Technique for nitrogen treatment of diesel cylinder cover

A technology of nitriding treatment and cylinder liner, applied in metal material coating process, coating, solid-state diffusion coating, etc. Less, clear texture, good oil storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

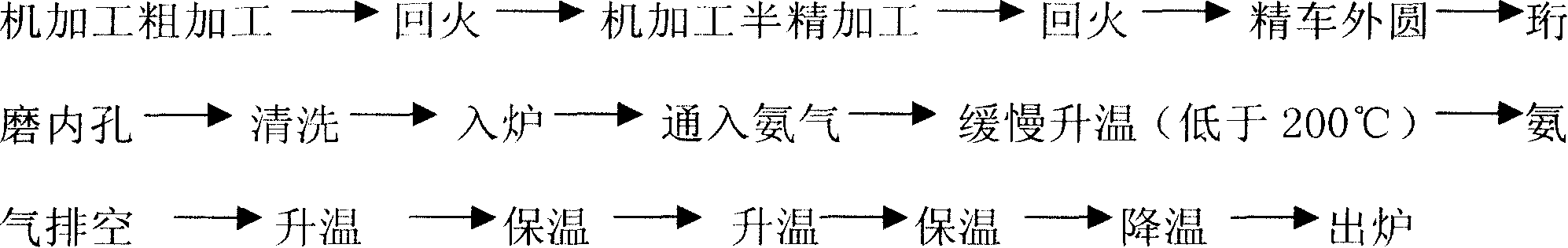

[0009] The technology adopted by the present invention to solve the technical problem is: the nitriding treatment of the cylinder liner is not only a problem of nitriding a process, but a system problem. In order to ensure the quality of nitriding, the problem of nitriding deformation is firstly solved. During the machining process After rough machining, tempering treatment should be carried out to eliminate the internal stress of rough machining and thermal processing. For semi-finishing machining, tempering treatment should also be carried out to eliminate the internal stress of machining, and then the outer circle of finishing car and honing Bore. After machining, the cylinder liner that has passed the geometric dimension inspection is strictly cleaned with gasoline, then dried naturally and put into the furnace. The ammonia gas is introduced at a temperature lower than 200°C, and the air in the furnace is exhausted. The air in the furnace should not be higher than 50 Slowl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com