Compressor with built-in oil separator

A compressor and oil separation technology, applied in the field of compressors, can solve problems such as low energy efficiency of compressor reliability systems, limited oil storage space, and discharge of lubricating oil, so as to improve safety and reliability, improve oil storage capacity, and relax The effect of manufacturing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

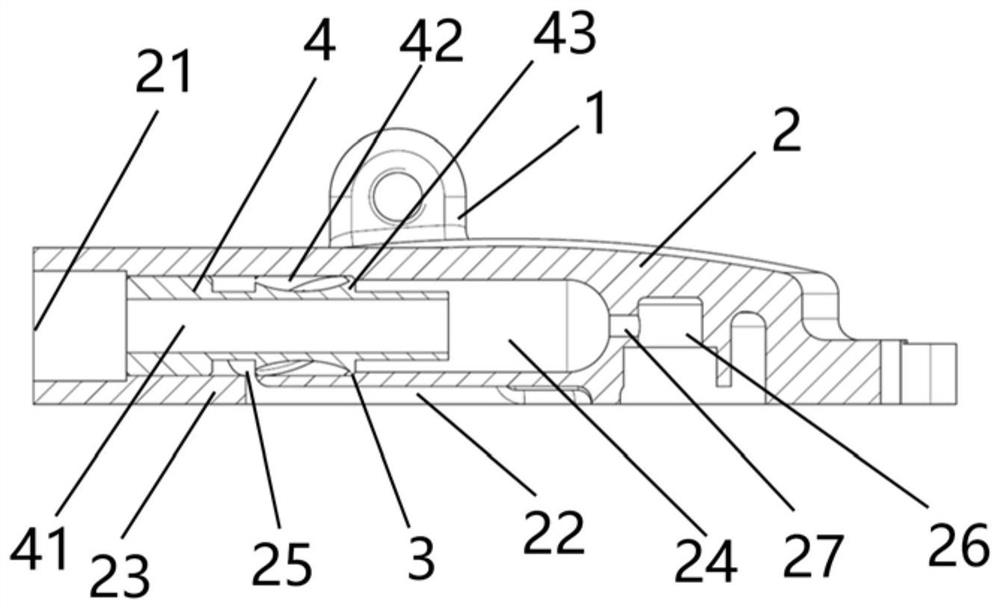

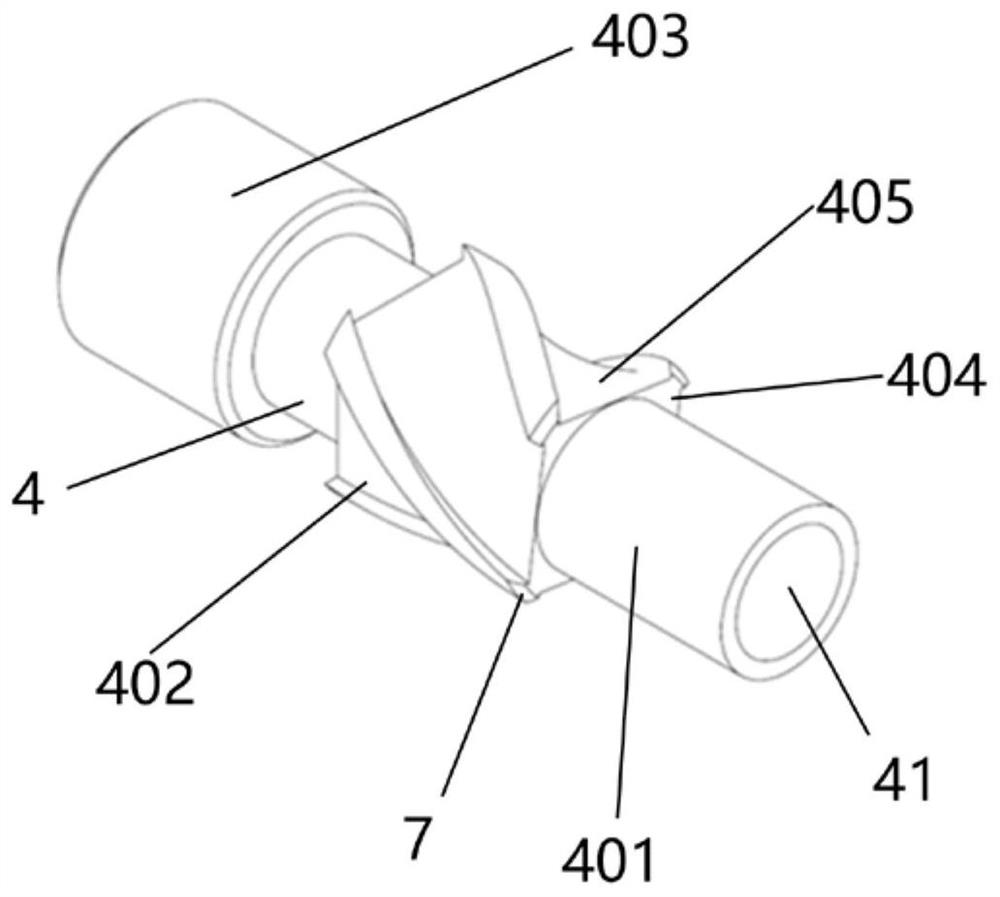

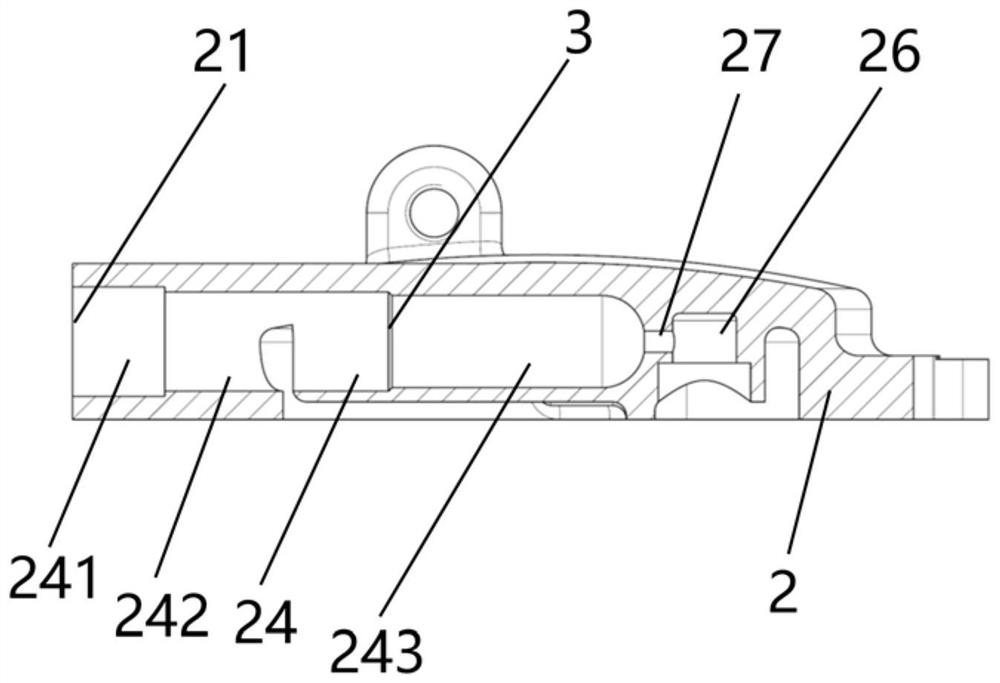

[0034] In a further embodiment of the present invention, the contact portion 43 is formed on the end of the spiral blade 402 away from the exhaust port 21, the contact portion 43 has at least one vertical contact surface 404 and at least one spiral connection surface 405, the vertical contact surface 404 One end is connected to the spiral connection surface 405, and a chamfer structure 7 is formed at the joint between the vertical contact surface 404 and the spiral connection surface 405, and the chamfer structure 7 has an abutment surface, and the abutment surface 7 and the stopper 3, the abutting surface and the axis of the oil channel 24 are set at an angle of 20°. Further, it facilitates the installation and axial positioning of the oil separation mandrel 4, and reduces the noise generated during operation.

[0035] Further, as a preferred embodiment, the stopper portion 3 is an annular surface, and the outer edge of the annular surface protrudes toward the exhaust port 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com