacer block 12, cylindrical surface 13, etc.

[0014] Such as Figure 1~3 As shown, the present invention is a silent cage for bearings, which includes a circular cage body 2 on which several spacers 12 are evenly distributed, and pockets 5 are formed between two adjacent spacers 12 , the bottom surface of the pocket 5 is a first arc surface 10, the side of the pocket 5 is a cylindrical surface 13, a locking portion 8 is formed on both sides of the upper opening of the pocket 5, and the inner surface of the locking portion 8 forms a second arc Surface 9.

[0015] A steel ball 1 is placed in each pocket 5 , and there is an eccentri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com