Multi-surface detection equipment

A surface detection and equipment technology, applied in the field of multi-surface detection equipment, can solve the problems of low work efficiency, high labor cost, large floor area, etc., and achieve high detection and transfer efficiency, high stability and reliability, and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

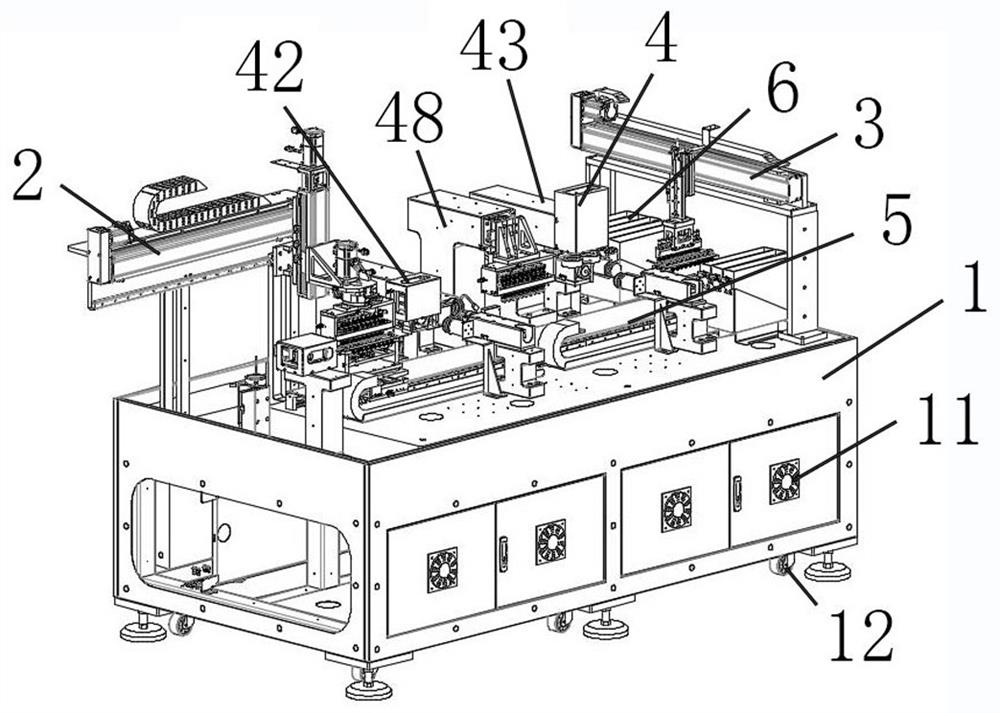

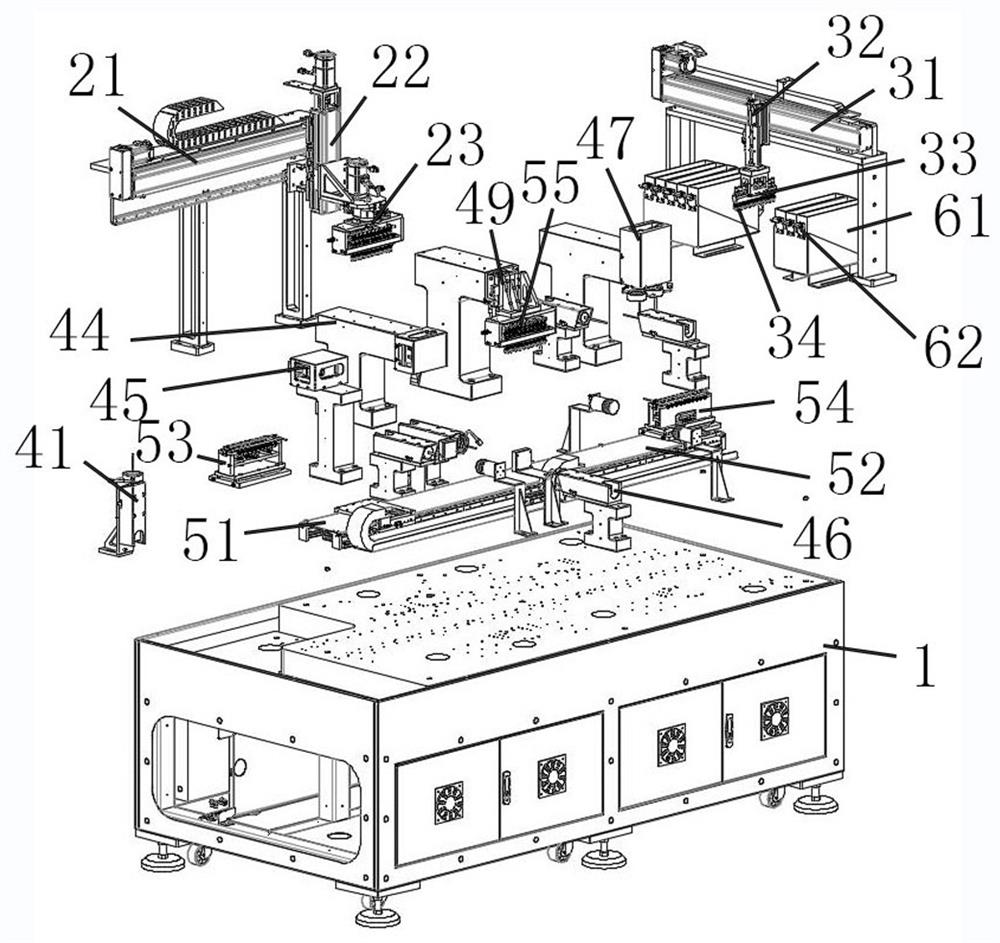

[0065] see figure 1 and figure 2 , a multi-faceted detection equipment, comprising a chassis 1, a first transport module 2, a second transport module 3, a detection device 4, a transfer module 5, a distribution box 6 and a control system;

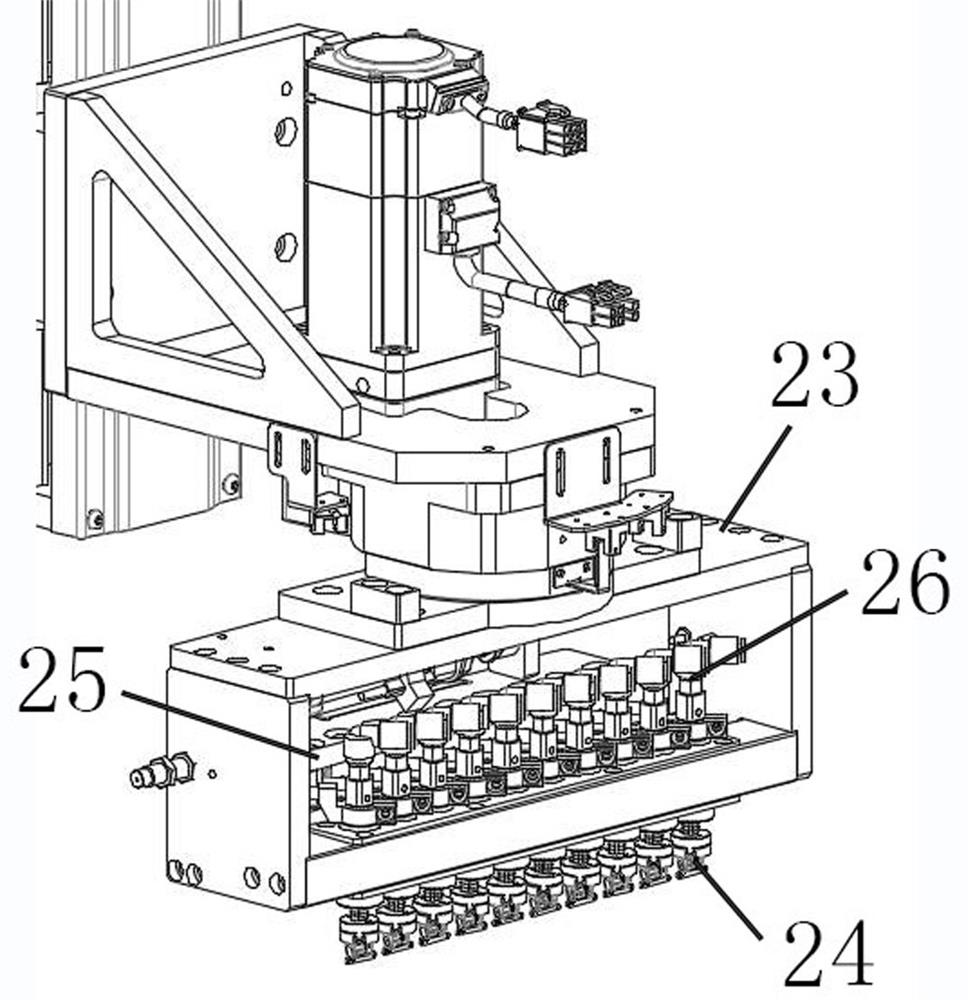

[0066] The first handling module 2 includes a first lateral movement device 21 , a first longitudinal movement device 22 disposed on the first transverse movement device 21 and a first suction device 23 disposed on the first longitudinal movement device 22 , Several rotary suction heads 24 are arranged in the first suction device 23;

[0067] The second handling module 3 includes a second lateral movement device 31 , a second longitudinal movement device 32 disposed on the second transverse movement device 31 and a second suction device 33 disposed on the second longitudinal movement device 32 , Several suction heads 34 are arranged in the second suction device;

[0068] The transfer module 5 includes a first transfer device 51 and a se...

Embodiment 2

[0118] This embodiment is carried out on the basis of the first embodiment above, and the similarities with the first embodiment will not be repeated.

[0119] In this embodiment, the first detection component is disposed around the second transfer device, and the second detection component is disposed around the first transfer device.

[0120]Further, the first detection component includes two 3D side cameras and a 3D top camera, the 3D top camera is located above the second transfer device, and the two 3D side cameras are respectively located The two adjacent sides of the second transfer device; the second detection component includes two 2D side cameras and a 2D top camera; the 2D top camera is located above the first transfer device, so The 2D side cameras are located on opposite sides of the first transfer device.

[0121] Further, when the first material suction device transfers on the first lateral moving device, the bottom surface camera takes pictures; when the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com