A carbonitriding surface treatment method for piston rings using liquid-phase arc discharge

An arc discharge and carbonitriding technology, applied in metal material coating process, coating, solid diffusion coating and other directions, to achieve the effect of high fatigue strength, good lubrication performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

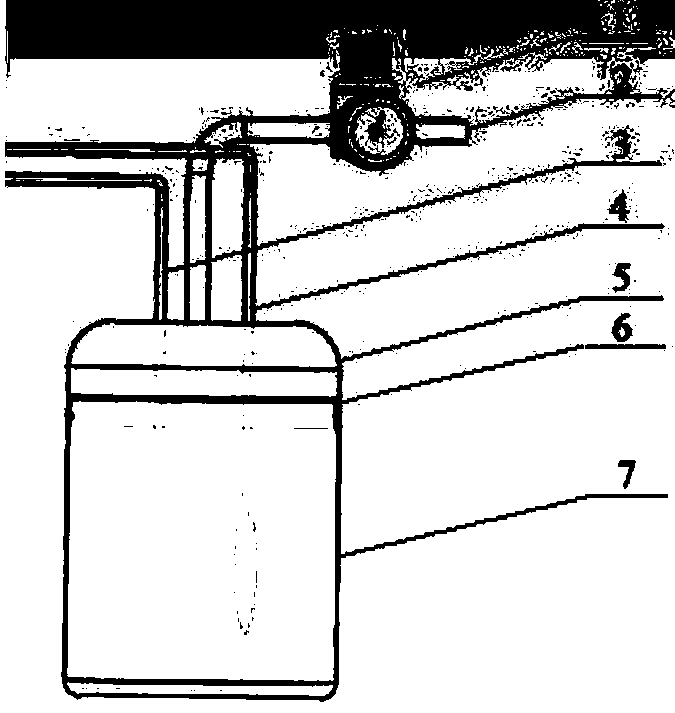

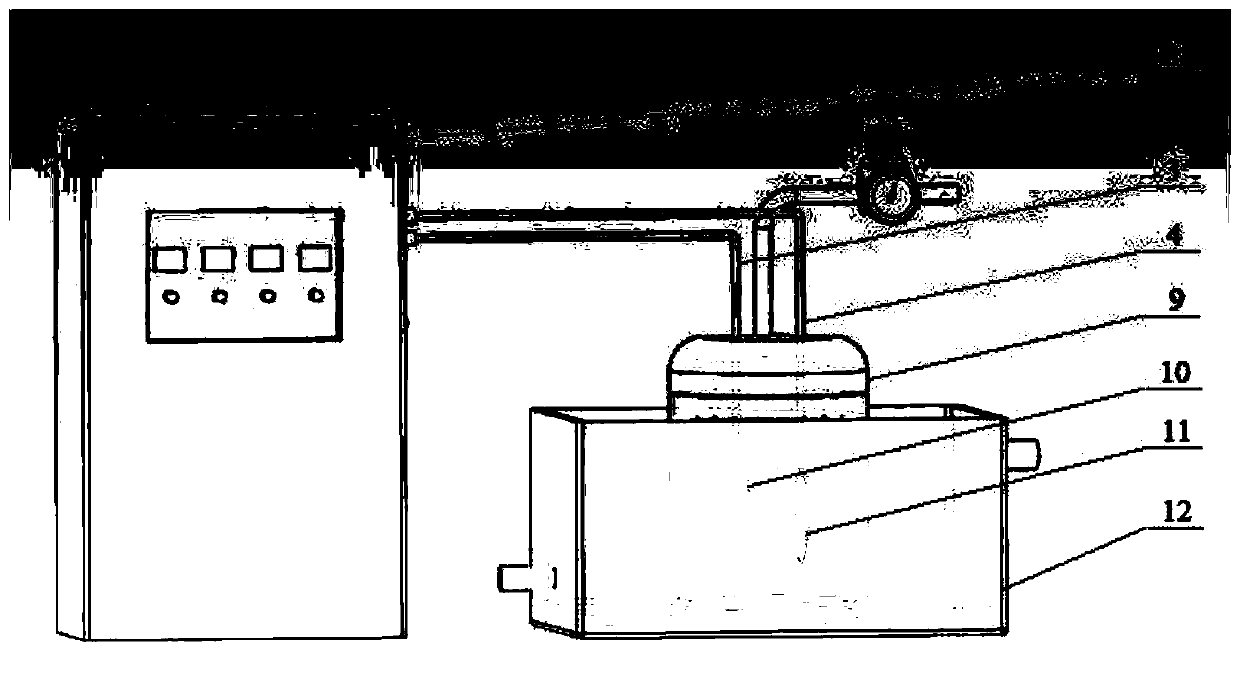

Method used

Image

Examples

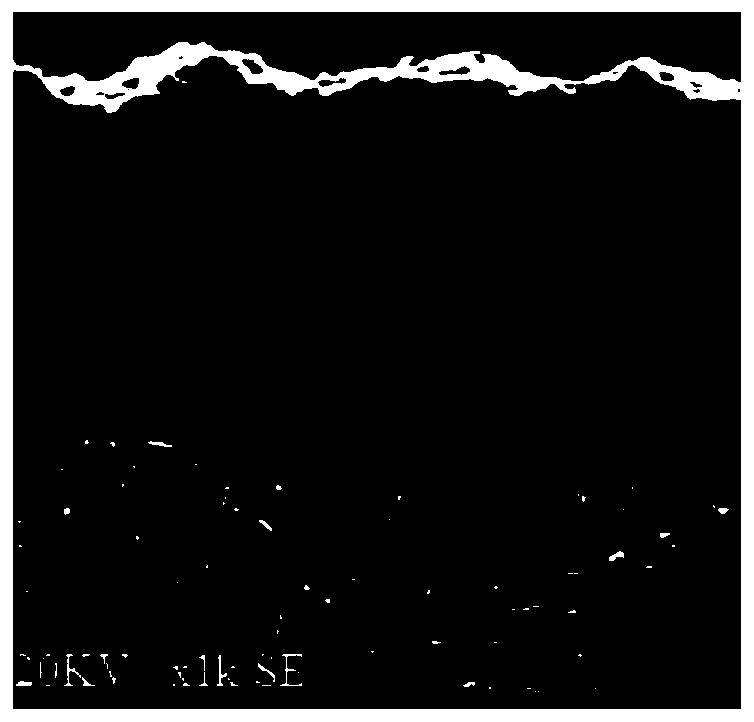

Embodiment 1

[0053] First, the outer diameter surface of the alloy cast iron piston ring obtained after the shaping and cleaning process is polished on metallographic sandpaper to a particle size of 1000#, then the polished piston ring is cleaned with acetone and wiped clean, and then the upper and lower steps of the piston ring are polished. , The inner diameter surface and the end surface are coated with high-temperature resistant insulating varnish, and put into a drying oven to dry at 105°C for 3 hours for later use. Take 1.5L of tap water, add 500g of urea, stir rapidly until it is completely dissolved, pour it into a container, add tap water to 2L and mix evenly to obtain a reaction solution. Connect the pretreated piston ring and the inert electrode to the cathode and anode wires respectively, then immerse in the prepared solution, apply voltage to 360V, keep the pressure in the container at 0.8bar, and treat for 5min to obtain a thickness of 80μm In the penetration layer, the micro...

Embodiment 2

[0055] First, the outer diameter surface of the alloy cast iron piston ring obtained after the shaping and cleaning process is polished on metallographic sandpaper to a particle size of 1000#, then the polished piston ring is cleaned with acetone and wiped clean, and then the upper and lower steps of the piston ring are polished. , The inner diameter surface and the end surface are coated with high-temperature resistant insulating varnish, and put into a drying oven to dry at 105°C for 3 hours for later use. Take 1.5L of tap water, add 800g of urea, stir rapidly until it is completely dissolved, pour it into a container, add tap water to 2L and mix evenly to obtain a reaction solution. Connect the pretreated piston ring and the inert electrode to the cathode and anode wires respectively, then immerse in the prepared solution, apply a voltage of 400V, keep the pressure in the container at 1bar, and treat for 10min to obtain a thickness of 120μm. In the permeable layer, the micr...

Embodiment 3

[0057] First, the outer diameter surface of the alloy cast iron piston ring obtained after the shaping and cleaning process is polished on metallographic sandpaper to a particle size of 1000#, then the polished piston ring is cleaned with acetone and wiped clean, and then the upper and lower steps of the piston ring are polished. , The inner diameter surface and the end surface are coated with high-temperature resistant insulating varnish, and put into a drying oven to dry at 105°C for 3 hours for later use. Take 1.5L of tap water, add 500g of urea, stir rapidly until it is completely dissolved, pour it into a container, add tap water to 2L and mix evenly to obtain a reaction solution. Connect the pretreated piston ring and the inert electrode to the cathode and anode wires respectively, then immerse in the prepared solution, apply voltage to 420V, keep the pressure in the container at 1.6bar, and treat for 5min to obtain a thickness of 100μm. The penetration layer, the covera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com