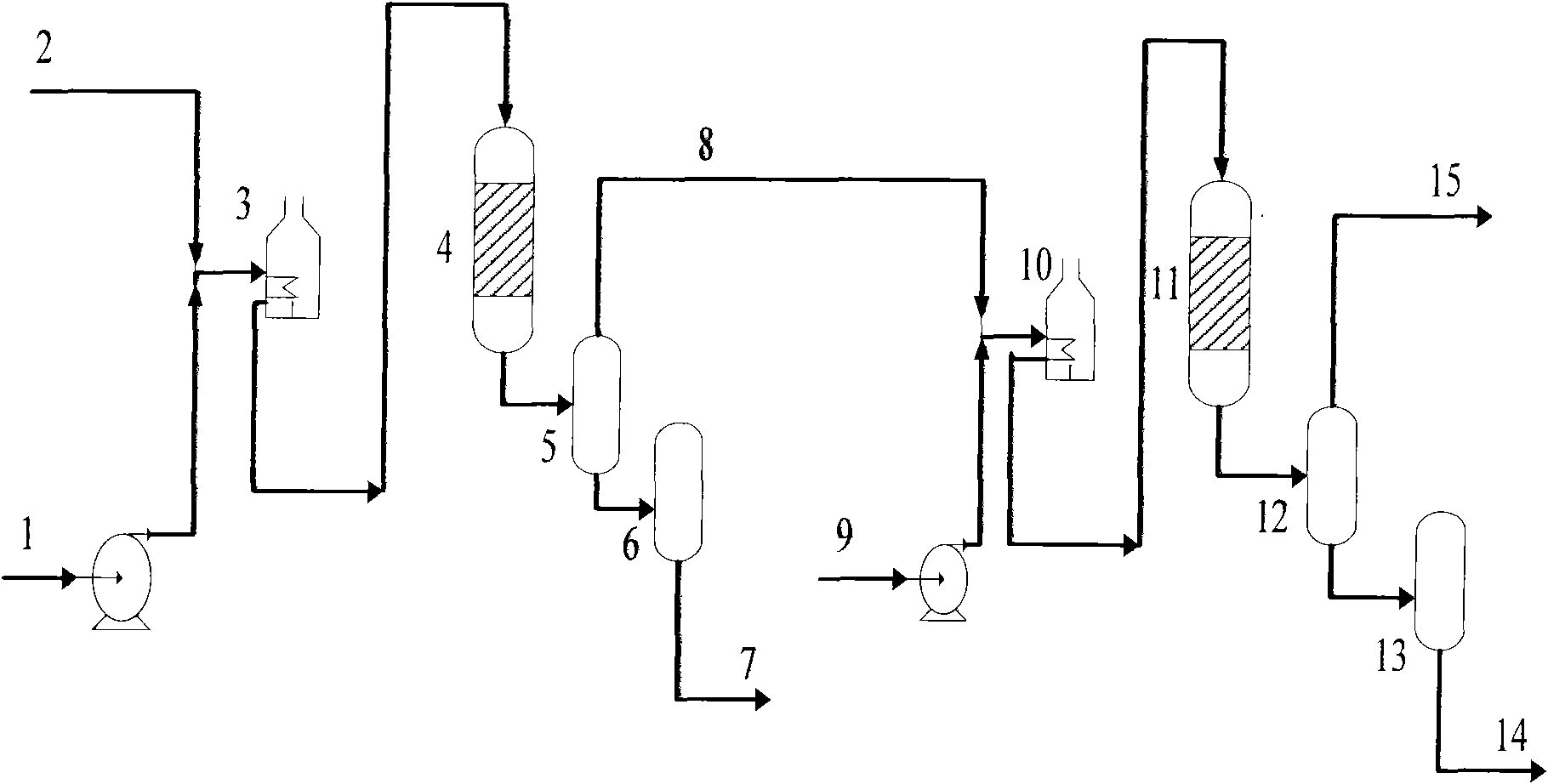

Combined hydrogenation process

A process method and pre-hydrogenation technology, which can be used in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problems of complex process flow, and achieve the effect of simple process flow, lower equipment investment cost and lower investment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

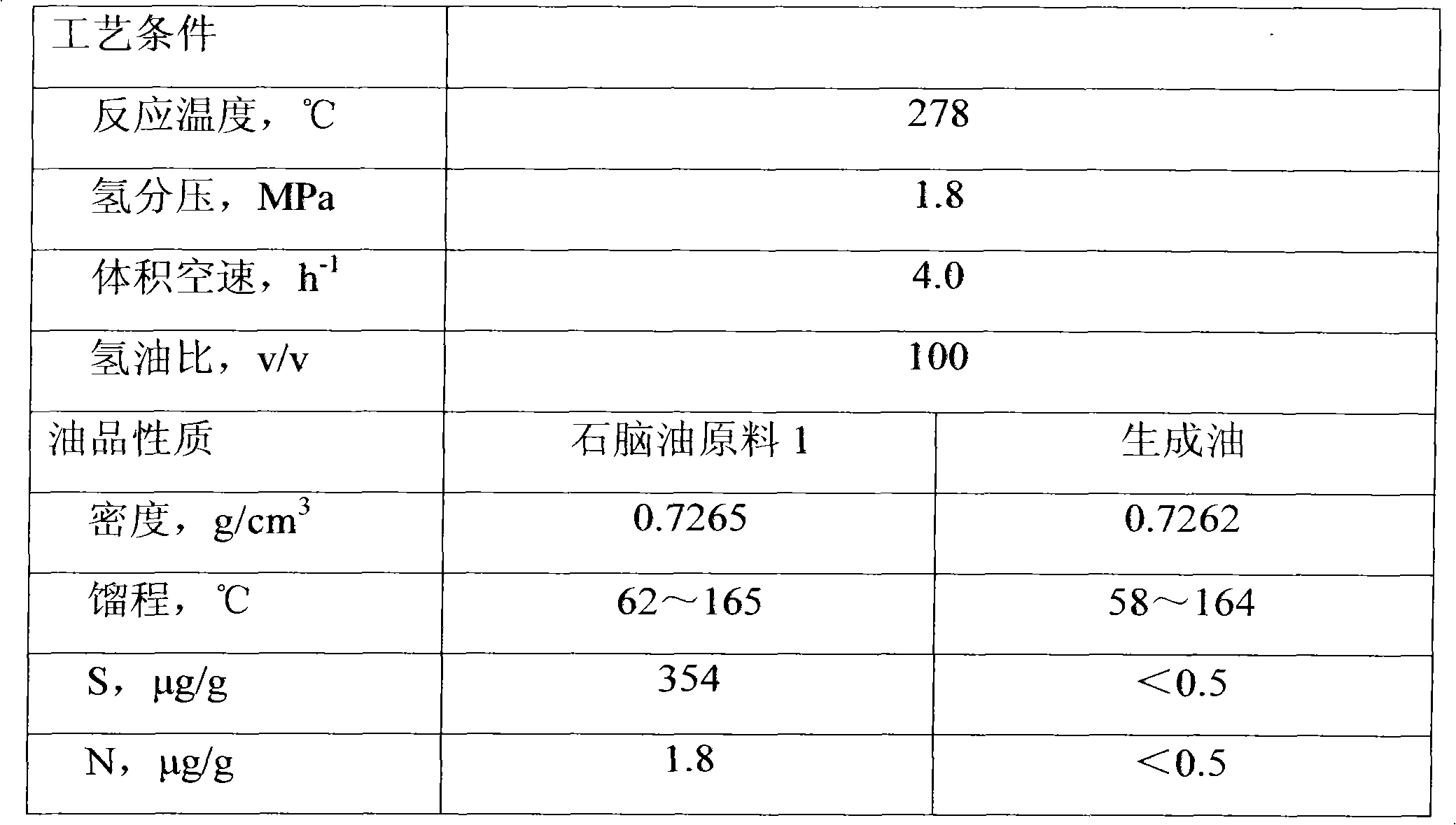

[0028] Adopt the method of the present invention to process naphtha raw material 1 and kerosene fraction raw material 1, the reforming pre-hydrogenation reaction conditions are: hydrogen partial pressure 1.8MPa, volume space velocity 4.0h -1 , The reaction temperature is 278°C, the volume ratio of hydrogen to oil is 100:1; the hydrogenation reaction conditions of jet fuel are: hydrogen partial pressure 1.5MPa, volumetric space velocity 4.2h -1, The reaction temperature is 265° C., and the volume ratio of hydrogen to oil is 95:1. The raw material oil properties and product properties are listed in Table 2.

[0029] It can be seen from Table 2 that the sulfur and nitrogen content of the reforming pre-hydrogenation unit products can be kept below 0.5 μg / g by adopting this process technology, and the jet fuel hydrogenation unit products can meet the quality requirements of 3# jet fuel.

Embodiment 2

[0031] The naphtha raw material 2 and the kerosene fraction raw material 2 are processed by the method of the present invention, and the reforming prehydrogenation reaction conditions are: hydrogen partial pressure 2.1MPa, volume space velocity 4.6h -1 , The reaction temperature is 281°C, the volume ratio of hydrogen to oil is 120:1; the hydrogenation reaction conditions of jet fuel are: hydrogen partial pressure 1.7MPa, volumetric space velocity 3.5h -1 , The reaction temperature is 260°C, and the volume ratio of hydrogen to oil is 158:1. The raw material oil properties and product properties are listed in Table 3.

[0032] It can be seen from Table 3 that the sulfur and nitrogen content of the reforming pre-hydrogenation unit products can be kept below 0.5 μg / g by using this process technology, and the aviation fuel hydrogenation unit products can meet the quality requirements of 3# jet fuel.

Embodiment 3

[0034] The naphtha raw material 3 and the kerosene fraction raw material 3 are processed by the method of the present invention, and the reforming prehydrogenation reaction conditions are: hydrogen partial pressure 2.3MPa, volume space velocity 3.8h -1 , The reaction temperature is 280°C, the volume ratio of hydrogen to oil is 150:1; the hydrogenation reaction conditions of jet fuel are: hydrogen partial pressure 1.9MPa, volumetric space velocity 3.5h -1 , The reaction temperature is 252°C, and the volume ratio of hydrogen to oil is 163:1. The raw material oil properties and product properties are listed in Table 4.

[0035] It can be seen from Table 4 that the sulfur and nitrogen content of the reforming pre-hydrogenation unit products can be kept below 0.5 μg / g by adopting this process technology, and the jet fuel hydrogenation unit products can meet the quality requirements of 3# jet fuel.

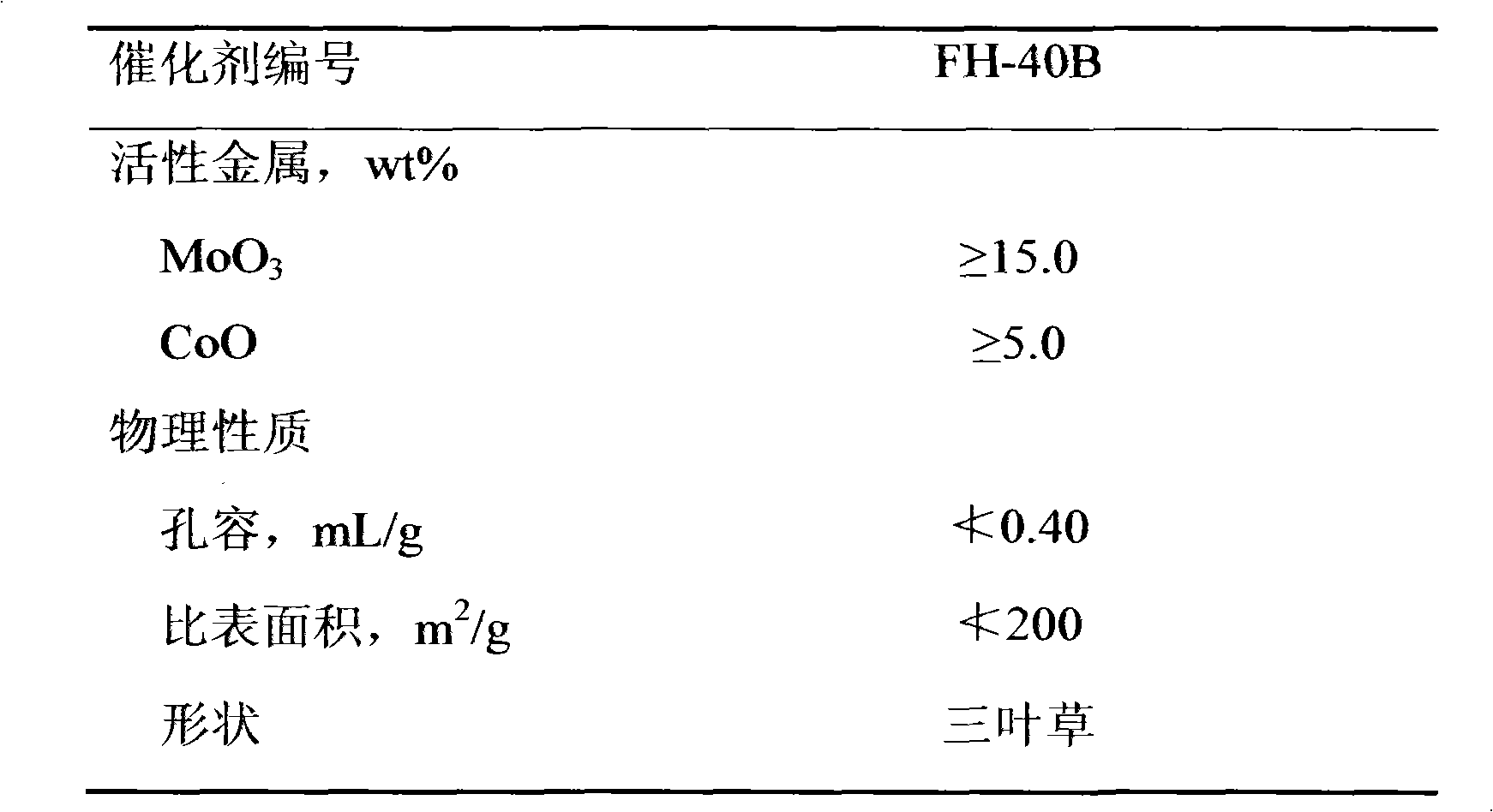

[0036] The physicochemical property index of table 1 catalyst

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com