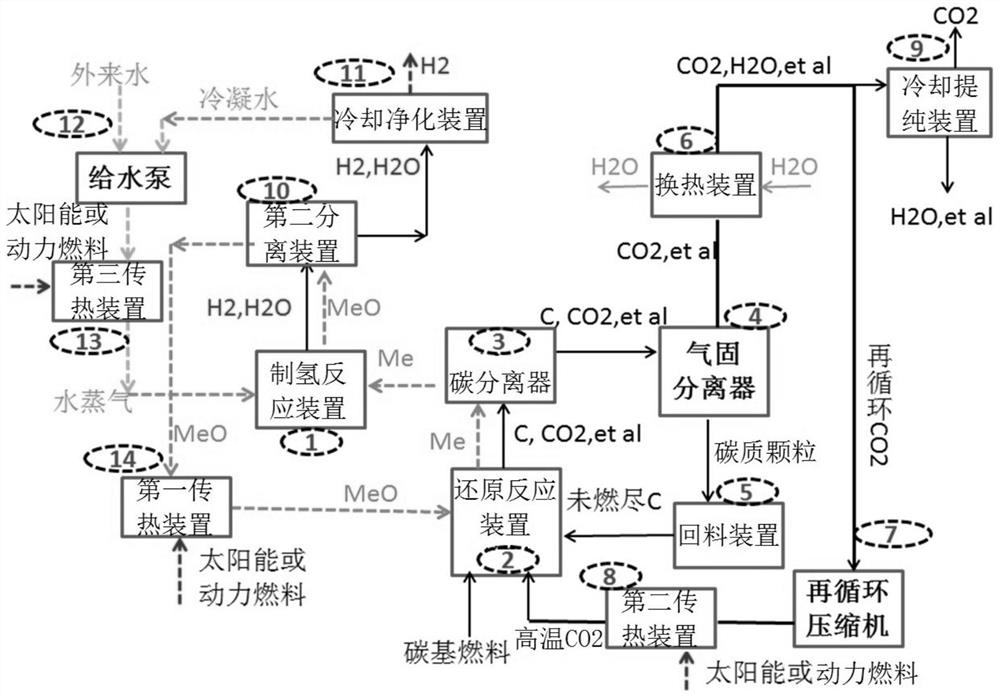

Chain reaction hydrogen production system and hydrogen production method

A chain reaction and hydrogen production system technology, applied in the field of hydrogen production, can solve the problems of low conversion rate and selectivity, complex process, low hydrogen purity, etc., and achieve sustainable and stable production, reduce water consumption, efficient capture and The effect of archiving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]All features disclosed in this specification, or all disclosed methods or steps in the process, except for mutually exclusive features and / or steps, can be combined in any manner.

[0037]Any feature disclosed in this specification, unless specifically stated, can be replaced by other equivalent or equivalent alternative features. That is, unless otherwise stated, each feature is just one example of a series of equivalent or similar features.

[0038]The present invention is based on the problems in the prior art, starting from the chain combustion reaction mechanism, by converting traditional carbon-based solid fuels into high-purity clean hydrogen energy, it can not only achieve efficient capture and storage of carbon dioxide gas products, but also The physical sensible heat of the high-temperature gas produced by the reaction is used to produce high-quality water / steam for the production of heat or power generation.

[0039]First, the chain reaction hydrogen production system of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com