Fuel-saving type Cr-O-N nanocrystalline composite ceramic coated piston ring of diesel engine and preparation method thereof

A diesel engine, nanocrystalline composite technology, applied in piston rings, engine components, machines/engines, etc., can solve the problems of wear resistance and oil storage performance that need to be further improved, and achieve improved service life, high efficiency, and fine structure. while the dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

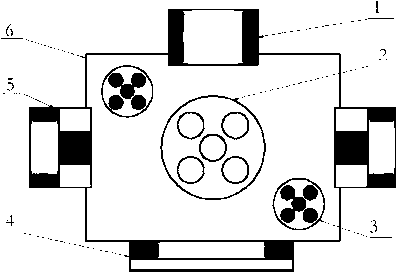

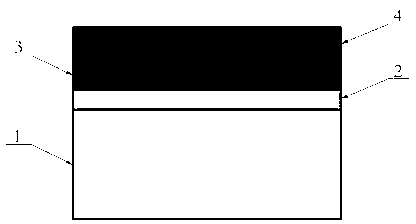

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Under the condition of 200 ℃ and argon gas, the piston ring was glow cleaned; after the end, the transition metal Cr bonding layer was deposited under the conditions of pressure 0.01Pa and bias voltage -800V, and the thickness of the Cr bonding layer was 20 nanometers; Nitrogen, deposited a CrN transition layer at a pressure of 0.1Pa and a bias of -100V, and the thickness of the CrN transition layer was 100 nanometers; finally deposited a Cr-O-N nanocrystalline wear-resistant coating at a pressure of 0.1Pa and a bias of -100V. The flow ratio of nitrogen and oxygen is constant at 1:1, and the Cr-O-N nano-grain size is 200nm. The thickness of the Cr-O-N wear-resistant coating is 0.5 microns. The total thickness of the coating is controlled at 0.62 microns, and after the preparation is completed, it is naturally cooled to obtain a Cr-O-N nanocrystalline composite ceramic coating piston ring.

Embodiment 2

[0040] Example 2: Under the condition of 250 ℃ and argon gas, the piston ring was glow cleaned; after the completion, the transition metal Cr bonding layer was deposited under the condition of air pressure 0.01Pa and bias voltage -800V, and the thickness of the Cr bonding layer was 100 nm; Nitrogen, deposit a CrN transition layer under the condition of pressure 0.5Pa, bias -200V, the thickness of the CrN transition layer is 300 nanometers; finally, deposit Cr-O-N wear-resistant coating under the condition of pressure 0.5Pa, bias -200V, control nitrogen and The flow ratio of oxygen is 2:1, the Cr-O-N nano-grain size is 140 nm, and the thickness of the Cr-O-N wear-resistant coating is 10 microns. The total thickness of the coating is controlled at 10.4 microns, and after the preparation is completed, it is naturally cooled to obtain a Cr-O-N nanocrystalline composite ceramic coating piston ring.

Embodiment 3

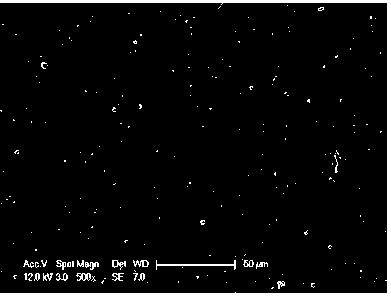

[0041] Example 3: Under the condition of 350 ℃ and argon gas, the piston ring was glow cleaned; after the end, the transition metal Cr bonding layer was deposited under the condition of air pressure 0.05Pa and bias voltage -900V, and the thickness of the Cr bonding layer was 200 nanometers; Nitrogen, deposited a CrN transition layer under the conditions of pressure 1Pa, bias -200V, and the thickness of the CrN transition layer was 500 nanometers; finally, deposited a Cr-O-N wear-resistant coating under the conditions of pressure 1Pa, bias -200V, and controlled the gap between nitrogen and oxygen. The flow ratio is such that it is 5:1 and 1:1 alternately every five minutes, and the Cr-O-N nanocrystal grain size is 40-50 nm. The thickness of the Cr-O-N wear-resistant coating is 20 microns. The total thickness of the coating is controlled at 20.7 microns, and after the preparation is completed, it is naturally cooled to obtain a Cr-O-N nanocrystalline composite ceramic coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com