Hydrogenation method and system suitable for filling pressure of 35 or 70 MPa

A hydrogenation system and pressure technology, which can be applied to the method of container discharge, equipment loaded into pressure container, equipment discharged from pressure container, etc., can solve the problem of high risk, low utilization rate of hydrogen compression equipment 3', high pressure There are many problems such as the number of hydrogen storage bottles, which can reduce the risk, reduce the number, and improve the reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

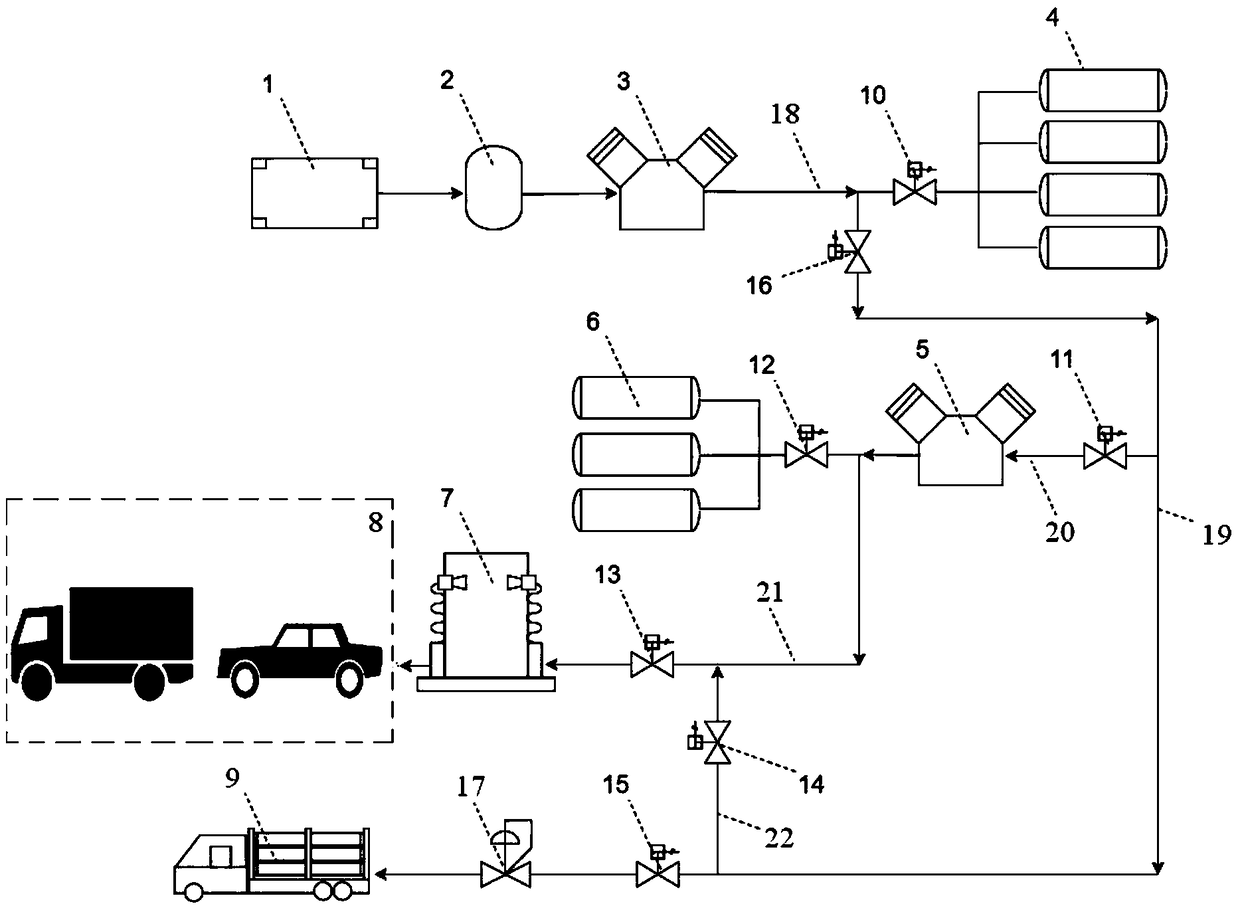

[0070] The specific structure of this embodiment is as image 3 As shown, in this embodiment, the injection pressure is 35MPa and the hydrogenation unit 7 is a low-pressure hydrogenation machine with an injection pressure of 35MPa as an example for illustration.

[0071] The 0.6-3MPa hydrogen produced by the hydrogen production unit 1 in the station is temporarily stored in the buffer tank 2, and after being pressurized to 15-20MPa by the low-pressure hydrogen compression equipment 3 (such as a compressor or pump), it is stored in the low-pressure hydrogen storage unit 4 Among them, the low-pressure hydrogen storage unit 4 is composed of several hydrogen storage bottles with a rated working pressure of 20MPa. The 15-20MPa hydrogen in the low-pressure hydrogen storage unit 4 is further pressurized to above 40MPa (such as 45MPa) by the high-pressure hydrogen compression unit 5, and then stored in the high-pressure hydrogen storage unit 6. The high-pressure hydrogen storage bottl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com