Solid hydrogen storage material for hydrogen refueling station and preparation method and application thereof

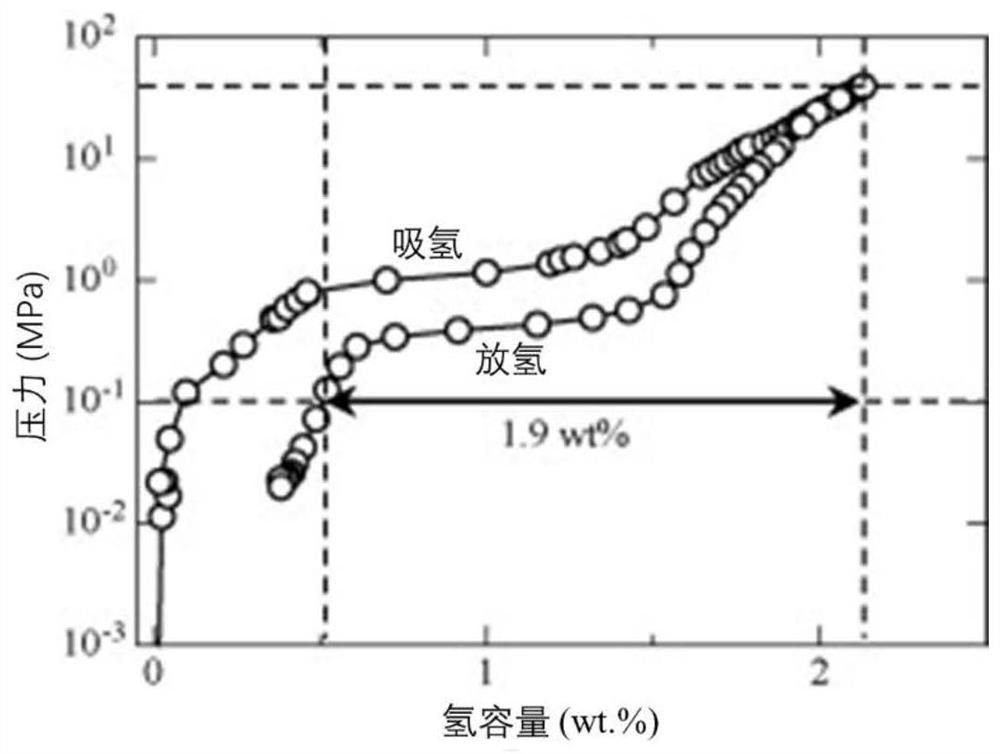

A hydrogen storage material and hydrogen refueling station technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve problems such as deviation of effective hydrogen storage, inability to refuel, and low decomposition pressure of hydrogen desorption balance, and achieve good cycle stability properties, excellent room temperature hydrogen absorption and desorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The chemical composition of TiCr-based high-entropy intermetallic compounds is Ti 0.9 Zr 0.1 Cr 1.8 mn 0.1 Fe 0.1 , Calculate the addition amount of Ti, Zr, Cr, Mn, Fe elemental raw materials according to the above chemical formula. Among them, the purity of the Ti, Zr, Cr, Mn, and Fe elemental raw materials used is above 99%. The above raw materials are weighed according to the calculated addition amount after the surface is cleaned and dried. Put the weighed raw materials in the water-cooled copper crucible of the magnetic levitation induction melting furnace. After evacuating to a vacuum of 0.9 Zr 0.1 Cr 1.8 mn 0.1 Fe 0.1 Ingot casting of high-entropy intermetallic compounds.

Embodiment 2

[0035] The chemical composition of TiCr-based high-entropy intermetallic compounds is Ti 0.85 Zr 0.15 Cr 1.7 mn 0.15 Fe 0.15 , Calculate the addition amount of Ti, Zr, Cr, Mn, Fe elemental raw materials according to the above chemical formula. Among them, the purity of the Ti, Zr, Cr, Mn, and Fe elemental raw materials used is above 99%. The above raw materials are weighed according to the calculated addition amount after the surface is cleaned and dried. Put the weighed raw materials in the water-cooled copper crucible of the magnetic levitation induction melting furnace. After evacuating to a vacuum of 0.85 Zr 0.15 Cr 1.7 mn 0.15 Fe 0.15 Ingot casting of high-entropy intermetallic compounds.

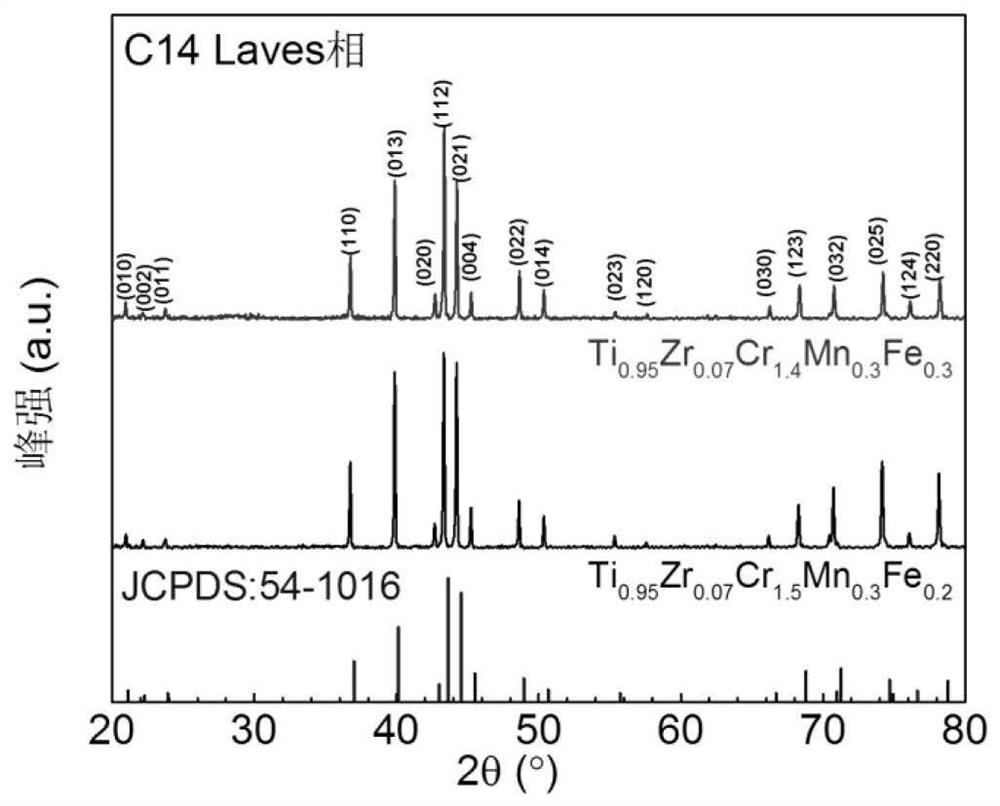

[0036] The ingot XRD collection of illustrative plates of embodiment 1~2 is as figure 2 As shown, it can be found that the prepared Ti 1-x Zr x Cr 2-x mn x Fe x (x = 0.1, 0.15) high-entropy intermetallic compounds have a highly ordered single C14 Laves phase structure, ...

Embodiment 3

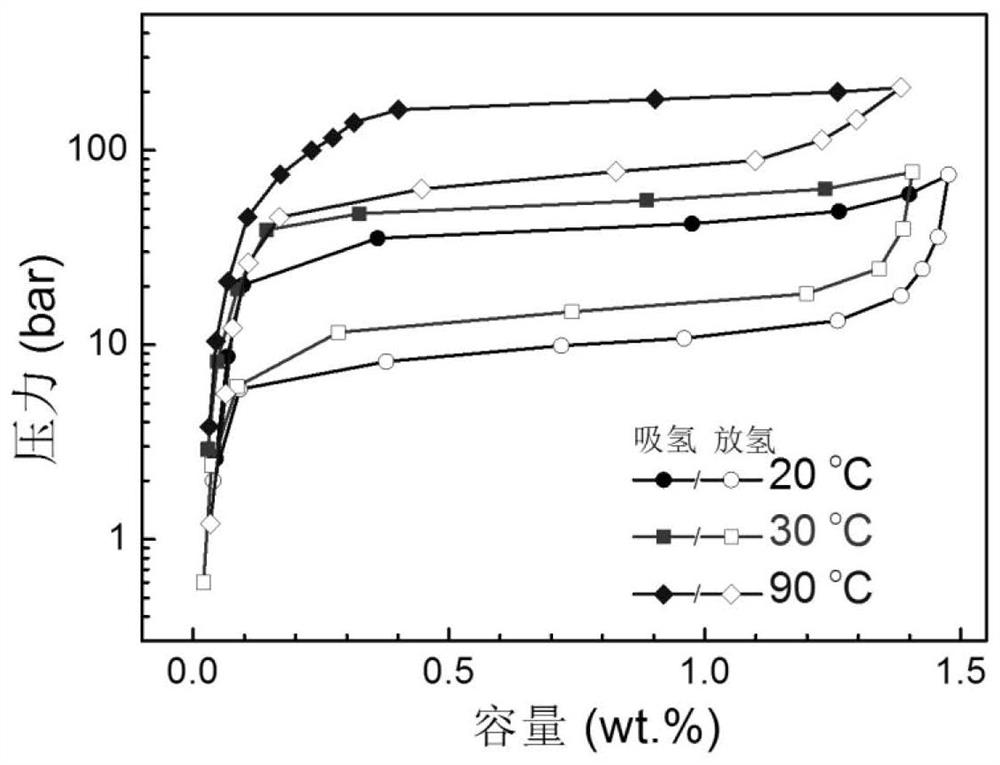

[0038] The MmNi of comparative example 1 and embodiment 1~2 5 Alloy, Ti 0.9 Zr 0.1 Cr 1.8 mn 0.1 Fe 0.1 、Ti 0.85 Zr 0.15 Cr 1.7 mn 0.15 Fe 0.15 The surface of the ingot is cleaned and polished, then mechanically pulverized and placed in a sealed container for evacuation for 1 hour, and then 100 bar high-purity hydrogen is filled into the container at room temperature (25°C) to absorb hydrogen for 0.5 hours to activate the ingot. The ingot is fully activated by hydrogen absorption and completely crushed into a powder sample to obtain a hydride sample; then vacuumized at 25°C for 15 minutes to obtain an active fully dehydrogenated material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com