Equipment and method for enriching germanium in low-grade germanium concentrate through two-stage reduction volatilization

A germanium concentrate, low-grade technology, applied in the field of germanium recovery and extraction, can solve the problems of high technical difficulty, low volatility, high cost, etc., and achieve the effect of improving reaction efficiency, increasing enrichment multiple, and improving grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

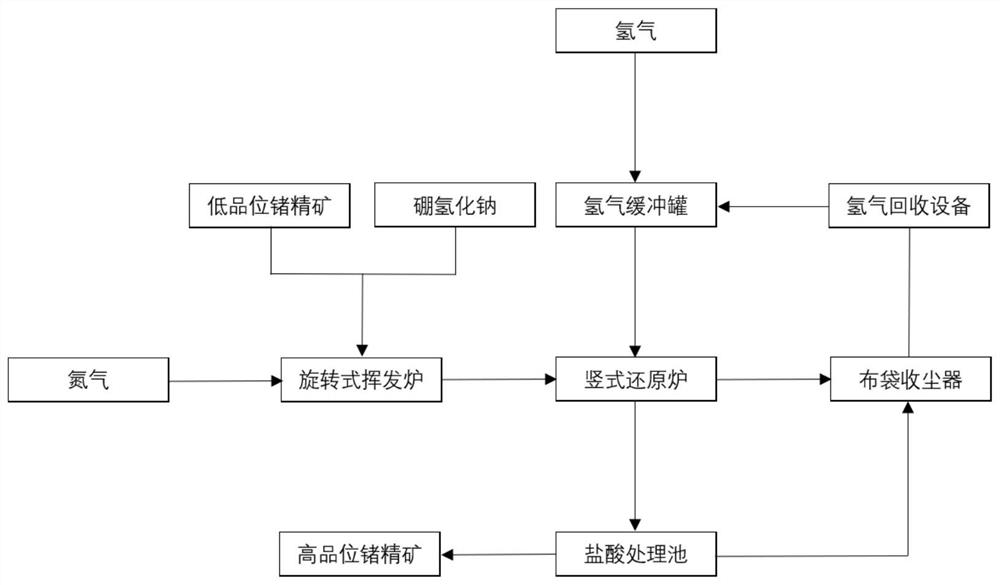

[0049] Such as figure 1 As shown, a device for twice reduction volatilization and enrichment of germanium in low-grade germanium concentrates, including sequentially connected nitrogen gas supply equipment, rotary volatilization furnace, vertical reduction furnace and bag filter, vertical reduction furnace also It is connected with a hydrogen gas supply device and a hydrochloric acid treatment tank. The nitrogen gas supply device is a nitrogen bottle. The hydrogen gas supply device includes a hydrogen source and a hydrogen buffer tank. The bag filter is also connected with a hydrogen recovery device, which will recover the recovered The hydrogen is input into the hydrogen buffer tank for recycling.

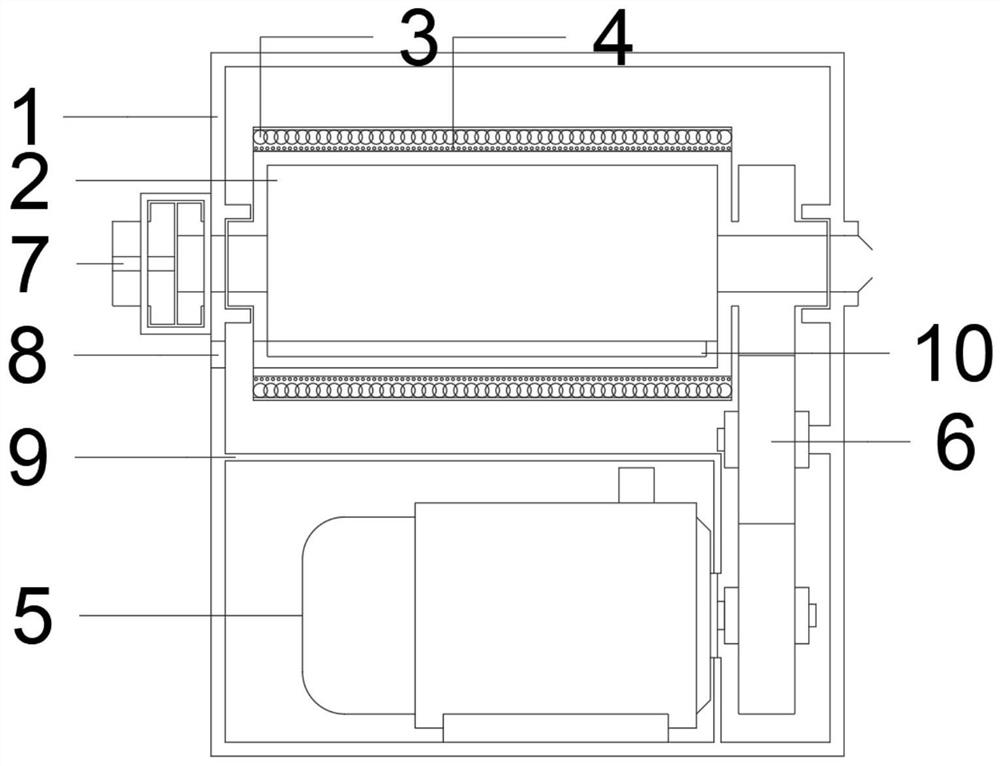

[0050] Such as figure 2 As shown, the rotary volatilization furnace includes a closed rotary air inlet 7, a first shell 1, a first furnace body 2, a first heat insulation cotton 3, a first heating resistance wire 4 and a motor 5, and the first shell 1 is set on Outside the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com