Hydrogen elimination device for hydrogen fuel cell and hydrogen elimination method in closed environment

A fuel cell and hydrogen elimination device technology, which is applied in the direction of fuel cells, fuel cell additives, circuits, etc., and can solve the problems of large devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

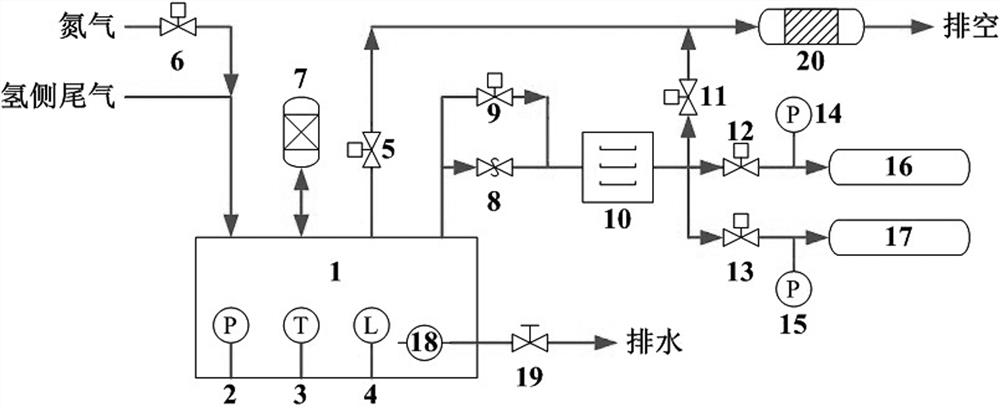

[0029] Such as figure 1 As shown, a hydrogen fuel cell dehydrogenation device disclosed in the present invention includes a hydrogen side product water tank 1 and a catalytic combustion type dehydrogenator 20 connected to the hydrogen side product water tank 1 through an emptying solenoid valve 5, and the hydrogen side tail gas is directly introduced into hydrogen Side product water tank 1, nitrogen is introduced into the hydrogen side product water tank 1 through the nitrogen solenoid valve 6, the hydrogen side product water tank 1 is provided with a water pump 18, and the water pump 18 is connected to the drain pipe through the manual valve 19, and the hydrogen side The product water tank 1 is also respectively provided with a pressure sensor 2, a temperature sensor 3, a liquid level sensor 4 and an oxygen concentration analyzer 7. The hydrogen-side product water tank 1 is connected with a dryer 10 through a pressure relief valve 8, and the pressure relief valve 8 is connecte...

Embodiment 2

[0035]The difference from Example 1 is that it is divided into four lines at the end, three of which are hydrogen elimination pipelines, leading to three small alloy hydrogen storage tanks, and solenoid valves and pressure sensors are installed on the pipelines. value in turn to eliminate hydrogen in turn; the fourth is the overpressure discharge pipeline, which is connected in series with the solenoid valve 11 and then introduced into the catalytic combustion hydrogen eliminater 20.

[0036] For a higher plateau pressure (but not exceeding the minimum back pressure for normal operation of the fuel cell) alloy hydrogen storage tank, close the solenoid valve 9 during the hydrogen elimination process, and when the hydrogen side product water tank 1 accumulates hydrogen pressure rises to the opening pressure of the pressure relief valve 8 At this time, the hydrogen gas from the hydrogen side of the fuel cell is discharged intermittently and absorbed by the alloy hydrogen storage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com