Method for increasing hydrogen utilization ratio of guaiacol during hydrodeoxygenation under normal pressure and reducing carbon atom loss

A technology of guaiacol and deoxygenation reaction, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, molecular sieve catalysts, etc., can solve the problems of adding aromatic hydrocarbon compounds and other problems, and achieve the improvement of hydrogen Utilization rate, reduced loss, effect of reducing carbon atom loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

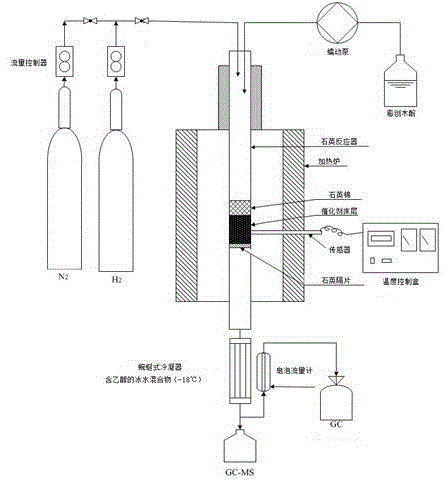

Method used

Image

Examples

Embodiment 1

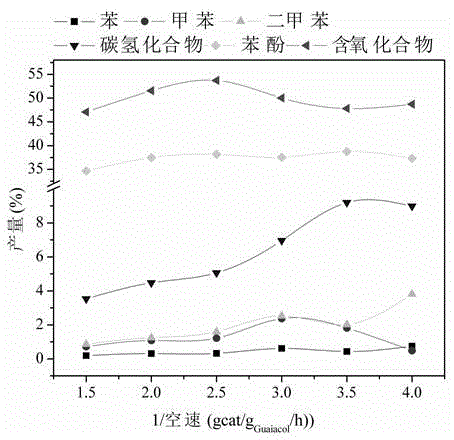

[0028] Example 1 Effect of Different Catalysts on the Synergistic Transmethylation of Guaiacol Hydrodeoxygenation

[0029] Experimental conditions: feed rate 0.1g / min, catalyst dosage 18g, hydrogen flow rate 0.29L / min. The feed amount of guaiacol and hydrogen was controlled at a molar ratio of 1:40. Reaction temperature: 350°C, reaction pressure: normal pressure, 1 / WHSV is 3.0h -1 , Selected catalysts: Fe / Ni / HBeta, Fe / Ni / ZSM-5, Fe / Ni / HY, Fe / Ni / MCM-41, Fe / Ni / SiO 2 , Fe / Ni / Al 2 o 3 .

[0030] The results are shown in Table 1. Among the products of guaiacol hydrodeoxygenation, several products with more content are benzene, toluene, xylene, phenol, and other oxygen-containing compounds (such as 3-methylphenol, 3 , 5-dimethylphenol, etc.), other hydrocarbons with less content (such as trimethylbenzene, tetramethylbenzene, etc.).

[0031]

[0032] It can be seen from Table 1 that under the action of different catalysts, there are significant differences in the conversion r...

Embodiment 2

[0039] Example 2 Effect of Ni / Fe loading on the distribution of guaiacol hydrodeoxygenation products

[0040] Experimental conditions: feed rate 0.1g / min, catalyst dosage 18g, hydrogen flow rate 0.29L / min. The feed amount of guaiacol and hydrogen was controlled at a molar ratio of 1:40. Reaction temperature: 350℃, 1 / WHSV is 3.0h -1 , Reaction time 1h, reaction pressure: normal pressure. Selected catalyst: Fe / Ni / HY.

[0041] Changing the content of Ni / Fe significantly changed the selectivity and yield of each product (Table 4). When increasing the content of active substances, the content of benzene, toluene, xylene and other hydrocarbons all showed an upward trend, especially when the content of Ni / Fe increased from 5% to 10%, the selectivity of BTX changed from the original 5.84% of the active material increased to 13.94%, and then increased the loading of Fe / Ni, the content of BTX decreased instead, the yield of oxygenated compounds decreased first and then increased wit...

Embodiment 3

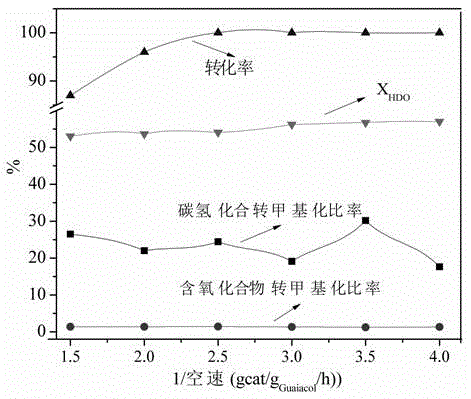

[0044] Example 3 Effect of reaction temperature on the effect of guaiacol hydrodeoxygenation reaction

[0045] Experimental conditions: feed rate 0.1 g / min, catalyst dosage 18 g, hydrogen flow rate 0.29 L / min. The feed amount of guaiacol and hydrogen was controlled at a molar ratio of 1:40. Reaction pressure: normal pressure, 1 / WHSV is 3.0h -1 , Reaction time 1h, selected catalyst: 10%Fe / Ni / HY.

[0046]

[0047]

[0048]In combination with Table 5, it can be seen that the conversion rate of guaiacol is significantly improved by increasing the reaction temperature. From the original 92% to 100%, the distribution of each product also showed significant differences. The yields of benzene, toluene, and xylene all increased significantly. With the increase of reaction temperature, the selectivity of oxygen-containing compounds did not change much, and the selectivity of phenol decreased to a certain extent. Deoxygenated compounds such as benzene, toluene, and xylene mainl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com