System and method for rapid hydrogen filling

A hydrogen, fast technology, used in container filling methods, piping systems, gas/liquid distribution and storage, etc., can solve problems such as alarming costs, improve safety, reduce temperature rise, and reduce pipeline resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

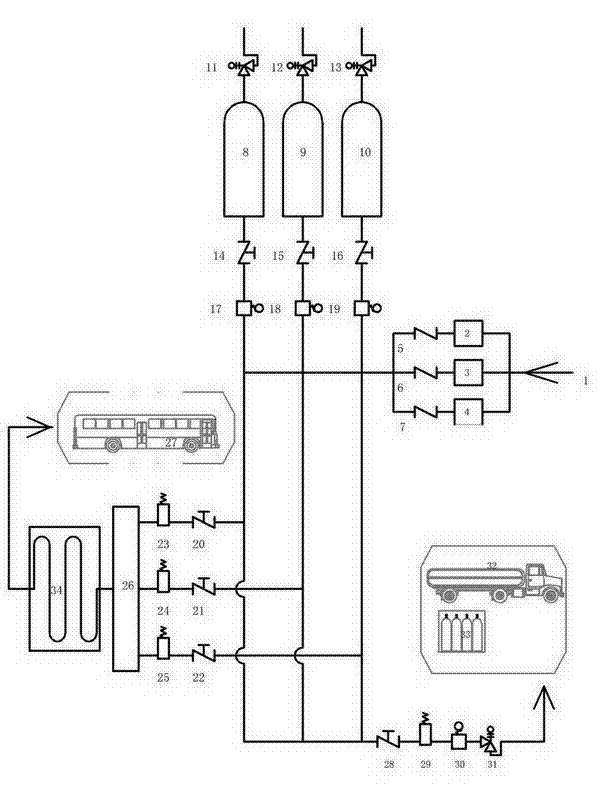

[0016] The rapid filling system provided by the present invention includes: hydrogen compression equipment, hydrogen storage equipment and hydrogen filling equipment. The hydrogen compression equipment includes 75MPa compressors 2, 3, and 4 and check valves 5, 6, and 7. Hydrogen storage equipment includes 75MPa hydrogen storage tanks 8, 9, 10 and safety valves 11, 12, 13. Hydrogen filling equipment includes energy hydrogen filling equipment for filling hydrogen for automobiles and industrial hydrogen filling equipment for filling long-tube bundle vehicles or gas cylinders with hydrogen. The hydrogen filling equipment for energy includes needle valves 20 , 21 and 22 , pressure sensors 23 , 24 and 25 , a hydrogenation machine 26 , and a pre-cooling device 34 . The industrial hydrogen filling equipment includes a needle valve 28 , a pressure sensor 29 , a solenoid valve 30 and a safety valve 31 . The connecting pipelines of the hydrogen storage equipment, the hydrogen compressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com