Hydrogenation system and hydrogenation method

A technology of hydrogenation system and hydrogenation machine, applied in pipeline system, container filling method, container discharge method, etc., can solve the problems of low daily filling capacity and low hydrogen utilization rate of hydrogenation stations, and reduce fixed equipment Input and energy consumption, reduction of hydrogen supply costs, and the effect of improving hydrogen utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

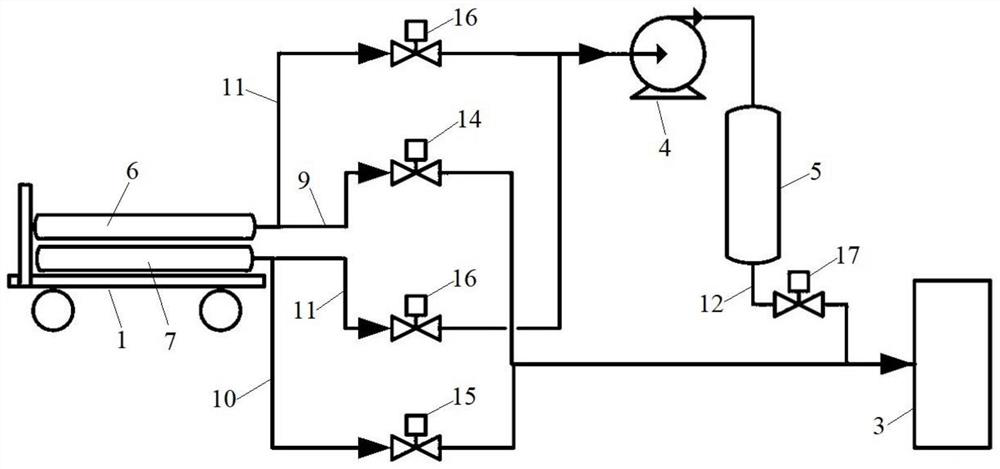

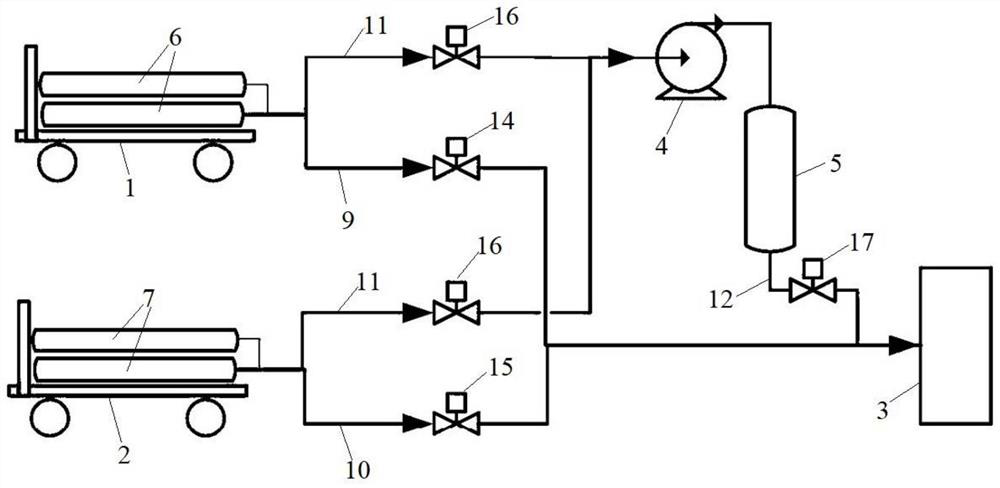

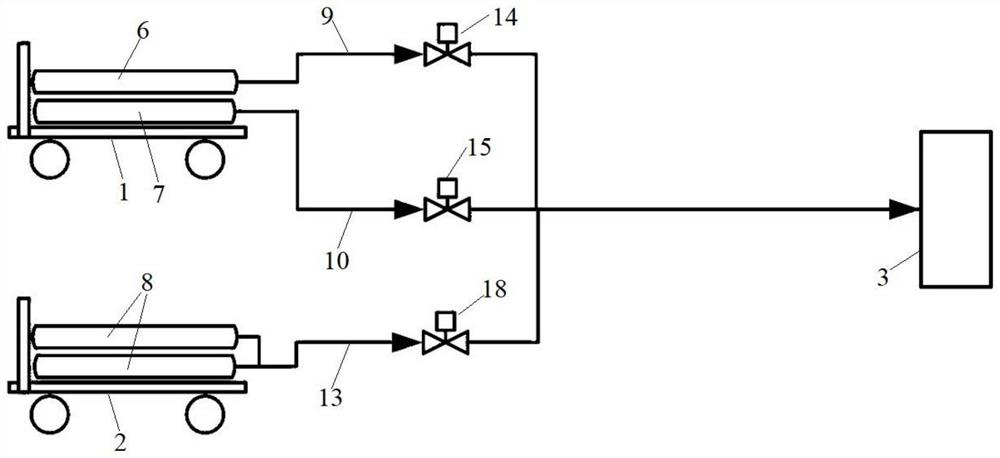

[0049] In the present invention, the number of tube bundle vehicles and the number of groups of hydrogen supply tube bundles can be determined according to actual needs. Specifically, according to the first embodiment of the present invention, the tube bundle vehicle set includes a tube bundle vehicle and two sets of hydrogen supply tube bundles arranged on the tube bundle vehicle, and the two groups of hydrogen supply tube bundles are respectively the first group of hydrogen supply tube bundles. 6 and the second group of hydrogen supply tube bundles 7, wherein: the gas outlet of the first group of hydrogen supply tube bundles 6 communicates with the inlet of the hydrogenation machine 3 through the first communication pipeline 9, and the first communication pipeline 9 is provided with a The first valve 14 that controls the opening and closing of the first communication pipeline 9; the gas outlet of the second group of hydrogen supply tube bundles 7 communicates with the inlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com