Asymmetric groove type sand storage wear-resistant oil well pump plunger

A groove-type, asymmetrical technology, applied in the direction of pump components, variable displacement pump components, components of pumping devices for elastic fluids, etc., can solve problems such as easy wear and tear, and achieve increased work cycle and single well oil production The effect of continuous cost reduction, improvement of oil storage capacity and sand storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

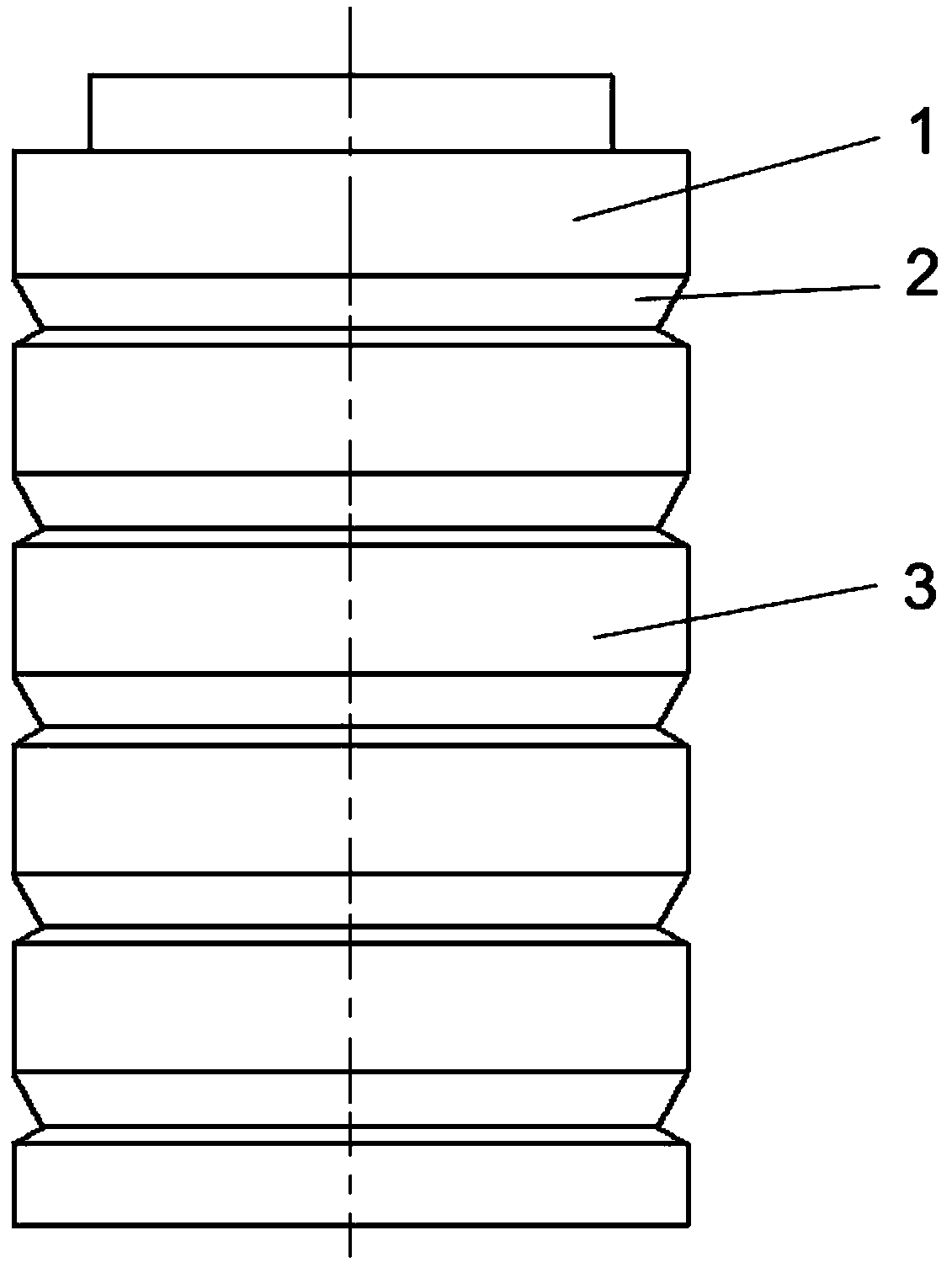

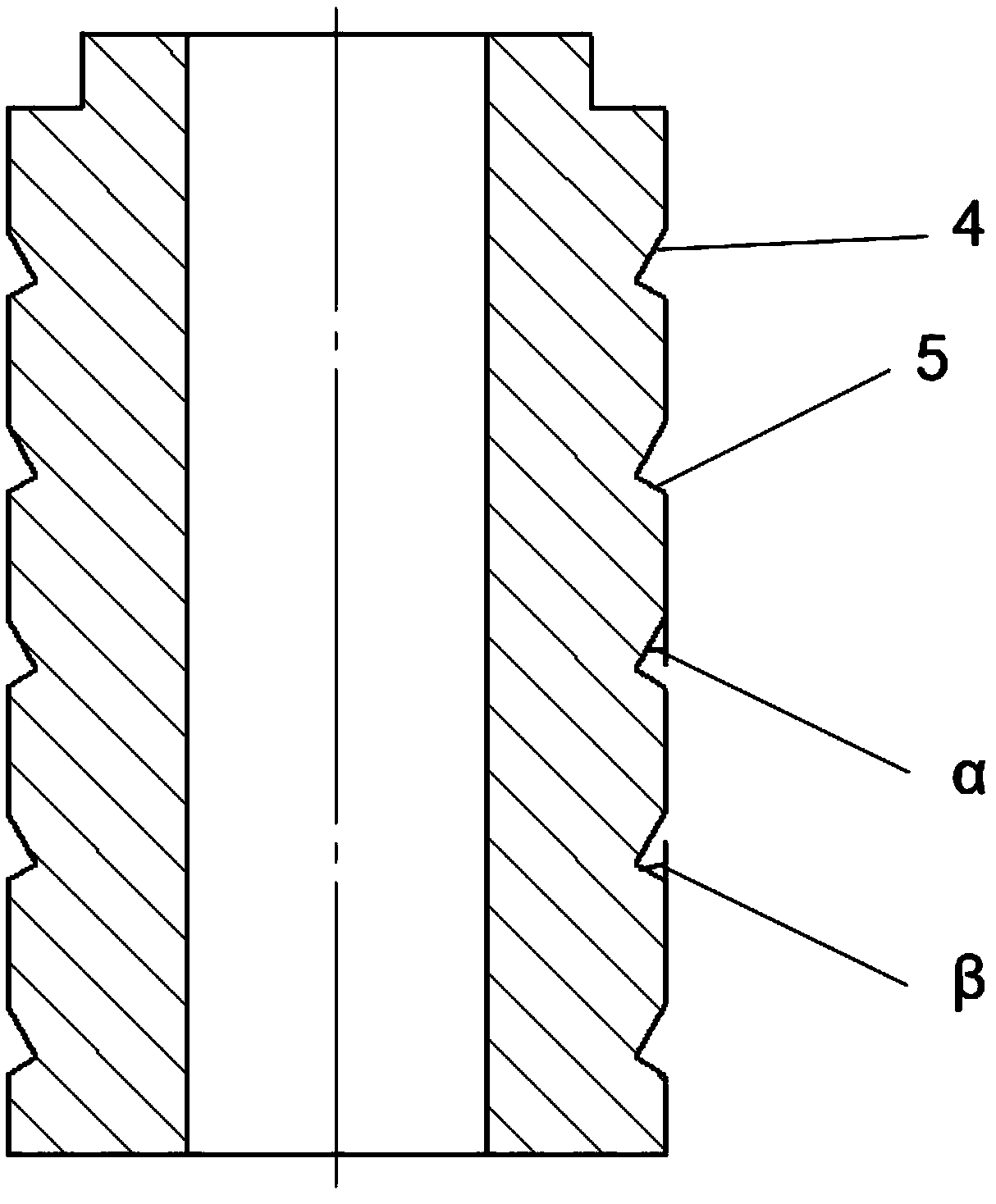

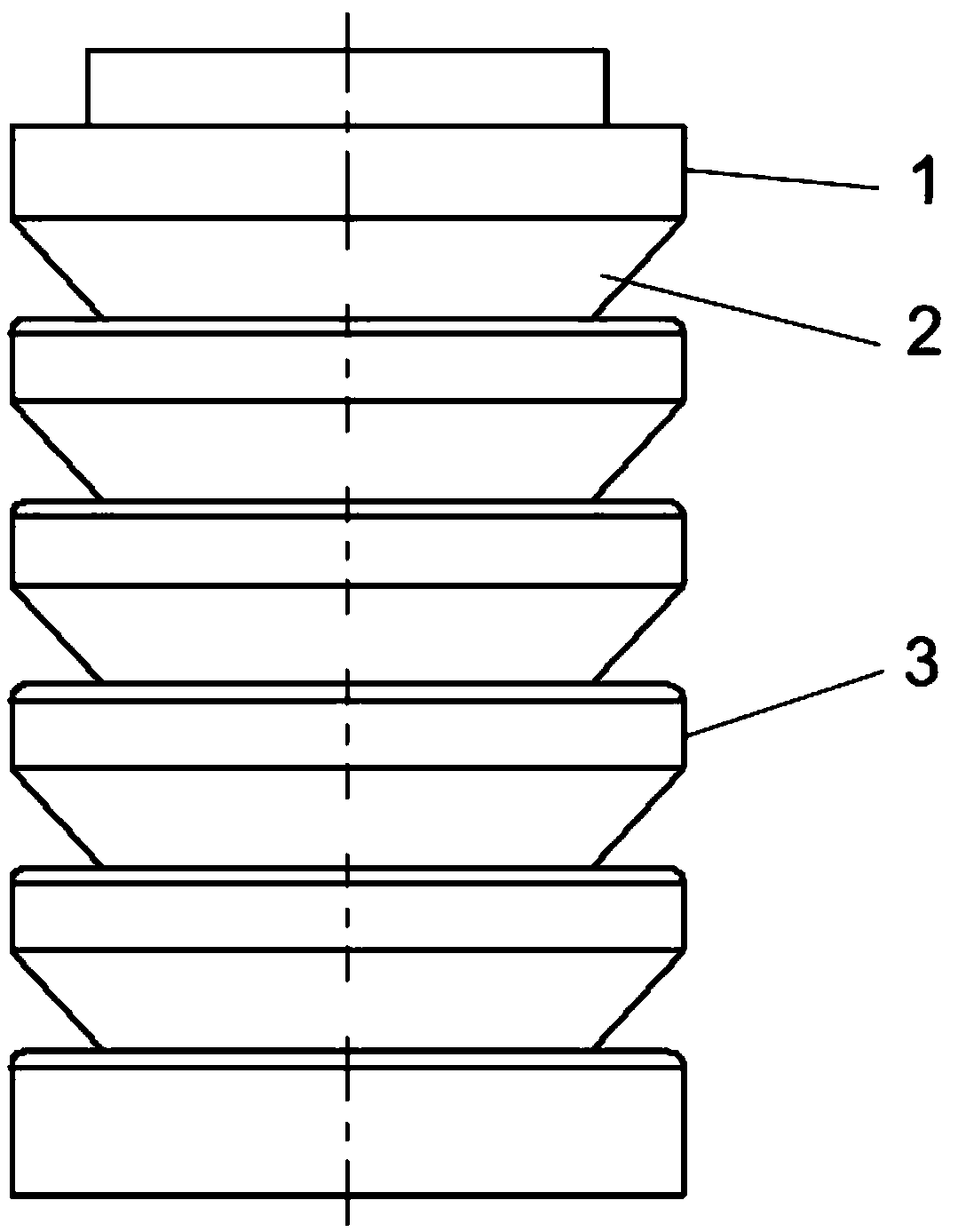

[0020] Such as Figure 1 to Figure 4 As shown, the asymmetric grooved sand storage wear-resistant oil pump plunger provided by the present invention, the asymmetric groove sand storage wear-resistant oil well pump plunger is provided with an annular groove coaxial with the plunger body 1 surface 2, and arranged at equal intervals along the axial direction of the plunger body 1, the width of the annular groove 2 along the axial direction of the plunger body 1 is L 1 , the interval width between two adjacent annular grooves 2 is set as L 2 , and L 1 :L 2 =1: (1.5~3); the angle between the upper wall surface 4 of the annular groove 2 and the plunger body 1 is α, and the axial inclination angle between the lower wall surface 5 of the annular groove 2 and the plunger body 1 The included angle is β, where α>β.

[0021] The surfaces of the plunger body 1 and the annular groove 2 are coated with a wear-resistant coating 3 to form a distribution structure with wear-resistant charac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com