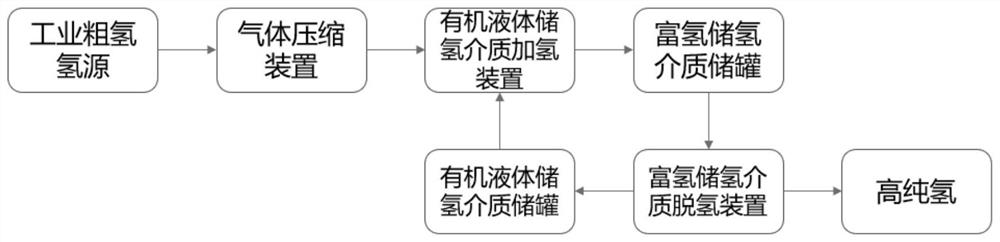

Industrial crude hydrogen purification and hydrogen storage and release system and method based on organic liquid hydrogen storage medium

An organic liquid and hydrogen storage technology, applied in chemical instruments and methods, using liquid contact hydrogen separation, gas/liquid distribution and storage, etc., can solve the problem of uneven distribution of hydrogen source space and time, and reduce equipment cost investment and operating cost input, reduce complexity, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention proposes an industrial crude hydrogen purification and hydrogen storage and release system and method based on an organic liquid hydrogen storage medium. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be described in detail below in conjunction with specific examples.

[0035]Throughout the specification and claims, the term "comprise" or variations thereof such as "comprises" and the like will be understood to include stated elements or components and not to exclude other elements or components, unless otherwise expressly stated otherwise. other components.

[0036] As the main improvement point of the present invention, it is to combine various devices in the prior art to form an industrial crude hydrogen purification and hydrogen storage and release system based on organic liquid hydrogen storage medium of the present invention, which does not require additional hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com