Novel technology for producing fluorine-free chromium-based composite ceramic material coating

A composite ceramic and new process technology, applied in coatings, electrolytic coatings, etc., can solve the problems of insufficient wear resistance, lubricity and strength, and achieve the effects of good wear resistance, low friction coefficient and improved lubricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Take the production of Φ200 oil cylinder as an example to illustrate the main process of production:

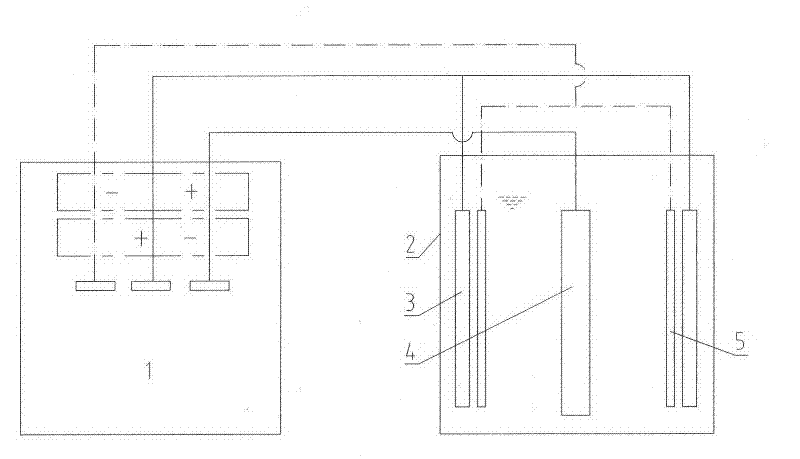

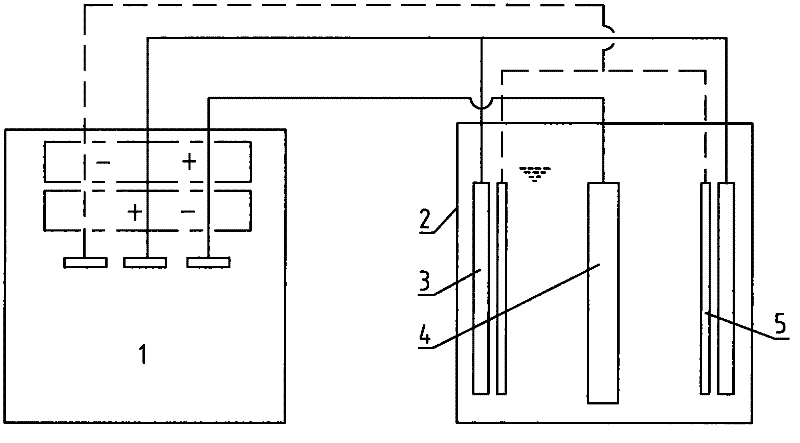

[0013] 1. Prepare 3000L plating solution in chromium-based composite ceramic electrodeposition tank 2, including chromic anhydride 180g / l, sulfuric acid 1.8g / l, FHD additive 3ml / l, trivalent chromium 2g / l, and the rest is pure water; heating plating liquid to 55°C;

[0014] 2. Put the oil tank on the hanger and carry out the necessary pretreatment, then hang it into the tank 2, connect the conductive mechanism, turn on the DC power supply 1, after proper etching and impact, deposit a chromium layer on the inner surface of the oil cylinder for 15 minutes , the current density of this process is 50A / dm 2 ;

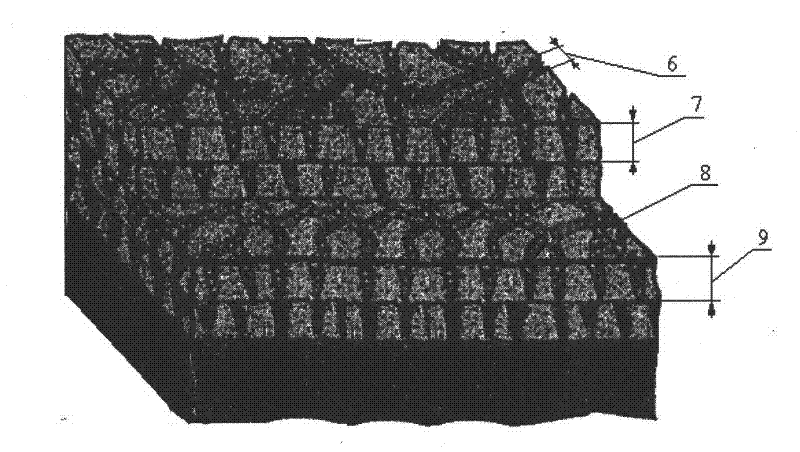

[0015] 3. Switch the electrode, switch the workpiece 4 to the anode, the intermediate cathode 5 is turned on, and the insoluble anode 3 is disconnected; at this time, the reticulation of the chromium layer on the surface of the workpiece 4 is deepened and thickened...

Embodiment 2

[0020] Take the production of high-power 165 piston rings as an example to illustrate the main process of production:

[0021] 1. Prepare 2000L plating solution in chromium-based composite ceramic electrodeposition tank 2, including chromic anhydride 250g / l, sulfuric acid 2.5g / l, FHD additive 5ml / l, trivalent chromium 3g / l, and the rest is pure water; heat plating liquid to 60°C;

[0022] 2. After assembling the piston ring into a cylinder, install the hanger and sandblast it, activate it and hang it into the groove 2, connect the conductive mechanism, turn on the DC power supply 1, and deposit a chromium layer on the outer surface of the piston ring cylinder for 30 minutes. The current density of this process is 60A / dm 2 ;

[0023] 3. Switch the electrode, switch the workpiece 4 to the anode, the intermediate cathode 5 is turned on, and the insoluble anode 3 is disconnected. At this time, the reticulation of the chromium layer on the surface of the workpiece 4 is deepened a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com