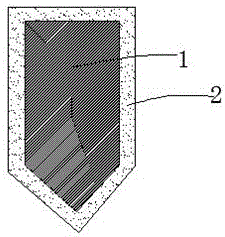

Valve guide pipe coated with ion nitriding layer

A technology of ion nitriding and valve guide, which is applied in the direction of lift valves, engine components, machines/engines, etc. It can solve the problems that the performance of valve guides cannot be fully satisfied, achieve good oil storage effect, increase service life, and high material utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Described cobalt is 1.3 parts;

[0035] Described nickel is 1.6 parts;

[0036] Described manganese disulfide is 2.2 parts;

[0037] Described sulfur is 0.6 part;

[0038] Described iron is 92 parts;

[0039] The other substances mentioned are 1.3 parts;

[0040] The number of parts mentioned is the number of parts by mass;

[0041] The thickness of the ion nitride layer is 40 microns;

[0042] The hardness of the ion nitrided layer is 645HRC.

Embodiment 2

[0044] Described cobalt is 1.4 parts;

[0045] Described nickel is 1.8 parts;

[0046] Described manganese disulfide is 2.4 parts;

[0047] Described sulfur is 0.5 part;

[0048] Described iron is 91 parts;

[0049] The other substances mentioned are 1.2 parts;

[0050] The number of parts mentioned is the number of parts by mass.

[0051] The thickness of the ion nitride layer is 40 microns.

[0052] The hardness of the ion nitrided layer is 700HRC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com