Lubricating structure and mechanical lubricating device having same

A technology of lubricating structure and center position, applied in mechanical equipment, engine lubrication, engine components, etc., can solve the problems of thin oil film thickness, low oil film pressure, low oil film bearing capacity, etc., to reduce direct contact and improve oil storage. capacity, the effect of increasing service life and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

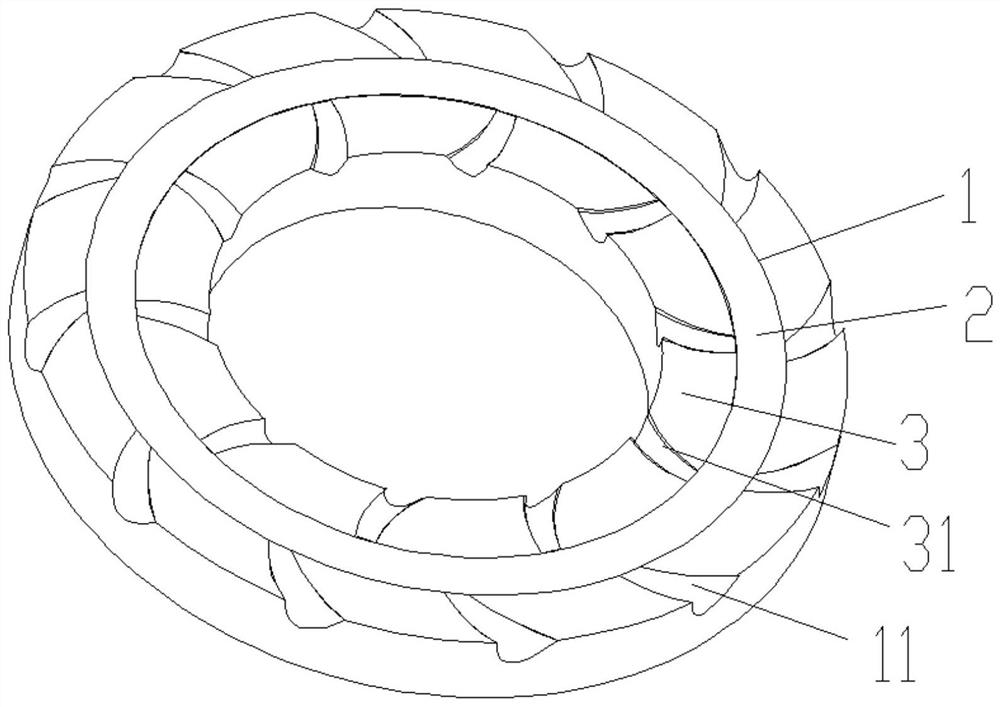

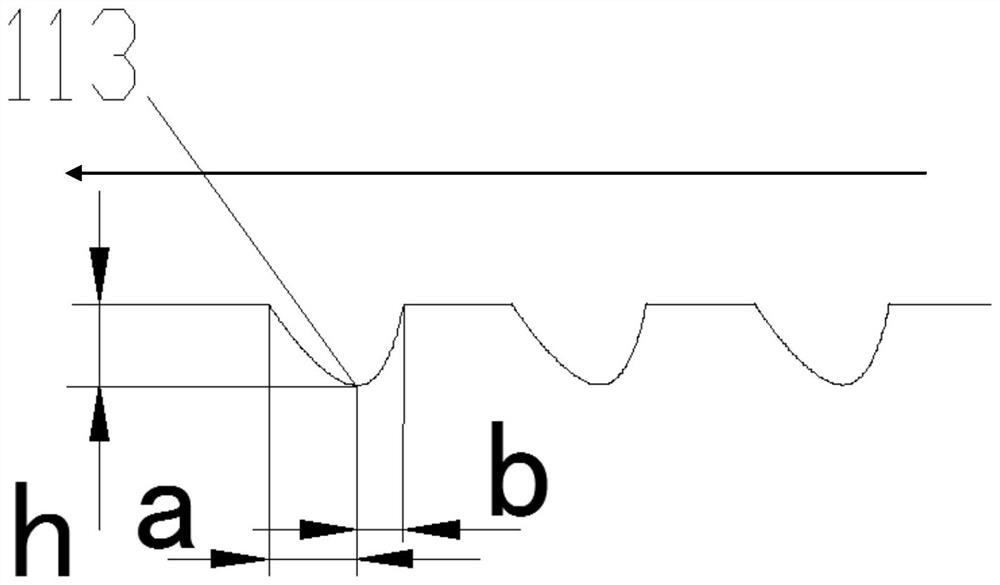

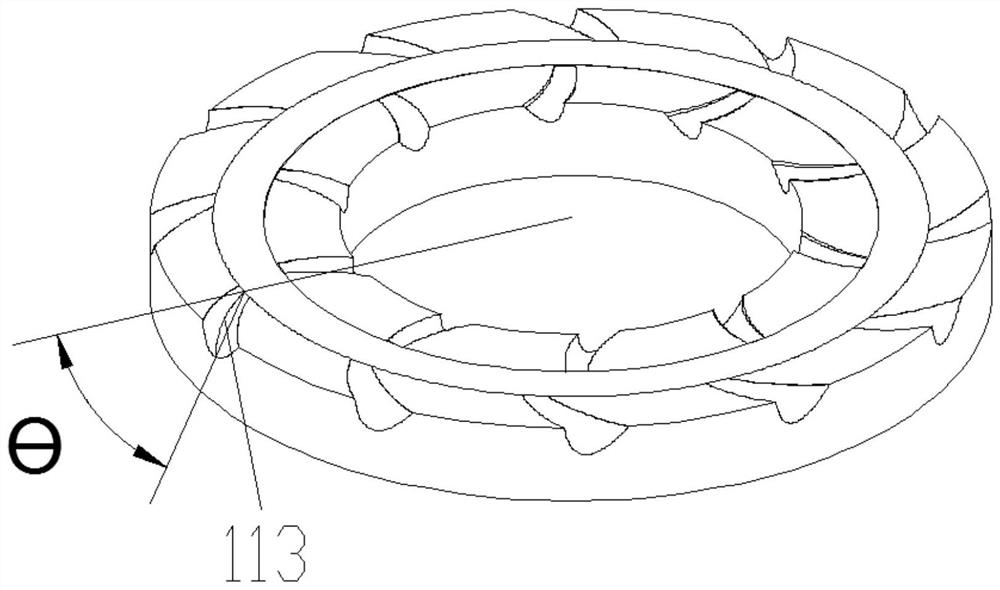

[0030] see in conjunction figure 1 As shown, according to an embodiment of the present application, a lubricating structure includes: an annular lubricating end surface, which includes an annular first converging area 1, an annular dam area 2 and an annular The second converging area 3 is formed, the first converging area 1 and the second converging area 3 are arranged circumferentially around the center point of the lubricating end face; the first converging area 1 is provided with a plurality of The first helical groove 11 extending on the outer peripheral side, a plurality of first helical grooves 11 are arranged circumferentially along the center position of the first converging area 1; and / or, the second converging area 3 is provided with a plurality of A second helical groove 31 extending from the outer peripheral side to the inner peripheral side of 3 , and a plurality of second helical grooves 31 are circumferentially arranged along the central position of the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com