Miniature grinding device for mechanical manufacturing design

A kind of mechanical manufacturing and miniature technology, which is applied in the field of micro-grinding devices for mechanical manufacturing design, can solve problems such as easy-to-produce errors, and achieve the effect of improving grinding efficiency and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

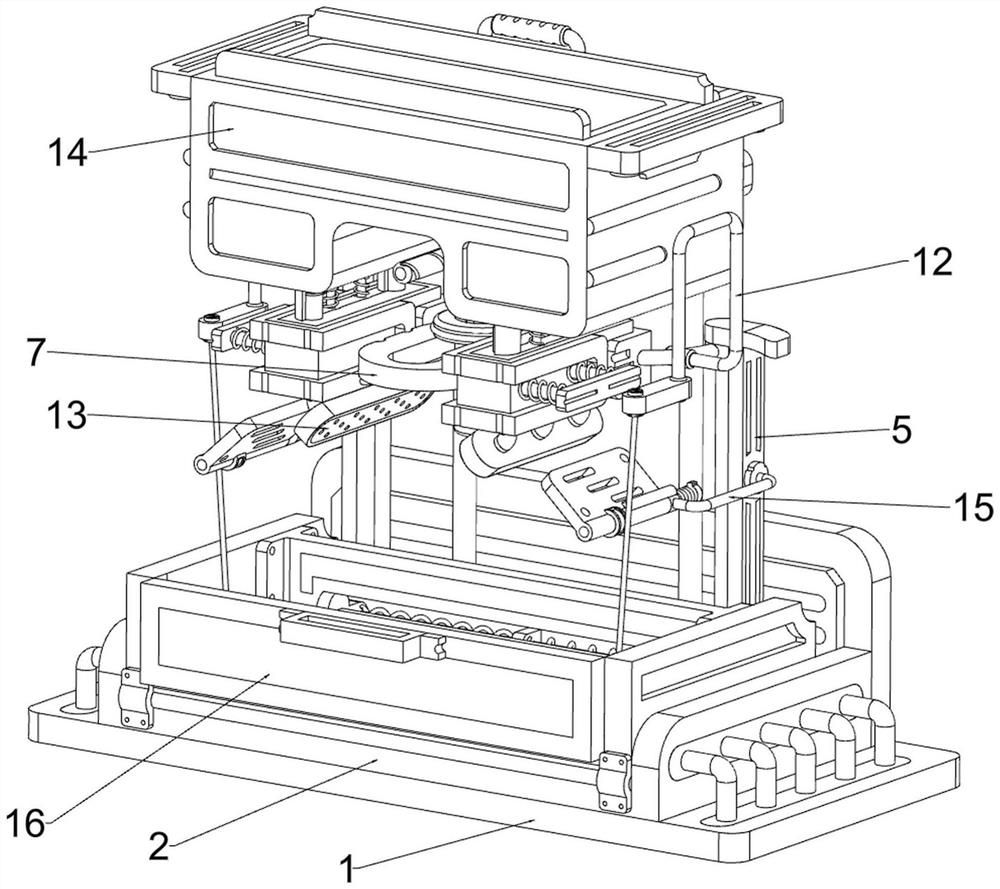

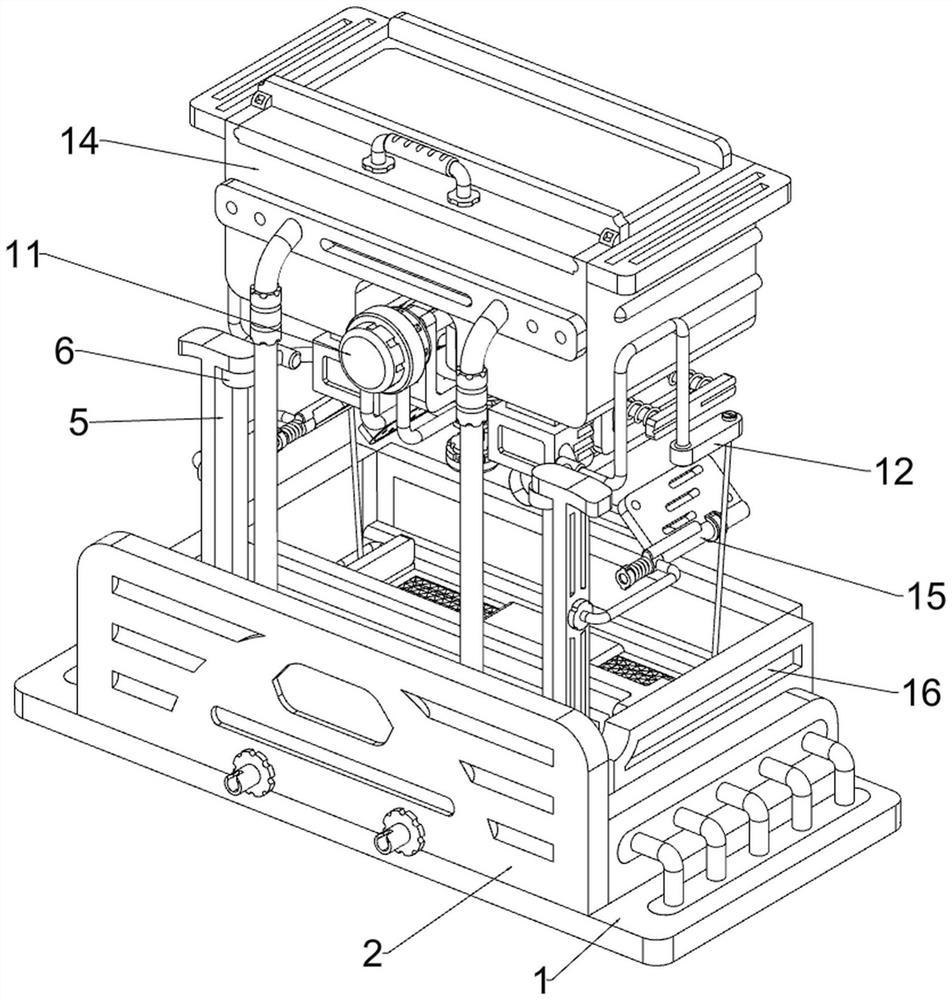

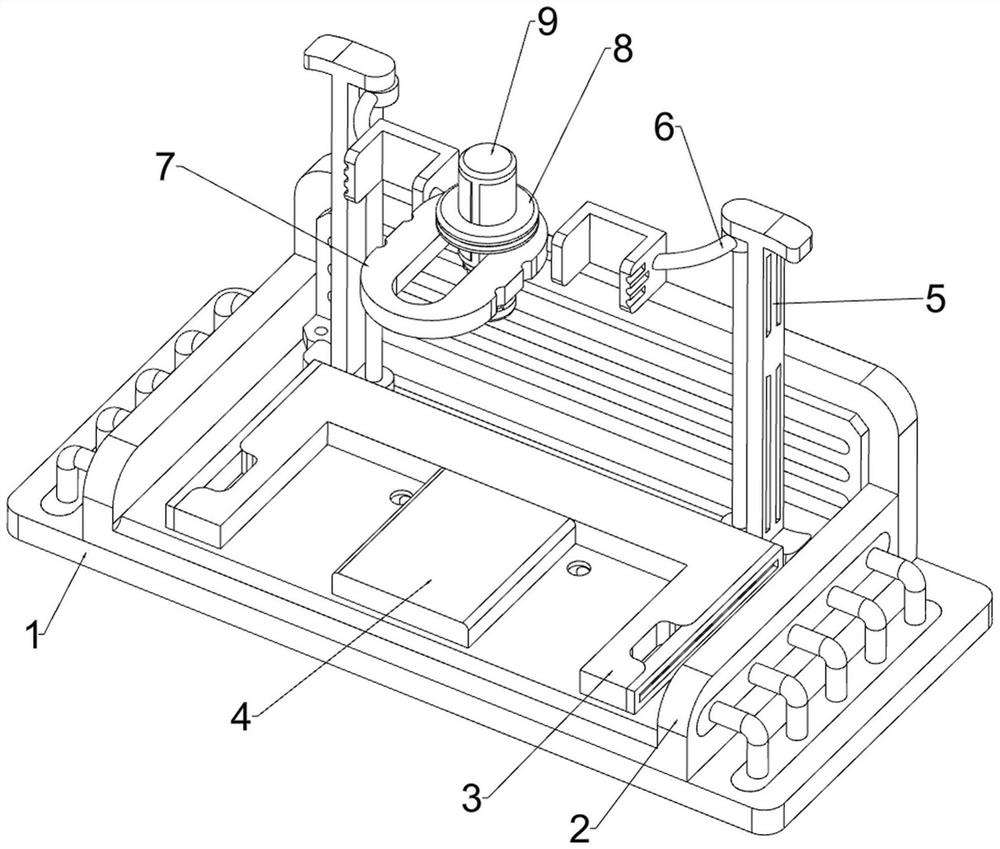

[0039] A micro-grinding device for mechanical manufacturing design, in Figure 1-4 As shown in the figure, it includes a base 1, a support base 2, a connecting base 3, a workbench 4, an electric slide rail 5, a slider 6, a lifting frame 7, a limit block 8, a motor 9, a grinding block 10, an adjustment mechanism 11 and Clamping mechanism 12, the top of the base 1 is provided with a support seat 2, the support seat 2 is provided with a connecting seat 3, the middle of the support seat 2 is welded with a worktable 4 for placing mechanical parts, and the left and right sides of the inner rear of the support seat 2 are The electric slide rails 5 are installed, the upper sides of the two electric slide rails 5 are slidably provided with a sliding block 6, a lifting frame 7 is connected between the two sliding blocks 6, and the lifting frame 7 is slidably provided with a limit block 8 to limit the sliding block 8. A motor 9 for driving is installed on the position block 8, and a grin...

Embodiment 2

[0044] On the basis of Example 1, in figure 1 , Figure 8 , Figure 9 and Figure 10 It also includes a cooling mechanism 13, and the cooling mechanism 13 includes a housing 131, a spray head 132, a connecting pipe 133, a second fixing frame 134, a blocking frame 135, a telescopic spring 136, a push frame 137 and an extension spring 138, The front sides of the two sliders 6 are connected with housings 131 for storing cooling liquid by means of bolts. The bottoms of the two housings 131 are provided with spray heads 132 capable of spraying the cooling liquid, and the tops of the two housings 131 are provided with The connecting pipes 133 for transmitting the cooling liquid are symmetrically arranged in the front and rear. The four connecting pipes 133 are all communicated with the casing 131 on the same side. A second fixing frame 134 is welded to each of the two second fixing frames 134 , and a baffle frame 135 capable of blocking the feeding chute is slidably provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com