Chromium-based ceramic composite plating process for piston ring

A ceramic composite and piston ring technology, applied in electrolytic inorganic material coating, electrolytic process, electrolytic components, etc., can solve problems such as cylinder scuffing, achieve the effects of improving lubrication conditions, reducing friction loss, and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

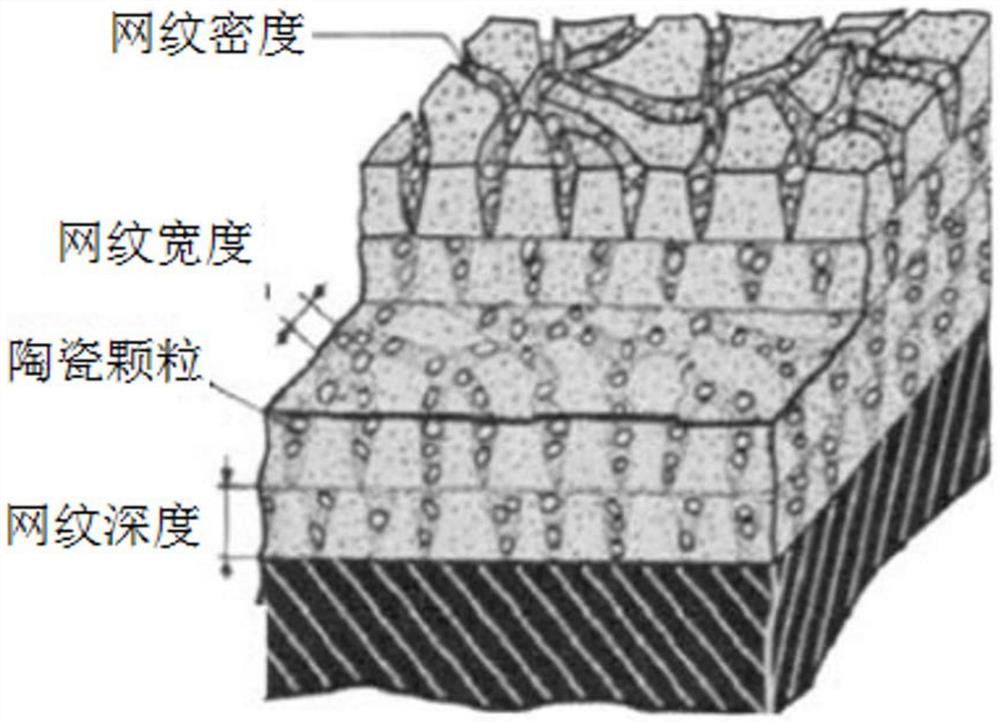

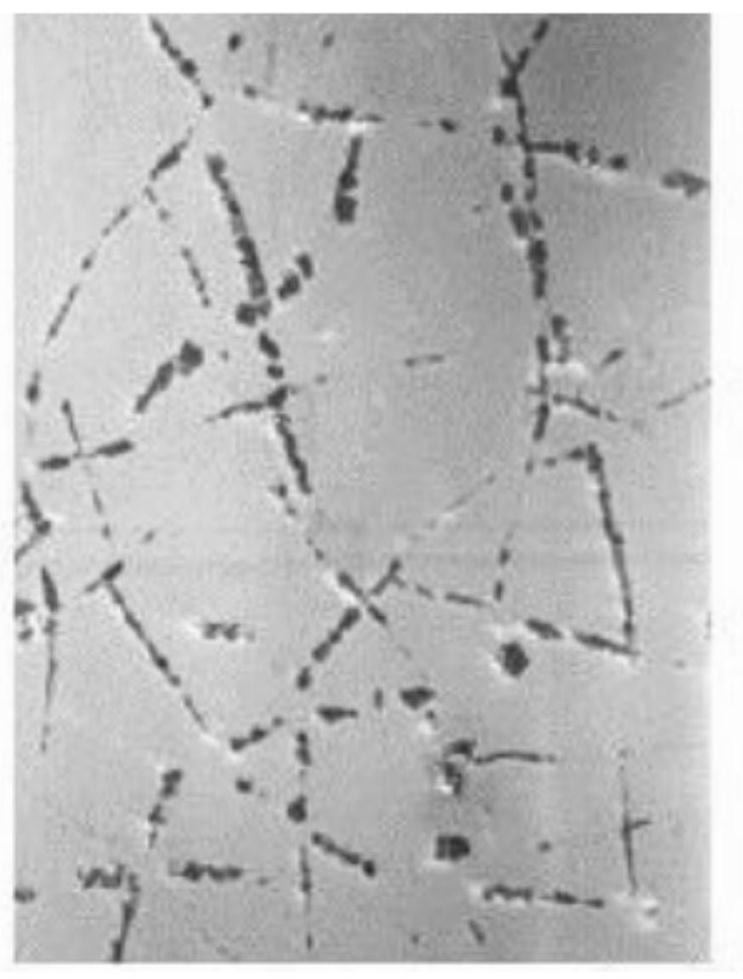

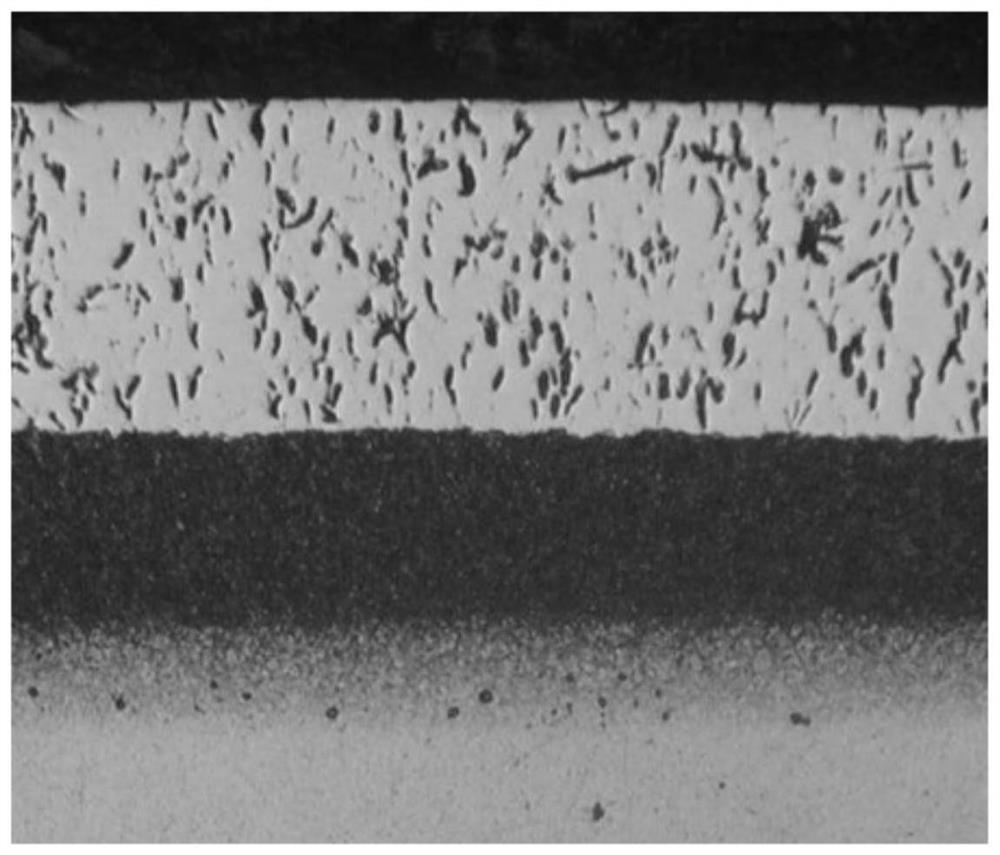

[0103] see Figure 1~3 , in the embodiment of the present invention, the piston ring chromium-based ceramic composite plating process includes the following steps:

[0104] Step 1: clamping, sealing, cleaning

[0105] S1: Receive the corresponding clamping fixture;

[0106] S2: Put the demagnetized piston ring on the special angle iron to straighten the piston ring opening;

[0107] S3: Place the piston ring whose opening alignment height is equal to the clamping length of the shaft on the mandrel in the semicircular tile;

[0108] S4: Use a special tool to apply varnish to the opening gap of the piston ring, then stagger the opening of the piston ring by about 90°, open the pneumatic valve, put the corresponding nut on the mandrel, and tighten it with a wrench;

[0109] S5: Move the shaft with the piston ring to the bracket, brush the varnish on the surface of the piston ring with an iron brush, and wipe the opening with cotton gauze dipped in acetone within 45°, and wipe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com